Cromemco D+7A I/O User manual

CROMEMCO

D+zA

LO

instruction

manual

e

CROMEMCO

D+7ALO

OWN

AA

©Copyright

1978.

All

rights

reserved.

0

incorporated

Specialists

in

computers

and

peripherals

280

Bernardo

Ave.,

Mountain

View,

CA

94041

TABLE

OF

CONTENTS

INTRODUCTION

s

orcs

GRY

IIA

TARA

VA

RRA

ASSEMBLY

INSTRUCTIONS

CALIBRATION

PROCEDURE

OPERATING

INSTRUCTIONS

.

THEORY

OF

OPERATION

....

Analog

Output

Analog

Input

Digital

Output

Digital

Input

TECHNICAL

SPECIFICATIONS:

ana

ae

ee

nee

9

Computer

Digital

Port

Analog

Port

Source

Impedance

Effects

Input

Accuracy

Output

Accuracy

Output

Drift

Bipolar/Unipolar

Operation

APPLICATIONS:INFORMATION

i

visna

vas

ers

re

GÓRA

11

Setting

the

Analog

Voltage

Range

Input

Scaling

Output

Scaling

Using

the

D+7A

with

Cromemco

Dazzler

Using

the

D+7A

with

Cromemco

Joystick

Console

PARTS

IS

Tic

ii

IS

ok

SHS

ER

NO

RR

AAT

KA

15

LIST

OF

TABLES

Table

1

Technical

Specifications

D+7A

A/D

&

D/A

Interface

Table

2

Resistor

Color

Codes.

.....

a

Table

3

Connector

Pin

Assignments.

A z s A .

Table

.POrLASIGNMEN(S

cda

it

Na

IG

de

a

M

Table

5

Input

Scaling

Component

Values

...................................

Figure

1%»

a

na

encanta

A

A

NR

Figure

2

TO-5

IC

Installation

...

é

Figure'3.

‘Parts‘Location

Disgrani\.c.

in,

22:22

0

ua

A

IR

Fint’

‚Port

Address’

Selection

size

cti

eno

ads

aa

aka

GAGA

ja

Figure

5

D+7A1/O

Block

Diagram

.

Figure

6

Input

Scaling...........

Figure

7

Output

Scaling

.

Figure

8

Joystick

Schematic

Diagram

.

Figure

9

Joystick

Wiring

Diagram

..

.

4

Figure

10

D+7A

NO

Schematic

Diagram......................................

17

0

D+ZA

LO

INTRODUCTION

The

Cromemco

D+7A

I/O

Module

is

a

fast

and

easy

way

to

input

and

output

both

analog

and

digital

signals

from

a

computer.

This

high

performance

module

gives

seven

channels

of

8-bit

analog-to-digital

conversion

and

seven

channels

of

digital-to-analog

conversion

with

a

fast

conversion

time

of

5.5

microseconds.

The

D+7A

I/O

Module

makes

it

easy

to

use

a

computer

for

appli-

cations

ranging

from

process

control

and

digital

filtering

to

speech

and

music

synthesis.

Using

the

D+7A

1/0

Module,

analog

data

can

be

input

from

joysticks,

measurement

instruments,

machine

tools,

control

systems,

motors,

recorders,

plotters,

and

a

large

number

of

other

devices.

The

D+7A

I/O

Module

plugs

directly

into

an

industry

standard

S-100

microcomputer

bus.

There

are

eight

I/O

ports

on

the

D+7A

I/O

Module

card,

one

digital

and

seven

analog.

Five port

address

jumpers

on

the

board

are

used

to

select

the

addresses

of

these

ports.

This

manual

describes

the

operation

of

the

D+7A

1/0

Module

in

detail,

and

explains

how

it

is

used.

A

summary

of

the

technical

specifications

of

the

D+7A

1/0

Module

is

given

in

Table

1.

Table

1

Technical

Specifications

D+7A

A/D

&

DA

Interface

TECHNICAL

SPECIFICATIONS

D+7A

A/D

8:

D/A

INTERFACE

ANALOG

INPUT

PORTS:

Number

of

input

ports:

7

Input

voltage

range:

-2.56

to

+2.54

volts

Input

bias

current:

2

microamps

max.

20

Megohms

Il

.001

uF,

1

kHz

sample

rate.

2

Megohms

II

.001

uF,

10

kHz

sample

rate.

Resolution:

8

bits.

Conversion

time:

5.5

microseconds

Accuracy:

+

20

millivolts

ANALOG

OUTPUT

PORTS:

Number

of

output

ports:

7

Output

voltage

range:

-

2.56

to

+2.54

volts

Output

impedance:

0.25

ohm.

PARALLEL

1/O

PORT:

GENERAL

INFORMATION:

Maximum

load

current:

1.5

mA

Resolution:

8

bits

Conversion

time:

5.5

microseconds

Accuracy:

+

20

millivolts

Drift

rate:

Less

than

10

mV/sec

at

25°C

Input

port:

8

bits

Output

port:

8

bits

Input

load:

one

TTL

equivalent

Output

drive:

10

TTL

loads

Bus:

S-100.

Power

requirements:

+8

volts

©

0.4

A

+18

volts

©

30

mA

-

18

volts

©

60

mA

D+ZA

LO

ASSEMBLY

INSTRUCTIONS

If

you

purchased

your

D+7A

as

a

kit

you

will

find

the

assembly

to

be

straightforward.

To

facilitate

assembly,

the

location

and

value

of

every

component

is

printed

directly

on

the

PC

card.

The

components

are

simply

inserted

in

the

locations

shown

in

figure

3

and

soldered

into

position.

Be

sure

to

use

a

low-wattage

soldering

iron

and

high-quality

rosin-core

solder.

IC

Case

Table

2

Resistor

Color

Codes

Frequency

Compensation

Nonlnverting

Input

Note:

Pin

4

Connected

to

Case

1.

Install

all

IC

sockets.

Note

that

IC

sockets

must

be

used

for

all

IC's

except

voltage

regulators

(1C3,

1C6,

and

1C28.)

2.

Install

all

resistors.

The

resistor

color

codes

are

shown

in

Table

2.

3.

Install

calibration

potentiometers

R2,

R5,

R10,

R12.

NOTE:

R2

is

25K,

and

the

other

three

are

500

ohms.

4.

Install

resistor

network

RN2.

Note

that

pin

1

is

leftmost,

as

indicated

by

the

arrow

on

the

PC

board.

