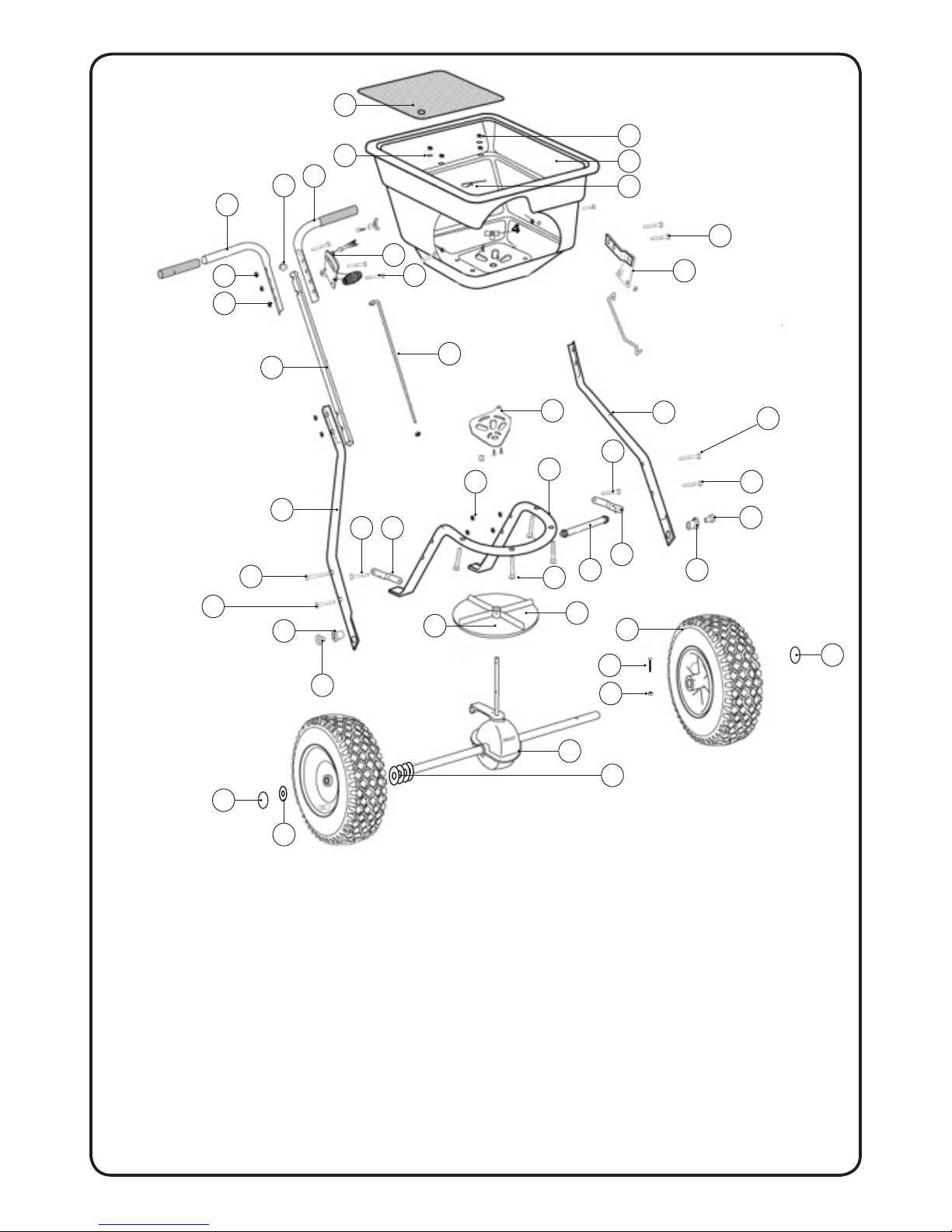

Push the Handle of the Gauge

and Lever Assembly (ITEM 24) to

its lowest position and insert the

upper end of the Control Rod

(ITEM 28) into the hole at the

rear of the Handle.

Take off one of the nuts on

the Control Rod (ITEM 28) and

insert the threaded end into

the angled bracket of the Pivot

Bracket Assembly (ITEM 19)

and afx the nut back onto the

threaded Control Rod.

Take the Rod of the Pivot

Bracket Assembly (ITEM 19) and

insert the threaded end into

the Flow Control Plate (ITEM 29)

located on the underside of the

Hopper (ITEM 25).

ITEM 30 ITEM 28

ITEM 19

ITEM 19 (ROD)

ITEM 29

ITEM 25

ITEM 19

G.

Ensure a 6mm Flat Washer (ITEM 23 - 2 off) is positioned on either side of the Flow Control

Plate and secure in position with an M6 Lock Nut (ITEM 9).

