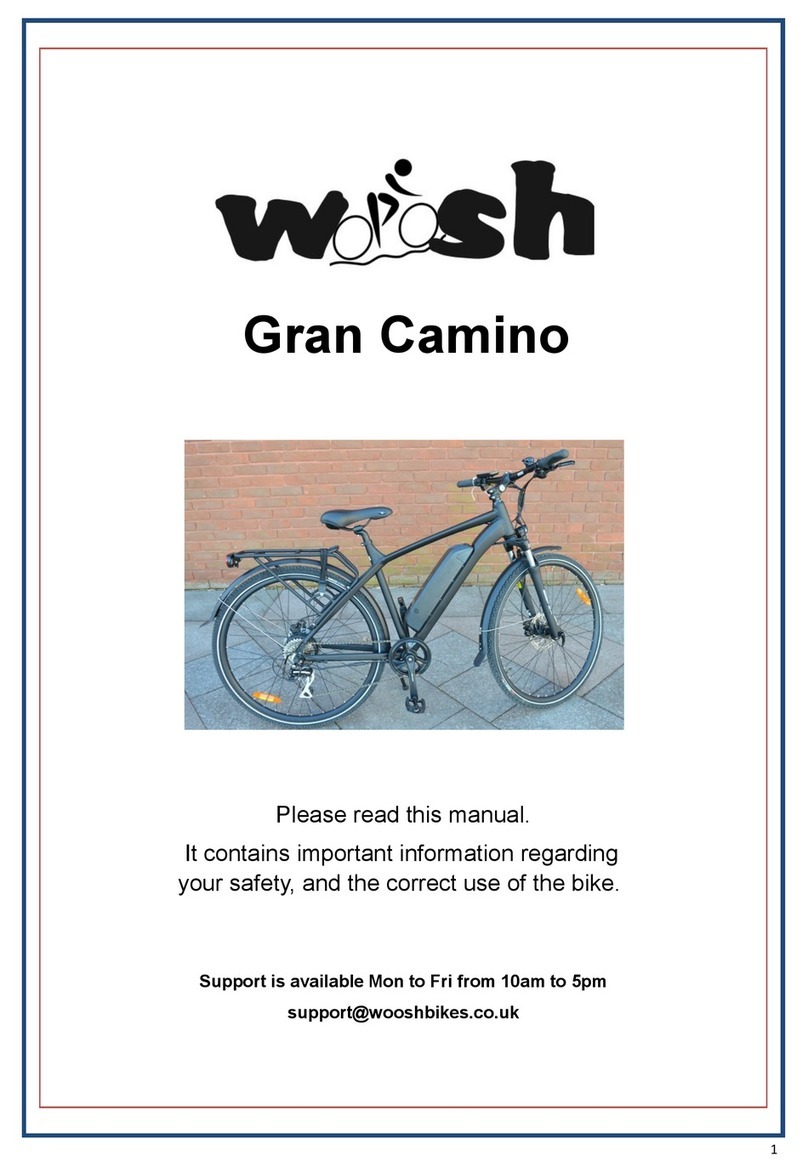

Critical Cycles city User manual

owner's manual

owner's manual

Hello!

Thank you for your purchase and congratulations on joining the

Critical Cycles Family!

We are a small team of outdoor enthusiasts who strive to provide

the joy that comes with riding a bicycle to anyone who wants to

experience it. We achieve this by oering well made, value priced

bikes that are delivered straight to you.

Like what we’re doing?

Feel free to let us know by writing a review for your new bike on

Amazon and by tagging us on social: #MyCritical

By doing so you are helping our small business grow, as we rely on

happy customers and word of mouth.

Having any issues?

Please contact us immediately so we can help you:

team@westridgeoutdoors.com

We work hard to ensure each and every Critical Cycles customer is

pedaling around on a bike that they love!

Don’t Forget!

Be sure to register your serial number with us so we have it on le in

case we need to assist you in the future. We send a lot of bikes to a

lot of people and can’t keep track of everyone’s serial number on our

own. You can register your bike with us at

www.CriticalCycles.com

Helpful Hint: You can nd your serial number on the bottom bracket

of your bike. We recommend keeping a record of this number

somewhere else safe so you will always have access to it to.

Happy Cycling,

The Critical Cycles Team

A Westridge Outdoors Company

@CriticalCycles

/CriticalCycles

@CriticalCycles

Bicycle Owner’s Manual

12th Edition, 2017

This manual meets ISO-4210, 16 CFR 1512 and EN 14764, 14766 and 14781 Standards

IMPORTANT:

This manual contains important safety, performance and service information. Read

it before you take the rst ride on your new bicycle, and keep it for reference.

Additional safety, performance and service information for specic components

such as suspension or pedals on your bicycle, or for accessories such as helmets

or lights that you purchase, may also be available. Make sure that your dealer

has given you all the manufacturers’ literature that was included with your bicycle

or accessories. In case of a conict between the instructions in this manual and

information provided by a component manufacturer, always follow the component

manufacturer’s instructions.

If you have any questions or do not understand something, take responsibility for

your safety and consult with your dealer or the bicycle’s manufacturer.

NOTE: This manual is not intended as a comprehensive use, service, repair

or maintenance manual. Please see your dealer for all service, repairs or

maintenance. Your dealer may also be able to refer you to classes, clinics

or books on bicycle use, service, repair or maintenance.

YOU CAN DOWNLOAD THIS GUIDE AT

www.criticalcycles.com/handbook

CONTENTS

GENERAL WARNING 1

A NOTE TO PARENTS 1

KEEP IN MIND 2

IN THE BOX 2

MAINTAIN 3

1. FIRST

A. Bike Fit 5

B. Safety First 5

C. Mechanical Safety Check 6

D. First Ride 8

2. SAFETY

A. The Basics 9

B. Riding Safety 10

C. O Road Safety 11

D. Wet Weather Riding 11

E. Night Riding 12

F. Extreme, Stunt or Competition Riding 13

G. Changing Components or Adding Accessories 14

3. FIT

A. Stand Over Height 15

B. Saddle Position 16

C. Handlebar Height and Angle 18

D. Control Position Adjustments 19

E. Brake Reach 19

4. TECH

A. Wheels 21

1. Secondary Retention Devices 23

2. Wheels with Cam Action Systems 23

3. Removing and Installing Wheels 24

B. Seat Post Cam Action Clamp 27

C. Brakes 28

D. Shifting Gears 30

E. Pedals 33

F. Bicycle Suspension 34

G. Tires and Tubes 35

5. SERVICE

A. Service Intervals 39

B. If your bicycle sustains an impact 41

APPENDIX A: Intended Use 43

APPENDIX B: Lifespan of your bike and its components 51

APPENDIX C: Coaster Brakes 58

APPENDIX D: Fastener Torque Specications 59

12

GENERAL WARNING:

Like any sport, bicycling involves risk of injury and damage. By choosing to ride

a bicycle, you assume the responsibility for that risk, so you need to know and

practice the rules of safe, responsible riding and of proper use and maintenance.

Proper use and maintenance of your bicycle reduces risk of injury.

This Manual contains many “Warnings” and “Cautions” concerning the

consequences of failure to maintain or inspect your bicycle and of failure to follow

safe cycling practices.

• The combination of the safety alert symbol and the word WARNING indicates

a potentially hazardous situation that, if not avoided, could result in injury or death.

• The combination of the safety alert symbol and the word CAUTION indicates

a potentially hazardous situation which, may result in minor or moderate injury, or is

an alert against unsafe practices.

•The word CAUTION used without the safety alert symbol indicates a situation

that, could result in serious damage to the bicycle or the voiding of your warranty.

Many of the Warnings and Cautions say, “you may lose control and fall”. Because

any fall can result in serious injury or even death, we do not always repeat the

warning of possible injury or death.

Because it is impossible to anticipate every situation or condition that can occur

while riding, this Manual makes no representation about the safe use of the bicycle

under all conditions. There are risks associated with the use of any bicycle which

cannot be predicted or avoided, and which are the sole responsibility of the rider.

A NOTE FOR PARENTS:

WARNING: This manual does not cover Juvenile or BMX bikes

As a parent or guardian, you are responsible for the activities and safety of your

minor child, and that includes making sure that the bicycle is properly tted to the

child; that it is in good repair and safe operating condition; that you and your child

have learned and understand the safe operation of the bicycle; and that you and

your child have learned, understand, and obey not only the applicable local motor

vehicle, bicycle and trac laws, but also the common sense rules of safe and

responsible bicycling. As a parent, you should read this manual, as well as review

its warnings and the bicycle’s functions and operating procedures with your child,

before letting your child ride the bicycle.

WARNING: Make sure that your child always wears an approved bicycle

helmet when riding and that your child understands that a bicycle helmet

is for bicycling only - It must be removed when not riding.

KEEP IN MIND

Our bikes are 85% assembled. That last 15% can be tricky, though. We highly

recommend taking your bike to a professional mechanic to get it built and/or

checked out. Properly truing wheels and setting up the derailleur requires nesse

(and specialized tools) that the average cyclist doesn’t necessarily possess. We

want you to ride happy and healthy and bike mechanics can help you to do that.

Please keep in mind, our bikes have traveled quite a distance to get from us to you.

Despite our eorts to keep your bike properly packaged and protected, damage

can occur during transit.

If your bike got banged up or you’re missing a screw or two, please

contact us as soon as you receive your order. Be sure to give us a

shout before contacting the store you bought it from!

Call us: 888-488-2369

Email us: team@criticalcycles.com

IN THE BOX

ASSEMBLY CHECKLIST (for all bikes):

• Frame

• Front wheel

• Handlebar

• Pedals

• Seat and seat post

• Reector set

Some of our city bikes also come with a bell, headlight, hardware for the headlight,

and fenders.