5.Install

all

six

diodes

in

place

taking

care

that

the

banded

(cathode)

end

of

each

diode

is

properly

oriented.

6.

Install

transistor

Q1

(2N3906)

and

install

1C6

(78L05).

Note

that

the

flat

surface

of

each

of

these

parts

faces

the

top

of

the

PC

board.

7.

Install

voltage

regulator

IC's

3

and

28.

A

heatsink

should

be

placed

between

the

regulator

and

the

PC

board

and

the

assembly

secured

with

6-32

hardware.

Note

that

IC3

is

a

LM340T-5

or

7805

part.

1028

is

a

10

brown-black-black

1.5K

brown-green-red

100

brown-black-brown

2.2K

red-red-red

150

brown-green-brown

2.4K

red-yellow-red

180

brown-gray-brown

2.7K

redwiolet-red

220

red-red-brown

4.7K

yellow-violet-red

470

yellow-violet-brown

5.1K

green-brown-red

560

green-blue-brown

10K

brown-black-orange

1K

brown-black-red

18K

brown-gray-orange

s

brown-red-red

100K

brown-black-yellow

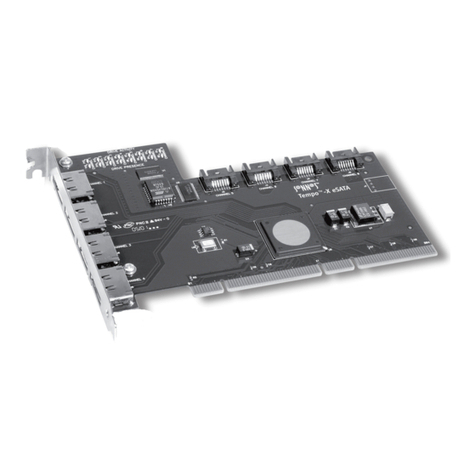

Figure

2

TO-5

IC

Installation

LM320T-5

or

7905

part.

BE

CAREFUL

NOT

TO

INTERCHANGE

THESE

TWO

IC's.

8.

Install

the

two

inductors

L1

and

L2.

9.

Install

all

capacitors

as

marked

on

the

PC

board.

Note

that

the

“+”

end

of

each

of

the

tantalum

capacitors

must

be

oriented

properly.

Capacitors

C31,

C32,

C33,

and

C34

are

mounted

side-by-side

but

should

NOT

be

in

physical

contact

with

one

another.

10.

Install

all

IC's

and

RN1

in

their

sockets

taking

care

to

see

that

pin

one

of

each

part

is

oriented

as

indicated

by

the

arrow

on

the

PC

board.

When

installing

1C's

in

the

metal

TO-5

style

case,

note

that

the

metal

tab

denotes

pin

8

of

the

IC

as

shown

in

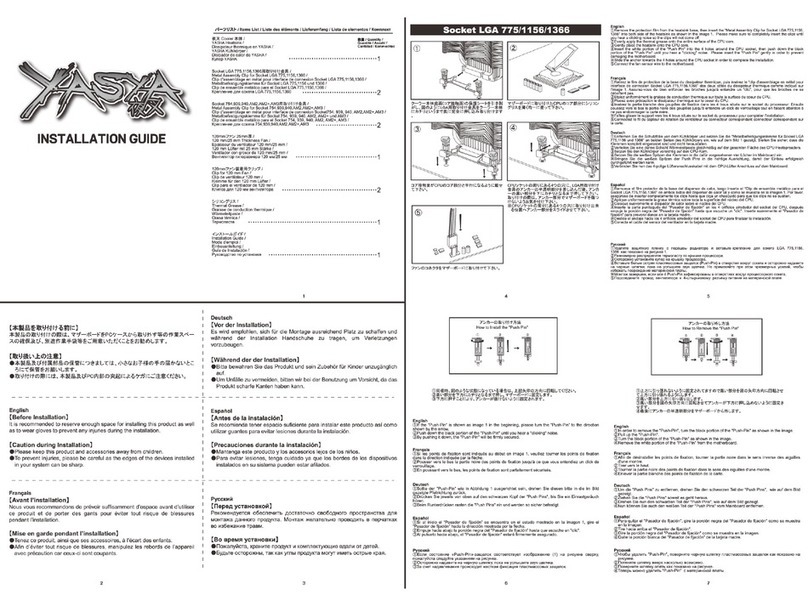

figure

1.

The

leads

of

the

TO-5

style

IC's

should

be

shaped

into

two

rows

of

four

and

inserted

into

the

IC

socket

in

the

order

shown

in

figure

2.

11.

Carefully

inspect

your

work.

Make

certain

that

the

IC's

are

all

properly

oriented

and

that

every

pin

of

every

IC

is

properly

engaged

in

its

socket.

Carefully

inspect

your

soldering

for

cold

solder

joints

or

acci-

dental

solder

bridges.

an3031

aa

OI

vera

kampit

nnn

6,

Location

Dia

—

io

00000004

Figure

3

Parts

©

=

5

+

=

D+ZA

LO

CALIBRATION

PROCEDURE

Two

potentiometers

are

used

for

calibration

of

the

A/D

converter

(R12

and

R10)

and

two

potentiometers

are

used

for

calibration

of

the

D/A

converter

(R2

and

R5).

Calibration

of

the

A/D

converter

must

be

done

before

calibration

of

the

D/A

converter.

The

analog

I/O

channels

use

two's

complement

notation

for

ease

of

representing

both

positive

and

negative

voltages.

The

least

significant

bit

represents

a

20

millivolt

increment.

The

analog

voltage

range

on

both

input

and

output

is

from

-2.56

volts

to

+2.54

volts.

For

example,

the

following

8-bit

codes

are

used

to

represent

these

analog

voltages:

01111111

+2.54

volts

00000001

+0.02

volts

00000000

O

volts

11111111

-0.02

volts

10000000

-2.56

volts

To

calibrate

the

A/D

converter,

known

voltages

must

be

applied

to

any

one

of

the

seven

analog

input

channels

(e.g.,

analog

channel

7,

port

037,

on

contact

B

of

the

top

edge

connector).

You

should

enter

and

execute

on

your

computer

the

following

program

to

input

from

analog

port

037

and

output

to

digital

port

030:

Address

Data

Description

000 000

333

Input

DB

000

001

037

from

port

037

iF

000 002

323

Output

D3

000

003

030

to

port

030

13

000 004 303

Jump

ca

000 005

000

000

00

000 006

000

000

oc

Apply

a

-2.56

volt

signal

to

contact

B

of

the

top

edge

connector

and

adjust

R12

for

an

output

address

of

1000000

on

pins

14

to

21.