To complete the assembly, insert the R Clip (ITEM 30) into the hole in the vertical shaft of

the Gear Box and Axle Assembly (ITEM 2) from the inside of the Hopper (ITEM 25).

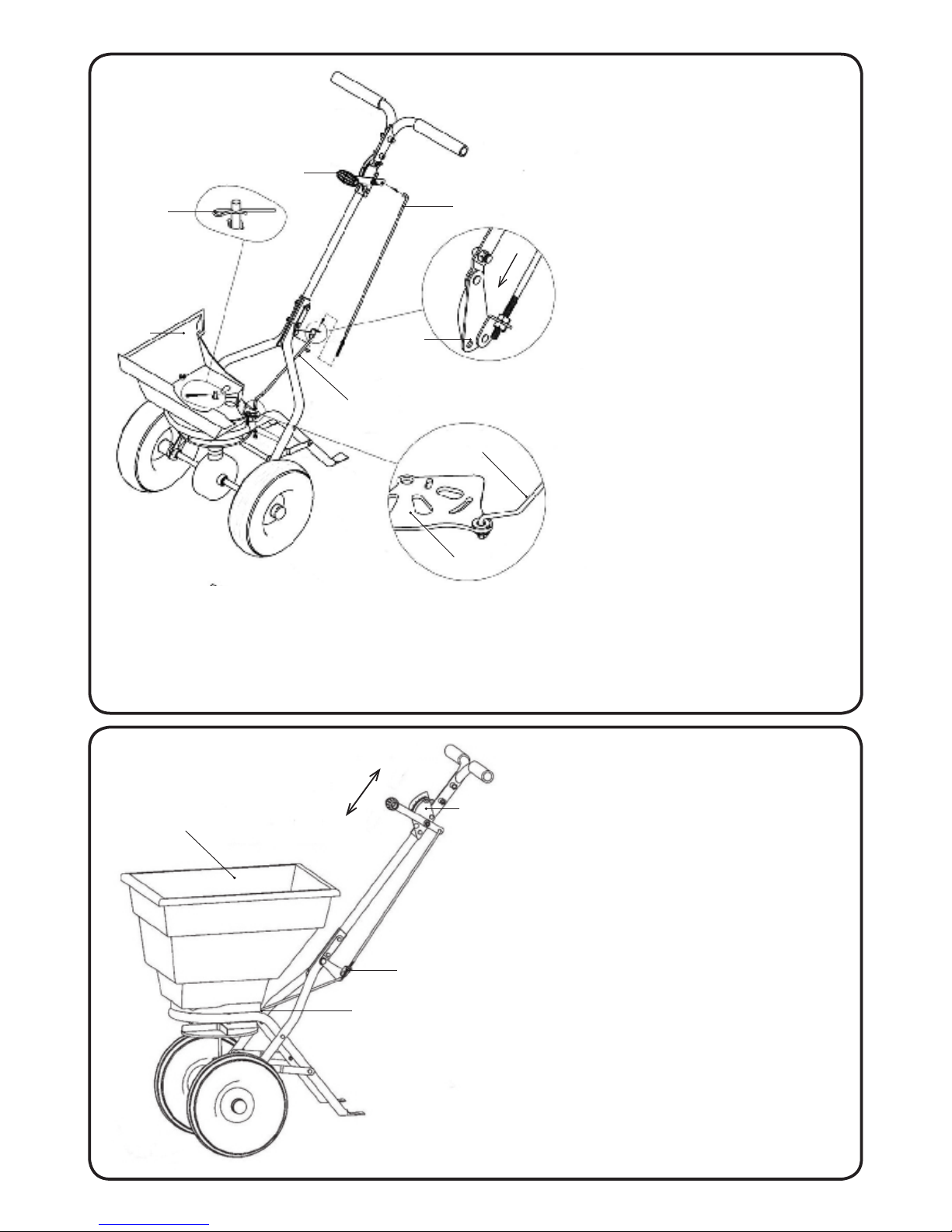

OPEN

CLOSED

ITEM 24

Before use, push the Lever (ITEM 24)

downwards to close the apertures in

the base of the Hopper (ITEM 25) and

pull the Lever upwards to open the

apertures.

If the apertures in the base of the

Hopper do not match the apertures in

the Flow Control Plate (ITEM 29), adjust

the position of the two nuts along the

threaded Control Rod (ITEM 28).

Once the apertures are aligned, fully

tighten both nuts.

To limit the size of the open apertures

when operating the Lever, move the

position of the Wing Nut (ITEM 24).

ITEM 25

ITEM 28

ITEM 29

H.

ITEM 24