Crison 44 User manual

CRI10032.99

MultiMeter 44

3 channel process multi-meter

User manual

Manual del usuario

12, 2017 Edition 2

1

Table of contents

Section 1 Specifications.................................................................................................................... 3

Section 2 General information.......................................................................................................... 7

2.1 Safety information......................................................................................................................... 7

2.2 Overview of product...................................................................................................................... 9

2.3 Instrument composition............................................................................................................... 10

Section 3 Installation......................................................................................................................... 13

3.1 Operating environment ............................................................................................................... 13

3.2 Wall mounting ............................................................................................................................. 13

3.3 Panel mounting........................................................................................................................... 15

3.4 Connections................................................................................................................................ 15

3.5 Installation verification................................................................................................................. 18

Section 4 Operation........................................................................................................................... 19

4.1 Startup ........................................................................................................................................ 19

4.2 Functioning. Keypad ................................................................................................................... 19

4.3 General diagram ......................................................................................................................... 20

4.4 Instrument configuration ............................................................................................................. 21

4.5 pH / mV channel ......................................................................................................................... 22

4.6 Conductivity channel (EC) .......................................................................................................... 27

4.7 DO channel (membrane sensor)................................................................................................. 31

4.8 D.O. Channel (optical sensor)..................................................................................................... 33

4.9 Chlorine channel (galvanic) ........................................................................................................ 36

4.10 Chlorine channel (amperometric).............................................................................................. 42

4.11 Cleaning relay........................................................................................................................... 48

4.12 Alarm relay................................................................................................................................ 48

4.13 Limit relays................................................................................................................................ 49

4.14 Analogical output ...................................................................................................................... 51

4.15 Data Logger .............................................................................................................................. 53

4.16 Temperature readjustment, °C or °F......................................................................................... 54

4.17 Recognized solutions................................................................................................................ 54

Section 5 Advanced operations ..................................................................................................... 57

5.1 RS 232 communication............................................................................................................... 57

5.2 RS 485 output............................................................................................................................. 61

5.3 PROFIBUS DP/V0 Output .......................................................................................................... 66

Section 6 Maintenance ..................................................................................................................... 71

6.1 Clean the measuring instrument................................................................................................. 71

6.2 Fuse replacement ....................................................................................................................... 71

6.3 Instrument power cord ................................................................................................................ 72

6.4 Disconnecting device.................................................................................................................. 72

Section 7 Troubleshooting............................................................................................................... 73

7.1 Error messages........................................................................................................................... 73

Section 8 Replacement parts and accessories........................................................................... 75

Section 9 Garantía limitada.............................................................................................................. 77

Appendix A Channel extension (addition)................................................................................... 79

A.1 Board installation....................................................................................................................... 79