Now

apply

a

+2.54

volt

signal

to

contact

B

of

the

top

edge

connector

and

adjust

R10

for an

output

address

of

0111111

on

pins

14

to

21

of

the

digital

output

port.

Since

R10

and

R12

interact,

you

may

need

to

repeat

the

above

procedure

once

or

twice.

To

calibrate

the

D/A

converter,

a

voltmeter

must

be

used

to

measure

the

output

voltage

at

any

one

of

the

seven

analog

output

ports

(say

analog

port

037,

on

contact

“2”

on

the

top

edge

connector).

Now

enter

and

execute

the

following

program:

Description

Address

Data

000

000

076

000

001

177

000 002 323

000

003

037

000 004

303

000 005 000

000 006

000

Move

into

accumulator

177

Output

to

port

037

Jump

000

000

While

the

above

program

is

executing,

adjust

R5

for an

output

voltage

of

+2.54

volts

on

contact

2.

Now

modify

the

above

program

so

that

the

second

byte,

177,

is

replaced

by

“0007.

Execute

this

modified

pro-

gram

and

adjust

R2

so

that

the

output

voltage

on

pin

2

is

zero.

Calibration

is

now

complete.

©

©

OPERATING

INSTRUCTIONS

All

input

and

output

signals

are

connected

to

the

edge

connector

on

the

top

of

the

D+7A

I/O

Module.

The

connector

pin

assignments

are

shown

on

Table

3

below.

Table

3

Connector

Pin

Assignments

CONNECTOR

PIN

ASSIGNMENTS

COMPONENT

SIOE

PNNe

p]

PINNe

SOUDER

SIOE

JANALOGGROWN0

|

1

ANALOG

crouno

ANALOG

INPUT

7

8

2

ANALOG

OUTPUT

7

I

ELA

3 y

G

so

]

a

s

ae

s

4

E.

s

3

t

z

7

t

z

ANALOG

PUT

u

OSEA

12

Y

REGULATED:

CEE

|

9

+¡2V

REGULATED

INALOG

GROUND

To

ANALOG

GROUND

-ITV

UNREGULATED

4

11

HIT

Y

UNREGULATED

=

SV

REGULATED

~

12

+

SV

REGULATED

input

578

O

8

—ovreur

378

PARALLEL

INPUTBIT

7

A

14

PARALLEL

OUTPUT

BIT

7

T

e s

Es

Y

s

s"

||

e

5

Iv

D

3

|

zw

D

z

I

ix

20

1

i

PARALLEĆ

INPUT

BT

0

SEA

DIGITAL

GROUND

z

2E

DIGITAL

GROUND

hr

The

digital

ports

and

analog

ports

are

accessed

as

input

and

output

ports

of

the

computer

system.

In

the

standard

configuration,

the

port

assignments

in

Table

4

are

used.

Provision

has

been

made

on

the

D+7A

I/O

Module

for

changing

port

assignments.

This

may

become

necessary

if

particular

port

addresses

are

already

used

or

if

more

than

one

D+7A

I/O

Module

is

used

in

the

computer

at

one

time.

The

traces

just

above

1C32

set

the

five

high

order

bits

of

the

port

address.

In

the

standard

configuration,

PC

board

traces

connect

the

five

bits

as

shown

in

figure

4.

If

other

port

addresses

are

desired,

the

traces

must

be

cut

and

jumper

wires

used

to

select

the

desired

address.

Table

4

Figure

4

Port

Address

Selection

Port

Assignments

Octal

Hex

Parallel

address

address

Parallel

port

030

18

Analog

port

1

031

19

Analog

port

2

032

1A

Analog

port

3

033

18

Analog

port

4

034

1C

Analog

port

5

035

1D

Analog

port

6

036

1E

Analog

port

7

037

1F

Aa

AG

A

AM

A

hi

>»

>|

J

o

pa

HI

LO

THEORY

OF

OPERATION

Introduction

The

D+7A

interface

is

able

to

perform

four

functional

operations:

1)

analog

output,

2)

analog

in-

put,

3)

digital

output,

and

4)

digital

input.

A

simpli-

fied

block

diagram

is

shown

in

tigure

5.

A

detailed

schematic

diagram

is

shown

in

figure

10.

When

referring

to

the

schematic

diagram

note

that

numbers

in

square

boxes

refer

to

S-100

bus

contacts

on

the

bottom

edge

connector

of

the

D+7A

card.

Numbers

or

letters

in

circles

refer

to

contacts

on

the

top

I/O

connectors

of

the

D+7A

card.

Figure

5

D+7A

I/O

Block

Diagram

7

CHANNELS

ANALOG

IN

7

CHANNELS

ANALOG

OUT

+

8BITS

8

BITS

PARALLEL

PARALLEL

OUT

IN

TOP

EDGE

CONNECTOR

)

-7

SAMPLE

a

ee

AND

HOLD

La

es

AMPLIFIERS

|

|

8

DE-

/

TRI

STATE

——

=

emp]

MULTIPLEXER

e

==]

BUS

DRIVERS

ic

20

IC

16,

27,

36

DECODER

SELECTION

LOGIC

H

DIA

/

ic

12

8

a

TIMING

DIGITAL

&

STATUS

SWITCH

LOGIC

IC

26,35

-8

COMPARATOR

8

MICROCOMPUTER

BUS

S-100

)

ADDRESS

PRDY

CLOCK

&

STATUS

SIGNALS

Do

DI

DATA

OUTPUT

BUS

DATA

INPUT

BUS

D+7A

LO

pas

Output

Analog

output

begins

with

an

8-bit

data

output

word

appearing

on

the

S-100

DO

(data

output)

bus.

These

8-bits

of

data

are

routed

through

an

8-channel

digital

switch

(IC's

26,35)

to

the

input

of

an

8-bit

digital-to-analog

(D-to-A)

converter

(IC

12).

The

output

of

the

D-to-A

converter

is

switched

to

one

of

seven

sample-and-hold

output

amplifiers

by

a

demulti-

plexer

switch

(IC

20).

The

output

of

the

sample-and-

hold

amplifiers

(IC's

4,5,7,8,17,18,19)

are

brought

to

the

top

edge

connector

contacts

of

the

D+7A

card.

When

the

CPU

sends

PSYNC

and

SOUT

(at

the

start

of

an

analog

output

cycle)

in

coincidence

with

a

port

address

(in

the

range

31

to

37),

1C30

output

pin

6

goes

high

to

indicate

this

event.

