Cray T3E User manual

HMM-369-0 Cray Research Proprietary 1

CRAY T3E AC Multiple-cabinet Installation

HMM-369-0

Record of Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hazard Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

ESD Smock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Wrist Strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Preinstallation Activities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Checking Site Planning Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Checking the Power Cord Receptacles . . . . . . . . . . . . . . . . . . . . . . . . . 14

Power Wiring for High-leakage Current . . . . . . . . . . . . . . . . . . . . . . . . 16

Unloading the Computer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Inspecting the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Opening the “OPEN FIRST” Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Transporting the Mainframe to the Designated Location . . . . . . . . . . . . . . 20

Shipping Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Unpacking the CRAY T3E AC Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Unpacking a Crate that Contains a Single Cabinet . . . . . . . . . . . . . . . . 22

Unpacking a Crate that Contains Two or Three Cabinets . . . . . . . . . . . 30

Unpacking and Positioning the PC-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Unpacking and Positioning the System Workstation (SWS) . . . . . . . . . . . . 37

Unpacking and Positioning Additional System Components . . . . . . . . . . . 37

(continued)

CRAY T3E AC Multiple-cabinet Installation

2 CrayResearchProprietary HMM-369-0

Complete the following tasks when you bolt cabinets together:

Joining Two or More CRAY T3E AC Cabinets . . . . . . . . . . . . . . . . . . . . . . 38

Preparing the CRAY T3E Cabinets for Internal Wiring . . . . . . . . . . . . 38

Positioning Cabinets Temporarily When No Cabinets Are

Prejoined . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Positioning Cabinets Temporarily When Some Cabinets Are

Prejoined . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Removing Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Removing the Blower Exhaust Shields . . . . . . . . . . . . . . . . . . . . . . 47

Removing Access Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Removing Wire-duct Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Removing the Side Trim and Logic Panels (Optional) . . . . . . . . . . 51

Attaching Cable Troughs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Joining the Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Opening the Cable Ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Grounding the Mainframe Chassis . . . . . . . . . . . . . . . . . . . . . . . . . 58

Removing Clock and Logic Modules . . . . . . . . . . . . . . . . . . . . . . . 59

Preparing the Rails for Wire Insertion . . . . . . . . . . . . . . . . . . . . . . . 62

Removing Slot Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Removing Rail Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Removing Connector Pin Locks . . . . . . . . . . . . . . . . . . . . . . . . 66

Completing the Internal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Completing the Clock Connections . . . . . . . . . . . . . . . . . . . . . . . . . 67

Completing the Boundary Scan Connections . . . . . . . . . . . . . . . . . 74

Connecting the Point-to-point Wires – 4 or More Cabinets . . . 75

Connecting 4-pin Edge-to-Pigtail Cables – P/N 15237701 . . . . 77

Connecting the Daisy Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Connecting Scan Chain 0 to the Scan Master . . . . . . . . . . . . . . 82

Connecting Scan Chain 1 to the Scan Master . . . . . . . . . . . . . . 84

Reinstalling the Connectors in the Top Clock Rail . . . . . . . . . . . . . 88

Completing the Torus Interconnect Network Connections . . . . . . . 90

Closing the Cable Ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Installing Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Installing Side Access Panels and Trim . . . . . . . . . . . . . . . . . . . . . . . . . 95

CRAY T3E AC Multiple-cabinet Installation

HMM-369-0 Cray Research Proprietary 3

Complete the following tasks when you DO NOT bolt cabinets together:

Positioning Cabinets (for Prejoined Cabinets) . . . . . . . . . . . . . . . . . . . . . . . 97

Grounding the Mainframe Chassis (for Prejoined Cabinets) . . . . . . . . . . . . 100

Installing the Cabinet Side Panels (for Prejoined Cabinets) . . . . . . . . . . . . 101

Complete the following tasks for ALL cabinets:

Verifying the CRAY T3E AC Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Verifying the Voltage Selector Switch . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Connecting the Optional Customer Alarm . . . . . . . . . . . . . . . . . . . . . . 105

Verifying the Control System Hardware . . . . . . . . . . . . . . . . . . . . . . . . 108

Verifying Additional Power Hardware . . . . . . . . . . . . . . . . . . . . . . . . . 110