2

Table of contents

3

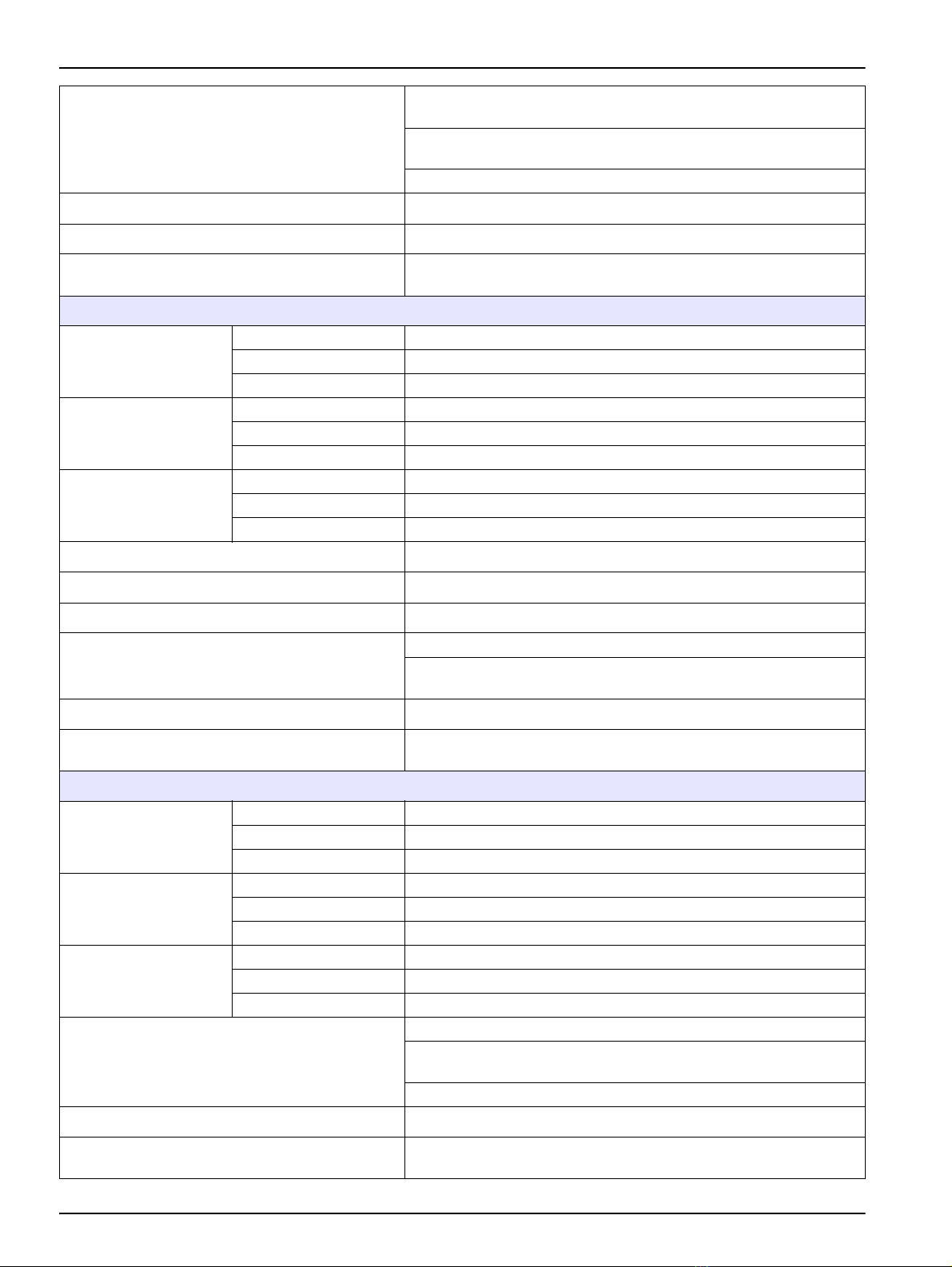

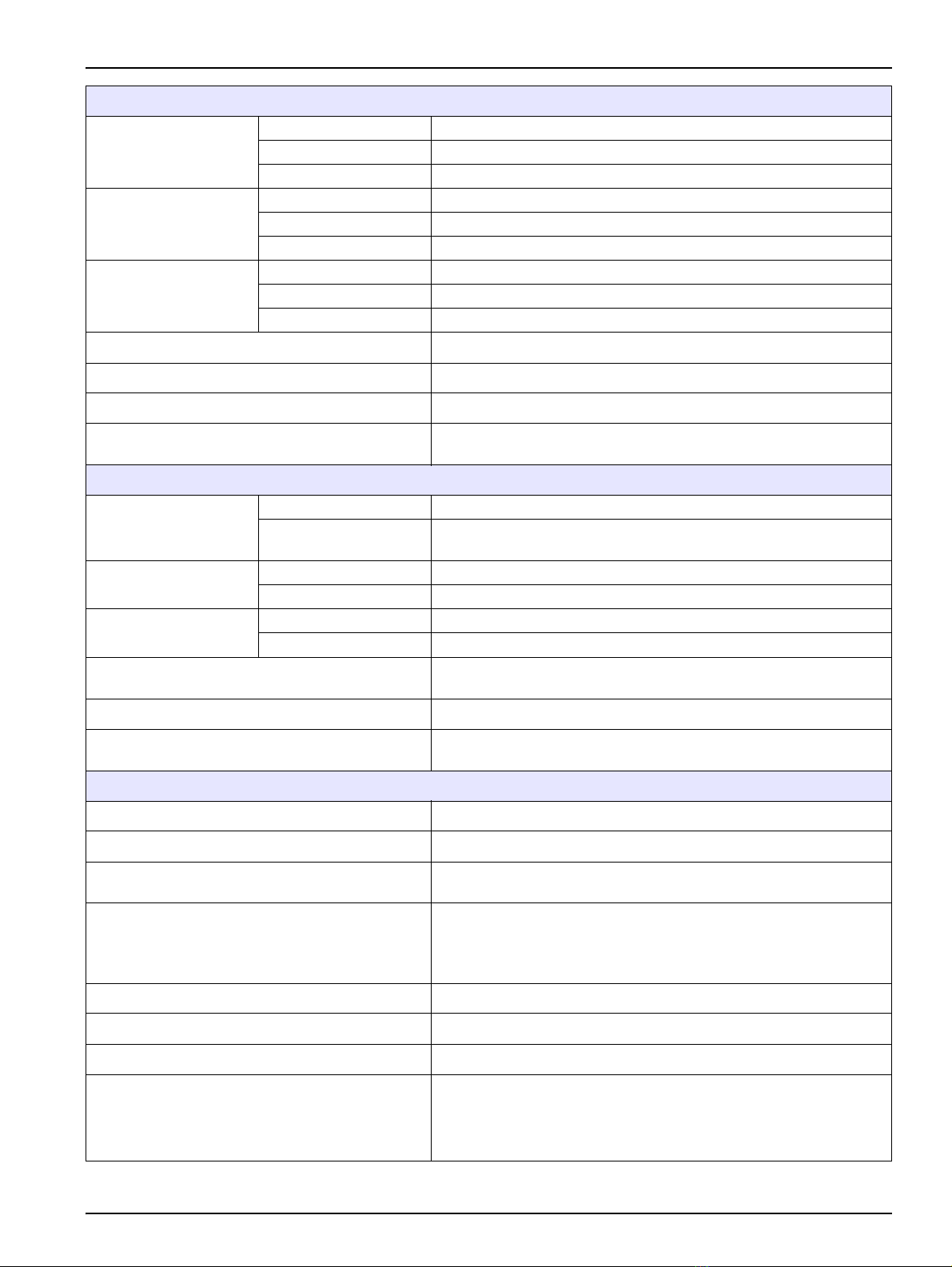

Section 1 Specifications

Specifications are subject to change without prior warning.

pH / mV measuring channel

Measuring Range

pH -2 to16 pH

mV ± 2000 mV

Temperature –20 to 150 ºC

Resolution

pH 0.01

mV 1

Temperature 0.1 ºC (0.18 ºF)

Measuring error

(± 1 digit)

pH ≤0.05

mV ≤3

Temperature ≤0.5 ºC (≤0.9 ºF)

Temperature

compensation

pH With Pt 1000 probe or manual introduction

mV Compensation is not carried out

Calibration

pH

1, 2 or 3 buffers to choose among pH 2.00, 4.01, 7.00, 9.21 and 10.90

at 25 ºC (77 ºF)

Acceptance criteria: asymmetry ± 58 mV, sensibility 70 to 105%

Indirect calibration at any pH value

Manual introduction of electrode calibration data

mV

In one point, 220 mV at 25 ºC (77 ºF)

Acceptance criteria: ± 60 mV respect to the theoretical value of the

standard at the calibration temperature

Indirect calibration or manual readjustment at any mV value

Manual introduction of electrode calibration data

Temperature readjustment Correction of the probe deviation

Relays 2 for limit. Switch N/O. Maximum load: AC < 250 V / < 3 A / < 750 VA.

Analogical outputs Two 4 to 20 mA outputs. One for pH or mV and the other for

temperature. R. maximum 500 Ohm

Channel for E. C. measurement (electrical conductivity)

Measuring interval

(resolution according

to measured range)

Conductivity 0.01* µS/cm to 1000** mS/cm (* with C = 0.1 cm-1 ** with C ≥9 cm-1)

Salinity 5.85 mg/L to 278 g/L NaCl

T.D.S. 0 mg/L to 200 g/L

Resistivity 5 Ohm×cm to 100 MOhm×cm

Temperature –20 to 150 ºC (–4 to 302 ºF)

Measuring error

(± 1 digit)

Conductivity ≤1% of measured value

Salinity ≤1% of measured value

T.D.S . ≤1% of measured value

Resistivity ≤1% of measured value

Temperature ≤0.4 ºC (≤0.72 º)

Temperature compensation Using Pt 1000 integrated probe in the cell or data entrance by keypad

Reference temperature, TR 20 or 25 ºC

Temperature coefficient, TC 0.00 to 5.00% / ºC

4

Specifications

Calibration

1, 2 or 3 standards to choose among: 147 µS/cm, 1413 µS/cm,

12.88 mS/cm and 80.4 mS/cm at 25 ºC (77 ºF)

Indirect (manual) calibration readjusting any value of conductivity,

salinity, TDS, resistivity or temperature

Manual introduction of the cell constant

TDS conversion factor Programmable between 0.40 to 1.00. Factory setting: 0.64

Relays 2 for limit. Switch N/O. Maximum load: AC < 250 V / < 3 A / < 750 VA

Analogical output Two 4 to 20 mA outputs. One for conductivity, salinity, TDS or

resistivity and the other for temperature. R. maximum 500 Ohms

DO measuring channel (membrane electrode)

Measuring Range

% 0 to 500

ppm 0 to 50

Temperature 0 to 50 ºC (32 to 122 ºF)

Resolution

%0.1

ppm 0.01

Temperature 0.1

Measuring error

(± 1 digit)

%≤0.1%

ppm ≤0.1%

Temperature ≤0.4 ºC (≤0.72 ºF)

Temperature compensation With NTC probe integrated inside the sensor

Salinity compensation Automatic with manual entrance by keypad

Pressure compensation Automatic with manual entrance by keypad

Calibration

In 1 point, in air, relative humidity 100%

Indirect calibration or manual readjustment at any DO value in % or

ppm

Relays 2 for limit. Switch N/O. Maximum load: AC < 250 V / < 3 A / < 750 VA

Analogical outputs Two 4 to 20 mA outputs. One for D.O. and the other for temperature.

R. maximum 500 Ohms

DO measuring channel (optical electrode)

Measuring Range

% 0 to 250

ppm 0 to 25

Temperature 0 to 60 ºC (32 to 140 ºF)

Resolution

%0.1

ppm 0.01

Temperature 0.1

Measuring error

(± 1 digit)

%≤0.1%

ppm ≤0.1%

Temperature ≤0.5 ºC (≤0.9 ºF)

Calibration

In 2 points, one of them 0.00 ppm

Indirect calibration or manual readjustment at any DO value in % or

ppm

Reset of calibration

Relays 2 for limit. Switch N/O. Maximum load: AC < 250 V / < 3 A / < 750 VA

Analogical outputs Two 4 to 20 mA outputs. One for D.O. and the other for temperature.

