9

The manual Defrost thermostat is located in the

bottom left of the service area. The Defrost control is

preset and is not adjustable.

LOADING THE VENDER

CAN/BOTTLE DRINK TRAYS

The BevMax 4 5800-4/3800-4 Vender does not

require spacers or shims to vend most packages.

Load product in each column one package at a time

insuring that the package being loaded is in front of

the product pusher. Insure that the package is stable

within the column (doesn’t move excessively from side

to side). After loading the vender, test vend each

column to insure proper operation. Please contact a

Service Representative or refer to the proper

Technical Publication for any special settings you may

need.

LOADING CHANGE TUBES

The changer tubes can be loaded using one of the

following methods:

1. Load the coin mechanism with coins to the

desired level by inserting coins in the loading

slots on the coin tube front.

Minimum coin tube levels are:

6-8 nickels

7-8 dimes

5-6 quarters

Note: A low coin level in the coin tubes will

interfere with operation of the bill validator.

2. For exact cash accountability and to insure

maximum dollar bill acceptance, load the

mechanism utilizing the coin insert slot on the

front of the vender while in the coin TUBE

FILL/DISPENSE mode in the test menu in the

programming section of Technical Manual for

more information.

For additional information about coin mechanism,

refer to the manufacturer’s instructions.

POWER AC DISTRIBUTION BOX

The power distribution box is where the 120VAC or

220VAC input voltage is broken down to the main

operating voltages of the vender (24 VAC and 12

VAC) by a transformer. Those voltages are sent to

the controller via the P1 (3 pin) connector. Domestic

Venders contain a 15 Amp Outlet which provides

power to the Refrigeration Unit. It contains a main

power switch/plug that allows power to the AC

Distribution Box to distribute AC power to the lights,

evaporator fan, and refrigeration system, which are

always energized when the vender is powered up. It

is located inside the service area, mounted to the

back wall.

VENDING MACHINE CONTROLLER (VMC)

The vending machine controller is the heart of the

Glass Front Vender and is located on the rear wall

inside the service area. It is flash programmable and

may or may not include the program chip (EPROM),

which controls all aspects of the vender. It also

contains the power supply which regulates the

voltages required to operate the motors as well as the

coin mechanism, digital display, and all logic functions

in the vender.

KEYPAD

The keypad is located on the front of the service door.

It consists of a 6” X 3” (15.2 mm X 7.6 mm) matrix,

tactile feel membrane switch pad and an overlay. The

pad utilizes the letters A thru F on the left side and

numbers 1 thru 0 along with the symbol and Clr to

the right. The keypad is where the vender

programming is accomplished and where the

customers make their selections.

DIGITAL DISPLAY

The digital display is located directly above the

keypad on the front of the service door. It is used to

convey information to the consumer as well as to the

person programming the vender.

REFRIGERATION SYSTEM

The refrigeration system is a single piece unit and is

hermetically sealed. The Model BevMax 4 units

consist of a 1/3 plus horsepower compressor, with a

single fin and tube style condensing unit with one

condenser fan, condensation overflow pan,

evaporator, and evaporator fan motor. The

refrigeration unit is located behind the refrigeration

unit cover panels, mounted in the bottom of the

cabinet. This unit is designed for easy removal and

replacement from the front or rear of the vender as a

complete assembly. An electronic thermostat

regulates the cabinet temperature. The control of the

thermostat is attached to the evaporator coils and

reads the temperature of air being pulled in to the

evaporator coil.

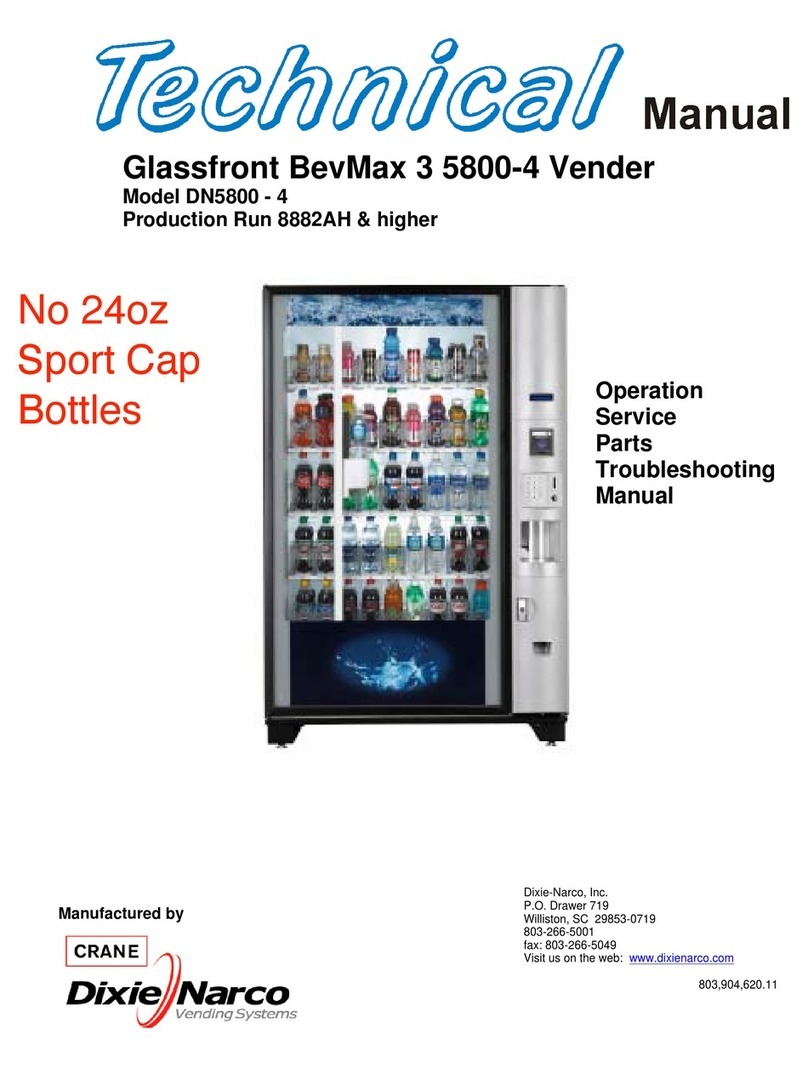

SHELF ASSEMBLY

Typically, there are 5 shelf assemblies in every

vender; however, this can vary depending upon the

configuration specified at the time of ordering. Each

can/bottle shelf consists of 9 or 7 columns. Each shelf

is capable of holding a variety of packages. The shelf

assembly consists of the tray, where all of the

following parts are mounted: Double Gate assembly

and the slide/pusher assembly. These items are

discussed in detail below.

DOUBLE GATE ASSEMBLY (Can/Bottle

Trays)

The double gate assembly is mounted on the front

portion of the tray assembly and contains the vending

mechanism. Incorporated in the gate assembly are

the front and rear knuckle assemblies as well as the

product kicker. In standby operation, the front knuckle