Gating

logic

then

causes

PRDY

to

be

pulled

to

a

logic

O,

causing

the

CPU

to

enter

a

wait

state.

One

CLK

cycle

later,

IC31

output

pin

8

goes

low

thereby

instructing

the

successive

approximation

register

(SAR),

IC

15,

to

begin

oper-

ation

on

the

following

CLK

rising

edge.

The

SAR

then

begins

operation

and

holds

down

its

CC

output

for

an

additional

8

CLK

cycles.

During

analog

output,

the

SAR

is

used

only

as

a

timing

device

to

generate

a

sufficient

number

of

wait

states

to

cause

proper

circuit

0

operation.

Other

outputs

are

ignored.

The

logic

gating

holds

down

PRDY

until

the

SAR

has

completed

oper-

ation

and

released

its

CC

output,

causing

1C31

pin

5

to

go

low

on

the

next

02

positive

edge.

A

total

of

5.5

us

of

wait

states

are

produced

at

2MHz

and

a

total

of

5.0

us

of

wait

states

are

produced

at

4MHz.

As

a

result

of

SOUT

going

to

a

logic

1,

1C34

pin

12

goes

to

a

logic

®.

This

signal

switches

most

of

the

circuitry

between

input

and

output

modes.

In

particu-

lar,

pin

1

of

IC26

and

pin

1

of

IC35

go

low,

selecting

the

A

inputs,

and

Q1

produces

+5V

at

the

control

inputs

of

IC22,

turning

its

sections

ON.

With

1C26

and

1C35

switched

to

their

A

inputs,

the

Analog

Input

One

of

seven

analog

input

channels

is

selected

by

the

input

multiplex

switch,

IC

9.

The

signal

on

this

channel

is

connected

to

one

input

of

an

analog

comparator,

IC

11.

The

other

input

to

the

analog

comparator

is

derived

from

the

output

of

the

D-to-A

converter,

IC

12.

A

successive

approximation

shift

register

(SAR,

IC

15)

receives

the

output

of

the

analog

comparator

and

outputs

a

successively

larger

or

smaller

W

digital

word

to

the

D/A

converter

based

on

the

com-

parator

output.

When

conversion

is

complete

the

8-bit

output

of

the

SAR

is

put

on

the

data

input

(DI)

bus

eight

data

bits

flow

from

the

DO

bus

to

the

inputs

of

the

D/A

converter

1C12.

This

causes

a

current

to

be

pulled

by

the

Ig

output,

pin

4,

towards

the

-12V

supply,

with

the

magnitude

proportional

to

the

binary

number

at

inputs

A1-A8.

Resistors

R10

and

R11

pro-

vide

the

full

scale

reference

current

for

the

D/A

con-

verter.

Resistors

R12

and

R14

produce

a

half

scale

offset

so

that

the

code

address

10000000

at

the

D/A

converter

input

produces

a

O

volt

output.

Inverter

1C34

complements

DO7

so

that

a

O

volt

output

occurs

for

the

code

00000000

on

the

DO

bus,

thereby

giving

two's

complement

operation.

This

allows

bipolar

operation

of

the

D/A

converter

with

binary

numbers

generated

by

the

CPU.

Since

the

CMOS

transmission

gate

1C22

is

ON,

a

resistance

of

about

30

ohms

connects

the

D/A

converter

output

to

pin

2

of

IC10.

This

produces

whatever

voltage

is

needed

at

its

output

pin

6

(in

the

range

£2.56)

so

that

current

through

R5

and

R7

exactly

balances

the

D/A

converter

output

current.

The

output

voltage

at

IC10

output

pin

6

then goes

to

the

output

of

multiplexer

IC20

pin

3.

The

output

port

address

bits

AQ-A2

direct

the

multiplexer

IC20

to

connect

1C10

pin

6

to

one

of

the

0.0022

voltage

hold

capacitors

of

the

CMOS

transmission

gate.

Current

then

flows

to

charge

the

selected

holding

capacitor

to

the

desired

output

voltage.

Charging

is

enabled

only

during

the

wait

states

of

an

analog

input

function.

Voltage

follower

amplifiers

with

MOS

inputs

copy

the

holding

capacitor

voltages

to

the

analog

output

pins,

thereby

preventing

drift

due

to

loading.

Residual

voltage

drift

primarily

results

from

CMOS

multiplexer

leakage

cur-

rents.

Because

of

the

drift,

the

analog

outputs

in

use

must

be

refreshed

at

a

1Hz

or

faster

rate

by

OUTPUT

instructions.

through

bus

drivers

IC

27

and

IC

36.

At

the

start

of

an

analog

input

cycle,

the

CPU

sends

PSYNC

and

SINP

in

coincidence

with

an

analog

port

address.

IC30

detects

this

event

and

initiates

a

cycle

ina

manner

similar

to

the

analog

output

sequence.

In

this

case,

however,

the

SAR

output

is

connected

by

multiplexers

1C26

and

1C35

to

the

D/A

converter's

data

inputs.

The

input

port

command

for

channels

1

to

7

is

taken

from

AQ

through

A2

by

the

analog

multiplexer

1C9

and

used

to

connect

an

analog

input

to

the

voltage

follower

1C21.

In

this

case,

1C22

is

an

open

circuit.

Voltage

follower

1C21

has

a

very

low

input

current

requirement

in

combination

with

a

fast

slewing

capabil-

ity.

This

prevents

loading

of

the

signal

sources

and

allows

full

accuracy

for

source

impedances

of

up

to

10K

ohms.

Output

from

the

voltage

follower

goes

through

R20

to

inject

current

into

the

summing

node

at

1C12

pin

4

and

IC11

pin

2.

After

the

time

delay

generated

by

1C31,

to

allow

for

settling

of

the

input

circuit,

the

SAR

begins

the

conversion

process.

When

the

conversion

cycle

starts,

the

SAR,

1C15,

first

sets

the

Q7

output

bit

to

a

logic

Ø

and

the

OB

through

O6

output

bits

to

a

logic

1.

This

causes

the

D/A

to

sink

a

current

equal

to

127/256

of

the

full

scale

value

of

approximately

2mA.

At

the

end

of

the

first

clock

period,

the

SAR

checks

the

output

of

the

comparator

IC11.

If

the

analog

input

voltage

is

neg-

Digital

Output

When

the

digital

output

from

the

CPU

to

port

@

occurs,

data

flows

from

the

DO

bus

through

1C26

and

1C35,

bus

buffers,

to

the

port

latches

IC1

and

1C2.