Verifying that the Modules Are Seated and Cammed . . . . . . . . . . . . . . 111

Completing the System Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Cable Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Connecting the WACS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Connecting the GigaRing Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Verifying System Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Powering Up the System Workstation (SWS) . . . . . . . . . . . . . . . . . . . . . . . 119

Powering Up the PC-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Connecting the Input Power to the CRAY T3E Cabinets . . . . . . . . . . . . . . 119

Verifying Cabinet Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Verifying WACS Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Verifying Operation of the Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Verifying Operation of the Thermistors . . . . . . . . . . . . . . . . . . . . . . . . . 121

Verifying Cabinet Power Switch and Shunt Trip Operation . . . . . . . . . 121

Verifying Remote Alarm Operation (Optional) . . . . . . . . . . . . . . . . . . . 122

Powering Up the Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Verifying Remote Power On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Running Boundary Scan and Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Installing Panels and Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Installing Rear Access Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Installing the Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Appendix – Wire Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

CRAY T3E AC Multiple-cabinet Installation

4 CrayResearchProprietary HMM-369-0

Figures

Figure 1. Power Plugs and Receptacles . . . . . . . . . . . . . . . . . . . . . . . . . 16

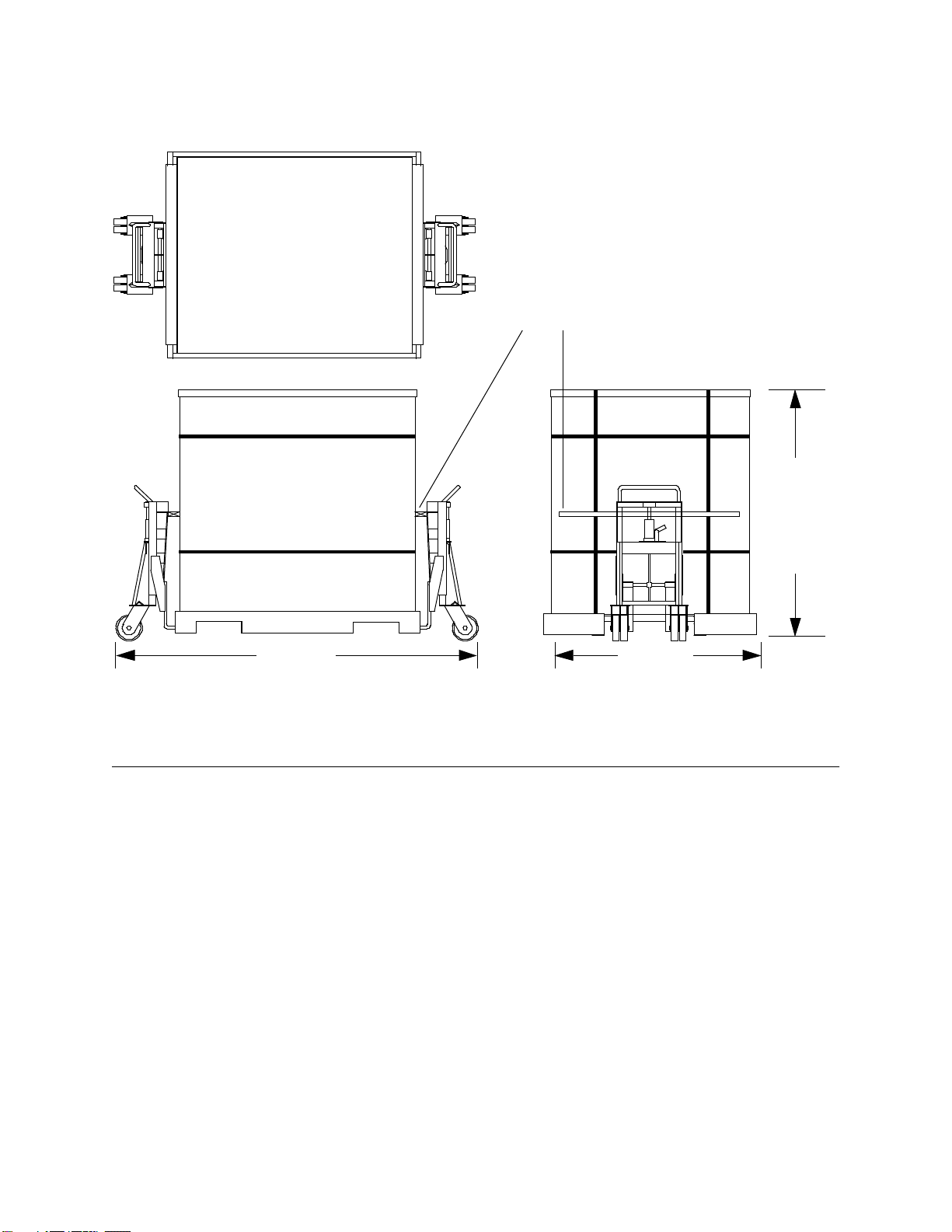

Figure 2. Single-cabinet Shipping Configuration . . . . . . . . . . . . . . . . . . 18

Figure 3. Three-cabinet Shipping Configuration . . . . . . . . . . . . . . . . . . 19

Figure 4. Cabinet Shipping Crate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 5. Retaining Block and Screws . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 6. Installing the Ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 7. Cardboard Shipping Container . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 8. Removing the Inside Retaining Bar . . . . . . . . . . . . . . . . . . . . 27

Figure 9. Shipping Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 10. Remove the Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 11. Remove the Bumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 12. Place the Blocks beneath the Corner Levelers . . . . . . . . . . . . 32

Figure 13. Lower the Cabinets onto the Blocks and Remove the Lifts . . 32

Figure 14. Remove the Straps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 15. Remove the Cardboard Lid and Panels . . . . . . . . . . . . . . . . . . 33

