Cresco 20 SW User manual

Other manuals for 20 SW

1

This manual suits for next models

3

Table of contents

Other Cresco Spreader manuals

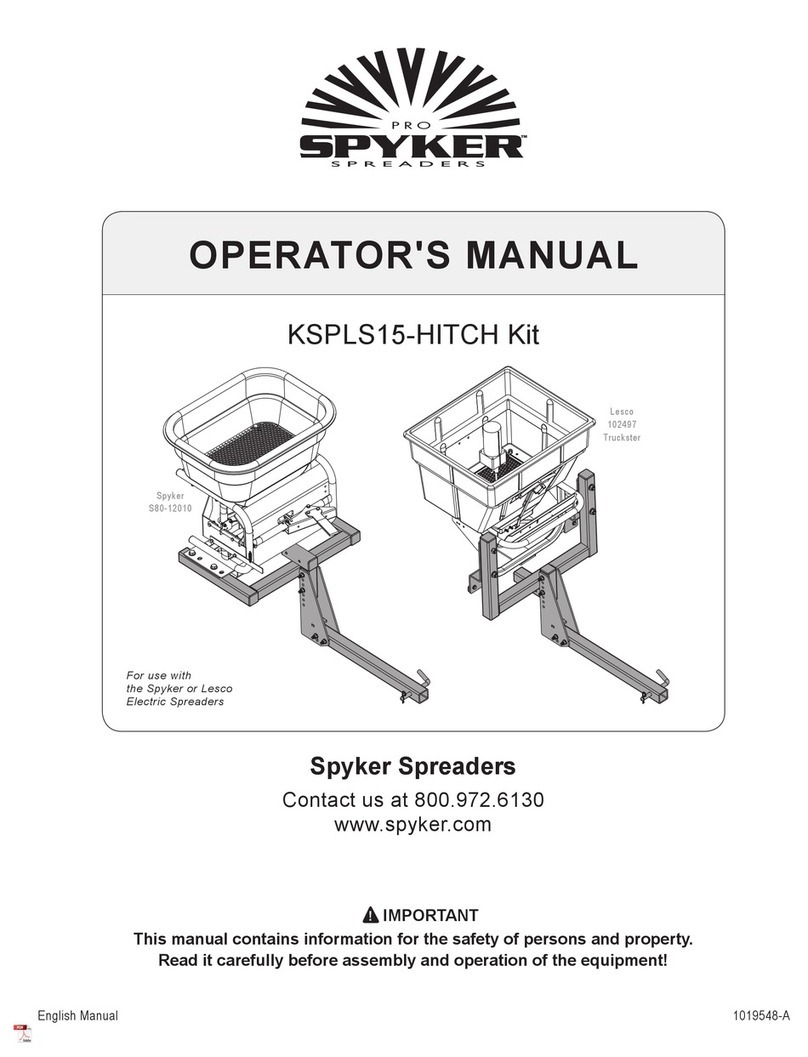

Popular Spreader manuals by other brands

Marshall Amplification

Marshall Amplification MS45 Operating/safety instructions

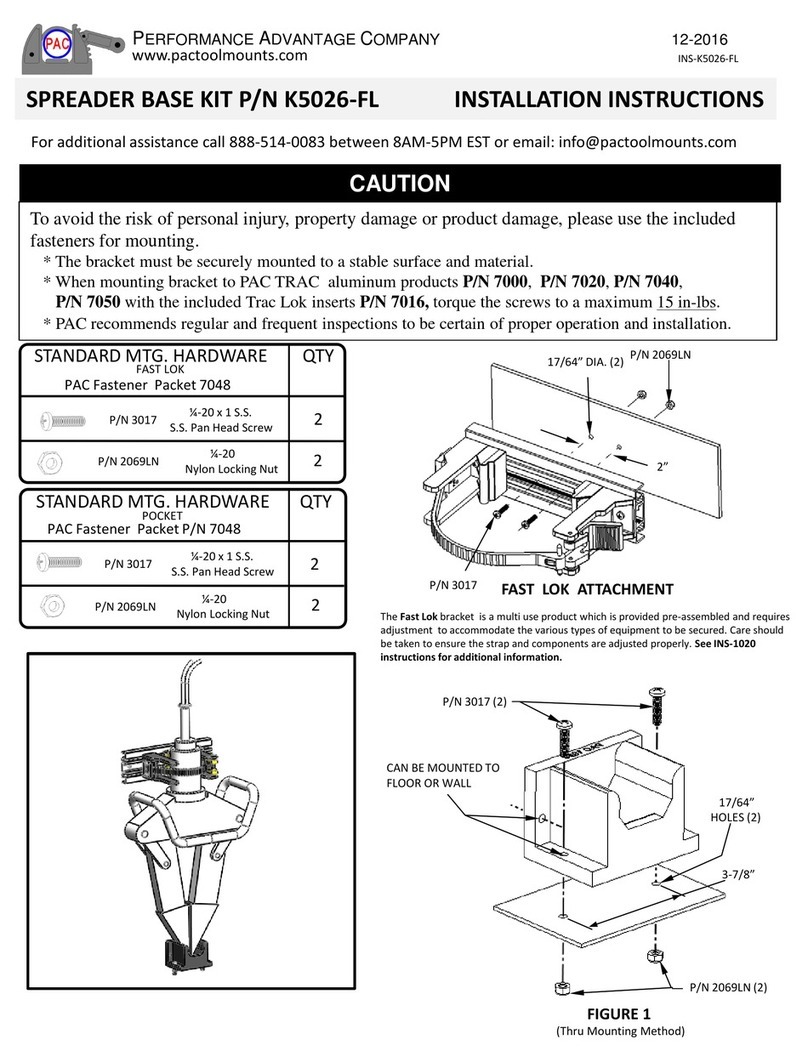

PERFORMANCE ADVANTAGE COMPANY

PERFORMANCE ADVANTAGE COMPANY K5026-FL installation instructions

Pik Rite

Pik Rite Hydra-Ram HR550 Operation and parts manual

Vicon

Vicon RO-M EW user manual

XtremepowerUS

XtremepowerUS 65057 Owner's manual and safety instructions

Fisher Engineering

Fisher Engineering WB-160D Owner's manual and installation instructions

Craftsman

Craftsman 486.1992 owner's manual

Agri-Fab

Agri-Fab 45-02114 owner's manual

Earth Way

Earth Way 2130 Assembly and operating instructions

BOSSCO

BOSSCO TGS 1100 Installation & owner's manual

Hi-Spec

Hi-Spec Xcel 1250 Operator's instruction manual

Earth Way

Earth Way 2040Pi-Plus Assembly and operating instructions