Decoder

1C13

then

uses

PWR

to

generate

an

output

strobe

and

latch

the

data

into

1C1

and

1C2.

Digital

Input

When

digital

input

from

port

Ø

to

the

CPU

occurs,

1C13

generates

an

input

strobe

to

the

tristate

bus

drivers

1C16, 1C27,

and

1C36.

The

digital

input

data

is

then

passed

directly

to

the

DI

bus.

ative,

the

SAR

leaves

bit

Q7

clear.

Otherwise,

it

is

set.)

JĄ

At

the

same

time,

the

SAR

also

sets

bit

Q6

to

a

logic

Ø.

`

It

then

waits

one

clock

cycle

before

using

the

com-

parator

output

to

set

the

state

of

bit

Q6

and

clears

bit

05.

In

a

similar

manner,

the

successive

approximation

procedure

continues

until

all

bits

00-07

have

been

set

and

subsequently

tested.

This

procedure

corresponds

to

the

use

of

a

set

of

balance

scales

using

binary

weight

values

to

weigh

an

object

and

is

the

fastest

procedure

operating

on

only

one

bit

at

a

time.

At

the

end

of

the

conversion

cycle,

the

SAR

outputs

contain

the

desired

data

word.

The

CC

output

goes

to

a

logic

®,

signalling

the

end

of

the

conversion

process

and

allowing

the

CPU

to

proceed.

The

CPU

then

inputs

bits

Q@-Q6

and

Q7

as

its

data.

Q7

is

complemented

to

produce

a

two's

complement

binary

code

and

allow

straightforward

bipolar

operation.

The

digital

output

data

is

available

on

contacts

14

through

21 of

the

top

edge

connector.

The

output

strobe

signal

is

available

on

contact

13

of

this

connector.

Digital

input

data

is

applied

to

the

D+7A

1/0

Module

on

contacts

R

through

Y

of

the

top

edge

con-

nector.

An

input

strobe

signal

is

available

on

contact

P

of

this

connector.

D+7A

LO

»

TECHNICAL

SPECIFICATIONS

Computer

Known

computibility

with

ALTAIR,

IMSAI,

and

CROMEMCO

machines

using

8080

and

Z80

CPU's

at

Digital

Port

Standard

TTL

signal

levels

Input

8

bits

—

one

TTL

equivalent

load

Output

8

bits

—

can

drive

up

to

10

TTL

loads

Logic

levels

>+2.0V

—

logic

1

<+0.8V

—

logic

@

Analog

Port

(after

calibration;

typical

values)

Signal

levels

for

standard

configuration:

+2.54V

—

01111111

-

.02V

—

11111111

+

.02V

—

00000001

-2.54V

—

10000001

0.0V

—

00000000

-2.56V

—

10000000

Two's

complement

code

Data

Input.

Absolute

Maximum

allowed

+5,0V

Input

impedance

Zin

=

20MQ

II

.001pf,

1KHZ

sample

rate

Zin

=

2MQ

II

.0O1uf,

10

KHZ

sample

rate;

Recommended

source

impedance

Rs

<10KA

Source

Impedance

Effects

The

analog

inputs

have

a

DC

input

impedance

and

bias

current

that

are

a

function

of

the

sampling

rate

for

the

port

under

consideration.

At

a

10KHZ

sampling

rate,

Rın=2MN

and

Ig=-.24A.

These

values

vary

inversely

with

the

sampling

rate.

To

prevent

loss

of

gain

accuracy

and

zero

offset,

a

maximum

source

impedance

of

10KQ

is

recommended

for

most

appli-

cations.

If

the

signal

port

will

be

digitized

at

the

max-

imum

rate

of

100KHZ

or

so,

the

signal

source

should

have

Rs

<

1009.

This

requirement

also

stems,

in

part,

from

frequency

response

limitations

imposed

by

the

Input

Accuracy

Since

the

analog

input

has

a

very

high

input

impedance,

and

is

commutated

among

the

input

ports

with

a

low

impedance

multiplexer,

all

input

channels

track

very

closely

when

attached

to

a

common

voltage

2

or

4

MHZ.

Strobes

—

output

is

normally

a

logic

1

state

Trailing

edge

of

a

pulse

to

logic

Q

state

indicates

occurrence

of

data

transfer.

Separate

input

and

output

strobes.

Output

8

data

bits

are

latched.

Input

bias

current

|

Ig

|

<

2

HA

and

flows

into

inputs

Accuracy

+

1

LSB

No

missing

codes

Data

Output.

Maximum

load

current

|

|||

<1.5mA

RLmin

2

2KQ

Output

impedance

Zout

<.250,

F

Ś10KHZ

Accuracy

+

1

LSB

when

refreshed

Drift

rate

|

gy.

|

<

10mV/sec

at

25°C

1KQ

resistor

and

0.001uf

capacitor

on

each

analog

input.

These

components

give

some

protection

to

the

multiplexer

in

general

purpose

applications

and

may

be

omitted

if

the

user

is

especially

careful

about

static

voltage,

discharges,

and

overvoltage

inputs.

Usually

only

the

capacitor

must

be

removed.

This

is

recom-

mended

for

best

accuracy

on

high

frequency

inputs.

If

sampling

rates

of

100HZ

or

less

are

used,

the

analog

inputs

may

be

treated

as

an

essentially

infinite

input

impedance

and

used

accordingly.

source.

They

normally

differ

by

an

unmeasurable

quantity.

The

only

factor

disturbing

tracking

is

the

source

impedance

effect

as

described

above.

DA

LO

Output

Accuracy

As

with

inputs,

the

analog

outputs

use

a

common

set

of

hardware

down

to

the

point

where

the

demulti-

plex,

sample

and

hold,

and

voltage

follower

activity

occurs.

Accordingly,

the

primary

causes

of

inaccuracy

are

pedestal

error

in

charging

the

output

capacitor

and

offset

in

the

voltage

follower.

The

pedestal

error

has

a

dynamic

dependence

on

the

magnitude

of

voltage

change

for

the

output

in

question.

Under

worst

case

conditions,

the

pedestal

error

may

be

as

much

as

+3

LSB's

(60mv)

for

a

full

scale

voltage

change

of

5.12V

For

smaller

step

changes

the

pedestal

error

diminishes

rapidly

in

size,

since

it

is

a

2nd

order

phenomenon.

Pedestal

error

can

be

practically

elim-

inated

by

doing

two

outputs

of

the

same

value

in

succession

when

large

changes

occur.

