Crathco Simplicity Bubbler CS-3L User manual

Operator Manual

Grindmaster-Cecilware

4003 Collins Lane, Louisville, KY 40245 USA

Phone: 502.425.4776 Toll Free: 800.695.4500

Fax: 502.425.4664

Web: gmcw.com Email: info@gmcw.com

Thank you for purchasing this quality cold beverage dispenser. For your safety and the safety of

others, read all warnings and the operator’s manual before installing or using the product. Properly

instruct all operators. Keep training records. For future reference, record serial number here:

Table of Contents

Simplicity™Bubbler CS-3L

Crathco®Cold Beverage Dispensers

for Panera Bread®

Grindmaster-Cecilware provides the industry’s

BEST warranty. Visit gmcw.com for warranty

terms and conditions.

©2016 Grindmaster-Cecilware

Printed in Thailand

0816 Form # CC-331-01

Part # 390-00092

Model CS-3L-16_PANERA

Part # 1101-016

Safety Information ...................................................2

Specifications ............................................................3

Installation and Set-Up ............................................4

Installation - Agitator Function (Model CS-3L-XX).5

Product Preparation & Use ......................................6

Daily Cleaning...........................................................7

Maintenance .............................................................9

Troubleshooting .....................................................10

Basic Machine Parts ...............................................13

Spacer Bracket Installation ....................................15

2 Crathco®Simplicity CS-3L Panera Bubbler

Lifting hazard. Single person lift could cause injury. Use assistance when moving or lifting.

Sharp edges can cause personal injury. Handle with care.

The appliance is not to be used by persons with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision or instruction. Be sure to provide supervision

or instruction concerning use of the appliance in a safe way and understand the hazards involved.

Children must be supervised to ensure they do not play with the appliance.

For safe and proper operation the appliance has to be placed in a stable horizontal position.

The appliance is only to be installed in locations where it can be overseen by trained personnel.

Safety Information

Observe machine voltage configuration. Do not apply improper voltage to machine or damage to machine will

occur.

Do not use extension cord.

Do not operate the appliance below 1.7°C (35°F) or above 40°C (104°F).

NOTICE

The appliance is not intended for outdoor use.

Do not clean with a water jet or use in an area where a water jet may be used.

Cleaning and maintenance shall be made only by properly trained persons with supervision.

Important Safety Information

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

For your safety and the safety of others, read all warnings and the operator manual before installing or using

the product.

DANGER: This term warns the user of imminent hazard that will result in serious injury or death.

WARNING: This term refers to a potential hazard or unsafe practice, which could result in serious injury or death.

CAUTION: This term refers to a potential hazard or unsafe practice, which could result in minor or moderate

injury.

NOTICE: This term refers to information that needs special attention or must be fully understood.

CAUTION

WARNING

Simplicity CS-3L Panera Bubbler Crathco®3

Specifications

Model Description Dimensions (H x W x D) Electrical Certifications

CS-3L-16 (3) 4.75 gallon (18L) bowls, 31.0” x 20.4” x 17.7” 115V / 60 Hz / 8.5A C-UL US, NSF

agitator model.

CS-3L-16-S (3) 4.75 gallon (18L) bowls, 31.0” x 20.4” x 17.7” 115V / 60 Hz / 8.5A C-UL US, NSF

spray model.

(Height includes 4” legs)

4 Crathco®Simplicity CS-3L Panera Bubbler

Installation and Set-Up

1.

2.

Place machine on counter with proper spacing.

• The appliance must be placed in a horizontal position.

• The appliance is suitable for indoor use only.

• If legs are not attached, screw into base and level unit.

a. Place dispenser on

stable counter strong

enough to support

its weight.

b. Allow 5 cm (2”) on sides

and 13 cm (5”) on back

for proper ventilation.

Install power cord.

a.

Do not use extension cord.

Failure to follow proper installation

guidelines can damage equipment

and void warranty.

Plug cord into power outlet.

b.

Note proper voltage.

Observe machine voltage configuration.

Do not apply improper voltage to

machine or damage to machine will

occur.

1. This appliance is not intended for the use by persons (including children) with reduced physical, sensory, or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by person responsible for their safety.