Figure 16. Remove the Four Shipping Bolts . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 17. Remove the Pallet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 18. Remove the Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 19. Lower the Cabinets to the Floor . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 20. CRAY T3E AC Cabinet Layout . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 21. Door Latches and Handle (Front Door) . . . . . . . . . . . . . . . . . . 39

Figure 22. Cabinet Floor Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 23. Temporary Cabinet Positions . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 24. CRAY T3E AC Cabinet Layout . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 25. Door Latches and Handle (Front Door) . . . . . . . . . . . . . . . . . . 43

Figure 26. Cabinet Floor Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 27. Temporary Cabinet Positions for Prejoined Cabinets . . . . . . . 45

Figure 28. Access Panel Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 29. Frame-bolt Holes and Wire-duct Locations . . . . . . . . . . . . . . 50

Figure 30. Cable Troughs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

CRAY T3E AC Multiple-cabinet Installation

HMM-369-0 Cray Research Proprietary 5

Figure 31. Six-cabinet System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 32. Frame-joiner Bolt Locations . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 33. Frame-joiner Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 34. Intercabinet Cable Duct Locations . . . . . . . . . . . . . . . . . . . . . 56

Figure 35. Intercabinet Cable Duct (as viewed from inside cabinet) . . . . 57

Figure 36. Chassis Ground Connections (Rear View of Cabinet) . . . . . . 58

Figure 37. Module Camming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 38. Module Setscrew Locations (Rear View of Cabinet) . . . . . . . 61

Figure 39. Removing Plugs from the Top Clock Rail . . . . . . . . . . . . . . . . 62

Figure 40. Loosening the Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 41. Clock Connector Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 42. Removing Clock Rail Connectors . . . . . . . . . . . . . . . . . . . . . . 64

Figure 43. Connector Locations – Bottom Clock Rail . . . . . . . . . . . . . . . 65

Figure 44. Removing a Connector Spring . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 45. Removing a Connector Pin Lock . . . . . . . . . . . . . . . . . . . . . . 66

Figure 46. Example – Clock Wire Labels . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 47. Clock Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 48. System and GigaRing Clock Wire Connections . . . . . . . . . . . 69

Figure 49. Pin Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 50. 2-pin Connector Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 51. Wire Insertion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 52. Wire Insertion with Wire Rod . . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 53. Edge-to-edge Connection – P/N 15224009 . . . . . . . . . . . . . . . 75

Figure 54. Edge-to-edge Connection – P/N 15223701 . . . . . . . . . . . . . . . 75

Figure 55. Direct Boundary Scan Connections . . . . . . . . . . . . . . . . . . . . . 76

Figure 56. 4-pin Edge-to-pigtail Connections . . . . . . . . . . . . . . . . . . . . . 78

Figure 57. 4-pin Edge-to-Pigtail Cable – P/N 15237701 . . . . . . . . . . . . . 79