Output

Drift

Since

the

analog

outputs

use

a

sample

and

hold

to

retain

the

output

voltage

after

each

output

action,

periodic

refreshing

of

the

capacitor

voltage

is

necessary.

The

typical

drift

rate

is

<

10mv/sec

at

25°C,

requiring

refresh

at

a

rate

of

1HZ

or

faster.

In

continuous

control

situations

this

usually

doesn’t

cause

a

problem

since

the

feedback

iteration

rate

is

faster.

Incidentally,

10mv/sec

drift

corresponds

to

a

total

leakage

of

20

x

10-12

amperes

from

the

capacitor.

Therefore,

cleanliness

of

the

printed

circuit

board

is

essential

for

good

operation.

The

drift

rate

exhibits

a

strong

Bipolar/

Unipolar

Operation

The

D+7A

I/O

Module

is

normally

used

for

analog

voltages

in

the

range

of

-2.56

to

+2.54

volts.

Since

both

positive

and

negative voltages

are

included

in

this

range

this

is

referred

to

as

“bipolar

operation.”

Bipolar

operation

is

selected

by

a

trace

on

the

printed

circuit

board

connecting

the

“polarity”

pad

to

the

"bipolar"

pad.

Also,

during

steady

state

operation

there

is

a

static

error

caused

by

the

demultiplexer

switching

transients.

This

causes

a

nonlinearity

evidenced

by

the

full

scale

positive

output

being

slightly

high

(~20mv)

when

the

zero

and

full

scale

negative

outputs

are

correct.

This

error

term

is

a

function

of

the

internal

demultiplexer

construction.

Offset

voltage

in

the

voltage

follower

for

each

analog

output

adds

directly

to

the

output

for

that

channel.

Typically,

this

is

less

than

8

mv

(<

1/2

LSB)

for

the

CA3140

devices,

so

no

offset

adjustment

is

provided

on

a

per

channel

basis.

In

applications

requir-

ing

careful

channel

matching,

the

CA3140's

may

have

to

be

rearranged

or

selected

to

give

the

desired

per-

formance.

Alternately,

offset

adjustment

pots

can

be

added

according

to

the

manufacturer's

data

sheet.

dependence

on

temperature,

high

temperatures.

If

problems

with

excessive

drive

occur,

first

try

interchanging

the

associated

CA

3140

with

one

from

a

good

port

location.

If

the

drift

is

not

reduced,

then

exchange

the

input

and

output

CD4051

multiplexer

IC's.

The

input

multiplexer

location

is

much

more

tolerant

of

leakage

currents.

Persistent

problems

with

drift

indicate

either

a

defective

holding

capacitor

or

contamination

on

the

capacitor

or

associated

printed

circuit

board

area.

increasing

rapidly

at

If

you

desire

unipolar

operation

(O

to

2.54v

or

O

to

-2.56)

this

is

also

possible.

Simply

sever

the

trace

connecting

“polarity”

to

“bipolar”

and

in

its

place

install

a

jumper

from

“polarity”

to

“unipolar.”

See

Table

5

for

proper

resistor

values

with

this

mode

of

operation.

Table

5

Input

Scaling

Component

Values

MODE

R22

R5

R7

8

R20

R12 R14

|

R23

VOLTAGE

BIPOLAR

OMIT

500

27K

500

5.1K

1.2K

-2.56

to

2.54

Y

UN

47K

200

13K

20K

39K

|

2.7K

Oto

2.54

4

-UNIPOLAR

|

OMIT

|

200

13K

200

|

24K

|

OMIT

-2.56

to

0

D+ZA

LO

©

APPLICATIONS

INFORMATION

Setting

the

Analog

Voltage

Range

In

its

standard

configuration

the

D+7A

I/O

Module

is

designed

to

be

used

with

analog

voltage

levels

from

-2.56

volts

to

+2.54

volts.

Minor

modification

can

be

made

to

accommodate

other

voltage

ranges.

Bipolar

(both

positive

and

negative

voltages)

or

unipolar

(voltages

of

just

one

polarity)

operation

can

be

selected

by

a

jumper

wire.

Normally

bipolar

operation

is

selected

Input

Scaling

The

nominal

input

voltage

range

is

-2.56V

to

+2.54V.

This

can

be

altered

for

unipolar

operation

or

larger

bipolar voltage

ranges.

The

component

values

of

Table

5

tell

what

resistor

values

to

alter

for

unipolar

operation.

Note

that

the

input

voltage

range

must

lie

between

+2.56V

to

prevent

saturation

problems

in

the

multiplexers

and

buffer

amplifiers.

However,

resistor

dividers

may

be

added

at

the

appropriate

points

to

permit

input

ranges

to

+100V

and

output

Dr»

to

£10V.

The

only

restriction

is

that

all

inputs

and

outputs

must

be

of

the

same

type,

i.e.,

unipolar

or

bipolar,

as

this

is

determined

by

the

bipolar/unipolar

jumper

wire

selection.

When

the

nominal

maximum

converter

input

is

2.56

volts,

the

input

bypass

capacitor

may

be

replaced

by

a

resistor

RN3.

The

resistors

RN1

and

RN3

then

form

a

voltage

divider

to

reduce

the

maximum

input

Vm

to

2.56

volts

according

to

the

equation

in

figure

6.

The

PCB

layout

allows

substitution

of

a

resistor

DIP

network

for

the

capacitors

if

all

inputs

are

to

be

sim-

by

the

printed

circuit

board

trace

connecting

“polarity”

to

“bipolar.

*

Unipolar

operation

is

selected

by

cutting

this

trace

and

installing

a

jumper

wire

between

“polarity

'

and

“unipolar”

on

the

printed

circuit

board.

In

either

unipolar

or

bipolar

operation

the

analog

inputs

and

outputs

may

be

scaled

to

select

the

desired

voltage

range.

ilarly

scaled.

When

all

inputs

are

scaled

to

the

same

sensitivity,

the

A/D

gain

and

offset

adjustments

may

be

used

to

alter

the

basic

ADC

range.

This

permits

use

of

standard

resistor

values

for

RN1

and

RN3.

In

order

to

preserve

the

ADC

accuracy

in

critical

gain

matched

applications,

the

input

divider

RN1

and

RN3

must

be

metal

film

devices

with

a

+0.1%

toler-

ance.

Most

engineering

applications

will

allow

use

of

1%

resistors.

Type

RN55C

metal

film

resistors

are

preferred.