2. Children should be supervised to ensure that they do not play with the appliance.

3. This appliance is only to be installed in locations where it can be overseen by trained personnel.

2”

(5 cm)

2”

(5 cm)

5”

(15 cm)

5” (13 cm) minimum

machine spacing from

wall

2” (5 cm) minimum

machine spacing from

wall or other machines

Recommended ambient temperature

75° F (25° C).

Top View

Front View

CAUTION

Simplicity CS-3L Panera Bubbler Crathco®5

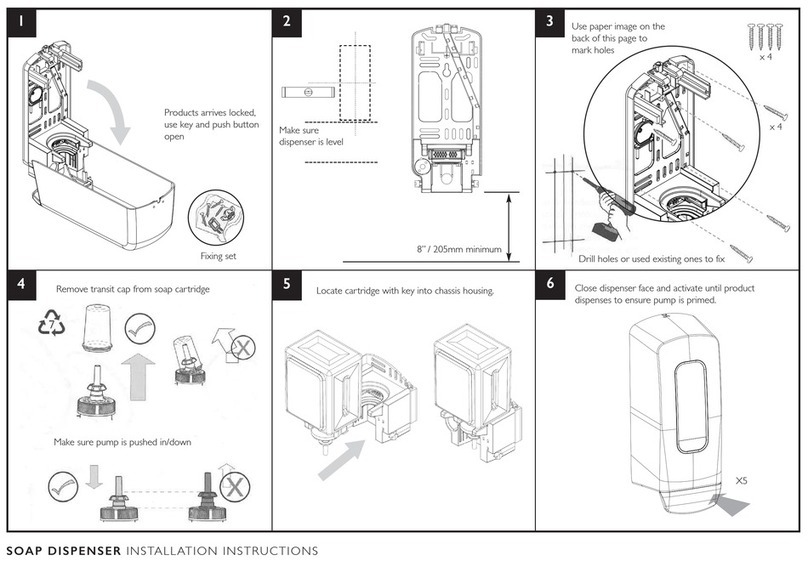

Installation - Agitator Function (Model CS-3L-16)

1. 2.

4.

3.

5. 7.

8.

6.

9. 10.

Install mixing impeller.

Install bowl gasket.

Place o-ring on dispense valve

(check if nicked or twisted). Place in

bowl.

Install assembled bowl.

NOTICE:

Machine must be OFF.

Insert bowl lip underneath

of lock position on the back

of top tray.

Then, press down on the

front of the bowl until

you hear a click indicating

the bowl is locked proper-

ly in place.

Install handle. Flip out support bracket for

drip tray.

Place drip tray

cover on drip

tray.

Install drip tray.

Mix product in clean container.

Fill bowl with product.

Install bowl cover. Turn power “on”.

a. b.

a. b.

CAUTION

Sharp edges can cause personal

injury. Handle with care.

Replace axle if flange

thickness is less than

0.75mm

(0.03 inch)

thick.

Replace impeller if

bearing surface is

worn more than

0.5mm (0.02 inch).

Inspect for wear.

NOTICE:

Product Preparation & Use

1. Wash hands thoroughly when handling

dispenser and product. 2.

Pail

Wire whisk

Measuring pitcher

3. 4.

5.

Pour concentrate into dispenser and then add

remaining water per product label.

7.

Turn on main power

switch.

Correct way

to dispense.

Install lid.

8. 18L

Bowl

To ensure safe and quality beverage, use only

reliable, purified, or potable water source to

prepare the product.

Prepare concentrate by mixing powder with water

using wire whisk until completely dissolved. Follow

recommended dilution per product label.

Always observe minimum 3 liter fill level to prevent

foaming of product at low level.

Min.

(3L)

Max.

6.

Incorrect way

to dispense.

Mixing tools.

Use only clean mixing tools to prepare product.

9. PRODUCT PREPARATION AND USE

1. Prepare concentrate by mixing powder with water using wire whisk until completely

dissolved. Follow recommended dilution per product label.

2. Pour concentrate into dispenser and then add remaining water per product label.

3. Install lid and turn on main power switch.

4. 25~30° C (77~86° F) ambient temperature is suitable for the operation.

5. This machine maintains beverage temperature of 1~5° C (34~41° F).

6. The dispenser is not for dispensing potentially hazardous beverage.

6 Crathco®Simplicity CS-3L Panera Bubbler

Simplicity CS-3L Panera Bubbler Crathco®7

Daily Cleaning

Machine Disassembly

1. 2.