Our folding bikes come assembled! All you need is put air in the tires.

Again, if you suspect your bike is missing a component, please contact us as soon

as possible!

34

MAINTAIN

EVERYTHING IN LIFE NEEDS A LITTLE

TENDER LOVING CARE.

There’s not too much you need to do on a daily basis to make sure your

bike stays in tip-top shape. But you should always make sure there is air in

your tires. If you notice that you’re lling up your tires often, inspect them for

punctures. Every other week, check to make sure everything on your bike

that should be tightened is tightened. This includes (but isn’t limited to) bolts

on your tires, seat post, and handlebars. If you feel like something isn’t quite

right, whether it’s the direction of your wheels or the tautness of your chain,

check it out. Always consult with your local bike shop to ensure the safety of

you, your bike, and the people around you.

As you ride, you should always be aware of the terrain you’re riding on. Avoid

obvious hazards like nails and try not to run into anything, like open car doors

(though this makes it into plenty of fail videos…we know it hurts).

BE GOOD.

Yes, we know, we already mentioned this. But it’s important to take your

bike into a bike mechanic to get it checked out. Bike mechanics have a lot of

experience with properly tuning bikes and setting up derailleurs and brakes.

Be good to yourself and be good to your bike and take it into a mechanic to

make sure everything is A-OK.

56

1. FIRST

NOTE: We strongly urge you to read this Manual in its entirety before your rst ride.

At the very least, read and make sure that you understand each point in this section,

and refer to the cited sections on any issue that you don’t completely understand.

Please note that not all bicycles have all of the features described in this Manual. Ask

your dealer to point out the features of your bicycle.

A. Bike Fit

1. Is your bike the right size? To check, see Section 3.A. If your bicycle is too large

or too small for you, you may lose control and fall. If your new bike is not the right

size, ask your dealer to exchange it before you ride it.

2. Is the saddle at the right height? To check, see Section 3.B. If you adjust your

saddle height, follow the Minimum Insertion instructions in Section 3.B.

3. Are saddle and seat post securely clamped? A correctly tightened saddle will

allow no saddle movement in any direction. See Section 3.B.

4. Are the stem and handlebars at the right height for you? If not, see Section 3.C.

5. Can you comfortably operate the brakes? If not, you may be able to adjust their

angle and reach. See Section 3.D and 3.E.

6. Do you fully understand how to operate your new bicycle? If not, before your

rst ride, have your dealer explain any functions or features which you do not

understand.

B. Safety First

1. Always wear an approved helmet when riding your bike, and follow the helmet

manufacturer’s instructions for t, use and care.

2. Do you have all the other required and recommended safety equipment? See

Section 2. It’s your responsibility to familiarize yourself with the laws of the areas

where you ride, and to comply with all applicable laws.

3. Do you know how to correctly secure your front and rear wheels? Check Section

4.A.1 to make sure. Riding with an improperly secured wheel can cause the

wheel to wobble or disengage from the bicycle, and cause serious injury or

death.

4. If your bike has toeclips and straps or clipless (“step-in”) pedals, make sure you

know how they work (see Section 4.E). These pedals require special techniques

and skills. Follow the pedal manufacturer’s instructions for use, adjustment, and

care.

5. Do you have “toe overlap”? On smaller framed bicycles your toe or toeclip may

be able to contact the front wheel when a pedal is all the way forward and the

wheel is turned. Read Section 4.E. to check whether you have toeclip overlap.

6. Does your bike have suspension? If so, check Section 4.F. Suspension can

change the way a bicycle performs. Follow the suspension manufacturer’s

instructions for use, adjustment and care.

C. Mechanical Safety Check - Check your bicycle before every ride

Nuts, bolts screws & other fasteners: Because manufacturers use a wide variety

of fastener sizes and shapes made in a variety of materials, often diering by model

and component, the correct tightening force or torque cannot be generalized. To

make sure that the many fasteners on your bicycle are correctly tightened, refer to

the Fastener Torque Specications in Appendix D of this manual or to the torque

specications in the instructions provided by the manufacturer of the component

in question. Correctly tightening a fastener requires a calibrated torque wrench. A

professional bicycle mechanic with a torque wrench should torque the fasteners

on you bicycle. If you choose to work on your own bicycle, you must use a torque

wrench and the correct tightening torque specications from the bicycle or

component manufacturer or from your dealer. If you need to make an adjustment

at home or in the eld, we urge you to exercise care, and to have the fasteners

you worked on checked by your dealer as soon as possible. Note that there are

some components that require special tools and knowledge. In Sections 3 and 4

we discuss the items that you may be able to adjust yourself. All other adjustments

and repairs should be done by a qualied bicycle mechanic.

WARNING: Correct tightening force on fasteners–nuts, bolts, screws–on

your bicycle is important. Too little force, and the fastener may not hold

securely. Too much force, and the fastener can strip threads, stretch,

deform or break. Either way, incorrect tightening force can result in

component failure, which can cause you to loose control and fall.

• Make sure nothing is loose. Lift the front wheel o the ground by two or three

inches, then let it bounce on the ground. Anything sound, feel or look loose? Do

a visual and tactile inspection of the whole bike. Any loose parts or accessories?

If so, secure them. If you’re not sure, ask someone with experience to check.

Tires & Wheels: Make sure tires are correctly inated (see Section 4.G.1). Check by

putting one hand on the saddle, one on the intersection of the handlebars and stem,

then bouncing your weight on the bike while looking at tire deection. Compare

what you see with how it looks when you know the tires are correctly inated; and

adjust if necessary.

• Tires in good shape? Spin each wheel slowly and look for cuts in the tread and

sidewall. Replace damaged tires before riding the bike.

• Wheels true? Spin each wheel and check for brake clearance and side-to-side

wobble. If a wheel wobbles side to side even slightly, or rubs against or hits

the brake pads, take the bike to a qualied bike shop to have the wheel trued.

CAUTION: Wheels must be true for rim brakes to work eectively.

Wheel trueing is a skill which requires special tools and experience. Do

not attempt to true a wheel unless you have the knowledge, experience

and tools needed to do the job correctly.

• Whe el r ims cle an a nd un dam ag ed? M ake s ur e t he r ims a re c le an a nd u nd amage d

at the tire bead and, if you have rim brakes, along the braking surface. Check to

make sure that any rim wear indicator marking is not visible at any point on the

wheel rim.

78

WARNING: Bicycle wheel rims are subject to wear. Ask your dealer about

wheel rim wear. Some wheel rims have a rim wear indicator that becomes

visible as the rim’s braking surface wears. A visible rim wear indicator on

the side of the wheel rim is an indication that the wheel rim has reached

its maximum usable life. Riding a wheel that is at the end of its usable life

can result in wheel failure, which can cause you to loose control and fall.

•Brakes: Check the brakes for proper operation (see Sections 4.C). Squeeze the

brake levers. Are the brake quick-releases closed? All control cables seated

and securely engaged? If you have rim brakes, do the brake pads contact the

wheel rim squarely and make full contact with the rim? Do the brakes begin

to engage within an inch of brake lever movement? Can you apply full braking

force at the levers without having them touch the handlebar? If not, your brakes

need adjustment. Do not ride the bike until the brakes are properly adjusted by a

professional bicycle mechanic.

•Wheel retention system: Make sure the front and rear wheels are correctly

secured. See Section 4.A

•Seat post: If your seat post has an over-center cam action fastener for easy

height adjustment, check that it is properly adjusted and in the locked

position.See Section 4.B.

•Handlebar and saddle alignment: Make sure the saddle and handlebar stem

are parallel to the bike’s center line and clamped tight enough so that you can’t

twist them out of alignment. See Sections 3.B and 3.C.

• Handlebar ends: Make sure the handlebar grips are secure and in good

condition, with no cuts, tears, or worn out areas. If not, have your dealer replace

them. Make sure the handlebar ends and extensions are plugged. If not, have

your dealer plug them before you ride. If the handlebars have bar end extensions,

make sure they are clamped tight enough so you can’t twist them.

WARNING: Loose or damaged handlebar grips or extensions can cause

you to lose control and fall. Unplugged handlebars or extensions can cut

you and cause serious injury in an otherwise minor accident.

VERY IMPORTANT SAFETY NOTE:

Please also read and become thoroughly familiar with the important

information on the lifespan of your bicycle and its components in Appendix

B on Page 45.

D. First Ride

When you buckle on your helmet and go for your rst familiarization ride on your new

bicycle, be sure to pick a controlled environment, away from cars, other cyclists,

obstacles or other hazards. Ride to become familiar with the controls, features and

performance of your new bike.

Familiarize yourself with the braking action of the bike (see Section 4.C). Test the

brakes at slow speed, putting your weight toward the rear and gently applying the

brakes, rear brake rst. Sudden or excessive application of the front brake could

pitch you over the handlebars. Applying brakes too hard can lock up a wheel,

which could cause you to lose control and fall. Skidding is an example of what can

happen when a wheel locks up.

If your bicycle has toeclips or clipless pedals, practice getting in and out of the

pedals. See paragraph B.4 above and Section 4.E.4. If your bike has suspension,

familiarize yourself with how the suspension responds to brake application and rider

weight shifts. See paragraph B.6 above and Section 4.F.

Practice shifting the gears (see Section 4.D). Remember to never move the shifter

while pedaling backward, nor pedal backwards immediately after having moved the

shifter. This could jam the chain and cause serious damage to the bicycle.

Check out the handling and response of the bike; and check the comfort.

If you have any questions, or if you feel anything about the bike is not as it should

be, consult your dealer before you ride again.

