Critical Room Control CRC-FHM User manual

Fume Hood Monitor and Controller – User Guide 2 © 2016 CRITICAL ROOM CONTROL

Contents

Introduction...........................................................................................................................3

Primary Screens .....................................................................................................................4

Main Screen............................................................................................................................. 4

Air Flow Alarm ......................................................................................................................... 5

Password Protection................................................................................................................ 6

Mode Change .......................................................................................................................... 6

Emergency Override ................................................................................................................ 7

Commissioning Info Screen ..................................................................................................... 8

Administrative Screens .......................................................................................................... 9

Hood Setup Functions: ............................................................................................................ 9

General Configuration: ............................................................................................................ 9

Exhaust Input Setup............................................................................................................... 10

Sash Sensing - Exhaust Input Setup.................................................................................. 10

Immediate Valve Control (IVC™) – Sash Sensing .............................................................. 11

Sidewall Sensing – Exhaust Input Setup ........................................................................... 12

Predictive Sash Valve Control (PSVC™) – Sidewall Sensing .............................................. 13

Constant Volume - General.............................................................................................. 14

Sash Setup ............................................................................................................................. 15

Vertical Sash – Sash Setup................................................................................................ 15

Combination Sash – Sash Setup ....................................................................................... 16

Set Point / Control Setup ....................................................................................................... 17

Min. Flow Feature ............................................................................................................ 17

Max. Flow Feature ........................................................................................................... 17

Alarm Setup ........................................................................................................................... 18

Sash Alarm - Sash Area..................................................................................................... 18

CFM Alarm – Sash Area.................................................................................................... 18

Energy Saver Delay........................................................................................................... 19

BACnet MS/TP ....................................................................................................................... 19

General Setup Screen (password, hood #, etc.) ..................................................................... 22

Hood Exhaust Summing ................................................................................................... 22

Decommission Mode............................................................................................................. 22

Commissioning Task List – Sash Sensing ................................................................................ 23

Commissioning Task List – Sidewall Sensing .......................................................................... 24

Diagnostic Screen .................................................................................................................. 25

Wiring / Device Connection Overview .................................................................................. 26

Installation .......................................................................................................................... 27

Mounting / Installation .......................................................................................................... 27

Controller I/O......................................................................................................................... 30

Troubleshooting................................................................................................................... 31

Display is not reading correct air volume or face velocity. .................................................... 31

Recalibrating Touch Screen ................................................................................................... 31

Limitation of Warranty and Liability ..................................................................................... 32

Fume Hood Monitor and Controller – User Guide 3 © 2016 CRITICAL ROOM CONTROL

Introduction

The CRC-FHM/C is a comprehensive, flexible, and easy to use fume hood monitor / controller.

Even though the CRC-FHM/C’s unique design allows for quick trouble-free set up, we suggest

reading this guide before use. This guide will help you take full advantage of the function and

performance of the FHM/C.

Functionality Overview

Both CRC-FHM (Fume Hood Monitor) and CRC-FHC (Fume Hood Controller) can monitor and

alarm the airflow of a fume hood using sash sensing, sidewall sensing, or constant volume

measurements. The CRC-FHC includes all of the functionality of the CRC-FHM, and has the added

ability to control the fume hood’s airflow with either face velocity / variable volume or constant

volume.

Feature Summary

•Immediate Valve Control™ (IVC) and Predictive Sash Valve Control™ (PSVC) adjusts

face velocity to the correct set point immediately after sash movement (less than 1

second).

•Clear indication of hood face velocity or air volume.

•Supports constant volume or variable volume hoods.

•One button "quick switch" to emergency override mode.

•Main screen commissioning info allows for quick and easy startup and PID tuning.

•Supports direct sidewall, vertical sash, horizontal sash and combination sash sensing.

•Optional minimum and maximum flow features.

•Can be automatically switched into "In Use" mode via occupancy sensor.

•Energy saving sequencing and control logic to put controller into "Standby" mode

when not in use.

•Optional sash and CFM alarms can be used to prompt user to lower sash in order to

increase energy savings without placing users at risk.

•Fully integrated BACnet MS/TP communications.

•Supports imperial and metric readouts.

•Full color LCD touch screen with LED backlight.

•Multiple user modes and set points.

•Proprietary control functionality for both constant volume and face velocity control

that provides industry leading speed of response.