R. maximum 500 Ohms

5

Specifications

Free residual chlorine measuring channel (galvanic)

Measuring Range

mg/L (ppm) 0 to 5

mV ± 2000

Temperature 0 to 60 ºC (32 to 140 ºF)

Resolution

mg/L (ppm) 0.01

mV 1

Temperature 0.1

Measuring error

(± 1 digit)

mg/L (ppm) ≤1%

mV ≤2

Temperature ≤0.4 ºC (≤0.72 ºF)

Temperature compensation With Pt 1000 sensor integrated in the probe

Calibration Indirect or manual calibration readjusting any value of free chlorine

Relays 2 for limit. Switch N/O. Maximum load: AC < 250 V / < 3 A / < 750 VA

Analogical outputs Two 4 to 20 mA outputs. One for chlorine and the other for

temperature. R. maximum 500 Ohms

Free residual chlorine measuring channel (membrane)

Measuring Range

mg/L (ppm) 0 to 20

Temperature 5 to 45 ºC (41 to 113 ºF) (Only if a temperature probe Pt1000 is

connected)

Resolution mg/L (ppm) 0.01

Temperature 0.1 (Only if a temperature probe Pt1000 is connected)

Measuring error

(± 1 digit)

mg/L (ppm) ≤1%

Temperature ≤0.4 ºC (≤0.72 ºF) (Only if a temperature probe Pt1000 is connected)

Calibration Calibration against a reference value obtained by DPD-1, readjusting

at any chlorine value in the measuring range

Relays 2 for limit. Switch N/O. Maximum load: AC < 250 V / < 3 A / < 750 VA

Analogical outputs Two 4 to 20 mA outputs. One for chlorine and the other for

temperature. R. maximum 500 Ohms

Common specifications for all channels

Control mode ON/OFF and Proportional

Data Logger Storage of 2000 data

Relays 1 sensors cleaning (N/O) and 1 alarm (N/C). Maximum load: CA < 250

V / < 3 A / < 750 VA

4-20 mA output

230 V and 115 V instruments: 4-20 mA signal is galvanically isolated

from mains ground.

24 V instrument: 4-20 mA signal is not galvanically isolated from

mains ground.

Communication RS 232 C (Optionally RS 485 and PROFIBUS)

Display Graphic, LCD, backlit, 128 x 64 dots.

Keypad Membrane, 7 keys. Material PET with protective treatment.

Power supply

230 V AC ±10 %, 45-65 Hz 10 VA (standard version)

24 V AC/DC ±10 %, 45-65 Hz 10 VA (standard version)

115 V AC ±10 %, 45-65 Hz 10 VA (under demand)

Overvoltage category: II.

6

Specifications

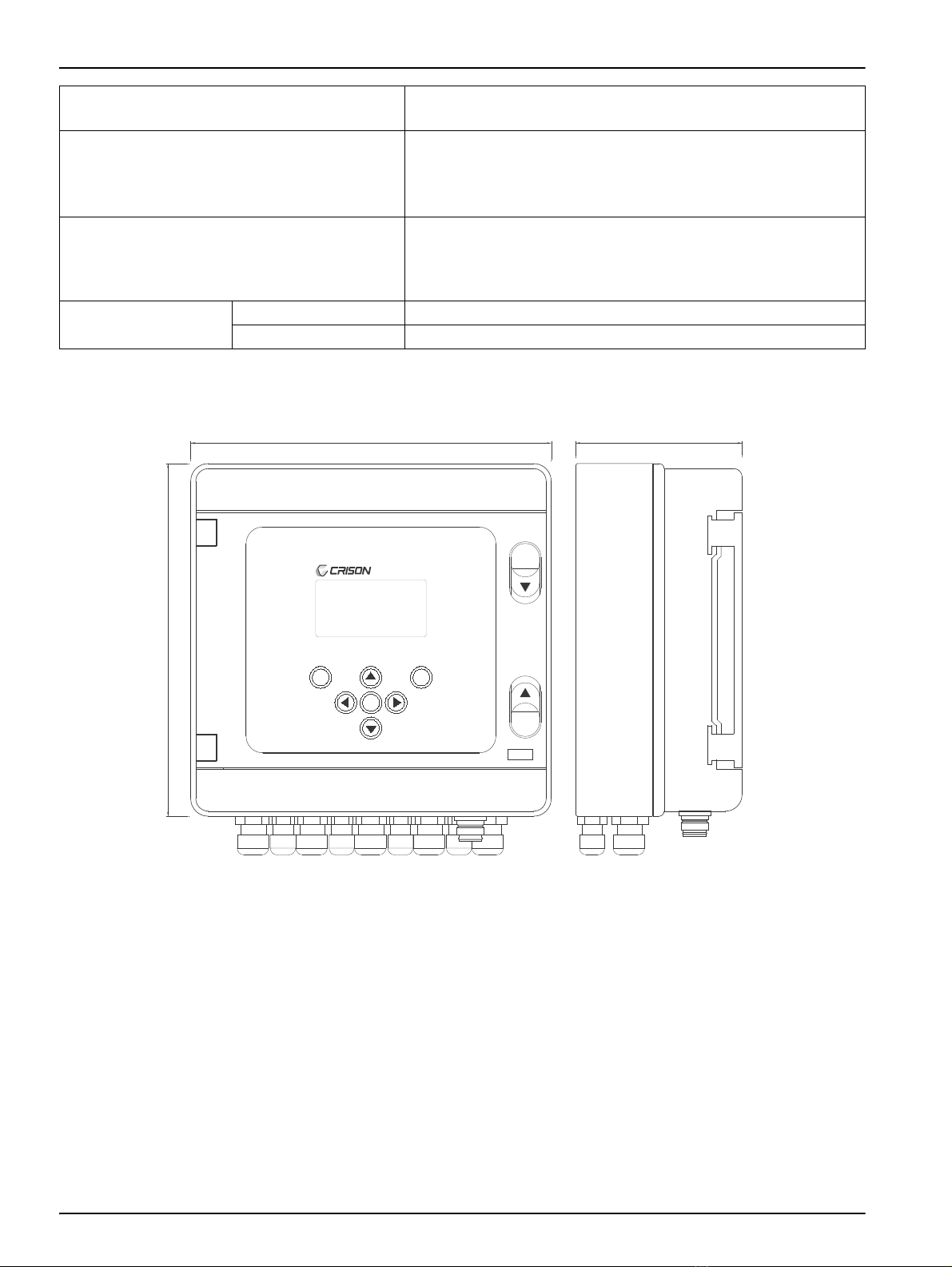

Figure 1 Instrument dimensions

EC Directives Electrical security according to 2006/95/EC

Electromagnetic compatibility according to 2004/108/EC.

Environmental conditions

Working temperature: 0 to 50 ºC (32 to 122 ºF)

Storage temperature: -20 to 65 ºC (-4 to 149 ºF)

Relative humidity < 80 % (non condensing)

Altitude requirements: max. 2000 m (6562 ft) ASL (Above Sea Level)

Enclosure

Protection IP 65 (With rear cover installed, transparent door closed

and connector MP-5 protected.)

Inflammability rate, Glow wire test 650ºC, UL 94 HB.

Material free of halogens

Physical parameters Weight 1800 g

Dimensions 210 x 215 x 100 mm. (see Figure 1)

MultiMeter 44

ESC

OK

*

IP 65

215

210

100

7

Section 2 General information

As a result of constant improvements to our products sometimes differences may exist

between this manual and the instructions supplied with the instrument.

2.1 Safety information

Please, read carefully this information before installing and using the instrument!

Pay attention to all danger and caution statements.

Follow all instructions and recommendations in this manual. Otherwise the protection

provided in the instrument may be compromised and damaged. If the instrument is used in

a manner not specified by the manufacturer, the protection provided by the instrument

may be impaired.