This

gives

an

absolute

channel

input

accuracy

of

+2%

worst

case.

Hobby

and

error

feedback

applica-

tions

may

permit

use

of

5%

tolerance

resistors.

It

is

recommended

that

the

parallel

combination

of

RN1

and

RN3

be

kept

below

10K

ohms.

This

may

be

easily

done

by

always

using

RN3=10K

ohms.

Then

for

Vm=10

volts,

use

RN1=28.7K

ohms

as

the

nearest

common

1%

value.

When

using

this

divider,

be

careful

that

its

equivalent

40K

ohm

input

impedance

does

not

seriously

load

the

signal

source.

Figure

6

Input

Scaling

RN1

ANALOG

IN

TO

MPX

RN3

TO

CD4051

IN

INPUT

MPK

D+ZA

LO

Output

Scaling

The

sample

and

hold

output

amplifiers

are

presently

configured

as

unity

gain

voltage

followers

for

£2.56

V

maximum

output.

If

greater

output

is

desired,

such

as

+10V,

two

changes

must

be

made.

First

the

amplifiers

are

connected

to

the

+18

and

-

18

voltage

busses

for

power

to

allow

larger

output

swings.

Second,

a

feed-

back

voltage

divider

as

shown

in

figure

7

permits

gain

in

the

voltage

follower.

Changing

the

amplifiers

to

+18V

power

requires

cutting

the

power

traces

on

the

PCB

and

installing

appropriate

jumpers.

Pads

are

provided

for

installa-

tion

of

resistors

RA

and

RB.

A

trace

on

the

PCB

solder

side

must

be

cut

to

permit

RA

to

function.

The

equations

for

RA

and

RB

are

identical

to

the

input

divider

equations,

and

similar

resistor

values

are

required.

Again,

10K

ohms

is

a

good

nominal

value

for

RB,

making

RA=28.7

ohms

for

Vm=+10V

max-

imum

output.

CA3140

k

a

Analog

Output

RA

Add

RB

RA

Vm-2.56

RB

256

Using

the

D:7A

With

Cromemco

Dazzler

If

the

Cromemco

Dazzler

is

being

used

to

display

a

picture

when

the

D+7A

I/O

Module

is

used

to

input

or

output

analog

data,

a

small

modification

must

be

made

to

REV

B

and

REV

B-1

series

of

the

Dazzler

to

avoid

flashes

in

the

picture.

The

modification

is

simply

to

remove

pin

10

of

Dazzler

IC

29

(a

7400

IC).

No

modification

is

required

to

REV

C

Dazzlers.

Using

the

D+7A

With

Joystick

Console

Cromemco

is

pleased

to

announce

a

new

joystick

console

(model

JS-1)

designed

specifically

to

interface

to

your

computer

using

the

D+7A

I/O

Module.

In

fact

two

such

consoles

can

be

completely

interfaced

using

just

one

D+7A

I/O

Module.

Each

console

consists

of

a

two-axis

joystick,

four

push-button

control

switches,

and

a

speaker

with

amplifier.

The

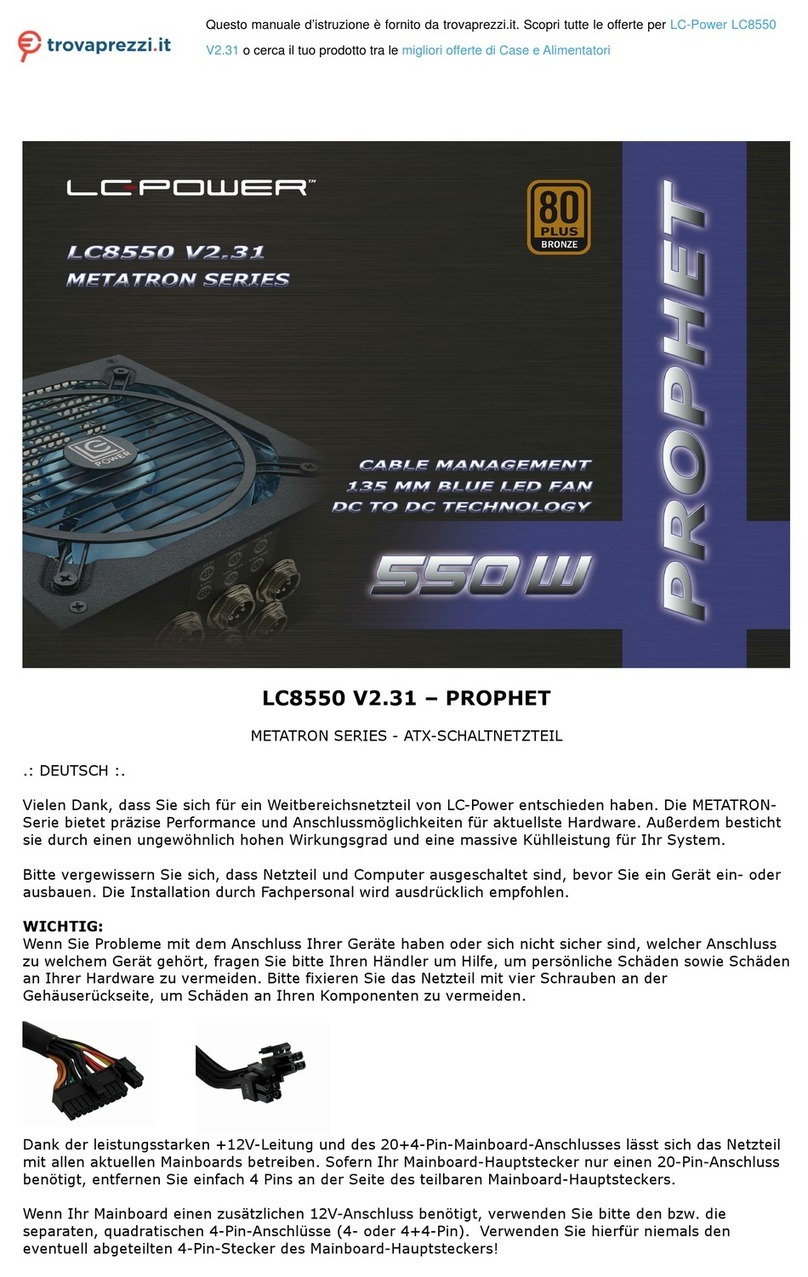

schematic

diagram

of

the

joystick

console

is

shown

in

figure

8.