910

2. SAFETY

A. The Basics

WARNING: The area in which you ride may require specic safety devices.

It is your responsibility to familiarize yourself with the laws of the area

where you ride and to comply with all applicable laws, including properly

equipping yourself and your bike as the law requires.

Observe all local bicycle laws and regulations. Observe regulations about

bicycle lighting, licensing of bicycles, riding on sidewalks, laws regulating

bike path and trail use, helmet laws, child carrier laws, and special bicycle

trac laws. It’s your responsibility to know and obey the laws.

1. Always wear a cycling helmet that meets the latest cer tication standards and is

appropriate for the type of riding you do. Always follow the helmet manufacturer’s

instructions for t, use and care of your helmet. Most serious bicycle injuries involve

headinjuriesthatmighthavebeenavoidediftheriderhadwornanappropriatehelmet.

WARNING: Failure to wear a helmet may result in serious injury or death.

2. Always do the Mechanical Safety Check (Section 1.C) before you get on a bike.

3. Be thoroughly familiar with the controls of your bicycle: brakes (Section 4.C.);

pedals (Section 4.E.); shifting (Section 4.D.)

4. Be careful to keep body parts and other objects away from the sharp teeth of

chainrings, the moving chain, the turning pedals and cranks, and the spinning

wheels of your bicycle.

5. Always wear:

• Shoes that will stay on your feet and will grip the pedals. Make sure that shoe

laces cannot get into moving parts, and never ride barefoot or in sandals.

• Bright, visible clothing that is not so loose that it can be tangled in the bicycle

or snagged by objects at the side of the road or trail.

• Protective eyewear, to protect against airborne dirt, dust and bugs — tinted

when the sun is bright, clear when it’s not.

6. Unless your bicycle was specically designed for jumping (See Appendix A,

Intended Use) don’t jump with your bike. Jumping a bike, particularly a BMX or

mountain bike, can be fun; but it can put unpredictable stress on the bicycle

and its components. Riders who insist on jumping their bikes risk serious

damage, to their bicycles as well as to themselves. Before you attempt to

jump, do stunt riding or race with your bike, read and understand Section 2.F.

7. Ride at a speed appropriate for conditions. Higher speed means higher risk.

B. Riding Safety

1. Obey all Rules of the Road and all local trac laws.

2. You are sharing the road or the path with others — motorists, pedestrians and

other cyclists. Respect their rights.

3. Ride defensively. Always assume that others do not see you.

4. Look ahead, and be ready to avoid:

• Vehicles slowing or turning, entering the road or your lane ahead of you, or

coming up behind you.

• Parked car doors opening.

• Pedestrians stepping out.

• Children or pets playing near the road.

• Pot holes, sewer grating, railroad tracks, expansion joints, road or sidewalk

construction, debris and other obstructions that could cause you to swerve

into trac, catch your wheel or cause you to have an accident.

• The many other hazards and distractions which can occur on a bicycle ride.

5. Ride in designated bike lanes, on designated bike paths or as close to the

edge of the road as possible, in the direction of trac ow or as directed by

local governing laws.

6. Stop at stop signs and trac lights; slow down and look both ways at street

intersections. Remember that a bicycle always loses in a collision with a

motor vehicle, so be prepared to yield even if you have the right of way.

7. Use approved hand signals for turning and stopping.

8. Never ride with headphones. They mask trac sounds and emergency

vehicle sirens, distract you from concentrating, and their wires can tangle in

the moving parts of the bicycle, causing you to lose control.

9. Never carry a passenger; and, before installing a child carrier or trailer, check

with your dealer or the bicycle manufacturer to make sure the bicycle is

designed for it. If the bicycle is suitable for a child carrier or trailer, make

sure that the carrier or trailer is correctly mounted and the child is secured

and wearing an approved helmet.

10. Never carry anything which obstructs your vision, or which could become

entangled in the moving parts of the bicycle.

11. Never hitch a ride by holding on to another vehicle.

12. Don’t do stunts, wheelies or jumps. If you intend to do stunts, wheelies,

jumps, or go racing with your bike despite our advice not to, read Section

2.F, Downhill, Stunt or Competition Biking, now. Think carefully about your

skills before deciding to take the large risks that go with this kind of riding.

13. Don’t weave through trac or make any moves that may surprise people

with whom you are sharing the road.

14. Observe and yield the right of way.

15. Never ride your bicycle while under the inuence of alcohol or drugs.

16. Avoid riding in bad weather, when visibility is obscured, at dawn, dusk or in

the dark, or when extremely tired.

11 12

C. O Road Safety

Children should be accompanied by an adult while riding on rough terrain.

1. The variable conditions and hazards of o-road riding require close attention

and specic skills. Start slowly on easier terrain and build up your skills. If your

bike has suspension, the increased speed you may develop also increases your

risk of losing control and falling. Get to know how to handle your bike safely

before trying increased speed or more dicult terrain.

2. Wear safety gear appropriate to the kind of riding you plan to do.

3. Don’t ride alone in remote areas. Even when riding with others, make sure that

someone knows where you’re going and when you expect to be back.

4. Always take along some kind of identication, so that people know who you

are in case of an accident; and take along some cash for food, a cool drink or

an emergency phone call.

5. Yield right of way to pedestrians and animals. Ride in a way that does not

frighten or endanger them, and give them enough room so that their unexpected

moves don’t endanger you.

6. Be prepared. If something goes wrong, help may not be close.

7. Before you attempt to jump, do stunt riding or race with your bike, read and

understand Section 2.F.

O Road Respect

Obey the local laws regulating where and how you can ride o-road, and respect

private property. You may be sharing the trail with others — hikers, equestrians,

other cyclists. Respect their rights. Stay on the designated trail. Don’t contribute to

erosion by riding in mud or with unnecessary sliding. Don’t disturb the ecosystem

by cutting your own trail or shortcut through vegetation or streams. It is your

responsibility to minimize your impact on the environment. Leave things as you

found them; and always take out everything you brought in.

D. Wet Weather Riding

WARNING: Wet weather impairs traction, braking and visibility, both for the

bicyclist and for other vehicles sharing the road. The risk of an accident is

dramatically increased in wet conditions.

Under wet conditions, the stopping power of your brakes (as well as the brakes of

other vehicles sharing the road) is dramatically reduced and your tires don’t grip

nearly as well. This makes it harder to control speed and easier to lose control. To

make sure that you can slow down and stop safely in wet conditions, ride more

slowly and apply your brakes earlier and more gradually than you would under

normal, dry conditions. See also Section 4.C.

E. Night Riding

Riding a bicycle at night is much more dangerous than riding during the day. A

bicyclist is very dicult for motorists and pedestrians to see. Therefore, children

should never ride at dawn, at dusk or at night. Adults who chose to accept the

greatly increased risk of riding at dawn, at dusk or at night need to take extra care

both riding and choosing specialized equipment which helps reduce that risk.

Consult your dealer about night riding safety equipment.

WARNING: Reectors are not a substitute for required lights. Riding

at dawn, at dusk, at night or at other times of poor visibility without an

adequate bicycle lighting system and without reectors is dangerous and

may result in serious injury or death.

CAUTION: Check reectors and their mounting brackets regularly to

make sure that they are clean, straight, unbroken and securely mounted.

Have your dealer replace damaged reectors and straighten or tighten any

that are bent or loose.

The mounting brackets of front and rear reectors are often designed as brake

straddle cable safety catches which prevent the straddle cable from catching on the

tire tread if the cable jumps out of its yoke or breaks.

WARNING: Do not remove the front or rear reectors or reector brackets

from your bicycle. They are an integral part of the bicycle’s safety system.

Removing the reectors reduces your visibility to others using the roadway.

Being struck by other vehicles may result in serious injury or death.

The reector brackets may protect you from a brake straddle cable

catching on the tire in the event of brake cable failure. If a brake straddle

cable catches on the tire, it can cause the wheel to stop suddenly, causing

you to loose control and fall.

If you choose to ride under conditions of poor visibility, check and be sure you comply

with all local laws about night riding, and take the following strongly recommended

additional precautions:

• Purchase and install battery or generator powered head/tail lights which

meet regulatory requirements for where you live and provide adequate visibility.

• Wear light colored, reective clothing and accessories, such as a reective vest,

reective arm and leg bands, reective stripes on your helmet, ashing lights

attached to your body and/or your bicycle ... any reective device or light source

that moves will help you get the attention of approaching motorists, pedestrians

and other trac.

• Make sure your clothing or anything you may be carrying on the bicycle does

not obstruct a reector or light.

• Make sure that your bicycle is equipped with correctly positioned and securely

mounted reectors.

13 14

While riding at dawn, at dusk or at night:

• Ride slowly.

• Avoid dark areas and areas of heavy or fast-moving trac.

• Avoid road hazards.

• If possible, ride on familiar routes.

If riding in trac:

• Be predictable. Ride so that drivers can see you and predict your movements.

• Be alert. Ride defensively and expect the unexpected.

• If you plan to ride in trac often, ask your dealer about trac safety classes or a

good book on bicycle trac safety.

F. Extreme, Stunt or Competition Riding

Whether you call it Aggro, Hucking, Freeride, North Shore, Downhill, Jumping, Stunt

Riding, Racing or something else: if you engage in this sort of extreme, aggressive

riding you will get hurt, and you voluntarily assume a greatly increased risk of injury

or death.

Not all bicycles are designed for these types of riding, and those that are may not

be suitable for all types of aggressive riding. Check with your dealer or the bicycle’s

manufacturer about the suitability of your bicycle before engaging in extreme riding.