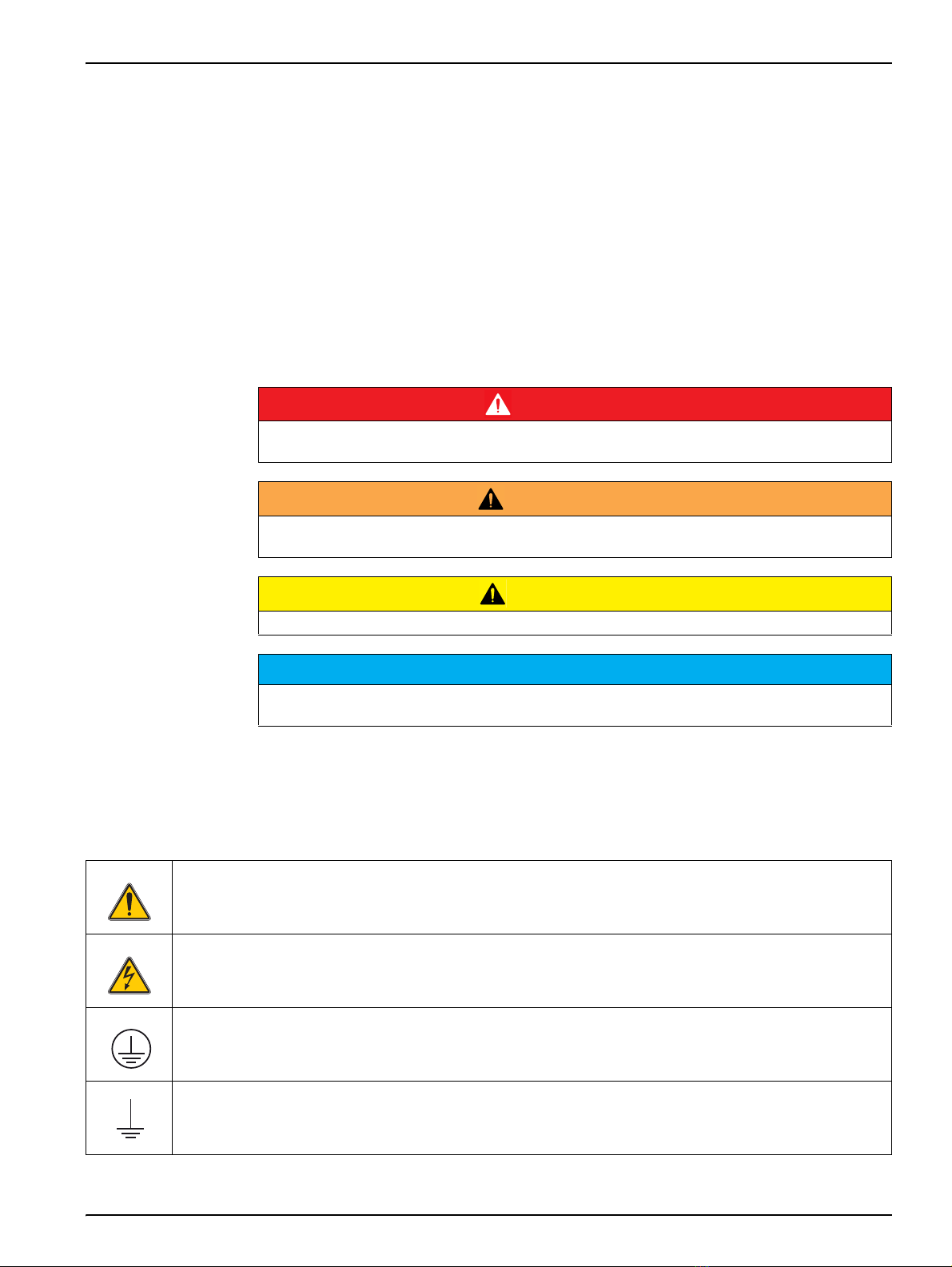

2.1.1 Use of hazard information

Note: Information that supplements points in the main text.

2.1.2 Warning labels

Read carefully all labels and tags attached to the instrument.

DANGER

Indicates a potentially or imminently hazardous situation that, if not avoided, results in death or

serious injury.

WARNING

Indicates a potentially or imminently hazardous situation that, if not avoided, could result in death

or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate injury.

NOTICE

Indicates a situation that, if not avoided, could result in damage to the instrument. Information that

requires special emphasis.

This symbol, if noted on the instrument, references the instruction manual for operation and/or safety

information

This symbol may be found on an enclosure or barrier within the product and indicates a risk of electrical shock

and/or death by electrocution

This symbol indicates the connection for Protective Earth

This symbol indicates the connection for ground

8

General information

2.1.3 Safety information for the correct use of the instrument

•Remember that the voltage across accessible parts of the open instrument, may be

dangerous to life. Do not open the instrument when it is connected to the power

supply, there are areas whose voltage could cause death.

•Always disconnect power to the instrument before it is opened.

•Repair or adjustment of an opened instrument under voltage shall be carried out only

by a qualified technician who is aware of the hazards involved.

•Never work in an environment subject to explosion hazards. The housing of the

instrument is not gas tight.

•The Company will not be responsible for any physical damage caused by non

authorised work or manipulation.

•It is the responsibility of whoever uses this instrument to consult and establish

appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

•Before connecting the instrument to a power supply unit, make sure that the mains

voltage lies within the range:

•230 V AC ±10 %, 45-65 Hz (standard version).

•24 V AC/DC ±10 %, 45-65 Hz (standard version).

•115 V AC ±10 %, 45-65 Hz (under demand).

Important notes:

•Read carefully the manual of the instrument.

•Avoid direct sunlight over the instrument.

•Exclude the following environmental influences:

•vibrations

•atmospheric humidity higher than 80 %

•corrosive gases present

•temperature < 0 °C, or > 50 °C (< 32 °F, or > 122 °F)