A

wiring

connection

diagram,

figure

9,

shows

exactly

how

two

joystick

consoles

can

be

connected

to

the

top

edge

connector

of

the

D+7A

1/0

Module.

D+ZA

LO

GREEN

BLUE

Y-AXIS

1N4742

Ą

GRAY

(-18V)

b

220

-12v

1N4740

Y

VIOLET

(+18)

RN

220

sw1

BROWN

q

10K

sw

2

©

L

12

CONDUCTOR

sen

o

A

CABLE

D

10k

|

SW3

Y

5

ORANGE

L

10K

swa

YELLOW

-L

10K

BLACK

(GND)

WHITE

(+5)

10K

PINK

-

4

AN

10uF

1452

|

ISPEAKER

|

TAN

(-5V)

Not

Used

13

D+ZA

LO

Figure

9

Joystick

Wiring

Diagram

Pink

#2

Pink

#1

Black

#1

Violet

#1

and

#2

White

#1

and

#2

Blue

#2

Green

#2

Blue

#1

Green

#1

Black

#2

Grey

#1

and

#2

Yellow

#2

Orange

#2

Red

#2

Brown

#2

Yellow

#1

Orange

#1

Red

#1

Brown

#1

e

Tan

#1

and

#2

Either

one

or

two

JS-1

consoles

may

be

interfaced

to

a

computer

using

the

Cromemco

D+7A

interface.

The

diagram

above

shows

how

to

connect

two

joystick

consoles

(#1

and

#2)

to

the

top

edge

connector

of

the

D+7A

interface

card.

The

colors

correspond

to

the

color

of

the

wires

in

the

12-conductor

cable

from

each

joystick.

D+ZA

LO

ores

—

—

1)

Voltage

Regulators

and

Hardware

IC

3

—

LM340T-5.0

(7805)

IC

6

—

78L05

1C28

—

LM320T-5.0

(7905)

2

—

6-32

x

3/8

screws

2

—

6-32

nuts

2

—

#6

lock

washers

2

—

Heatsinks

IC

Sockets

12

—

14

pin

16

—

16

pin

2-8pin

Integrated

Circuits

IC1

—

74175

IC2

—

74175

IC4

—

3130

or

3140

IC5

—

3130

or

3140

IC7

—

3130

or

3140

IC8

—

3130

or

3140

IC9

—

4051

IC

10

—

LM301

IC 11

—

72710

or

72810

IC

12

—

MC1408L8

IC

13

—

7442

IC

14

—

74LS02

IC

15

—

AM2502PC

IC

16

—

74367

IC 17

—

3130

or

3140

IC

18

—

3130

or

3140

IC

19

—

3130

or

3140

IC

20

—

4051

IC

21

—

310

IC

22

—

4066

IC

23

—

74LS30

IC

24

—

74LS08

IC

25

—

74LS10

IC

26

—

74LS157

1C

27

—

74367

IC

29

—

74LS04

1C

30

—

7474

IC 31

—

7474

IC

32

—74LS04

IC

33

—

741532

IC

34

—

74LS04

IC

35

—

74LS157

IC

36

—

74367

Resistors

and

Discrete

Semiconductors

R1

—470

R2

—

25k

pot

R3

—560

R4

—560

R5

—500

pot

R6

—

100K

R7

-2.7k

R8

—2.2k

R9

—2.7k

R

10

—

500

pot

R

11

—

2.4k

R

12

—

500

pot

R

13

—

2.4k

R

14

—

5.1k

R15-10

R

16

—

10

R

17

—

18k

R

18

—

1k

R

19

—4.7k

R

20

—

2.7k

R

21

—

220

R

22

—

omit

for

bipolar

operation

R

23

—

1.2k

R

24

—

2.7k

R

25

—

4.7k

R

26

—

1k

R

27

—

560

R

28

—

220

R

29

—

220

R

30

—

560

R

31

—

560

R

32

—

560

R

33

—

560

R

34

—

560

R

35

—

1.5k

RN1

—

14

pindip

7

resistors

1k

RN

2

—

8

pin

sip,

7

resistors,

4.7k

D

1

—

1N914

D

2-

1N914

D3

—

1N914

D

4

—

1N914

D

5

—

1N4742

D

6

—

1N4742

Q

1

—

2N3906

Capacitors

C1

-0.1

C2

—

10

uF

tantalum

C3

—

150

C4

—

150

c5

—.05

c6

—.001

C7

—.001

c8

—.001

c9

—.001

C

10

—

.001

C

11

—

.001

C

12

—

.001

C

13

—

.01

C

14

—

.05

C

15

—

0.1

C

16

—

0.1

C

17

—

.05

C

18

—

.05

6)

7)

8)

C

19

—

.01

C20—0.1

C21—0.1

c22—

0.1

C

23

—

150

C

24

—

150

C

25

—

.05

C

26

—

150

C

27

—

150

C

28

—

.05

C

29

—

150

C30—0.1

C

31

—.0022

C

32

—

.0022

C

33

—

.0022

C

34

—

.0022

C

35

—

.01

C

36

—

.05

C

37

—

150

C

38

—

18

C

39

-

0.1

C40—

0.1

C41-0.1

C42

—

150

C43—0.1

C

44

—

680

C

45

—

150

C

46

—

47

C47-0.1

C

48

—

10

uF

tantalum

C

49

—

10

uF

tantalum

C50

—

.05

C

51

—

.0022

C

52

—

.0022

C

53

—

.0022

C

54

—

0.1

C

55

—

0.1

C

56

—

0.1

C57

—

47

C

58

—

0.1

C

59

—

150

C

60

—

150

C61-—0.1

C

62

—

47

c

63

—

0.1

C

64

—

10uF

tantalum

C

65

—

10

Pf

Inductors

L1

—

22uH

L2—

22uH

Connector

Assembly

Dual

22

contact

connector,

hood,

assembly

hardware.

Miscellaneous

Printed

circuit

board.

Instruction

manual.

15

BAID

Notes

e

Figure

10

DA

I/O

f

SCHEMATIC

DIAGRAM

Table of contents

Other Cromemco Computer Hardware manuals

Cromemco

Cromemco Dazzler User manual

Cromemco

Cromemco BIART User manual

Cromemco

Cromemco 299B User manual

Cromemco

Cromemco BYTESAVER User manual

Cromemco

Cromemco 64KZ User manual

Cromemco

Cromemco Z80 User manual

Cromemco

Cromemco 32K Bytesaver User manual

Cromemco

Cromemco Multi-User BASIC User manual

Cromemco

Cromemco ZPU User manual