Figure 58. TDOM > TDIM Daisy Chain Connection - Between Cabinets 80

Figure 59. Scan Jumper/Intermediate Connection – P/N 15223802 . . . . . 81

Figure 60. Connection – Scan Master to End of Daisy Chain –

Scan Chain 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 61. 2-position Socket, Edge-to-Pigtail Cable – P/N 15237601 . . . 83

CRAY T3E AC Multiple-cabinet Installation

6 CrayResearchProprietary HMM-369-0

Figure 62. Boundary Scan Connections to Cabinet 3, Slot 1 . . . . . . . . . . 84

Figure 63. Scan Jumper/Intermediate Connection – P/N 15223802 . . . . . 85

Figure 64. 2-position Pin, Edge-to-Pigtail Cable – P/N 15237801 . . . . . . 86

Figure 65. 2-position Socket, Edge-to-Pigtail Cable – P/N 15237601 . . . 87

Figure 66. Inserting and Seating a Plastic Connector Pin Lock . . . . . . . . 88

Figure 67. Example of Torus Connections . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 68. Connectors P2 and P3 – Torus Cable Assembly . . . . . . . . . . . 91

Figure 69. Module Camming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 70. Installing the Side Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Figure 71. CRAY T3E AC Cabinet Layout . . . . . . . . . . . . . . . . . . . . . . . 97

Figure 72. Door Latches and Handle (Front Door) . . . . . . . . . . . . . . . . . . 98

Figure 73. Cabinet Floor Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Figure 74. Chassis Ground Connections (Rear View of Cabinet) . . . . . . 100

Figure 75. Installing Side Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Figure 76. CRAY T3E Cabinet Components -- Front View . . . . . . . . . . . 103

Figure 77. Voltage Selector Switch (SW1) . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 78. Power-cord Cover and Power-box Cover (Removed) . . . . . . . 105

Figure 79. Filter Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Figure 80. Remote Alarm Contacts - Locations . . . . . . . . . . . . . . . . . . . . 107

Figure 81. WACS Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Figure 82. WACS with Front Panel Open . . . . . . . . . . . . . . . . . . . . . . . . . 109

Figure 83. Power Supply Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Figure 84. Module Setscrew Locations (Rear View of Cabinet) . . . . . . . 111

Figure 85. Typical System - Block Diagram . . . . . . . . . . . . . . . . . . . . . . . 112

Figure 86. WACS Connector Location on I/O Bulkhead . . . . . . . . . . . . . 114

Figure 87. I/O Bulkhead – Connector Locations . . . . . . . . . . . . . . . . . . . 115

Figure 88. Example GigaRing Connections . . . . . . . . . . . . . . . . . . . . . . . 116

Figure 89. GigaRing Connectors on PC-10 (Rear View) . . . . . . . . . . . . . 117

Figure 90. NSR-1 GigaRing Connectors . . . . . . . . . . . . . . . . . . . . . . . . . 118

Figure 91. MPN-1 GigaRing Connectors . . . . . . . . . . . . . . . . . . . . . . . . . 118

Figure 92. WACS Summary Screen - Standby Mode . . . . . . . . . . . . . . . . 120

CRAY T3E AC Multiple-cabinet Installation

HMM-369-0 Cray Research Proprietary 7

Figure 93. Power Supply Circuit Breakers and LEDs . . . . . . . . . . . . . . . 123

Figure 94. T3EMS Main Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Figure 95. T3EMS Scan Tool Options Window . . . . . . . . . . . . . . . . . . . . 126

Figure 96. Load Program Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Figure 97. PE Configuration Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Figure 98. Access Panel Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Figure 99. Connector Removal with Mechanical Pencil . . . . . . . . . . . . . 133

Tables

Table 1. Required Power Receptacle Test Readings . . . . . . . . . . . . . . . 15

Table 2. Remote Alarm Contacts - Descriptions . . . . . . . . . . . . . . . . . . 107

Table 3. Bottom Scanner DIP Switch Functions . . . . . . . . . . . . . . . . . . 109

Table 4. Cable Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Table 5. Example Cable Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Table 6. CRAY T3E AC I/O Bulkhead GigaRing Connections . . . . . . 115

Table 7. Offline Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Record of Revision CRAY T3E AC Multiple-cabinet Installation

8 CrayResearchProprietary HMM-369-0

Record of Revision

Revision 0: October 1996

Original printing.