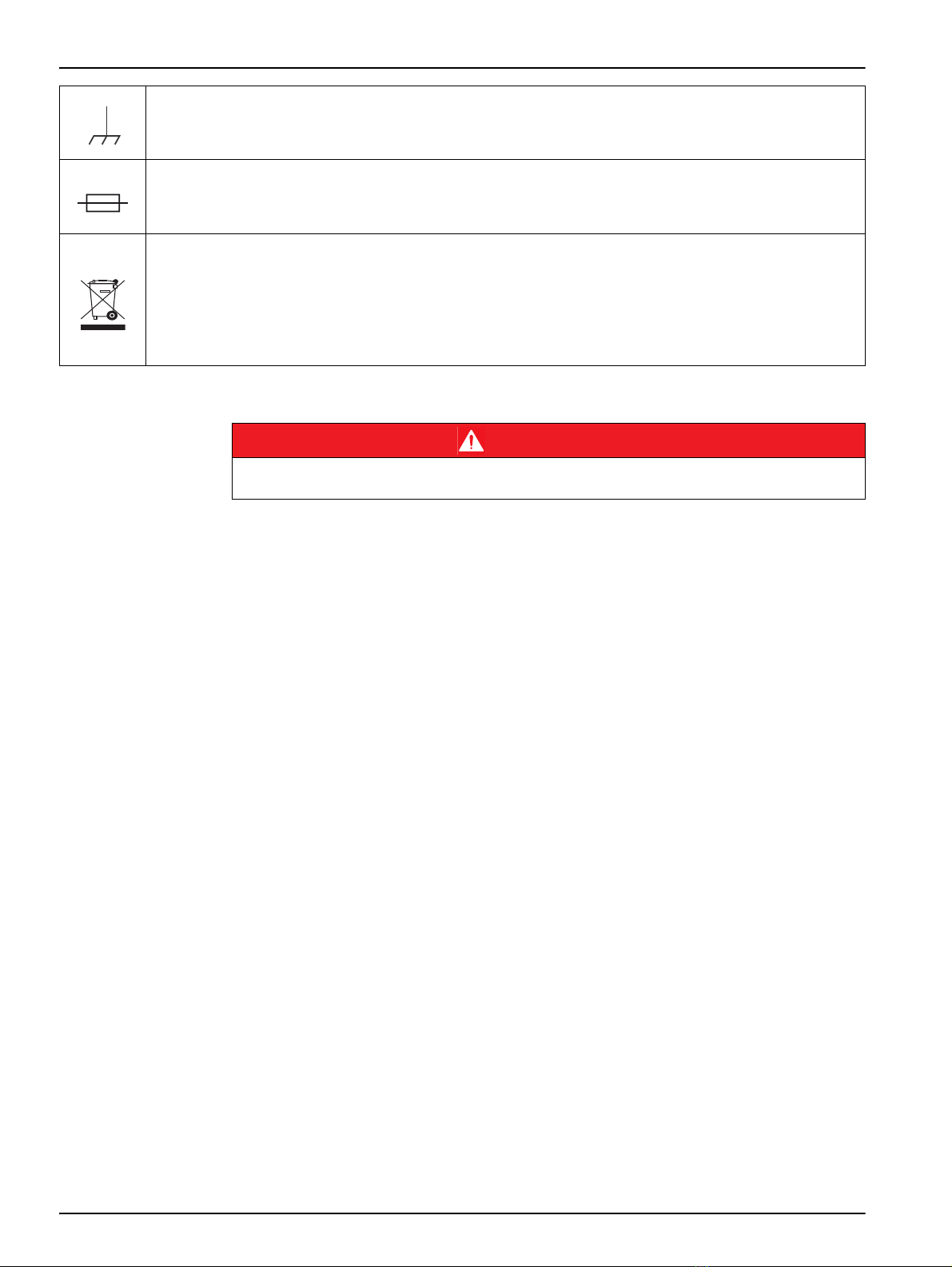

This symbol indicates the connection for analogic ground

This symbol identifies a fuse

Electrical equipment marked with this symbol may not be disposed of in European public disposal systems

after 12 August of 2005. In conformity with European local and national regulations (EU Directive 2002/96/EC),

European electrical equipment users must now return old or end-of life equipment to the Producer for disposal

at no charge to the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to

return end-of-life equipment, producer-supplied electrical accessories, and all auxiliary items for proper

disposal.

DANGER

Multiple hazards. Follow the following safety information, in addition to any local guidelines in

force.

9

General information

•powerful electric and magnetic fields.

•Only use original accessories and spare parts.

•Have the instrument serviced only by the Company Service.

2.2 Overview of product

The MULTIMETER 44 it’s a multi-meter for pH, EC, DO and Chlorine measure. It can

measure and display up to three different parameters. The instrument is able to send the

information to other instruments and also able to indicate, through relays or 4-20 mA

outputs, if the measures are inside or outside of certain limits.

The MULTIMETER 44 has a plastic enclosure highly resistant to impact, dust and water,

protection IP 65. It can be used to work outdoor and in any type of industry.

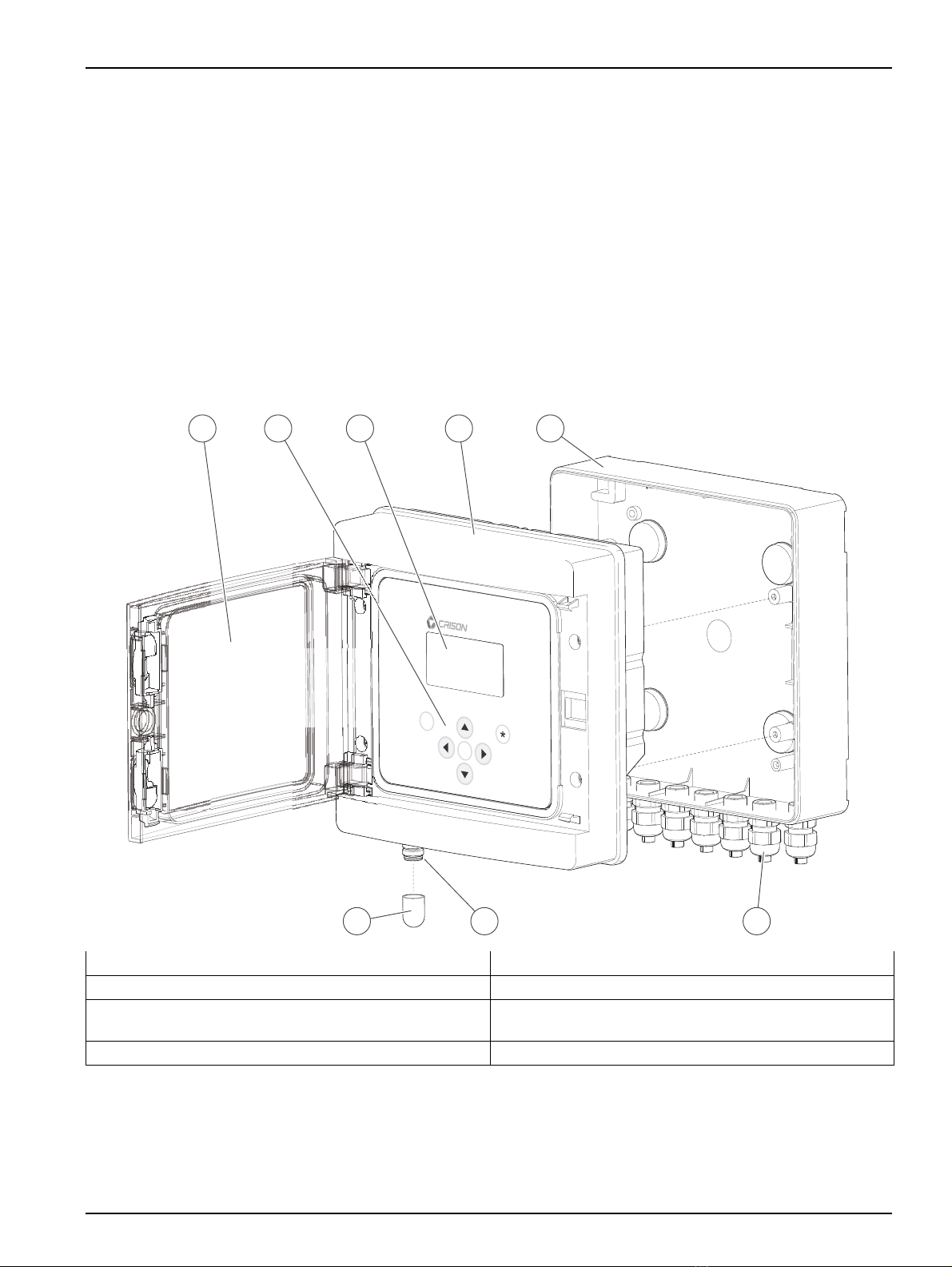

Figure 2 Instrument parts

2.2.1 Open the instrument door

Press as the arrows indicate to open the transparent frontal door, see Figure 3, Page 10.

1Transparent door 5Rear cover

2Membrane keypad 6Cable glands

3Graphic display 7MP-5 connector. Direct connection with RS 232 output

for data loading from the Data Logger.