When riding fast down hill, you can reach speeds achieved by motorcycles, and

therefore face similar hazards and risks. Have your bicycle and equipment carefully

inspected by a qualied mechanic and be sure it is in perfect condition. Consult with

expert riders, area site personnel and race ocials on conditions and equipment

advisable at the site where you plan to ride. Wear appropriate safety gear, including

an approved full face helmet, full nger gloves, and body armor. Ultimately, it is your

responsibility to have proper equipment and to be familiar with course conditions.

WARNING: Although many catalogs, advertisements and articles

about bicycling depict riders engaged in extreme riding, this activity is

extremely dangerous, increases your risk of injury or death, and increases

the severity of any injury. Remember that the action depicted is being

performed by professionals with many years of training and experience.

Know your limits and always wear a helmet and other appropriate safety

gear. Even with state-of-the-art protective safety gear, you could be

seriously injured or killed when jumping, stunt riding, riding downhill at

speed or in competition.

WARNING: Bicycles and bicycle parts have limitations with regard to

strength and integrity, and this type of riding can exceed those limitations

or dramatically reduce the length of their safe use.

We recommend against this type of riding because of the increased risks; but if you

choose to take the risk, at least:

• Take lessons from a competent instructor rst

• Start with easy learning exercises and slowly develop your skills before trying

more dicult or dangerous riding

• Use only designated areas for stunts, jumping, racing or fast downhill riding

• Wear a full face helmet, safety pads and other safety gear

• The stresses imposed on your bike by this kind of activity may break or

damage parts of the bicycle and void the warranty

• Take your bicycle to your dealer if anything breaks or bends. Do not ride your

bicycle when any part is damaged.

If you ride downhill at speed, do stunt riding or ride in competition, know the limits of

your skill and experience. Ultimately, avoiding injury is your responsibility.

G. Changing Components or Adding Accessories

There are many components and accessories available to enhance the comfort,

performance and appearance of your bicycle. However, if you change components

or add accessories, you do so at your own risk. The bicycle’s manufacturer may

not have tested that component or accessory for compatibility, reliability or safety

on your bicycle. Before installing any component or accessory, including a dierent

size tire, make sure that it is compatible with your bicycle by checking with your

dealer. Be sure to read, understand and follow the instructions that accompany the

products you purchase for your bicycle. See also Appendix A, p. 39 and B, p. 45.

WARNING: Failure to conrm compatibility, properly install, operate and

maintain any component or accessory can result in serious injury or death.

WARNING: Changing the components on your bike with other than

genuine replacement parts may compromise the safety of your bicycle

and may void the warranty. Check with your dealer before changing the

components on your bike.

15 16

3. FIT

NOTE: Correct t is an essential element of bicycling safety, performance

and comfort. Making the adjustments to your bicycle which result in

correct t for your body and riding conditions requires experience, skill

and special tools. Always have your dealer make the adjustments on your

bicycle; or, if you have the experience, skill and tools, have your dealer

check your work before riding.

WARNING: If your bicycle does not t properly, you may lose control and

fall. If your new bike doesn’t t, ask your dealer to exchange it before you

ride it.