3. 4. 5.

6.

7. 9.

DAILY

12345

678910 11 12

13 14 15 16 17 18 19

20 21 22 23 24 25 26

27 28 29 30

FRAGILE!

8.

Turn power “off”. Remove drip tray and cover.

Rotate support brackets for

drip tray.

Drain bowl. Remove handle.

Remove bowl cover. Press release latch on front of the

machine before removing the bowl.

Do not drop.

Remove valve with seal. Remove bowl gasket. Remove mixing impeller.

NOTICE:

8 Crathco®Simplicity CS-3L Panera Bubbler

Daily Cleaning (cont.)

Cleaning Procedures

Cleaning Materials & Tools

Take parts to sink.

4.

Units with spray agitators:

Remove pump cover and spray

tube.

Lift out dispense valve and

remove o-ring.

Wash with detergent

and warm water.

2. 3. 50°C (122°F)

Maximum water

temperature for

cleaning.

75mm (3 inch)

Maximum

water level for

cleaning

Rinse with clean water. Wipe evaporator plate with

detergent and warm water.

6.

5.

8. 9.

liquid detergent

(do not use laundry bar/

powdered detergents)

long brush

foam/sponge

(do not use abrasive)

sprayer

toothbrush

NSF approved

sanitizer

paper towels

Clean front panel, exterior panels

and release latch.

7.

1.

a. b.

Clean counter and bottom part

of dispenser with paper towel.

ABRASIVES WILL SCRATCH PLASTIC PARTS. WASH

BOWL LIDS IN COOL OR LUKEWARM WATER TO AVOID LEAKS DUE

TO SEALED SURFACE BEING DAMAGED.

The appliance is not suitable for installation in an

area where a water jet could be used. The appliance must not be

cleaned by water jet.

THOROUGHLY CLEAN ALL PARTS IN WARM WATER USING A MILD

NON-ABRASIVE DETERGENT AND RINSE THOROUGHLY.

NOTICE:

NOTICE:

Simplicity CS-3L Panera Bubbler Crathco®9

2.

Daily Cleaning (cont.)

Cleaning Procedures

DAILY

12345

678910 11 12

13 14 15 16 17 18 19

20 21 22 23 24 25 26

27 28 29 30 Prepare 8L of chlorine-based

sanitizing solution (to 100 ppm) per

package instructions.

Submerge parts in solution for 15

minutes.

5.

Spray inside of lid with sanitizer.

3. 4.

Air dry parts overnight.

1.

Spray inside of bowl with sanitizer.

XII

Maintenance

1. If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or a similarly

qualified persons in order to avoid a hazard.

2. When freezing occurs, the appliance must be powered off.

3. The appliance is suitable for liquid juice concentrate and beverage mixing powder.

4. Access to the service area is restricted to persons having knowledge and practical experience of the

appliance, in particular as far as safety and hygiene are concerned.

Leaking

No product agitation

1.

a. O-ring nicked,

deformed, or

twisted? Cracked bowl? Replace bowl.

1. 2.

Impeller and/or axle worn? Replace worn parts.

See routine maintenance.

?

Replace pump

axle if flange

thickness is

less than

.75mm

(0.03 inch)

thick.

Replace

impeller if

bearing

surface is

worn.

a.b.

5.

Valve securely in place? Push

and twist to seat.

Gasket secured in place? Push to

seat.

b. Foreign particles on

bowl valve seat?

2. 3.

Drain tray overflow? Empty tray.

4.

3.

Impeller installed correctly?

Pump motor magnet needs adjustment?

(Call for service.

Troubleshooting

10 Crathco®Simplicity CS-3L Panera Bubbler

Simplicity CS-3L Panera Bubbler Crathco®11

Troubleshooting (cont.)

No refrigeration

1.

Plugged in to wall outlet?

2.

3. Compressor does not operate;

fan does?

(Call for service.

4.

Poor refrigeration

1.

2. 3.

4. 5.

?

No product agitation?

See previous page.

Faulty thermostat?

Machine will not operate.

(Call for service.

Dirty condenser filter and condenser?

Clean condenser or (call for service.

Compressor does not operate;

fan does not operate.

Faulty fan motor?

(Call for service.