4Frontal. Remove for cable connection 8Protector cup for MP-5 connector

ESC

OK

MultiMeter 44

5

68 7

41 2 3

10

General information

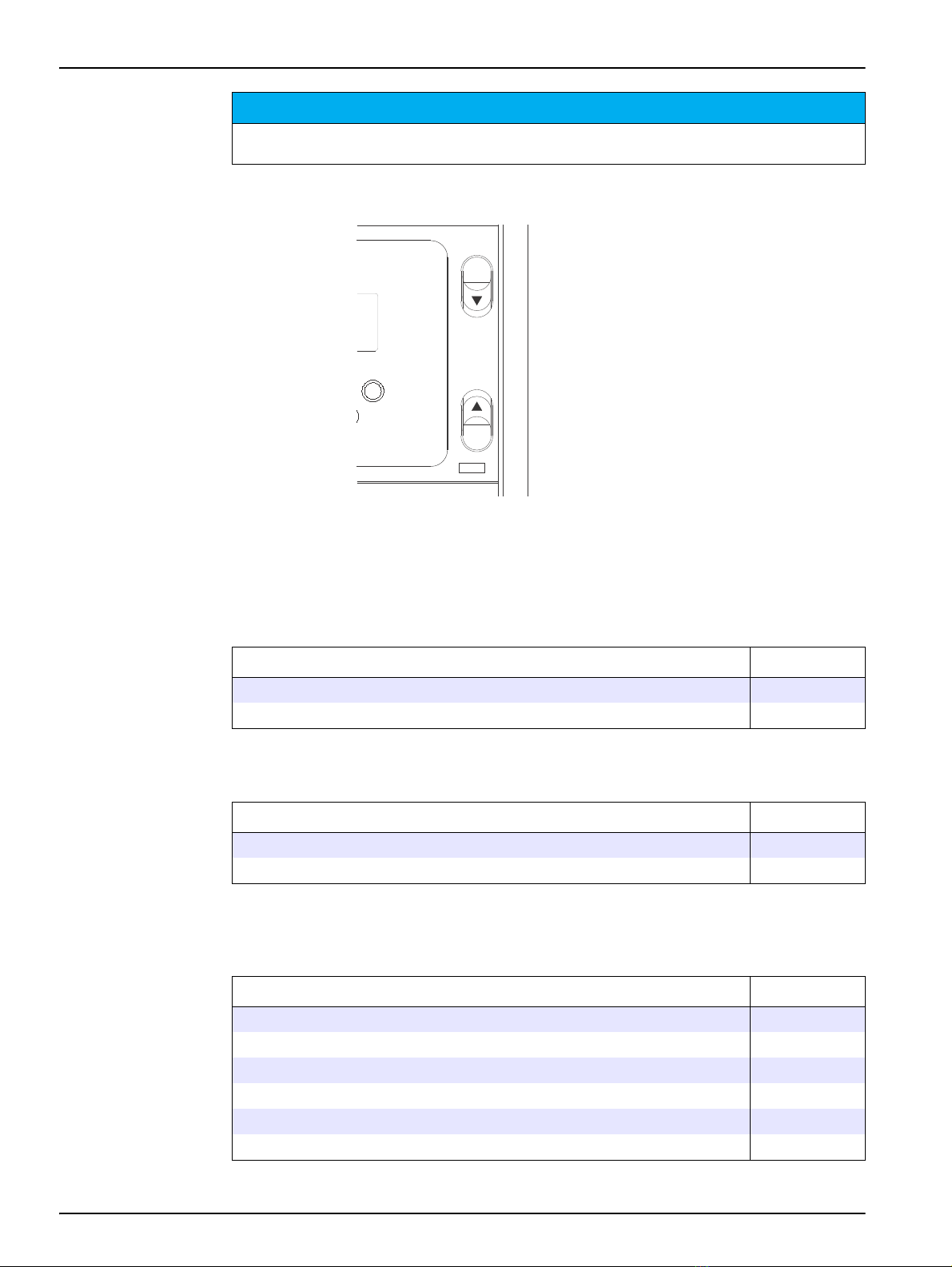

Figure 3 Door detail

2.3 Instrument composition

The MULTIMETER 44 is a modular instrument that can be configured with 1, 2 or 3

channels. The instrument can be delivered complete with 3 channels or the number of

channels can be extended as needed.

* To be completed with 1, 2 or 3 measuring boards

NOTICE

The instrument protection IP 65 is only ensured with the door closed and connector MP-5

protected. For Panel Mounting instruments, see 3.3 Panel mounting, page 15

*

IP 65

2.3.1 Base module

Description Code

MultiMeter 44, base instrument*, 220 V. 44 00

MultiMeter 44, base instrument*, 24 V 44 01

2.3.2 Additional communication

Description Code

RS 485 interface installed on MultiMeter 44 ...485

PROFIBUS DP output installed on 44 ...pro

2.3.3 Measuring boards

See instrument and measuring boards specifications in the corresponding chapter of the

manual.

Description Code

Measuring board: pH/mV + Temperature 44 10

Measuring board: Conductivity + Temperature 44 20

Measuring board: D.O. (membrane) + Temperature 44 30

Measuring board: D.O. (optical) + Temperature 44 40

Measuring board: Chlorine (galvanic) + Temperature 44 50

Measuring board: Chlorine (membrane) + Temperature 44 60

11

General information

* The measuring board can be used for temperature regulation too (ºC or ºF). Also two ferrite clamp

are included, see 4.5 pH / mV channel, page 22.

2.3.4 Accessories

Description Code

GSM module for data sending to mobile phone. Includes cable for

MultiMeter 44 connection 44 96

Memory module for Data Logger empty or capacity extension. Includes

union cable to MultiMeter 44 and USB to PC 44 97

RS 485 / USB convertor module. Includes cables and PC software 44 98

RS 232 / USB convertor module. Includes cables and PC software 44 99

12

General information

13

Section 3 Installation

3.1 Operating environment

•A minimum clearance of 5 cm (2 in.) must be ensured above and on all sides of the

device. This allows the air to circulate and prevents overheating of the electric parts. In

the lower part left a minimum clearance of 15 cm (6 in.) of space underneath must be

ensured for the cable connections.

•Don’t install the instrument directly exposed to the sun or rain to avoid possible

damage to it. When installing outdoor, place the instrument always under a small roof

protected from direct sun or rain. If not programming the instrument, left always the

front door closed.

•When positioning the instrument and the disconnecting device, It has to be guarantee

that it’s easy the access to operate the disconnecting device.

3.2 Wall mounting

1. Completely open the transparent door and pull to remove it.

Note: Make sure that you do not misplace the black hinges of the transparent door.

2. Unscrew the four screws of the frontal cover.

3. Remove the back cover and the four cover-screw caps.

4. Four drill holes are required as indicated in Figure 4.

5. Once the rear cover is fixed on the wall by the four screws, the cover-screw caps

must be put to ensure the waterproof IP 65.

6. Assemble the housing and screw the four screws.

7. Mount the transparent door.

DANGER

Only qualified personnel should conduct the installation tasks described in this section of the

manual.

Do not replace any component unless power has been switched off or the area is known to be

non-hazardous.

Install the instrument in ambient protected by corrosive fluids.

Safety of any system incorporating this instrument is responsibility of the assembler of the

system.

14

Installation

Figure 4 Wall mounting

1Completely open the transparent door and pull to

remove it 4Four drill holes are required as indicated in Fig. 6

5Fix the rear cover. Put the cover-screw cups

2Unscrew the four screws of the frontal cover 6Assemble the housing and screw the four screws

3Remove the back cover and the four cover-screw caps 7Mount the transparent door

1

3

5 6 7

4

2

1

180°

2

115 mm

[4.52t in]

110 mm

[4.33 in]

15

Installation

3.3 Panel mounting

Four adaptors for panel mounting are supplied with the instrument MULTIMETER 44. Panel

instruments are installed without the rear cover.

1. Completely open the transparent door and pull to remove it, see Figure 4.

Note: Make sure that you do not misplace the black hinges of the transparent door.

2. Unscrew the four screws for the extraction of the frontal part of the instrument, see

Figure 4.

3. A hole as indicated in figure 10 is required in the panel.

4. Use the four adaptors to screw the instrument in the panel.

5. Mount the transparent door.

Figure 5 Panel mounting

3.4 Connections

3.4.1 Safety information

When making any wiring connections to the instrument, any warnings and notes found

throughout the manual must be adhered to. For more safety information refer to

section 2.1, page 7.

DANGER

The voltage across accessible parts of the instrument may be dangerous to life.

The IP 65 protection only applies to the front part of the instrument (with door closed and MP-5

connector covered). In panel mounting installation the overall IP protection of the instrument will

depend on the panel and instrument installation.