A. Standover Height

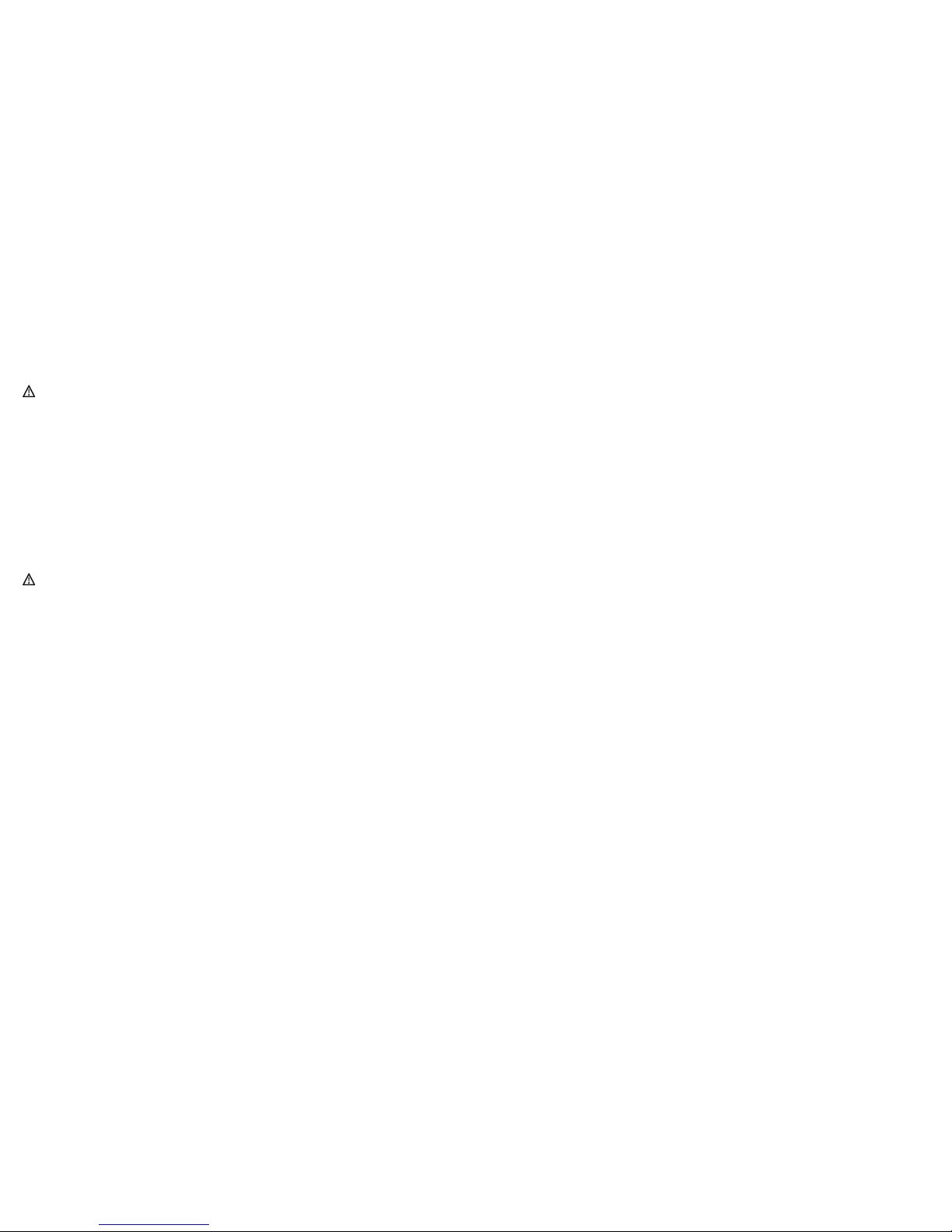

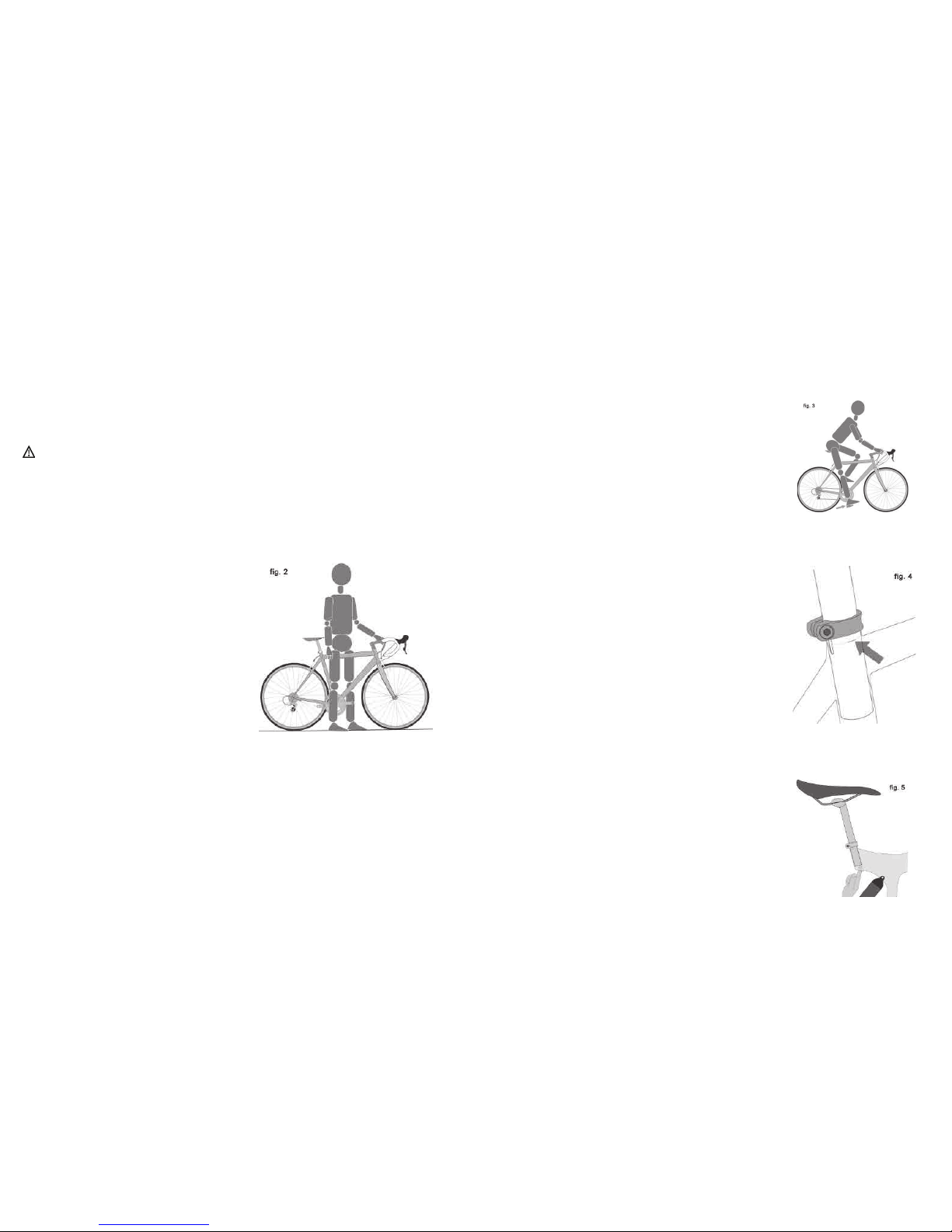

1. Diamond Frame Bicycles

Standover height is the basic element of

bike t (see g. 2). It is the distance from

the ground to the top of the bicycle’s frame

at that point where your crotch is when

straddling the bike. To check for correct

standover height, straddle the bike while

wearing the kind of shoes in which you’ll

be riding, and bounce vigorously on your

heels. If your crotch touches the frame,

the bike is too big for you. Don’t even ride

the bike around the block. A bike which

you ride only on paved surfaces and never

take o-road should give you a minimum

standover height clearance of two inches

(5 cm). A bike that you’ll ride on unpaved

surfaces should give you a minimum of

three inches (7.5 cm) of standover height

clearance. And a bike that you’ll use o

road should give you four inches (10 cm)

or more of clearance.

2. Step-Through Frame Bicycles

Standover height does not apply to bicycles with step-through frames. Instead,

the limiting dimension is determined by saddle height range. You must be able to

adjust your saddle position as described in B without exceeding the limits set by

the height of the top of the seat tube and the ”Minimum Insertion” or “Maximum

Extension” mark on the seat post.

B. Saddle Position

Correct saddle adjustment is an important factor in getting the most performance

and comfort from your bicycle. If the saddle position is not comfortable for you, see

your dealer.

The saddle can be adjusted in three directions:

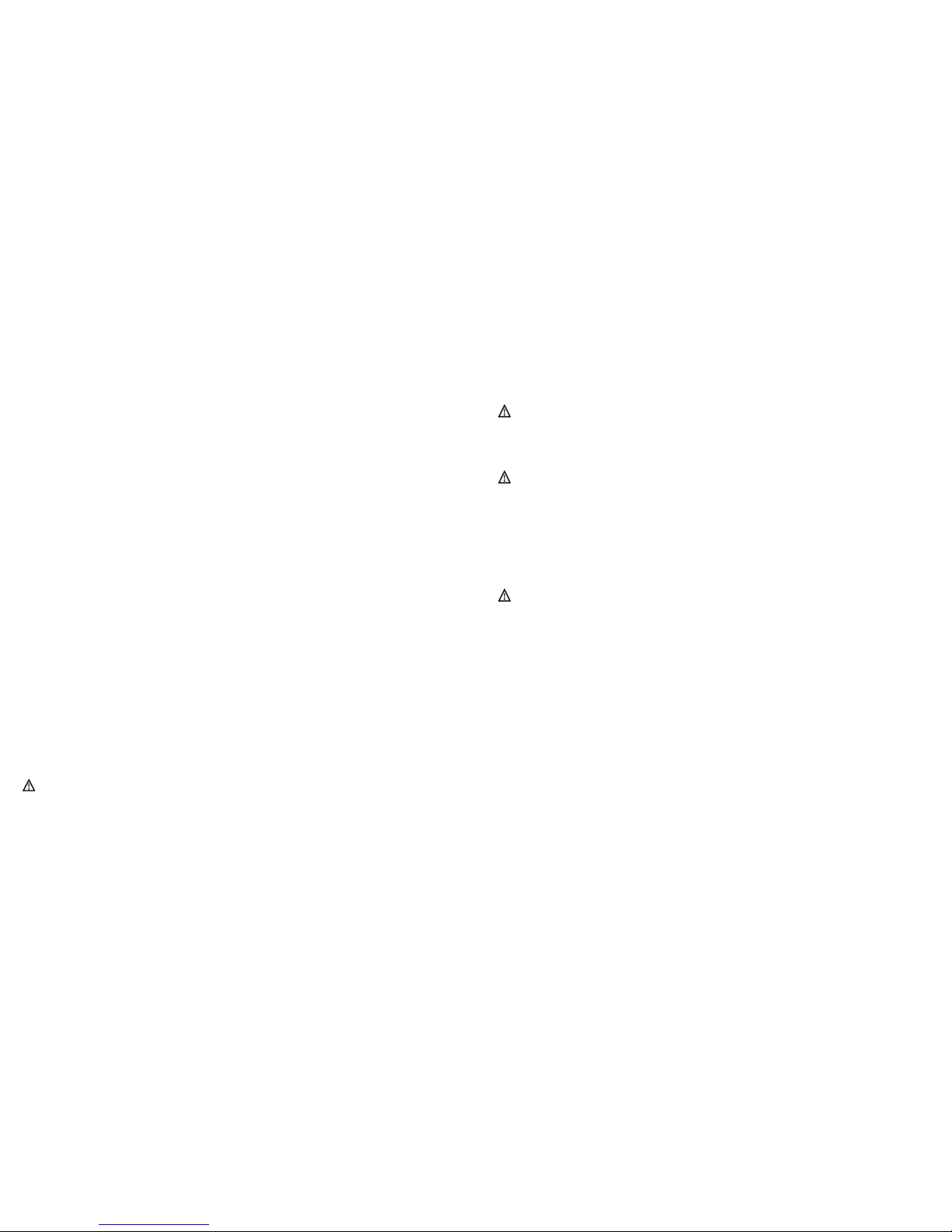

1. Up and down adjustment. To check forcorrect

saddle height (g. 3):

• Sit on the saddle.

• Place one heel on a pedal.

• Rotate the crank until the pedal withyour heel on it

is in the down position and the crank arm is parallel

to the seat tube.

If your leg is not completely straight, your saddle height

needs to be adjusted. If your hips rock for the heel

to reach the pedal, the saddle is too high. If your leg

is bent at the knee with your heel on the pedal, the

saddle is too low.

Ask your dealer to set the saddle for your optimal riding

position and show you how to make this adjustment.

If you choose to make your own saddle height

adjustment:

• loosen the seat post clamp

• raise or lower the seat post in the seat tube

• make sure the saddle is straight fore and aft

• re-tighten the seat post clamp to the recommended

torque (Appendix D or the manufacturer’s

instructions).

Once the saddle is at the correct height, make sure that

the seat post does not project beyond its “Minimum

Insertion” or “Maximum Extension” mark (g. 4).

NOTE: Some bicycles have a sight hole in the seat

tube, to make it easy to see whether the seat post is

inserted in the seat tube far enough to be safe. If your

bicycle has a sight hole, use it instead of the “Minimum

Insertion” or “Maximum Extension” mark to make sure

the seat post is inserted in the seat tube far enough.

If your bike has an interrupted seat tube, you must

make sure that the seat post is far enough into the

frame so that you can touch it through the bottom of

the tube with the tip of your nger without inserting

your nger beyond its rst knuckle. (g.5).

17 18

WARNING: If your seat post is not inserted in the seat tube as described

in B.1 above, the seat post, binder or even frame may break, which could

cause you to lose control and fall.

2. Front and back adjustment.

The saddle can be adjusted forward or back to help you get the optimal position

on the bike. Ask your dealer to set the saddle for your optimal riding position and

to show you how to make this adjustment. If you choose to make your own front

and back adjustment, make sure that the clamp mechanism is clamping on the

straight part of the saddle rails and is not touching the curved part of the rails,

and that you are using the recommended torque on the clamping fastener(s)

(Appendix D or the manufacturer’s instructions).

3. Saddle angle adjustment.

Most people prefer a horizontal saddle; but some riders like the saddle nose

angled up or down just a little. Your dealer can adjust saddle angle or teach you

how to do it. If you choose to make your own saddle angle adjustment and you

have a single bolt saddle clamp on your seat post, it is critical that you loosen the

clamp bolt suciently to allow any serrations on the mechanism to disengage

before changing the saddle’s angle, and then that the serrations fully re-engage

before you tighten the clamp bolt to the recommended torque (Appendix D or the

manufacturer’s instructions).

WARNING: When making saddle angle adjustments with a single bolt

saddle clamp, always check to make sure that the serrations on the

mating surfaces of the clamp are not worn. Worn serrations on the

clamp can allow the saddle to move, causing you to lose control and fall.

Always tighten fasteners to the correct torque. Bolts that are too tight

can stretch and deform. Bolts that are too loose can move and fatigue.

Either mistake can lead to a sudden failure of the bolt, causing you to

lose control and fall.

Note: If your bicycle is equipped with a suspension seat post, the

suspension mechanism may require periodic service or maintenance.

Ask your dealer for recommended service intervals for your seat post.

Small changes in saddle position can have a substantial eect on performance

and comfort. To nd your best saddle position, make one adjustment at a time.

WARNING: After any saddle adjustment, be sure that the saddle

adjusting mechanism is properly seated and tightened. A loose saddle

clamp/seat post clamp can cause damage to the seat post, or can cause

you to lose control. A correctly tightened saddle adjusting mechanism

will allow no saddle movement in any direction. Periodically check to

make sure that the saddle adjusting mechanism is properly tightened.

If, in spite of carefully adjusting the saddle height, tilt and fore-and-aft position,

your saddle is still uncomfortable, you may need a dierent saddle design.