Impeller does not spin. Faulty

pump motor?

(Call for service.

Faulty thermostat or improper

setting?

(Call for service.

Power switch on?

Operator Manual

Grindmaster-Cecilware

4003Collins Lane, Louisville, KY 40245 USA

Phone: 502.425.4776 Toll Free: 800.695.4500

Fax:502.425.4664

Safety Information........................2

Specifications.................................3

Installation and Set-Up.................4

Installation - Agitator Function...5

Installation - Spray Function........6

Product Preparation & Use...........7

Daily Cleaning ...............................8

Maintenance...............................10

Troubleshooting..........................11

Basic Machine Parts ...................14

Thankyou for purchasing this quality cold beverage dispenser. For your safety and the safety of

others,read all warnings and the operator’s manual before installing or using the product. Properly

instructall operators. Keep training records. For future reference, record serial number here:

Table of Contents

Simplicity™Bubbler CS-3L

Crathco®Cold Beverage Dispensers

Grindmaster-Cecilware provides the industry’s

BEST warranty. Visit gmcw.com for warranty

terms and conditions.

©2014Grindmaster-Cecilware

Printedin Thailand

0816Form # CC-331-01

Part# 390-00092

(cULuscertification applies only to

UnitedStates and Canada models.)

Model CS-3L-16

(CEdeclaration applies only to

Internationalmodels.)

?

12 Crathco®Simplicity CS-3L Panera Bubbler

Troubleshooting (cont.)

Noisy machine

3.

2.

4.

Bowl or pump installed while unit in “on” position?

Turn unit off. Reinstall parts.

6. Fan blade bent?

Unplug unit, remove side panel, inspect fan blade.

Faulty pump motor bearings.

(Call for service.

5.

Impeller and/or axle worn? Replace worn parts.

See routine maintenance.

Broken impeller? Replace it.

1.

Impeller installed correctly in bowl?

Chattering impeller? Ensure

correct drive magnet height or

(Call for service.

Replace pump

axle if flange

thickness is

less than

.75mm

(0.03 inch)

thick.

Replace

impeller if

bearing

surface is

worn.

If you still need help, call Grindmaster-Cecilware Technical Service Department, (502) 425-4776 or (800) 695-4500

(USA & Canada only) (Monday through Friday 8 AM - 6 PM EST). Please have the model and serial number ready

so that accurate information can be given.

Prior authorization must be obtained from Grindmaster-Cecilware for all warranty claims.

Grindmaster-Cecilware provides the industry’s BEST warranty. Visit our website at GMCW.com for

warranty terms and conditions.

Simplicity CS-3L Panera Bubbler Crathco®13

Basic Machine Parts

(CS-3L)

44

4

5

4

6

49

50

43

51

52

42

4

7

4

8

41

3

7a

3

7

39

38

41

29

28

3

2

a

32b

3

1

2

5

33

30

26

c

26b

26a

2

6

27

26b

32c

4

0

35

34

32

24

26d

22

23

25

1

2

36

19

20

2

1

3

4

5

1

7

19

1

8

6

7

11

9

8

10

12

1

3

1

5

16

14

11

53

14 Crathco®Simplicity CS-3L Panera Bubbler

Basic Machine Parts (continued)