1Measurements to punch the panel where the instrument

will be installed 34 screws of the frontal cover, see Figure 4

2Adapters for panel mounting 4Instrument mounted

202 mm

R5 mm

[7.95 in]

206 mm

[8.11 in]

2 3

1

4

16

Installation

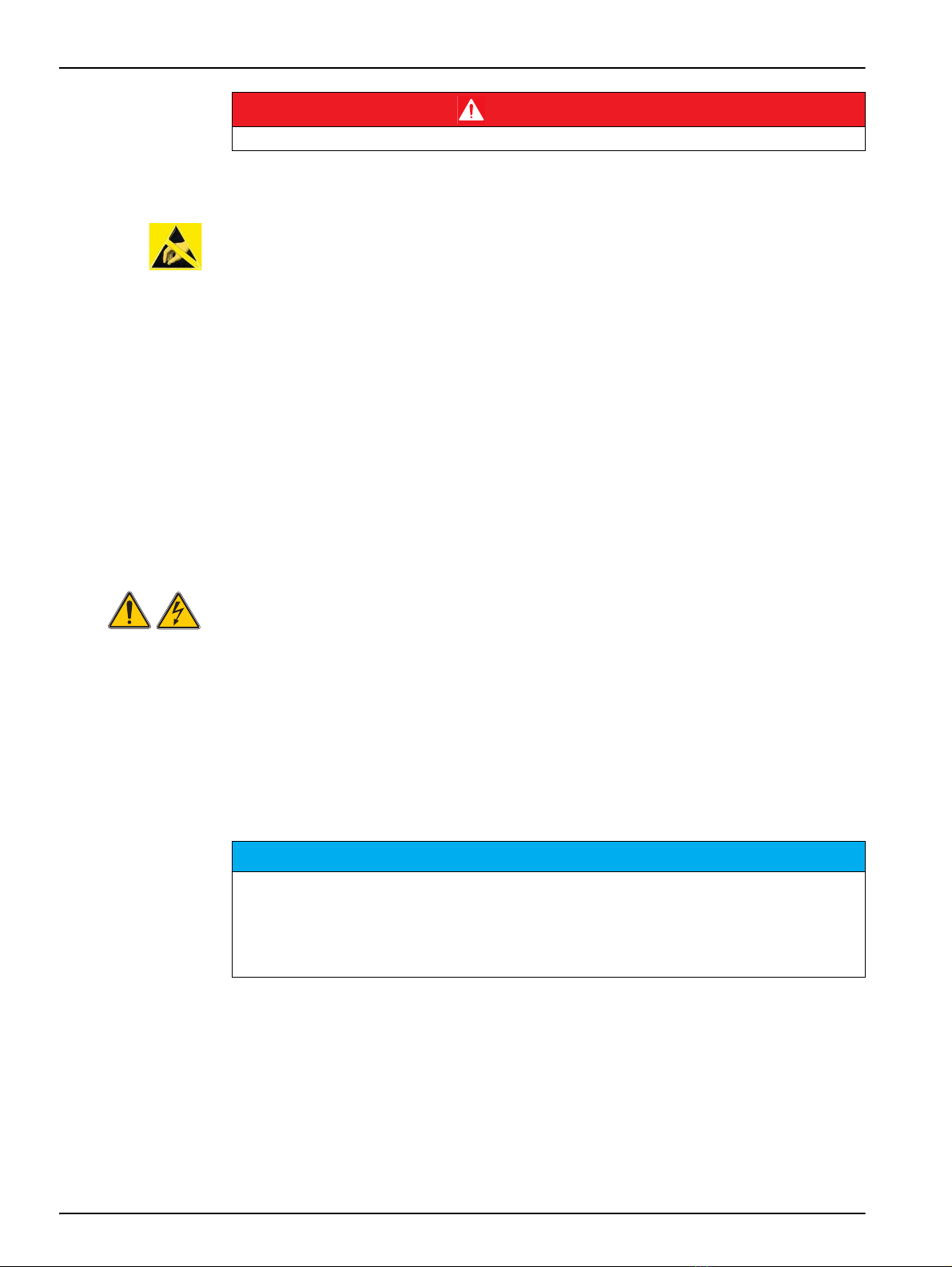

3.4.2 Electrostatic Discharge (ESD) Considerations

Some internal electronic components can be damaged by static electricity, resulting in

degraded instrument performance or eventual failure.

The manufacturer recommends taking the following steps to prevent ESD damage to the

instrument:

•Before touching any instrument electronic components (such as printed circuit cards

and the components on them) discharge static electricity from your body. This can be

accomplished by touching an earth-grounded metal surface such as the chassis of an

instrument, or a metal conduit or pipe.

•To reduce static build-up, avoid excessive movement. Transport static-sensitive

components in anti-static containers or packaging.

•To discharge static electricity from your body and keep it discharged, wear a wrist

strap connected by a wire to earth ground.

•Handle all static-sensitive components in a static-safe area. If possible, use anti-static

floor pads and work bench pads.

3.4.3 Electrical installation

High-voltage wiring for the instrument is protected by a protective casing. The protective

casing must remain in place unless a qualified installation technician is installing wiring for

power.

Always disconnect power to the instrument when making any electrical connections.

3.4.3.1 Protective earth

MULTIMETER 44 requires protective earth connection. Connect to terminal 8 a ground wire

of the electrical system.

3.4.3.2 Instrument power cord

The cable must be in accordance with IEC 60 227 or IEC 60 245 and designed to

withstand at least a current of 0.5 A with a voltage of 265 V.

3.4.4 Sensors connection

Follow the steps 1 to 3 on Figure 4 Wall mounting, page 14 to remove the frontal cover

and access to the interior view for the instrument connections.

See additional information in the sections of the corresponding channels.

DANGER

Always disconnect power to the instrument when making any electrical connections

NOTICE

The electrical installation where you connect the instrument should have an automatic switch

circuit breaker which must fulfill:

1It must be in the immediate proximity of the instrument and must easily be accessible for the

operator.

2It must be marked like device of disconnection of the instrument.