•Can operate as a standalone device, part of a Critical Room Control complete space

solution, or integrate with Building Automation System.

Application

The CRC – FHM/C is designed to fit on all fume hood applications including:

1. Hospital: Pharmacies, Oncology, Laboratories

2. Laboratories: Wet Chemistry, Open Bench

3. Animal Research Laboratories

4. Bio-Containment Laboratories

5. Cleanrooms / Manufacturing

Fume Hood Monitor and Controller – User Guide 4 © 2016 CRITICAL ROOM CONTROL

Primary Screens

Main Screen

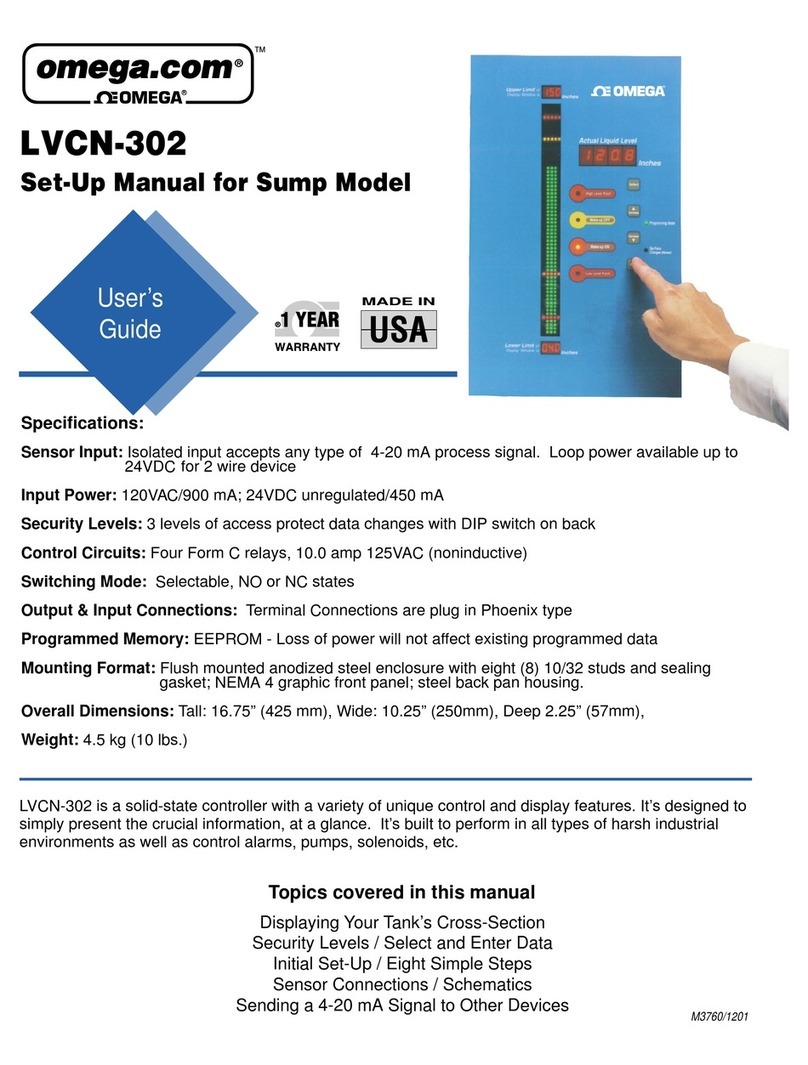

The FHM / FHC’s “Main Screen” indicates the current mode, flow rate, and alarm status of the

fume hood. Located in the upper quarter of the screen, the FHM/FHC displays current face

velocity or hood airflow volume depending on the user defined control strategy. The monitor also

displays current hood control mode, operating condition and associated graphic. The monitor

includes the ability to override the control function and drive the hood to fail safe operation.

Background color indicates Alarm status (Green indicates no alarm).