Saddles, like people, come in many dierent shapes, sizes and resilience. Your

dealer can help you select a saddle which, when correctly adjusted for your body

and riding style, will be comfortable.

WARNING: Some people have claimed that extended riding with a

saddle which is incorrectly adjusted or which does not support your

pelvic area correctly can cause short-term or long-term injury to nerves

and blood vessels, or even impotence. If your saddle causes you pain,

numbness or other discomfort, listen to your body and stop riding until

you see your dealer about saddle adjustment or a dierent saddle.

C. Handlebar Height and Angle

Your bike is equipped either with a “threadless” stem,

which clamps on to the outside of the steerer tube,

or with a “quill” stem, which clamps inside the steerer

tube by way of an expanding binder bolt. If you aren’t

sure whi ch typ e of ste m your bike has, a sk you r d eal er.

If your bike has a “threadless” stem (g. 6) your dealer

may be able to change handlebar height by moving

height adjustment spacers from below the stem to

above the stem, or vice versa. Otherwise, you’ll have

to get a stem of dierent length or rise. Consult your

dealer. Do not attempt to do this yourself.

If your bike has a “quill” stem (g. 7) ask your dealer to

adjust the handlebar height by adjusting stem height.

A quill stem has an etched or stamped mark on

its shaft which designates the stem’s “Minimum

Insertion” or “Maximum Extension.” This mark must

not be visible above the headset.

WARNING: A quill stem’s Minimum Insertion Mark must not be visible

above the top of the headset. If the stem is extended beyond the Minimum

Insertion Mark the stem may break or damage the fork’s steerer tube,

which could cause you to lose control and fall.

WARNING: O n s om e b icycl es , cha ng ing t he st em or ste m h eigh t c an a e ct

the tension of the front brake cable, locking the front brake or creating

excess cable slack which can make the front brake inoperable. If the front

brake pads move in towards the wheel rim or out away from the wheel rim

when the stem or stem height is changed, the brakes must be correctly

adjusted before you ride the bicycle.

19 20

Some bicycles are equipped with an adjustable angle stem. If your bicycle has

an adjustable angle stem, ask your dealer to show you how to adjust it. Do not

attempt to make the adjustment yourself, as changing stem angle may also require

adjustments to the bicycle’s controls.

WARNING: Always tighten fasteners to the correct torque. Bolts that are

too tight can stretch and deform. Bolts that are too loose can move and

fatigue. Either mistake can lead to a sudden failure of the bolt, causing you

to lose control and fall.

Your dealer can also change the angle of the handlebar or bar end extensions.

WARNING: An insuciently tightened stem clamp bolt, handlebar clamp

bolt or bar end extension clamping bolt may compromise steering action,

which could cause you to lose control and fall. Place the front wheel of

the bicycle between your legs and attempt to twist the handlebar/stem

assembly. If you can twist the stem in relation to the front wheel, turn

the handlebars in relation to the stem, or turn the bar end extensions in

relation to the handlebar, the bolts are insuciently tightened.

D. Control position adjustments

The angle of the brake and shift control levers and their position on the handlebars

can be changed. Ask your dealer to make the adjustments for you. If you choose

to make your own control lever angle adjustment, be sure to re-tighten the

clamp fasteners to the recommended torque (Appendix D or the manufacturer’s

instructions).

E. Brake reach

Many bikes have brake levers which can be adjusted for reach. If you have small

hands or nd it dicult to squeeze the brake levers, your dealer can either adjust the

reach or t shorter reach brake levers.

WARNING: The shorter the brake lever reach, the more critical it is to

have correctly adjusted brakes, so that full braking power can be applied

within available brake lever travel. Brake lever travel insucient to apply

full braking power can result in loss of control, which may result in serious

injury or death.

21 22

4. TECH

It’s important to your safety, performance and enjoyment to understand how things

work on your bicycle. We urge you to ask your dealer how to do the things described

in this section before you attempt them yourself, and that you have your dealer

check your work before you ride the bike. If you have even the slightest doubt as to

whether you understand something in this section of the Manual, talk to your dealer.

See also Appendix A, B, C and D.

A. Wheels

Bicycle wheels are designed to be removable for easier transportation and for repair

of a tire puncture. In most cases, the wheel axles are inserted into slots, called

“dropouts” in the fork and frame, but some mountain and road bikes use what is

called a “through axle” wheel mounting system.

If you have a mountain or road bike equipped with through axle front or

rear wheels, make sure that your dealer has given you the manufacturer’s

instructions, and follow those when installing or removing a through axle

wheel. If you don’t know what a through axle is, ask your dealer.

If you do not have a bicycle with a through-axle wheel mounting system, it will have

wheels secured in one of three ways:

• A hollow axle with a shaft (“skewer”) running through it which has an

adjustable tension nut on one end and an over-center cam on the other (cam

action system, g.8 a & b)

• A hollow axle with a shaf t (“skewer”) running through it which has a nut on one end

and a tting for a hex key, lock lever or other tightening device on the other (through

bolt, g. 9)

• Hex nuts or hex key bolts which are threaded on to or into the hub axle (bolt-on

wheel, g. 10)

Your bicycle may be equipped with a dierent securing method for the front wheel

than for the rear wheel. Discuss the wheel securing method for your bicycle with

your dealer.

It is very important that you understand the type of wheel securing method

on your bicycle, that you know how to secure the wheels correctly, and

that you know how to apply the correct clamping force that safely secures

the wheel. Ask your dealer to instruct you in correct wheel removal and

installation, and ask him to supply you with manufacturer’s instructions.

WARNING: Riding with an improperly secured wheel can allow the wheel

to wobble or fall o the bicycle, which can cause serious injury or death.

Therefore, it is essential that you:

1. Ask your dealer to show you how to install/remove your wheels safely.

2. Apply the correct technique for clamping your wheel in place.

3. Before you ride the bike, check that the wheel is securely clamped.

The clamping action of a correctly secured wheel must emboss the

surfaces of the dropouts.

23 24

1. Front Wheel Secondary Retention Devices

Most bicycles have front forks that utilize a secondary wheel retention device to

reduce the risk of the wheel disengaging from the fork if the wheel is incorrectly

secured. Secondary retention devices are not a substitute for correctly securing

your front wheel.

Secondary retention devices fall into two basic categories:

a. The clip-on type is a part that the manufacturer adds to the front wheel hub or

front fork.

b. The integral type is molded, cast, or machined into the outer faces of the front

fork dropouts.

Ask your dealer to explain the particular secondary retention device on your bike.

WARNING: Do not remove or disable the secondary retention device. As

its name implies, it serves as a back-up for a critical adjustment. If the

wheel is not secured correctly, the secondary retention device can reduce

the risk of the wheel disengaging from the fork. Removing or disabling the

secondary retention device may also void the warranty.

Secondary retention devices are not a substitute for correctly securing

your wheel. Failure to properly secure the wheel can cause the wheel to

wobble or disengage, which could cause you to loose control and fall,

resulting in serious injury or death.

2. Wheels with Cam Action Systems

There are currently two types of over-center cam wheel retention mechanisms: the

traditional over-center cam (g. 8a) and the cam-and-cup system (g. 8b). Both use

an over-center cam action to clamp the bike’s wheel in place. Your bicycle may

have a cam-and-cup front wheel retention system and a traditional rear wheel cam

action system.

a. Adjusting the traditional cam action mechanism (g. 8a)

The wheel hub is clamped in place by the force of the over-center cam pushing

against one dropout and pulling the tension adjusting nut, by way of the skewer,

against the other dropout. The amount of clamping force is controlled by the

tension adjusting nut. Turning the tension adjusting nut clockwise while keeping

the cam lever from rotating increases clamping force; turning it counterclockwise

while keeping the cam lever from rotating reduces clamping force. Less than

half a turn of the tension adjusting nut can make the dierence between safe

clamping force and unsafe clamping force.

WARNING: The full force of the cam action is needed to clamp the

wheel securely. Holding the nut with one hand and turning the lever like

a wing nut with the other hand until everything is as tight as you can get

it will not clamp a cam action wheel safely in the dropouts. See also the

rst WARNING in this Section, p. 20.

b. Adjusting the cam-and-cup mechanism (g. 8b)

The cam-and-cup system on your front wheel will have been correctly adjusted

for your bicycle by your dealer. Ask your dealer to check the adjustment every six

months. Do not use a cam-and-cup front wheel on any bicycle other than

the one for which your dealer adjusted it.

3. Removing and Installing Wheels

WARNING: If your bike is equipped with a hub brake such as a rear

coaster brake, front or rear drum, band or roller brake; or if it has an

internal gear rear hub, do not attempt to remove the wheel. The removal

and re-installation of most hub braktes and internal gear hubs requires

special knowledge. Incorrect removal or assembly can result in brake or

gear failure, which can cause you to lose control and fall.

CAUTION: If your bike has a disc brake, exercise care in touching the rotor

or caliper. Disc rotors have sharp edges, and both rotor and caliper can get

very hot during use.

a. Removing a Disk Brake or Rim Brake Front Wheel

1. If your bike has rim brakes, disengage the brake’s quick-release mechanism to

increase the clearance between the tire and the brake pads (See Section 4.C

g. 11 through 15).

2. If your bike has cam action front wheel retention, move the cam lever from the

locked or CLOSED position to the OPEN position (gs. 8a & b). If your bike has

through bolt or bolt-on front wheel retention, loosen the fastener(s) a few turns

counter-clockwise using an appropriate wrench, lock key or the integral lever.