Overview

These installation procedures are intended to assist Cray Research personnel

with the mechanical installation of 2 or more CRAY T3E air-cooled (AC)

cabinets. The installation includes the following tasks:

•Unpacking and positioning the system components

•Connecting cables

•Powering on the system and verifying operation

•Verifying system function with diagnostics

This document provides an efficient sequence for the installation. You may

deviate from the sequence as required; however, when possible, perform the

procedures in the order shown.

Cray Research ships CRAY T3E AC cabinets in three shipping configurations:

1 cabinet per shipping crate, 2 cabinets per crate, and 3 cabinets per crate. When

a crate contains 2 or 3 cabinets, the cabinets are bolted together and the wires

that pass between cabinets are connected.

As a result of these variable shipping configurations, you may not be required

to complete internal cabinet wiring. For example:

•If your system contains 2 or 3 cabinets, and the cabinets are bolted

together during shipment, then you do not need to complete internal

cabinet wiring.

•If your system contains 4 or more cabinets, or if you must otherwise bolt

cabinets together, then you must complete internal cabinet wiring.

Your system configuration and site access restrictions determine how your

system ships.

NOTE: This document uses the term prejoined to refer to cabinets that are

bolted together during shipment.

This document does not contain troubleshooting procedures, nor does it contain

installation procedures for peripheral equipment.

CRAY T3E AC Multiple-cabinet Installation Overview

HMM-369-0 Cray Research Proprietary 9

For information on the PC-10 installation, refer to Peripheral Cabinet (PC-10)

Installation, publication HMM-371. For information on the SWS installation,

refer to System Workstation, publication HMM-222.

For information on the CRAY T3E software installation, refer to the CRAY T3E

Software Installation and Configuration Guide, publication SG-2610. For

information on a single-cabinet installation, refer to CRAY T3E AC

Single-cabinet Installation Procedures, HMM-164.

Installationpersonnel shouldhaveabasicknowledgeof computersystem power

processes. They should also have a basic understanding of the control system,

the layout of the various cabinet components, and of running offline diagnostics.

The installation coordinator is responsible for CRUISE (Cray Research Unified

System Enterprise) registration and for installation reporting. The system log

book in the “OPEN FIRST” box contains a copy of the Web-based Installation

Reporting tool. You may use the paper copy to help track the installation and,

if necessary, to fax the information.

Safety Information CRAY T3E AC Multiple-cabinet Installation

10 CrayResearchProprietary HMM-369-0

Safety Information

The following subsections contain important safety information that you must

read and understand before you begin the CRAY T3E AC system installation.

Hazard Statements

During the installation of the computer system, be alert for hazard advisory

statements. The following list describes the hazard statement signal words:

•Danger indicates an imminently hazardous situation that, if not avoided,

will result in death or serious injury.

•Warning indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury.

•Caution indicates a potentially hazardous situation that, if not avoided,

may result in minor or moderate injury. This signal word is also used to

alert personnel against unsafe practices that can result in equipment

damage and/or data corruption.

ESD Precautions

Observe electrostatic discharge (ESD) precautions during the entire installation

process. Required apparel includes an ESD smock and an ESD wrist strap.

ESD Smock

Wear a Cray Research-approved static-dissipative smock when servicing or

handling an ESD-sensitive device. Completely button the smock and wear it as

the outermost layer of clothing. You must have a portion of the smock’s sleeves

in direct contact with the skin of your arms. Skin contact is essential for a

dissipativepath-to-earth groundthrough yourwriststrap. Tuck hairthatexceeds

shoulder length inside the back of the smock.

CAUTION

Observe all ESD precautions. Failure to

do so could result in damage to the

equipment.

CRAY T3E AC Multiple-cabinet Installation Safety Information

HMM-369-0 Cray Research Proprietary 11

Wrist Strap

Wear a Cray Research-approved wrist strap when servicing or handling an

ESD-sensitive device to eliminate possible ESD damage to equipment. Connect

the wrist strap cord directly to earth ground.

NOTE: The CRAY T3E AC cabinet contains two sets of jacks (front and

rear) for a mating ESD ground strap.

Safety Precautions

Beforeyouperformtheproceduresinthisdocument,takeafewminutestoreview

the Safety and ESD Guidelines, publication number HGM-016. In addition,

observethefollowingsafetymeasureswheninstalling,repairing,ormaintaining

the system.

•Use caution when removing the cabinets from the ramps. Moving these

cabinets can cause personal injury or property damage if the cabinets are

not handled properly.

•Ensure that the cabinet crates are positioned close to their final positions

before you unpack them.

•Do not move the cabinets while they are connected to power.

•Do not wear watches or jewelry when you work on a CRAY T3E system

cabinet.

•Keep fingers and conductive tools away from high-voltage areasand from

high-current areas.

•Ensure that a qualified electrician has properly installed the power

receptacles.

DANGER

Keep fingers and conductive tools away

from high-voltage areas. Serious injury

or death will occur if these precautions

are not followed.

Safety Information CRAY T3E AC Multiple-cabinet Installation

12 CrayResearchProprietary HMM-369-0

•Set all circuit breakers to the OFF (0) position before you plug in the

system power cord.

•Unplug, lock, and tag the cabinet power plug before you work on the

power system components.

•Remove all tools from the system cabinets after you service them.

•Replace all covers and panels that you removed from the system during

servicing.

•Power off the system only after the system software has been shut down

in an orderly manner.

DANGER

Unplug, lock, and tag the AC cord.

Failure to do so will result in damage to

the equipment and serious injury or

death to the maintenance person.

CAUTION

If you power off the system before you halt the

operatingsystem,youmaylose system and customer

files (data).

CRAY T3E AC Multiple-cabinet Installation Preinstallation Activities

HMM-369-0 Cray Research Proprietary 13

Preinstallation Activities

Before you install your system, read the following subsections and verify that

your site meets all site requirements.

Tools Required

Ensure that you have the following tools, which are necessary to complete the

hardware installation. These tools are available from Cray Research’s Customer

Service Logistics department or from any hand-tool vendor. (The Logistics part

number for the CRAY T3E tool kit is 57247800.)

•Multimeter

•Cutters

•Adjustable wrench or 11-mm, 15-mm, and 16-mm wrenches

•0.5-in., 3-mm, and 4-mm hex (Allen) wrenches with driver

•#1 and #2 Phillips screwdrivers

•Small and medium flatblade screwdrivers

•Flashlight

•Heat gun (optional)

•Wiring tools (if you must join cabinets), including:

•0.3-mm mechanical pencil, with no lead (or a wire removal tool)

•Dental pick

•Hemostats, tweezers, or wire insertion tool (all optional)

Checking Site Planning Requirements

Before you install your CRAY T3E system, ensure that your site meets all of the

site planning requirements included in Preparing for a CRAY T3E Air-cooled

SystemInstallation,CrayResearchpublicationnumberHR-04118.Forexample,

take some time to verify the following things:

•Verify that the site has appropriate means (pallet jacks, etc.) for unloading

and transporting the system components.

•Verify that the route to the computer room is free of obstacles.

•Verify that the computer room floor is prepared according to the floor

layout diagram for the system.

•Verify that floor cutouts are complete, correct, and free of sharp edges and

burrs.

Preinstallation Activities CRAY T3E AC Multiple-cabinet Installation

14 CrayResearchProprietary HMM-369-0

•Verify that all electrical services meet site planning specifications.

•Verify that the air-conditioning equipment meets site planning

specifications.

•Verify that the ground clamps (for grounding the cabinets to the floor

grid) are in the correct locations (near the floor cutouts for I/O cables).

Checking the Power Cord Receptacles

Ensure that a qualified electrician installed the correct power receptacles

accordingto siteplanning specifications.Then CrayResearch-trainedpersonnel

should use the following procedure to ensure that the power receptacles are

properly wired. Refer to Figure 1 for drawings of the 3-phase power plugs and

receptacles that are available for CRAY T3E AC cabinets.

Performthefollowingprocedureforeachpowercordreceptaclethatwillsupport

a CRAY T3E AC cabinet:

1. Turn off, lock, and tag the customer’s circuit breaker(s) that control power

for the CRAY T3E AC cabinet power receptacle before you perform

Step 2 and Step 3.