Background color indicates alarm status

(Green indicates no alarm)

Displays current Face Velocity or CFM

Indicates current hood operation mode

Easy to understand graphic indication of

hood operation

Displays current condition of fume hood

Emergency Override Button – user can

instantly drive the fume hood's exhaust to

maximum flow

Hood 12b

Fume Hood Monitor and Controller – User Guide 5 © 2016 CRITICAL ROOM CONTROL

Air Flow Alarm

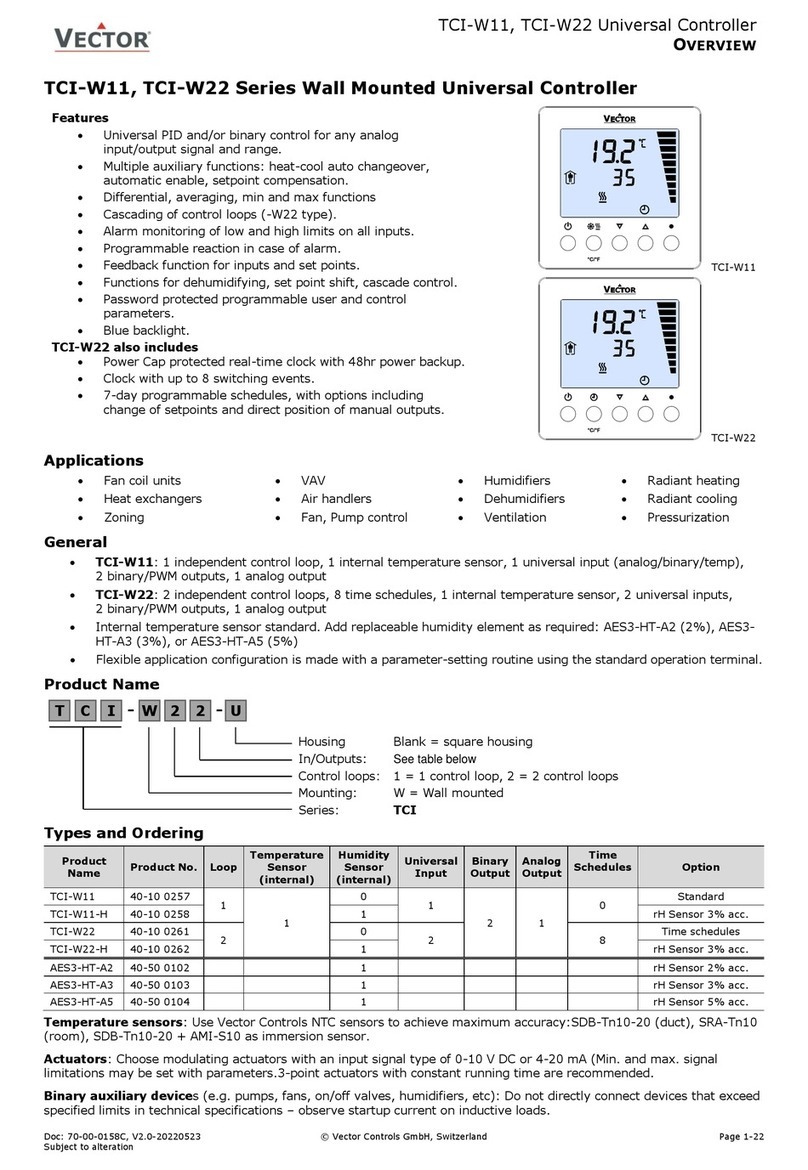

When the current face velocity (FPM) or volumetric (CFM) reading goes outside of the alarm high

and low parameters, the unit will go into alarm. The FHM/C can be configured with an audible

alarm delay (nuisance delay). When an audible alarm delay is used, the "Hood Caution” screen

with a yellow background will be displayed until the timer runs out and the unit goes into alarm.

It is important to note that the FHM/C's face velocity and CFM alarm is ONLY active when in the

“IN USE” mode. Face velocity and CFM alarms are not active while in the “STANDBY” or

“Decommission” mode.

t

AUDIBLE ALARM MUTE

HOOD FLOW NORMAL LOSS OF HOOD EXHAUST

No alarm /

hood normal

Green background

Easy to read "Safe

Flow" icon

LOSS OF HOOD EXHAUST

Displays current

drop in flow rate

Caution Icon

Caution text

with instructions

to user

HOOD EXHAUST ALARM

Audible alarm

sounds

Red background

Alarm icon

AUDIBLE ALARM DELAY EXPIRES

USER MUTES AUDIBLE ALARM

Alarm text

with instructions

to user

Audible alarm icon

/ mute button

Muted audible

alarm icon

All visual alarm

indications remain until

air flow is restored

Fume Hood Monitor and Controller – User Guide 6 © 2016 CRITICAL ROOM CONTROL

Password Protection

The CRC-FHM/FHC allows the user to change the password needed to access the administrative

menu. If the password is set to blank (no characters entered), then users are not prompted to

enter a password when accessing the administrative menu.