3. If your front fork has a clip-on type secondary retention device, disengage it.

If your front fork has an integral secondary retention device, and a traditional

cam action system (g. 8a) loosen the tension adjusting nut enough to allow

removing the wheel from the dropouts. If your front wheel uses a cam-and-

cup system, (g. 8b) squeeze the cup and cam lever together while removing

the wheel. No rotation of any part is necessary with the cam-and-cup system.

You may need to tap the top of the wheel with the palm of your hand to release

the wheel from the front fork.

b. Installing a Disk Brake or Rim Brake Front Wheel

CAUTION: If your bike is equipped with a front disk brake, be careful

not to damage the disk, caliper or brake pads when re-inserting the disk

into the caliper. Never activate a disk brake’s control lever unless the

disk is correctly inserted in the caliper. See also Section 4.C.

1. If your bike has cam action front wheel retention, move the cam lever so that it

curves away from the wheel (g. 8b). This is the OPEN position. If your bike has

through bolt or bolt-on front wheel retention, go to the next step.

25 26

2. With the steering fork facing forward, insert the wheel between the fork blades

so that the axle seats rmly at the top of the fork dropouts. The cam lever, if

there is one, should be on rider’s left side of the bicycle (g. 8a & b). If your bike

has a clip-on type secondary retention device, engage it.

3. If you have a traditional cam action mechanism: holding the cam lever in the

ADJUST position with your right hand, tighten the tension adjusting nut with

your left hand until it is nger tight against the fork dropout (g. 8a). If you have

a cam-and-cup system: the nut and cup (g. 8b) will have snapped into the

recessed area of the fork dropouts and no adjustment should be required.

4. While pushing the wheel rmly to the top of the slots in the fork dropouts, and

at the same time centering the wheel rim in the fork:

a. With a cam action system, move the cam lever upwards and swing it into

the CLOSED position (g. 8a & b). The lever should now be parallel to

the fork blade and curved toward the wheel. To apply enough clamping

force, you should have to wrap your ngers around the fork blade for

leverage, and the lever should leave a clear imprint in the palm of your hand.

b. With a through-bolt or bolt-on system, tighten the fasteners to the torque

specications in Appendix D or the hub manufacturer’s instructions.

NOTE: If, on a traditional cam action system, the lever cannot be pushed all

the way to a position parallel to the fork blade, return the lever to the OPEN

position. Then turn the tension adjusting nut counterclockwise one-quarter

turn and try tightening the lever again.

c. With a through-bolt or bolt-on system, tighten the fasteners to the torque

specications in Appendix D or the hub manufacturer’s instructions.

WARNING: Securely clamping the wheel with a cam action

retention device takes considerable force. If you can fully close the

cam lever without wrapping your ngers around the fork blade for

leverage, the lever does not leave a clear imprint in the palm of your

hand, and the serrations on the wheel fastener do not emboss the

surfaces of the dropouts, the tension is insucient. Open the lever;

turn the tension adjusting nut clockwise a quarter turn; then try

again. See also the rst WARNING in this Section, p. 20.

5. If you disengaged the brake quick-release mechanism in 3. a. (1) above,

reengage it to restore correct brake pad-to-rim clearance.

6. Spin the wheel to make sure that it is centered in the frame and clears the

brake pads; then squeeze the brake lever and make sure that the brakes are

operating correctly.

c. Removing a disk brake or rim brake Rear Wheel

1. If you have a multi-speed bike with a derailleur gear system: shift the rear

derailleur to high gear (the smallest, outermost rear sprocket).

If you have an internal gear rear hub, consult your dealer or the hub

manufacturer’s instructions before attempting to remove the rear wheel.

If you have a single-speed bike with rim or disk brake, go to bullet 4 below.

2. If your bike has rim brakes, disengage the brake’s quick-release mechanism to

increase the clearance between the wheel rim and the brake pads (see

Section 4.C, gs. 11 through 15).

3. On a derailleur gear system, pull the derailleur body back with your right hand.

4. With a cam action mechanism, move the quick-release lever to the OPEN

position (g. 8b). With a through bolt or bolt on mechanism, loosen the

fastener(s) with an appropriate wrench, lock lever or integral lever; then push

the wheel forward far enough to be able to remove the chain from the rear

sprocket.

5. Lift rear wheel o ground a few inches and remove from rear dropouts.

d. Installing a Disk Brake or Rim Brake Rear Wheel

CAUTION: If your bike is equipped with a rear disk brake, be careful not

to damage the disk, caliper or brake pads when re-inserting the disk

into the caliper. Never activate a disk brake’s control lever unless the

disk is correctly inserted in the caliper.

1. With a cam action system, move the cam lever to the OPEN position (see g.

8 a & b). The lever should be on the side of the wheel opposite the derailleur

and freewheel sprockets.

2. On a derailleur bike, make sure that the rear derailleur is still in its outermost,

high gear, position; then pull the derailleur body back with your right hand. Put

the chain on top of the smallest freewheel sprocket.

3. On single-speed, remove the chain from the front sprocket, so that you have

plenty of slack in the chain. Put the chain on the rear wheel sprocket.

4. Insert the wheel into the frame dropouts and pull it all the way in.

5. On a single speed or an internal gear hub, replace the chain on the chainring;

pull the wheel back in the dropouts so that it is straight in the frame and the

chain has about 1/4 inches of up-and-down play.

6. With a cam action system, move the cam lever upwards and swing it into the

CLOSED position (g. 8 a & b). The lever should now be parallel to the seat

stay or chain stay and curved toward the wheel. To apply enough clamping

force, you should have to wrap your ngers around the fork blade for leverage,

and the lever should leave a clear imprint in the palm of your hand.

7. With a through-bolt or bolt-on system, tighten the fasteners to the torque

specications in Appendix D or the hub manufacturer’s instructions.

27 28

NOTE: If, on a traditional cam action system, the lever cannot be pushed all

the way to a position parallel to the seat stay or chain stay, return the lever to

the OPEN position. Then turn the tension adjusting nut counterclockwise one-

quarter turn and try tightening the lever again.

WARNING: Securely clamping the wheel with a cam action retention

device takes considerable force. If you can fully close the cam lever

without wrapping your ngers around the seat stay or chain stay for

leverage, the lever does not leave a clear imprint in the palm of your

hand, and the serrations on the wheel fastener do not emboss the

surfaces of the dropouts, the tension is insucient. Open the lever;

turn the tension adjusting nut clockwise a quarter turn; then try again.

See also the rst WARNING in this Section, p. 20.

8. If you disengaged the brake quick-release mechanism in 3. c. (2) above,

re-engage it to restore correct brake pad-to-rim clearance.

9. Spin the wheel to make sure that it is centered in the frame and clears the

brake pads; then squeeze the brake lever and make sure that the brakes are

operating correctly.

B. Seat post cam action clamp

Some bikes are equipped with a cam action seat post binder. The seat post cam

action binder works exactly like the traditional wheel cam action fastener (Section

4.A.2) While a cam action binder looks like a long bolt with a lever on one end and

a nut on the other, the binder uses an over-center cam action to rmly clamp the

seat post (see g. 8a).

WARNING: Riding with an improperly tightened seat post can allow the

saddle to turn or move and cause you to lose control and fall. Therefore:

1. Ask your dealer to show you know how to clamp your seat post.

2. Apply the correct technique for clamping your seat post.

3. Before you ride, rst check that the seat post is securely clamped.

Adjusting the seat post cam action mechanism

The action of the cam squeezes the seat collar around the seat post to hold the seat

post securely in place. The amount of clamping force is controlled by the tension

adjusting nut. Turning the nut clockwise while keeping the cam lever from rotating

increases clamping force; turning it counterclockwise while keeping the cam lever

from rotating reduces clamping force. Less than half a turn can make the dierence

between safe and unsafe clamping force.

WARNING:The full force of the cam action is needed to clamp the seat

post securely. Holding the nut with one hand and turning the lever like a

wing nut with the other hand until everything is as tight as you can get it

will not clamp the seat post safely.

WARNING: If you can fully close the cam lever without wrapping your

ngers around the seat post or a frame tube for leverage, and the lever

does not leave a clear imprint in the palm of your hand, the tension is

insucient. Open the lever; turn the tension adjusting nut clockwise a

quarter turn; then try again.

C. Brakes

There are three general types of bicycle brakes: rim brakes, which operate by

squeezing the wheel rim between two brake pads; disc brakes, which operate by

squeezing a hub-mounted disc between two brake pads; and internal hub brakes.

All three can be operated by way of a handlebar mounted lever. On some models of

bicycle, the internal hub brake is operated by pedaling backwards. This is called a

Coaster Brake and is described in Appendix C.

WARNING:

1. Riding with improperly adjusted brakes, worn brake pads, or wheels on

which the rim wear mark is visible is dangerous and can result in serious

injury or death.

2. Applying brakes too hard or too suddenly can lock up a wheel, which

could cause you to lose control and fall. Sudden or excessive application

of the front brake may pitch the rider over the handlebars, which may

result in serious injury or death.

3. Some bicycle brakes, such as disc brakes (g.11) and linear-pull brakes

(g. 12), are extremely powerful. Become familiar with these brakes and

exercise particular care when using them.

4. Some brakes are equipped with a brake force modulator, a small,

cylindrical device through which the brake control cable runs and which

is designed to provide a more progressive application of braking force. A

modulator makes the initial brake lever force more gentle, progressively

increasing force until full force is achieved. If your bike is equipped

with a brake force modulator, take extra care in becoming familiar with

its performance characteristics. Some brake force modulators are

adjustable. If you don’t like the feel of your brakes, ask your dealer about

adjusting the brake force modulation.

5. Disc brakes can get extremely hot with extended use. Be careful not to

touch a disc brake until it has had plenty of time to cool.