2. Set the multimeter to a low-resistance setting.

3. Measure between the power receptacle ground-post hole and an

appropriate earth-ground location and ensure that resistance is less than

1 ohm. Figure 1 shows the post hole locations. (Appropriate earth-ground

locations could include the floor grid, a metal case receptacle, and a

circuit breaker shell.)

4. Remove the lock and tag and restore power through the customer’s circuit

breaker(s).

5. Set the multimeter to a high AC-voltage range.

DANGER

Ensure that the electrical circuit

breakers for the power receptacle being

checked are off, locked, and tagged.

Failure to do so could result in severe

shock and burns.

CRAY T3E AC Multiple-cabinet Installation Preinstallation Activities

HMM-369-0 Cray Research Proprietary 15

6. Measure between the ground-post hole and an appropriate earth-ground

location. If you detect voltage on the ground-post hole, contact a

site-approved electrician. Do not proceed with the installation.

NOTE: The ground wire may act as an antenna and, through

impedance, generate a low voltage (usually less than 1 Vac).

This is normal.

7. Perform voltage checks between the posts listed in Table 1. Refer again to

Figure 1, which shows the post locations.

Table 1. Required Power Receptacle Test Readings

Cord Assembly From Post To Post Meter Reading

P/N 57181600

60 A, 250 Vac

(4-post cord

[delta] used

commonly in

North America

and Japan)

L1 G Not to exceed 140 Vac

L2 G Not to exceed 140 Vac

L3 G Not to exceed 140 Vac

L1 L2 Between 180 and 240 Vac

L2 L3 Between 180 and 240 Vac

L1 L3 Between 180 and 240 Vac

P/N 57181700

32 A, 400 Vac

(5-post cord

[wye] used

commonly in

Europe)

L1 N Not to exceed 260 Vac

L2 N Not to exceed 260 Vac

L3 N Not to exceed 260 Vac

L1 L2 Between 360 and 440 Vac

L2 L3 Between 360 and 440 Vac

L1 L3 Between 360 and 440 Vac

Preinstallation Activities CRAY T3E AC Multiple-cabinet Installation

16 CrayResearchProprietary HMM-369-0

Figure 1. Power Plugs and Receptacles

Power Wiring for High-leakage Current

Please note the following statement by Underwriters Laboratories, Inc.

An insulated earthing conductor that is identical in size, insulation material, and

thickness to the earthed and unearthed branch-circuit supply conductors except

that it is green with or without one or more yellow stripes is to be installed as

partof thebranch circuitthatsuppliestheunitorsystem.Theearthingconductor

described is to be connected to earth at the service equipment or, if supplied by

a separately derived system, at the supply transformer or motor-generator

(UL 60 95).

L1

L2 L3

N

L2

L3

4-post (~250 Vac) Power

Plug and Receptacles

L1

Ground

L3

L2 L2

Ground

Ground

L1

N

L3

N

L1

Ground

5-post (400 Vac) Power

Plug and Receptacles

L2

CRAY T3E AC Multiple-cabinet Installation Unloading the Computer System

HMM-369-0 Cray Research Proprietary 17

Unloading the Computer System

Cray Research ships CRAY T3E AC cabinets in three shipping configurations:

1 cabinet per shipping crate, 2 cabinets per crate, and 3 cabinets per crate. Your

configuration and site access restrictions determine how your system ships.

If your system includes 1 or more cabinets that ship singly (1 cabinet per crate),

the side panels are installed on the single cabinet(s). If your system does not

include a cabinet that ships singly, then the side panels ship in separate boxes.

Figure 2 shows the CRAY T3E AC single-cabinet shipping configuration, lift

openings, and dimensions. Figure 3 shows the CRAY T3E AC 3-cabinet

shipping configuration, lift openings, and dimensions. The 2-cabinet shipping

configuration is a smaller version of the 3-cabinet configuration.

In most cases, if your loading dock is the same height as the transportation

vehicle, you may use ROL-A-LIFTs or pallet jacks to unload the system from

the transportation vehicle. Specifically, you may use a pallet jack to unload a

shipping crate that contains only 1 cabinet, and you must use ROL-A-LIFTs to

unload shipping crates that contains 2 or 3 cabinets.

When you use ROL-A-LIFTs, position the ROL-A-LIFTs on the ends of the

shippingcrateas shown in Figure 3.Ensurethat you place aboardbetween each

ROL-A-LIFT and the side of the shipping crate as shown in Figure 3; position

theboard 35 to40 in.(889to 1,016mm)from thetopof theshipping crate. (Two

2 in. x4 in. boards are supplied with each crate that contains 2 or 3 cabinets; the

boards are strapped to the outside of the crate.)

NOTE: You will use the ROL-A-LIFTs when you unpack crates that

contain 2 or 3 cabinets.

If the loading dock is not level with the vehicle, you must provide a forklift or

anotherapprovedmethod to unload thesystem.A platform or rampmaybe used

to obtain the desired level as long as the ramp does not exceed a ratio of 1 unit

vertical to 6 units horizontal. Refer to Preparing for a CRAY T3E Air-cooled

System Installation, publication HR-04118, for more information on site

requirements.

CAUTION

Prevent computer equipment from

rolling off the transportation vehicle.

Failure to do so could result in serious

damage to the computer equipment.

Unloading the Computer System CRAY T3E AC Multiple-cabinet Installation

18 CrayResearchProprietary HMM-369-0

Ifthecomputersitedoesnothavealoadingdock,arrangeforaforklifttoremove

the computer from the transportation vehicle.

Ensurethatatleasttwopeopleareavailabletohelpmovethemainframecabinets.

(We recommend that four or more people help move crates that contain 2 or 3

cabinets.) Perform all movement of the cabinets slowly and carefully. Follow

any instructions that are printed on the packing crates.

Figure 2. Single-cabinet Shipping Configuration

CRAY T3E AC Multiple-cabinet Installation Inspecting the System

HMM-369-0 Cray Research Proprietary 19

Figure 3. Three-cabinet Shipping Configuration

Inspecting the System

Theshippingcratescontainthemainframecabinets,PC-10,systemworkstation,

additional system components, and system maintenance and user

documentation. After the system is unloaded from the truck, perform the

following steps before you transport and unpack it.

1. Ensure that the boxes arrived unopened. If any boxes are open, identify

and record the opened boxes through the CRUISE system.

2. Inspect the shipping crate for signs of external damage such as dents,

holes, crushed corners, and water marks. Record any signs of external

damage as an installation defect through the CRUISE system.

Later, when you unpack the system, check the contents of each shipping crate

against the packing list, which is attached to the outside of the shipping crate.

112.5 in.

(2,858 mm)

76.5 in.

(1,943mm)

Rolling

Height

63.75 in.

(1,619 mm)

NOTE: The side panels

are shipped separately.

Board(35to40 in. [889to1,016mm]

from top of shipping crate)

Opening the “OPEN FIRST” Box CRAY T3E AC Multiple-cabinet Installation

20 CrayResearchProprietary HMM-369-0

Opening the “OPEN FIRST” Box

Afteryouinspecttheshippingcratesandboxesfordamage,opentheboxmarked

“OPEN FIRST.” This box contains up-to-date versions of this document and

associated installation documents. This box also includes the following

documents that you will refer to during the installation:

•System configuration documentation

•System deviation documentation

•Cable list

To ensure that you have the most accurate information available, use the

installationdocumentsfromthe“OPENFIRST”boxtocompletetheinstallation.

Transporting the Mainframe to the Designated Location

The method you use to move the CRAY T3E AC cabinets depends on the

shipping configuration. This section provides general guidelines. In addition,

follow any instructions that are printed on the packing crates.

Youmayusethefollowingmethodstotransporteachshippingcratethatcontains

1 CRAY T3E cabinet:

•One pallet jack on the side of the crate

•One long pallet jack (approx. 60 in. [152 cm]) on the end of the crate

•Two pallet jacks (one at each end of the crate) – short distances only

Youmayusethefollowingmethodstotransporteachshippingcratethatcontains

2 CRAY T3E cabinets:

•ROL-A-LIFTs at each end of the crate (refer again to Figure 3)

•One pallet jack on the side of the crate – short distances only

Foreachpalletthatcontains3CRAYT3Ecabinets,youmustuseROL-A-LIFTs

(positioned on the ends of the crate) to transport the cabinets.

Cray Research recommends that you leave each system cabinet in its shipping

crate until it reaches its final location. If the crate does not fit through the

planned access route, you may partially disassemble the crate.

Other manuals for T3E

2

Table of contents

Other Cray Industrial Equipment manuals