Factory default password for the administrative Menu is: 9876

Mode Change

User can select between two modes:

•IN USE

•STANDBY

User touches anywhere on

screen to make MODE and

ADMIN buttons appear

User selects change "Mode" button

Current Mode: In Use

Change Hood Mode

Please select hood’s mode

IN USE STANDBY

Exit -No Changes

User selects "IN USE" User selects "STANDBY"

Change Hood Mode

screen appears

Fume Hood Monitor and Controller – User Guide 7 © 2016 CRITICAL ROOM CONTROL

IN USE:

FHM (Monitor only) - Selecting IN USE will display the IN USE graphic and activate

alarms based on the IN USE face velocity or airflow volume set point

FHC (Monitor and Control) – Selecting IN USE will display IN USE graphics and activate

the programmed IN USE face velocity or airflow volume set point. The onboard control

loop will make volume adjustments to the fume hood airflow to attain the IN USE set

point and activate alarms based on IN USE set point.

STANDBY:

FHM (Monitor only) - Selecting STANDBY will display the STANDBY graphic and

deactivate alarms.

FHC (Monitor and Control) – Selecting STANDBY will display STANDBY graphics and

activate the programmed STANDBY face velocity or airflow volume set point. The

onboard control loop will make volume adjustments to the fume hood airflow to attain

the STANDBY set point and deactivate alarms.

Emergency Override

The CRC-FHM/FHC emergency override offers the ability to command the hood exhaust to

maximum flow from any of the main screens. When the unit is put into Emergency Override, the

screen changes to red background and an audible alarm will sound. The control loop output (CRC-

FHC only) will automatically drive the exhaust valve fully open.

User selects "EMERGENCY

OVERRIDE" from any main screen

and the unit will switch to

EMERGENCY OVERRIDE Mode

The CRC_FHM/C will return to

"In Use" mode when user selects

"CANCEL OVERRIDE"

Fume Hood Monitor and Controller – User Guide 8 © 2016 CRITICAL ROOM CONTROL

Commissioning Info Screen

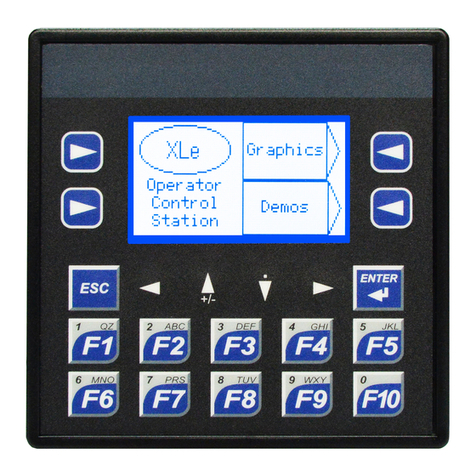

The commissioning info screen is a feature of the CRC-FHM/C that displays key information on

the front screen to aid in the setup / startup of the fume hood. It also allows the commissioning

agent to change the P and I gains values directly from the front screen.

This feature can be turned on / off from the Exhaust Setup Screen.

Commissioning information values include:

•Current Analog Input 1-3 values (percentage of 0-10V signal)

•Current PID output / valve position (percentage 0-10v signal on AO 0)

•Current "WC signal from CRC-CLV

•Current CFM being exhaust by this hood

•Current total exhaust of all hoods (see hood summing feature) – “T CFM CAS”

•Current Air flow without display dead band and influence from min / max feature

•Total Sash Area - “Tot Area” (applicable for sash sensing only)

•Vertical Sash Area (applicable for sash sensing only)

•Horizontal Sash Area (applicable for sash sensing only)

•Voltage offset (see zeroing valve)

•FPM Offset (applicable for sidewall sensing only)

FPM Offset button allows

balancer to easily fine tune

the FPM signal coming from

our sidewall sensor

Set Stop Position is used only

with sidewall sensing and PSVC.

See sidewall setup for more

information.

Fume Hood Monitor and Controller – User Guide 9 © 2016 CRITICAL ROOM CONTROL

Administrative Screens

The "Administration Menu" lists all of the functionality that a user is able to configure on the CRC-

FHM/FHC. The administrative menu is accessed from the main menu. The administration menu

requires the user to enter a password (Default Password: 9876) to gain access.

Hood Setup Functions:

•Exhaust Setup: used to configure the airflow device and hood control strategy

•Set Point / Control: used to configure IN USE and STANDBY set points, control

Proportional and Integral loop parameters, display dead band, min. and max. flow

•Hood/Sash Setup: used to set up fume hood sash sensor including Vertical,

Horizontal and combination vertical/horizontal sashes

•Alarm Setup: Used to set IN USE alarm range of face velocity or CFM, audible alarm

delay time, sash alarm and energy saver alarm delay

•Network Setup: used to set up BACnet communication parameters.

General Configuration:

•Password Set: Used to configure the administrative password and

setup screen timeout

•I/O Diagnostic: Visual indication and testing of controller inputs and outputs

•Factory Reset: Restores original factory settings

•Restart: Restarts the controller to access the touch screen calibration

Fume Hood Monitor and Controller – User Guide 10 © 2016 CRITICAL ROOM CONTROL

Exhaust Input Setup

The "Exhaust Input Setup" screen contains the parameters to configure the fume hood's flow rate

that is displayed on the main screen. The three types of flow sensing that can be selected are:

•Sash Sensing – which uses a sash sensor to translate air volume into face velocity

•Sidewall Sensing – which uses a velocity sensor that directly measures face velocity

•Constant Volume – which measures the volume of air that is being exhausted from

the fume hood

Sash Sensing - Exhaust Input Setup

Sash sensing calculates face velocity of the air traveling through the open sash area by using a

sash sensor to translate the current open area of the fume hood's sash relative to the amount of

air that the hood is currently exhausting. To calculate face velocity using this method, the CRC-

FHM/C must be connected to both a sash sensor and a CRC- Closed Loop Valve.

Select "Face Veloc. Sash"

Select "FPM" or "MPS"

Reduces or eliminates small fluctuations

in face velocity display

Set DP high value for valve (usually 2" WC)

Show / hide commissioning info on front screen

Gives access to screen to populate, view and reset

the hood exhaust valve’s air flow table

Set DP low value for valve (usually 0" WC)

Set K Factor for valve

To “Zero” the exhaust valve’s voltage signal, first

shunt the high and low port on the valve’s

transducer, then press “Zero Valve” to set the

voltage input that corresponds with zero air flow.

Fume Hood Monitor and Controller – User Guide 11 © 2016 CRITICAL ROOM CONTROL

Immediate Valve Control (IVC™) – Sash Sensing

Unlike conventional hood controllers that merely rely on a PI loop to slowly react to changes in

sash position, CRC fume hood controller’s Immediate Valve Control (IVC)™ technology continually

measures sash position and current CFM at a rate of 5 times per second to immediately react to

a change in sash position and instantly drive our valve to the correct valve position to maintain

face velocity.

CRC’s IVC™ algorithms utilize an air flow table that is created with an automated process that

takes less than 20 seconds during the commissioning of the fume hood.

To create this table, simply click on the “Valve Table” button on the Exhaust Input Setup screen

to show the “Valve Air Flow Table” screen.

To setup / enable IVC, first confirm that the exhaust flow is running at the lowest static pressure

to be used during operation, then press the “Pop Table” button to auto populate the flow values

of the hood’s exhaust valve. After pressing this button, the controller automatically records the

valve’s flow rate for different key actuator positions. This process takes approximately 20 seconds

to complete. When finished, the table status should read “NO ISSUE”.

To disable IVC, click the “Reset Table” button.

Please note the following:

•Changing the valve’s “K Factor” will NOT effect the table. Once the table is created – the

table values will automatically adjust to changes in K Factor.

•For optimized performance, the exhaust flow should be running at the lowest static

pressure to be used during operation of the hood before pressing the “Pop Table”

button.

•If “Zero Valve” status is displayed, then go through the Valve Zeroing process outlined

on previous page before repopulating the valve’s airflow table.

Click “Valve Table”

Click “Pop Table” to auto populate the

valve’s air flow table.

Table Status:

- NO ISSUE

- NOT SET UP

- SENSOR ERR

- ZERO VALVE

“Reset Table” will

disable IVC features

Fume Hood Monitor and Controller – User Guide 12 © 2016 CRITICAL ROOM CONTROL

Sidewall Sensing – Exhaust Input Setup

Sidewall sensing calculates face velocity of the open sash area by using CRC's direct velocity

measuring sensor (CRC-SWS) that is typically installed on the sidewall of the fume hood. This

methodology has the option to connect to a CRC Valve (CRC-CLV) to monitor and sum the volume

of air that is being exhausted for the room's overall exhaust volume.

The following is the simple three step process to commission the sidewall sensor. Make sure the

Commissioning Info option is set to "Show" on the Exhaust Input Setup Screen.

Reduces or eliminates small fluctuations

in face velocity display

Set DP high value for valve (usually 2" WC)

Show / hide commissioning info on front screen

Set DP low value for valve (usually 0" WC)

Set K Factor for valve

STEP 1: Open sash to stop position and

wait until hood's flow is stable at set point

STEP 2: Have air balancer read the actual

face velocity average from the sash

opening – then press "Set FPM" button

STEP 3: Enter the difference between actual face

velocity that the air balancer reads and what is shown

on the screen – then press "ENTER / SAVE" button

Select "Face Veloc. Sidewall"

Select "FPM" or "MPS"

Use / Disable PSVC

Fume Hood Monitor and Controller – User Guide 13 © 2016 CRITICAL ROOM CONTROL

Predictive Sash Valve Control (PSVC™) – Sidewall Sensing

Moving the sash from fully closed to fully open is the most likely time a fume hood can loose

containment. When opening a fume hood’s sash, the hood needs to respond immediately to

increase its exhaust so that the face velocity is maintained. The challenge with conventional hood

controllers using sidewall sensors is that they rely on dated hotwire technology to measure

airflow, which is relatively slow to sense and react to changes in air velocity. These hood

controllers also use conventional PI loops to slowly react to the lack of face velocity.

CRC’s fume hood controller and sidewall sensor does not use hotwire technology. Its sensor

calculates a change in air velocity within 1/5 of a second. Its PSMC algorithm can also detect when

a user is opening the sash and, before the user is able to raise the sash to stop position, it will

increase its exhaust rate to maintain proper face velocity. This technology allows CRC fume hood

controllers to control to set point in under 1 second (<800ms).

To configure PSVC™, simply follow these steps:

1. Enable “PSVC” on the Exhaust Input Setup screen.

2. Turn on commissioning info.

3. Open sash to stop position.

4. Wait until hood is maintaining correct face velocity.

5. Press the “Set Stop Position” button.

To configure PSVC™ - Open sash to stop

position, wait until hood is maintaining

correct face velocity, then press the “Set

Stop Position” button.

Fume Hood Monitor and Controller – User Guide 14 © 2016 CRITICAL ROOM CONTROL

Constant Volume - General

Constant Volume Sensing uses direct feedback from the CRC-CLV to monitor and sum the volume

of air that is being exhausted. This value is displayed on the front screen and can be

communicated to the rooms control system to accurately calculate total exhaust.

Reduces or eliminates small fluctuations

in air volume

Set DP high value for valve (usually 2" WC)

Show / hide commissioning info on front screen

Set DP low value for valve (usually 0" WC)

Set K Factor for valve

Select "Constant Volume"

Select "cfm" or "l/p"

To “Zero” the exhaust valve’s voltage signal, first

shunt the high and low port on the valve’s

transducer, then press “Zero Valve” to set the

voltage input that corresponds with zero air flow.

Fume Hood Monitor and Controller – User Guide 15 © 2016 CRITICAL ROOM CONTROL

Sash Setup

The FHM/C supports vertical sash, horizontal sash, and combination sash fume hoods.

Please note that the FHM/C's Sash Setup screens / options are only used when deriving face

velocity from sash position, a sash sensor is not needed for those fume hoods that are using

constant volume or sidewall sensing methodologies to display / control air flow.

Vertical Sash – Sash Setup

The following screen contains the configuration options for using a vertical sash sensor. The same

setup is used when the fume hood is equipped with just a horizontal sash.

Select "Vertical Sash"

Enter the total area in sqft. of the sash opening (width

x height). Do not include bypass area.

Close the sash to its fully closed position and click the

" Calib." Button – this will automatically enter the

voltage from the sash sensor for the closed position

Enter the total area in sqft. for just the bypass area

Open sash to its fully open position and click the

"Calib." Button – this will automatically enter the

voltage from the sash sensor for the open position

Fume Hood Monitor and Controller – User Guide 16 © 2016 CRITICAL ROOM CONTROL

Combination Sash – Sash Setup

The following screen contains the configuration options for a hood that has a horizontal sash

integrated into the vertical sash.

Select "Combo Sash"

Open sash to its fully open position and click the "Calib."

Button – this will automatically enter the voltage from

the sash sensor for the open position

Enter the total area in sqft. of the vertical sash opening

(width x height). Do not include bypass area.

Fully close the sash and click the "Calib." Button – this will

automatically enter the voltage for the closed position

Enter the total area in sqft. for just the bypass area

FIGURE 2: To set the Horizontal Start value -

open the vertical sash until the horizontal

start plane is aligned with the upper portion

of the vertical sash opening as shown here,

then press the Start "Calib." Button.

FIGURE 1: The following illustrates the Horizontal

START and STOP position when the vertical sash is

closed. Note that the horizontal sash (light blue) is

a sub component of the vertical sash (dark blue).

Fully open the Horizontal sash and click the "Calib." button.

Fully close the Horizontal sash and click the "Calib." button

Open the Vertical sash to the top of the Horizontal sash as

indicated in FIGURE 2 below and click the "Calib." button

Open the Vertical sash so that the bottom of the Horizontal

sash (stop) is at top of the Vertical sash opening and click

the "Calib." button

Enter the total sqft for open horizontal sash area

Fume Hood Monitor and Controller – User Guide 17 © 2016 CRITICAL ROOM CONTROL

Set Point / Control Setup

Used to configure IN USE and STANDBY set points, control Proportional and Integral loop

parameters, display dead band, minimum and maximum flow values.

Min. Flow Feature

Most hood manufacturers give a minimum CFM value for each hood model which is required to

safely operate that specific hood. The CRC-FHM/C will automatically control the hood exhaust

valve so that the minimum CFM entered is maintained. When configured to display face velocity

on the front screen, the CRC-FHM/C will display "Minimum Flow 100+ FPM" if controlling the

exhaust valve to the minimum CFM causes the face velocity to exceed set point (i.e. controlling

hood to maintain 300 cfm when the sash is fully closed).

Please note that this feature can only be used when the CRC-FHC is monitoring CFM.

Max. Flow Feature

The "Max. Flow" feature allows the CRC-FHC to be configured to not exceed a certain CFM (usually

dictated by hood manufacturer).

Please note that this feature only affects the PI control loop, and can only be used when the CRC-

FHC is monitoring CFM.

Control Deadband – used to stop small oscillations to

control loop

Direct or reverse acting PI loop

Set maximum CFM for hood (specified by hood

manufacturer).

"In Use" and "Standby" set points

P and I Gain values control the speed of

control loop ("P Gain" value should

always be greater than "I Gain" values")

Set minimum CFM for hood (specified by hood

manufacturer). CRC-FHC will not allow control loop to

drop air flow below this value

Fume Hood Monitor and Controller – User Guide 18 © 2016 CRITICAL ROOM CONTROL

Alarm Setup

This screen contains the parameters to set face velocity or volume alarm when monitor is in the

“IN USE” mode. This screen also contains the parameters used to configure the audible alarm

delay time, sash alarm and energy saver alarm delay.

Sash Alarm - Sash Area

If the total sash area is greater than the value entered for the "Area

Alarm", for a longer period of time than the time set in the "Delay

(Sec)." field, the sash visual and audible alarm will be triggered.

The audible alarm can be muted by the user by clicking on the

"Sash Alarm" button.

This feature can only be used when connected to a sash sensor.

CFM Alarm – Sash Area

Similar to the Area Alarm, the CFM Alarm will be triggered if the

current CFM is greater than the value entered for the "CFM

Alarm", for longer period of time than the time set in the "Delay

(Sec)." field. The audible alarm can be muted by the user by

clicking on the "Sash Alarm" button.

The CFM Alarm feature is used when the CRC-FHM/C is using a sidewall sensor to monitor face

velocity instead of a sash sensor.

Alarm range over and under set point. Visual and

audible alarm will occur when flow exceeds "In Use"

set point + (plus) High value, or falls below "In Use"

set point – (minus) Low value.

Audible alarm / nuisance delay

A sash area alarm will be triggered if total sash area

is greater than this value (see "Sash Alarm" below)

The delay before the FHM/C is put in standby

mode (see "Energy Saver Mode" on next page)

A sash area alarm will be triggered if total CFM area is

greater than this value (see "CFM Alarm" below)

Sash alarm delay – used for both Sash Area Alarm

and CFM Alarm

Fume Hood Monitor and Controller – User Guide 19 © 2016 CRITICAL ROOM CONTROL

Energy Saver Delay

This feature will automatically change the mode from “In Use” to “Standby” after the number of

minutes entered into the “Set Energy Saver Delay” has expired. This feature can be used with or

without an occupancy sensor. This feature can also be turned off by selecting “Off” in the Set

Energy Saver Delay value on the Alarm Setup Screen. Thirty (30) seconds before the unit is

automatically switched to “Standby” Mode, a warning will appear on the screen and a beep will

sound every second until mode is changed to standby.

With Occupancy Sensor: When an occupancy sensor is wired into DI1, the unit will not start the

Energy Saver Delay countdown until the occupancy sensor opens the contact to DI1 (unoccupied).

After the countdown is complete - the unit will switch to Standby Mode.

Without Occupancy Sensor: If no occupancy sensor is wired to DI1, then the unit will start the

Energy Saver Delay countdown as soon as it is put into the “In Use” mode. When the countdown

is completed, the unit will automatically change to “Standby” mode.

BACnet MS/TP

For BACnet communications over a three wire RS 485 trunk, enter the appropriate network

parameters for this device:

•Baud Rates: 9600, 19,200, 38,400, 57,600, 76,800, 115,200

•MAC Address: 0 - 254

•Instance ID: 1 - 4,194,304

Debug Information: If selected, this feature will display network traffic and communication

information on the main screen.

Configure as a Token Passing Device or as a Slave Device: If the device's MAC Address is set

between 0 and 127, it is configured as a token passing device – which enables "Dynamic Binding",

response to "Who Is" requests, and participation in token passing.

Setting this device's Slave Address between 126 and 254 will configure this device as a dedicated

slave device which will greatly reduce network overhead / traffic, but requires the device NOT to

support "Dynamic Binding", respond to "Who Is" requests, or participate in token passing.

Physical Network

Connection to the RS485 requires a three wire bus consisting of a positive, negative, and ground

/ common wire. Typically, devices on a RS485 network are a series circuit or “Daisy-Chained”

together.

An MS/TP EIA-485 network should use a three wire shielded twisted pair cable with characteristic

impedance between 100 and 130 ohms. Distributed capacitance between conductors should be

less than 100pf per meter. Foil and braided shields are acceptable. The maximum recommended

length of an MS/TP segment is 4,000 feet with AWG 18. The maximum number of nodes per

segment is 32. An MS/TP EIA-485 network should have no T connections. A termination of

20ohms +-5% should be connected at each of the two ends of the segment medium. No other

terminations should be used at intermediate nodes.

Fume Hood Monitor and Controller – User Guide 20 © 2016 CRITICAL ROOM CONTROL

BACnet Trouble Shooting / Debug Screen

The following section gives a brief overview of the network "Debug Information" that can be

selected to show on the front screen of the CRC-RM.

•Network Traffic: This number will increase if there is any network traffic regardless if

this unit's BAUD rate is correct. If this number is NOT increasing, then there is no

traffic on the network or the unit is not connected to the network.

•M In (Messages In): This number will increase when this unit receives a message

addressed specifically to it.

•S ACK (Simple Acknowledgement): This number increases as this unit responds to

requests to WRITE points.

•C ACK (Complex Acknowledgement): This number increases as this unit responds to

requests to READ points.

•M Sent (Messages Sent): This number increases with when this unit sends out a

message (including passing a token).

•Who Is: This number will increase when this unit receives a "who is" request that is

broadcasted to every device on its bus.

•Who Is (R) (Ranged Who Is): This number will increase when this unit receives a

"who is" request for a specific range of Instance IDs.

•I Am: This number increases when this unit responds to a Who Is request.

•Token: This number increases with when this unit receives and passes a token.

•Framing Errors or Break Errors: If this

number is increasing, then it usually

means that there is noise on the trunk

This manual suits for next models

1

Table of contents

Popular Controllers manuals by other brands

Endress+Hauser

Endress+Hauser Liquiline CM442R operating instructions

Fosworks

Fosworks COBRA ESC-160 quick start guide

APP

APP Solar controller APP and PC monitoring instruction manual

SMC Networks

SMC Networks ITV1000 series Operation manual

RSG

RSG UNIVERSAL CONTROLLER PLUS user guide

NETGEAR

NETGEAR ProSafe WC7520 datasheet