1Base Structure 200-00142

2Front Panel assembly with magnet, CS-3L231-00392

3Screw Truss Head SS. (Mat. 420)8-32 x 1/2"0069

6Screw, Support Drip Tray Bracket 220-00013

7Bracket, Support Drip Tray Lt. 200-00053

8Washer, Spring DIN 137B99299

9Sleeve, Bracket Support Drip Tray210-00119

10Bracket, Support Drip Tray Rt. 200-00052

11 Screw, TPH M4x15Plastite SS 99306

Leg, 2" Adjustable W/Rubber Pad 20-00021

Leg, 4" Adjustable W/Rubber Pad M005SA

13Screw,14x 1/2,Type "B",Hex Hd 0063

14Condenser Filter, CS-3L210-00585

15Bracket, Switch200-00058

16On-Off Switch Rocker 99066

17Right Side Panel, Simplicity 200-00056

18Temperature Control 1059

19Screw, M4x8mm,TH,PH,Trilobe,Blk 99059

20 Access Panel Screw 220-00021

21Back Panel 200-00145

22 Wire Saddle Locking Top Teardrop 354-00002

23 Dryer, D35, CS-4E1451

24 Compressor 3253

25 Nut, Hex, Lock, 1/4-20 "K" Type 0055

26 Pump Motor, Agitator models Assembly 231-00381

26a Magnet, Drive Assy 2049

26b Nut, M4, Nylon, A4SS 99406

26c Bracket, Pump Motor 200-00648

26d Pump Motor, Low Speed, 300 RPM 260-00027

27 Evaporator Assembly, CS-3L231-00405

28 Seal, Bearing Sleeve 290-00005

Bearing Sleeve, Agitator models 220-00305

Bearing Sleeve, Spray models 220-00295

30 Cam-Lock Remove Bowl Lt. Assembly (Double Cam - Lock) 231-00433

31Cam-Lock Remove Bowl Rt. Assembly (Single Cam-Lock) 231-00434

32 Fan Motor Assembly 3432

32a Fan blade1460

32b Fan Motor 3430

32c Bracket, Fan Motor 3429

33 Copper, Discharge 3763-2

34 Condenser 332-00003

35 Left Side Panel, Simplicity 200-00057

36 Grommet, for PlasticSides 2679

37 Pump Motor, Spray models Assembly 231-00382

37a Pump Motor, Spray models, 1500 RPM 260-00028

38 Drainage channel silicone, CS-4E290-00100

39 Drainage channel silicone, CS-3L290-00106

40 Wide Wire Saddle #WWS-A-2-01354-00001

BOWL ASSEMBLY PARTS

4Cover, Drip Tray200-00143

5Drip Tray210-00252

41 Impeller, Mixing 210-00130

42 Gasket, Bowl 18L, Tall 290-00089

44 Bowl 18Liters, Tall (4.8Gallon) 231-00404

45 Valve, Dispense with Seal99464

46 Bowl Cover, 18Liters, Tall 210-00495

47 Valve, Dispense 99463

48 Seal, Valve 99380

Push HandOH (Cup Activated)200-00063

29

12

5 %UDFNHW6SDFHU5HDU 200-0

Simplicity CS-3L Panera Bubbler Crathco®15

Spacer Bracket Installation

Installed Standoff Bracket Overview

Rear View

5 inch

rear distance

e

g

Left Rear Corner View

1 inch side spacing

allows 2 Bubblers to sit

side-by-side to allow a

total 2 inch clearance

Left Side View

Bracket extends

3.5 inches

down each side

Left Rear Corner View

Recommended Spacing:

Place Bubblers side-by-side in available

space then center them in total

available space.

1. 2. 3.

Tools needed:

Phillips head screw driver

Flathead screw driver

Rotate unit so that there is easy

access to each side and rear of unit.

(Recommended attaching spacer

during cleaning of unit during

closing or during opening).

Total attachment time is 15 minutes.

Orientation of bracket is with all 4

screw tabs against the base, as

shown.

Remove protective film from

bracket and discard film.

4. 5.

Orient bracket to base as before,

using a Phillips head screwdriver,

remove rear side panel screw from

either left or right side panel.

(Remove only the rear screw so that

the front screw holds side panel dur-

ing installation.)

Using a flat head screwdriver, remove rear thumb screw on the same

corner as the side panel screw that was removed. (Attach bracket at one

corner at a tome so that the other corner screw holds side and rear

panels.)

Spacer Bracket Installation (continued)

6. 7.

Lift panel into position with screw tabs aligned as indicated in the

images so that the tabs are on the outside of the existing side and

rear panels.

Drive the side panel screw first and

then drive the rear panel thumb

screw to attach the bracket at one

corner.

Side Panel View Rear Panel View

8. 9.

Repeat the same process for the

other rear corner of the product.

Place the two units back into

location, side spacer’s legs should be

contacting the other Bubbler and

then evenly space the two units

from the units on either side.

Grindmaster-Cecilware

4003 Collins Lane, Louisville, KY 40245 USA

Phone: 502.425.4776 Toll Free: 800.695.4500

Fax: 502.425.4664

Web: gmcw.com Email: info@gmcw.com

©2016 Grindmaster-Cecilware

Printed in Thailand

0816 Form # CC-331-01

Part # 390-00092

This manual suits for next models

1

Table of contents

Other Crathco Dispenser manuals