6. See the brake manufacturer’s instructions for operation and care of

your brakes, and for when brake pads must be replaced. If you do not

have the manufacturer’s instructions, see your dealer or contact the

brake manufacturer.

7. If replacing worn or damaged parts, use only manufacturer-approved

genuine replacement parts.

29 30

1. Brake Controls and Features

It’s very important to your safety that you learn and

remember which brake lever controls which brake on

your bike. Traditionally, in the U.S. the right brake lever

controls the rear brake and the left brake lever controls

the front brake; but, to check how your bike’s brakes

are set up, squeeze one brake lever and look to see

which brake, front or rear, engages. Now do the same

with the other brake lever.

Make sure that your hands can reach and squeeze the

brake levers comfortably. If your hands are too small

to operate the levers comfortably, consult your dealer

before riding the bike. The lever reach may be adjustable;

or you may need a dierent brake lever design.

Most rim brakes have some form of quick-release

mechanism to allow the brake pads to clear the tire

when a wheel is removed or reinstalled. When the

brake quick release is in the open position, the brakes

are inoperative. Ask your dealer to make sure that you

understand the way the brake quick release works on

your bike (see gs. 12, 13. 14 & 15) and check each time

to make sure both brakes work correctly before you get

on the bike.

2. How Brakes Work

The braking action of a bicycle is a function of the friction

between the braking surfaces. To make sure that you

have maximum friction available, keep your wheel rims

and brake pads or the disk rotor and caliper clean and

free of dirt, lubricants, waxes or polishes.

Brakes are designed to control your speed, not just to

stop the bike. Maximum braking force for each wheel

occurs at the point just before the wheel “locks up”

(stops rotating) and starts to skid. Once the tire skids,

you actually lose most of your stopping force and all

directional control. You need to practice slowing and

stopping smoothly without locking up a wheel. The

technique is called progressive brake modulation.

Instead of jerking the brake lever to the position where

you think you’ll generate appropriate braking force,

squeeze the lever, progressively increasing the braking

force. If you feel the wheel begin to lock up, release

pressure just a little to keep the wheel rotating just

short of lockup. It’s important to develop a feel for the

amount of brake lever pressure required for each wheel

at dierent speeds and on dierent surfaces. To better

understand this, experiment a little by walking your bike and applying dierent

amounts of pressure to each brake lever, until the wheel locks.

When you apply one or both brakes, the bike begins to slow, but your body wants

to continue at the speed at which it was going. This causes a transfer of weight to

the front wheel (or, under heavy braking, around the front wheel hub, which could

send you ying over the handlebars).

So, as you apply brakes and your weight is transferred forward, you need to

shift your body toward the rear of the bike, to transfer weight back on to the

rear wheel; and at the same time, you need to both decrease rear braking and

increase front braking force. This is even more important on descents, because

descents shift weight forward.

Two keys to eective speed control and safe stopping are controlling wheel

lockup and weight transfer. This weight transfer is even more pronounced if

your bike has a front suspension fork. Front suspension “dips” under braking,

increasing the weight transfer (see also Section 4.F). Practice braking and weight

transfer techniques where there is no trac or other hazards and distractions.

Everything changes when you ride on loose surfaces or in wet weather. It will take

longer to stop on loose surfaces or in wet weather. Tire adhesion is reduced, so

the wheels have less cornering and braking traction and can lock up with less

brake force. Moisture or dirt on the brake pads reduces their ability to grip. The

way to maintain control on loose or wet surfaces is to go more slowly.

D. Shifting gears

Your multi-speed bicycle will have a derailleur drivetrain (see 1. below), an internal

gear hub drivetrain (see 2. below) or a combination of the two.

1. How a Derailleur Drivetrain Works

If your bicycle has a derailleur drivetrain, the gear-changing mechanism will have:

• a rear cassette or freewheel sprocket cluster

• a rear derailleur

• usually a front derailleur

• one or two shifters

• one, two or three front sprockets called chainrings

• a drive chain

a. Shifting Gears

There are several dierent types of shifting controls: levers, twist grips,

triggers, combination shift/brake controls and push-buttons. Ask your dealer

to explain the type of shifting controls that are on your bike.

31 32

The vocabulary of shifting can be pretty confusing. A downshift is a shift to

a “lower” or “slower” gear, one that is easier to pedal. An upshift is a shift to

a “higher” or “faster”, harder to pedal gear. What’s confusing is that what’s

happening at the front derailleur is the opposite of what’s happening at the

rear derailleur (for details, read the instructions on Shifting the Rear Derailleur

and Shifting the Front Derailleur below). For example, you can select a gear

which will make pedaling easier on a hill (make a downshift) in one of two

ways: shift the chain down the gear “steps” to a smaller gear at the front, or up

the gear “steps” to a larger gear at the rear. So, at the rear gear cluster, what

is called a downshift looks like an upshift. The way to keep things straight is

to remember that shifting the chain in towards the centerline of the bike is for

accelerating and climbing and is called a downshift. Moving the chain out or

away from the centerline of the bike is for speed and is called an upshift.

Whether upshifting or downshifting, the bicycle derailleur system design

requires that the drive chain be moving forward and be under at least some

tension. A derailleur will shift only if you are pedaling forward.

CAUTION: Never move the shifter while pedaling backward, nor

pedal backwards immediately after having moved the shifter. This

could jam the chain and cause serious damage to the bicycle.

b. Shifting the Rear Derailleur

The rear derailleur is controlled by the right shifter. The function of the rear

derailleur is to move the drive chain from one gear sprocket to another. The

smaller sprockets on the gear cluster produce higher gear ratios. Pedaling

in the higher gears requires greater pedaling eort, but takes you a greater

distance with each revolution of the pedal cranks. The larger sprockets

produce lower gear ratios. Using them requires less pedaling eort, but takes

you a shorter distance with each pedal crank revolution. Moving the chain

from a smaller sprocket of the gear cluster to a larger sprocket results in a

downshift. Moving the chain from a larger sprocket to a smaller sprocket

results in an upshift. In order for the derailleur to move the chain from one

sprocket to another, the rider must be pedaling forward.

c. Shifting the Front Derailleur:

The front derailleur, which is controlled by the left shifter, shifts the chain

between the larger and smaller chainrings. Shifting the chain onto a smaller

chainring makes pedaling easier (a downshift). Shifting to a larger chainring

makes pedaling harder (an upshift).

d. Which Gear Should I Be In?

The combination of largest rear and smallest front gears (g. 16) is for the

steepest hills. The smallest rear and largest front combination is for the

greatest speed. It is not necessary to shift gears in sequence. Instead, nd

the “starting gear” which is right for your level of ability — a gear which is hard

enough for quick acceleration but easy enough to let you start from a stop

without wobbling — and experiment with upshifting and downshifting to get

a feel for the dierent gear combinations.

At rst, practice shifting where there are

no obstacles, hazards or other trac, until

you’ve built up your condence. Learn not

to use either the “smallest to smallest” or

“largest to largest” gear combinations

because they may cause unacceptable

stress on the drive train. Learn to

anticipate the need to shift, and shift to a

lower gear before the hill gets too steep.

If you have diculties with shifting, the

problem could be mechanical adjustment.

See your dealer for help.

WARNING: Never shift a derailleur onto the largest or the smallest

sprocket if the derailleur is not shifting smoothly. The derailleur may

be out of adjustment and the chain could jam, causing you to lose

control and fall.

e. What if it won’t Shift Gears?

If moving the shift control one click repeatedly fails to result in a smooth shift

to the next gear chances are that the mechanism is out of adjustment. Take

the bike to your dealer to have it adjusted.

2. How an Internal gGear Hub Drivetrain Works

If your bicycle has an internal gear hub drivetrain, the gear changing mechanism

will consist of:

• a 3, 5, 7, 8, 12 speed or possibly an innitely variable internal gear hub

• one, or sometimes two shifters

• one or two control cables

• one front sprocket called a chainring

• a drive chain

a. Shifting Internal Gear Hub Gears

Shifting with an internal gear hub drivetrain is simply a matter of moving the

shifter to the indicated position for the desired gear ratio. After you have

moved the shifter to the gear position of your choice, ease the pressure on

the pedals for an instant to allow the hub to complete the shift.

b. Which Gear Should I Be In?

The numerically lowest gear (1) is for the steepest hills. The numerically largest

gear is for the greatest speed.

Shifting from an easier, “slower” gear (like 1) to a harder, “faster” gear (like

2 or 3) is called an upshift. Shifting from a harder, “faster” gear to an easier,

“slower” gear is called a downshift. It is not necessary to shift gears in

sequence. Instead, nd the “starting gear” for the conditions — a gear which

33 34

is hard enough for quick acceleration but easy enough to let you start from a

stop without wobbling — and experiment with upshifting and downshifting to

get a feel for the dierent gears. At rst, practice shifting where there are no

obstacles, hazards or other trac, until you’ve built up your condence. Learn

to anticipate the need to shift, and shift to a lower gear before the hill gets too

steep. If you have diculties with shifting, the problem could be mechanical

adjustment. See your dealer for help.

c. What if it won’t Shift Gears?

If moving the shift control one click repeatedly fails to result in a smooth shift

to the next gear chances are that the mechanism is out of adjustment. Take

the bike to your dealer to have it adjusted.

E. Pedals

1. Toe Overlap is when your toe can touch the front wheel when you turn the

handlebars to steer while a pedal is in the forwardmost position. This is common

on small-framed bicycles, and is avoided by keeping the inside pedal up and the

outside pedal down when making sharp turns. On any bicycle, this technique will

also prevent the inside pedal from striking the ground in a turn.

NOTE: Changing tire size or pedal crank arm length aects toe overlap.