17

Installation

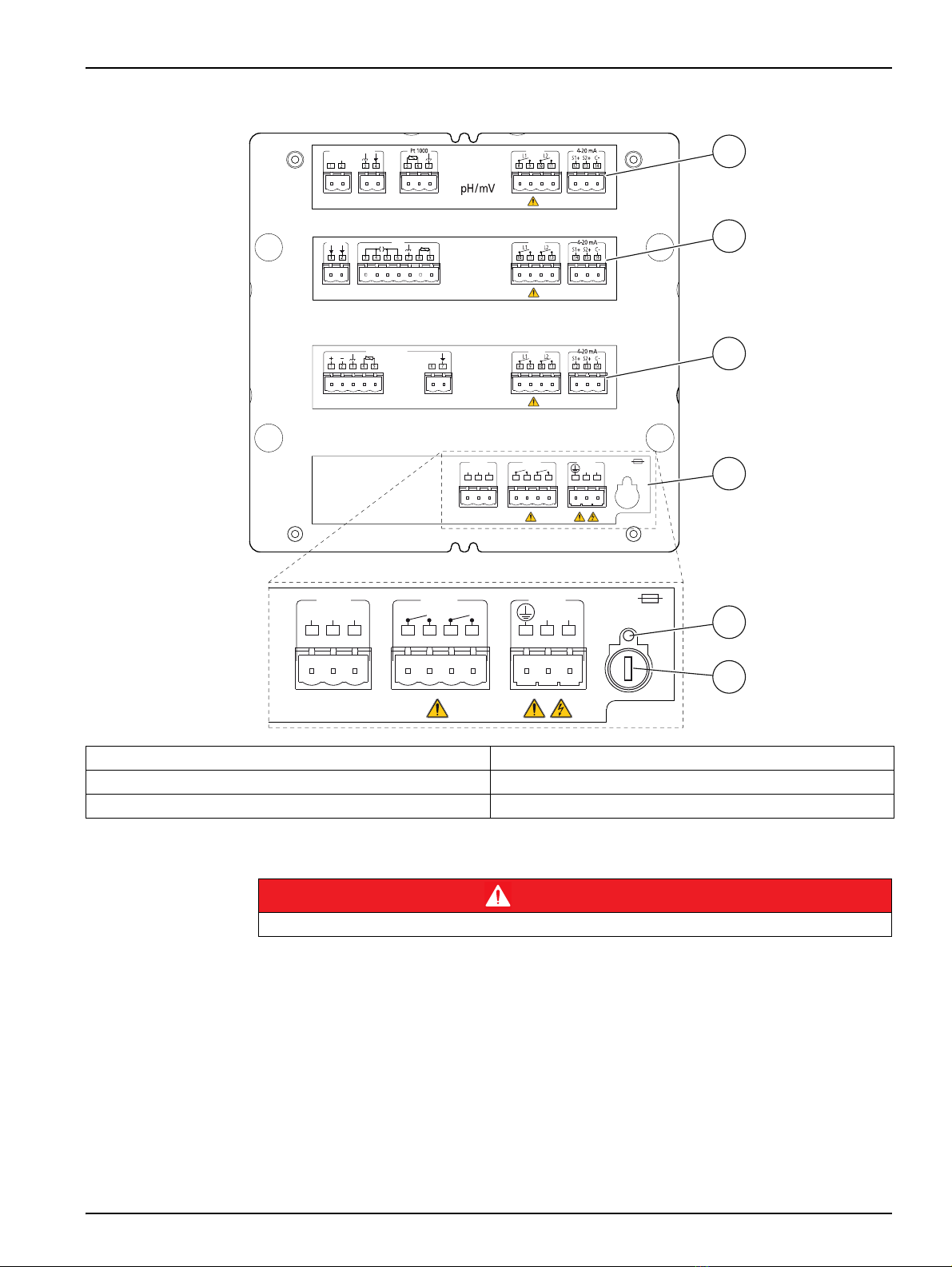

Figure 6 Interior view. Terminal assignment

3.4.5 Protecting wiring of switching contacts

The relays contacts are subjected to electrical erosion. Especially the inductive and

capacitive loads reduce the service life of the contacts. To eliminate sparks and arcing,

components such as combinations of resistances and capacitors (RC), non-linear

resistors, series resistors and diodes are used.

1Channel 1 4Power supply, relays and communication

2Channel 2 5Indicator for fused fuse

3Channel 3 6Fuse

Ground

Relays

E.C.

(Conductivity)

RelayspH/mV Electrode

Signal

Cell

D.O.

(Membrane)

RS 232 Relays

NL

Mains

Fuse

110/230V: T100L 250V

24V: T500L 250V

8910

GND

TxD

RxD

Alarm Cleaning

123 4567

Relays

DO Sensor (M)

RS 232 Relays

NL

Mains

Fuse

110/230V: T100L 250V

24V: T500L 250V

8910

GND

TxD

RxD

Alarm Cleaning

123 4567

1

2

3

4

5

6

DANGER

Limit the current up to 3A by using one fuse. Do not connect cables with voltage higher than 24 V

18

Installation

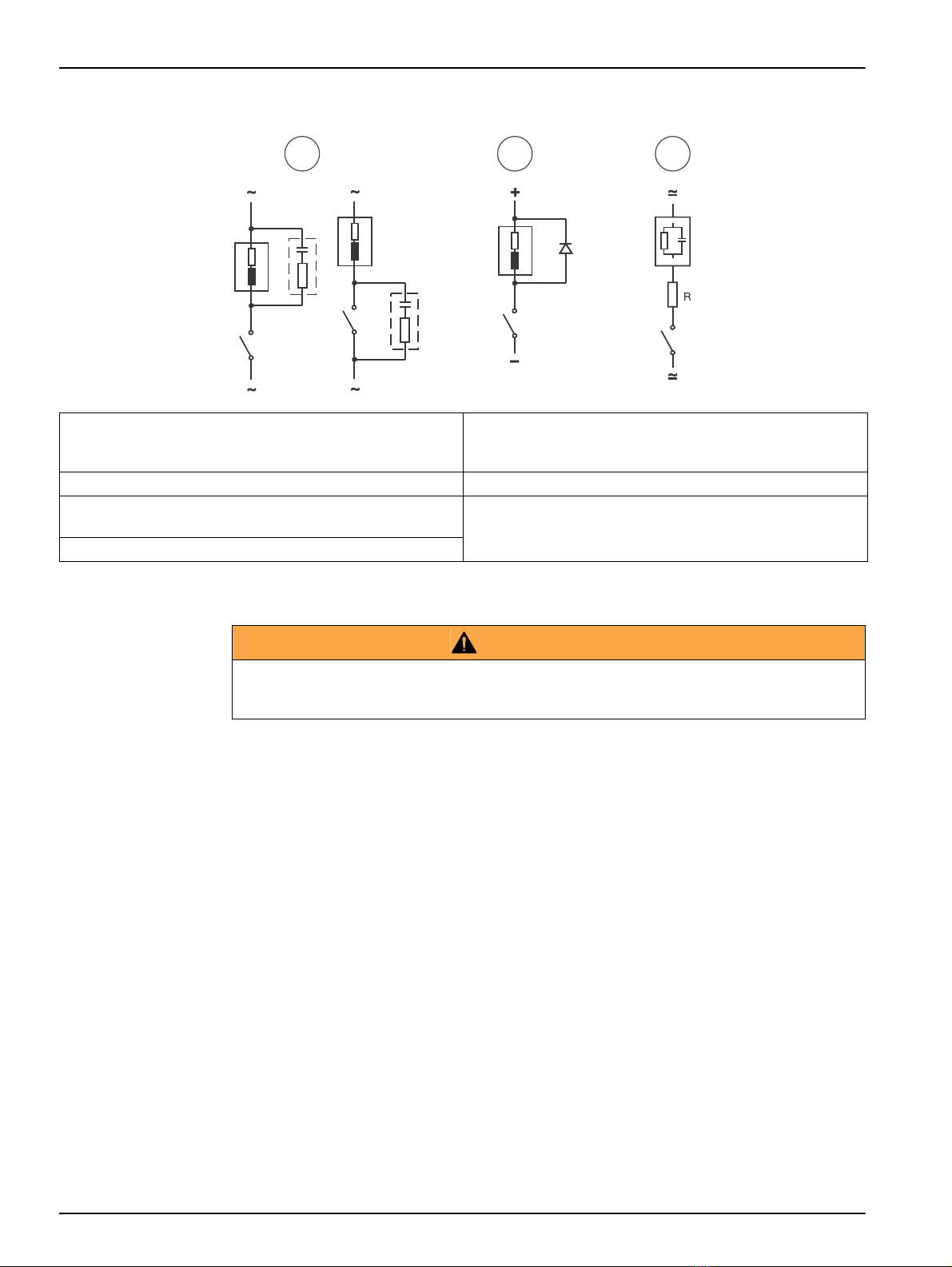

Figure 7 Typical protective wirings

3.5 Installation verification

Important notes:

•During the installation checking the limit relays and alarm relay stay deactivated.

•When a GSM sending is configured, it can be verified as well.

•The optional outputs, 485 and PROFIBUS, can be checked from this option too.

•The External Hold can be checked too.

1. From the measurement display press ESC.

2. Introduce the code 100 and accept with OK.

3. Go to SYSTEM and then CHECK INSTALLATION

4. Select RELAYS or 4-20 MA OUTPUTS to verify.

•Relays: Pressing OK the selected relay is activated. When the OK key is released the

relay is deactivated. The alarm relay acts in opposite manner.

•4-20 mA output: Select on display the mA value wanted to be simulated.

1In AC and inductive load

Typical RC at 230 VCA: Capacitor 0.1 µF/630 V;

Resistor 100 Ohms/1 W

5Load

2In DC and inductive load 6RC (resistance and capacitors)

3In AC/DC and capacitive load

(R example: 5 Ohms/ 1 W at 24 V/0.4 A) 7Diode: 1N4007

4Relay contact

1 2 3

4

5

5

6

6

7

55

44

4

WARNING

Relays or 4-20 mA outputs may be connected to control valves or pumps. Before using the relays

or 4-20 mA test options, be sure that those activations cannot produce any damage to people or

an environmental impact.

Table of contents

Languages: