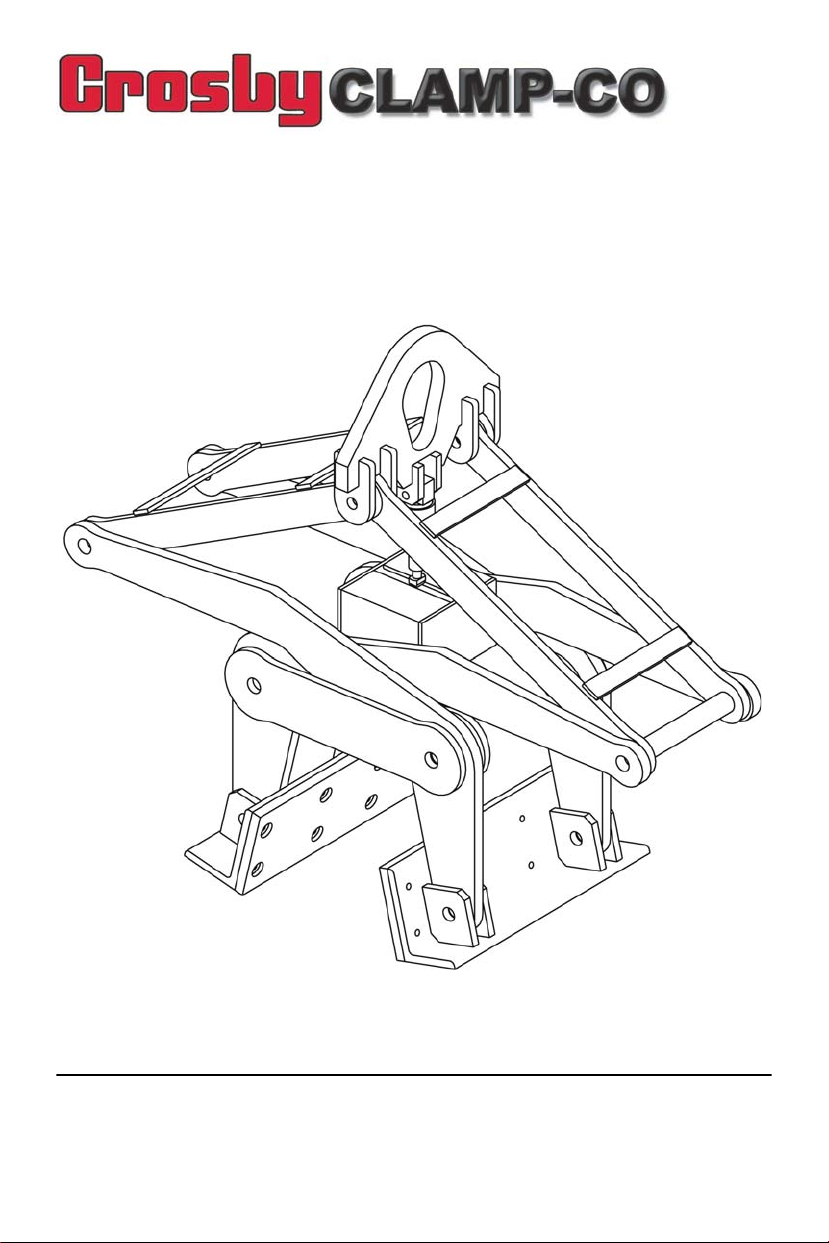

Crosby Clamp-Co BG-9000 User manual

IMPORTANT

Make certain all persons that may use, inspect, or maintain this equipment carefully read

and understand this manual. Retain this manual in a permanent file.

BARRIER GRAB CLAMP

USERS MANUAL

Model Numbers:

BG-9000

Barrier_Grab_Clamp_manual.fm Page 1 Thursday, May 28, 2009 3:10 PM

2 Copyright® 2009 The Crosby Group, Inc.

All Rights Reserved

INTRODUCTION

Crosby CLAMP-CO barrier grab (clamps) are below the hook lifting devices designed to

provide an efficient method for handling concrete road barriers. Always follow the stated

limitations discussed in this manual and shown on the products Warning and Operating

Procedure Labels.

Crosby Clamp-Co barrier grabs have been safely and successfully used in the field for

years. Your safe use of our products depends on you. Please be responsible and make

sure all people using our products follow these simple rules.

1. Barrier Grab (clamp) are used to the purpose for which they were designed.

2. They are not loaded beyond their Working Load Limit.

3. They are properly lubricated and maintained.

4. They are inspected regularly and tested in accordance with the relevant statutory

regulations.

5. They are used by competent persons trained in their use.

6. Barrier Grabs are returned to the factory every two years for inspection

retesting and recertification.

As with all mechanical handling equipment, there is a degree of hazard involved with the

use of these beam clamps if not properly used. Failure to follow the appropriate safety

precautions and operating instructions may cause the load to slip or fall, and may result in

serious injury, death, or property damage.

GENERAL INFORMATION

Each Crosby Clamp-Co barrier grab is proof tested and certified prior to shipping. Barrier

garb clamps are proof tested to 200% of Working Load Limit, unless specified otherwise

(See pages 6 & 7).

Follow all requirements of laws, rules, and regulations applicable in your country pertaining

to lifting operations, ensuring all maintenance, testing, inspection and operator training

requirements are strictly adhered to.

All Sizes are RFID EQUIPPED.

Barrier_Grab_Clamp_manual.fm Page 2 Thursday, May 28, 2009 3:10 PM

Copyright© 2009 The Crosby Group 3

All Rights Reserved

PRODUCT WARNING

WARNING

• Loads may disengage from clamp if proper procedures are not followed.

• A falling load may cause serious injury or death.

• The clamp shall not be loaded in excess of its rated load or handle any load for

which it is not designed.

• Never operate a damaged or malfunctioning clamp, or a clamp with missing

parts.

• Clamp not to be used for personnel hoisting.

• Do not carry a load over people.

• Do not leave suspended loads unattended.

• Operator and other personnel shall stay clear of the load.

• Never put your fingers, hand, arm, or a board, pipe or any object into the

mechanics of the barrier grab in an attempt to manually index the barrier grab.

• Do not lift loads higher than necessary.

• Do not make alterations or modifications to clamp.

• Do not remove or obscure warning or operating procedure labels.

• See ANSI/ASME B-30.20 BELOW-THE-HOOK LIFTING DEVICES for additional

information.

• LIFTING HEIGHT LIMITATION - This clamp is intended to be used to lift the

lowest part of the clamp to a height less than 6 feet or (1.8 m). NEN-EN 13155

requires a secondary positive holding device (e.g., sling, net, cage) for lifts

exceeding 6 feet or (1.8 m).

• Read, understand, and follow these instructions and the product safety

information.

Barrier_Grab_Clamp_manual.fm Page 3 Thursday, May 28, 2009 3:10 PM

4 Copyright® 2009 The Crosby Group, Inc.

All Rights Reserved

OPERATING PROCEDURES

• Perform regular DAILY inspections as recommended.

• Reference page 7 of this manual for Grip Width and Working Load Limitations.

• Barrier must be on level ground in it’s upright position. Do not use barrier grab to

rotate barrier from a horizontal position to vertical.

• Barrier grab must be free to move, not frozen to the ground or encumbered by other

barriers or debris.

• Make sure clamp is centered on concrete barrier and tongs are totally engaged.

• To ensure a proper grip on the barrier there must not be dirt, moisture, ice, grease,

scale, paint or other substance that will impede the grip of the barrier grip pads onto

the barrier. If sliding of the pads on the barrier occur, stop lift immediately.

• The grip on the barrier is totally dependant upon continuous and constant tension on

the lifting sling or hoist line. Do not allow tension to be relaxed during the lift by

inadvertently touching the ground, an object, or bouncing the barrier while it is being

lifted or carried over rough terrain.

• Use single (one) barrier grab in vertical lifting only, do not use in side loading

applications. Do not use barrier grab to drag or pull the barriers.

• The Crosby Clamp-Co barrier grab is not designed to be used in tandem with another

grab through use of a double leg sling, spreader beam, or other equipment.

• Temperature and environment: The temperature at which the standard lifting clamps

may be used lies between 160° F (71° C) and -40° F (-40° C). For other temperatures

and for use in hazardous environmental conditions, consult The Crosby Group, Inc.

technicians.

Barrier_Grab_Clamp_manual.fm Page 4 Thursday, May 28, 2009 3:10 PM

Copyright© 2009 The Crosby Group 5

All Rights Reserved

USING THE BARRIER GRAB CLAMP

The barrier grab is designed to automatically index to an open position or a gripping

position as required by following a simple procedure. Occasionally the barrier grab may tip

to one side or not index properly. In this event do not manually index the barrier grab, but

instead lower the barrier grab back onto the barrier and repeat the process following the

proper procedure. Never put your fingers, hand, arm, or a board, pipe or any object into the

mechanics of the barrier grab in an attempt to manually index. If barrier grab does not

index properly after repeating the process, remove from service and reference the

inspection and maintenance section of this manual. Do not attempt to repair a damaged

clamp by welding or with unauthorized replacement parts. We recommend returning the

clamp to the manufacture.

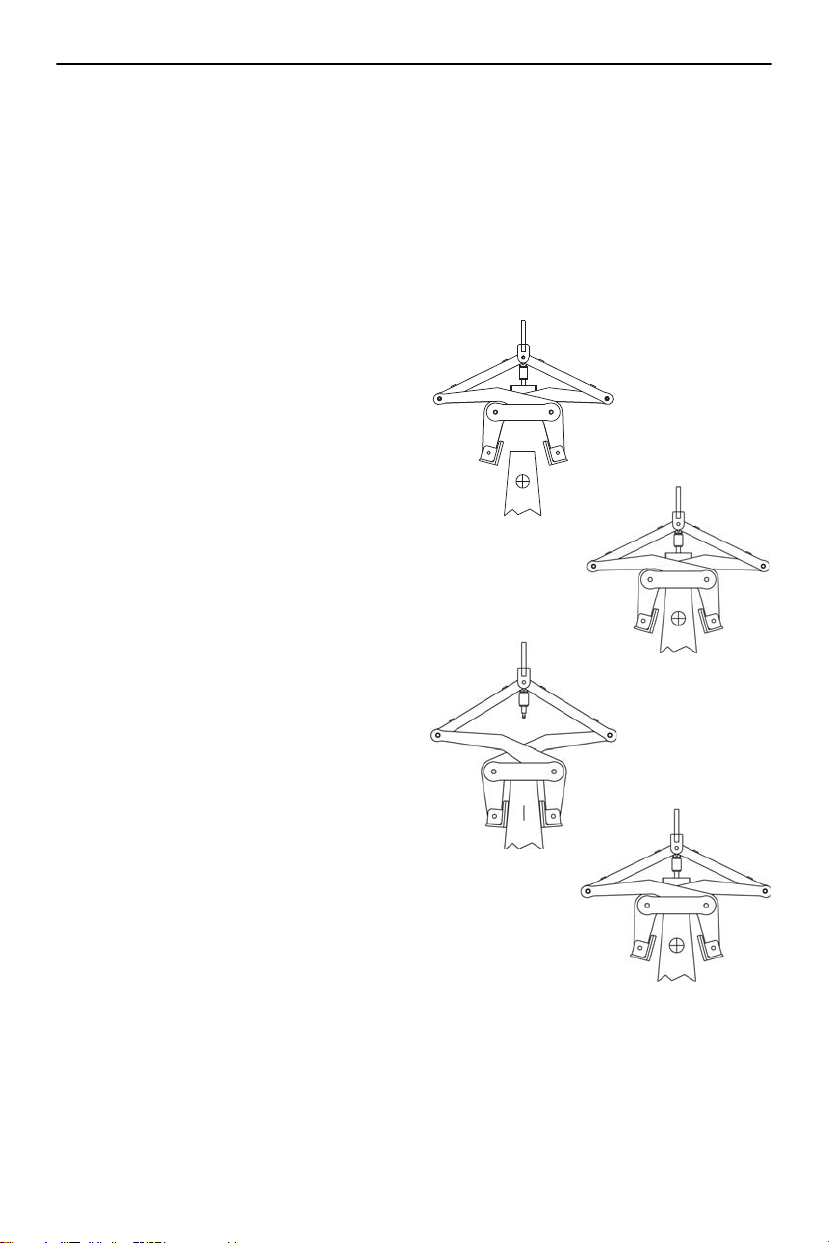

With the grab indexed to the open position,

slowly lower the grab onto the barrier and

center the grab in-line with the barrier’s

center of gravity. (See Figure 1).

Slowly release tension on the lifting cable

until the grab is completely relaxed on top

of the barrier (See Figure 2).

Slowly pick up on the lifting cable. The grab

will automatically index to the gripping

position. Grip pads will compress against

the sides of the barrier. Continue to lift barrier,

keeping lifting cable in tension (See Figure 3).

In the event the grab does not automatically

index to the gripping position, repeat above

process. Never put your fingers, hand, arm,

or a board, pipe or any object into the

mechanics of the barrier grab in an attempt

to manually index .

After placement of barrier, continue to release

tension on the lifting cable until it is fully

relaxed. This will allow the grab to index to

the open position (See Figure 4).

The barrier grab can now be lifted

away from barrier.

Figure 1

Figure 2

Figure 3

Figure 4

Barrier_Grab_Clamp_manual.fm Page 5 Thursday, May 28, 2009 3:10 PM

6 Copyright® 2009 The Crosby Group, Inc.

All Rights Reserved

INSPECTION AND MAINTENANCE

A visual inspection for cracks, wear, gouges and deformation as part of a comprehensive

documented inspection program should be conducted by trained personnel in compliance

with the schedule in ANSI B30.20. Proper maintenance of the barrier clamp includes a

daily inspection and weekly lubrication. There are labels attached to the clamp frame

which provides required maintenance, inspection and lubrication recommendations.

Product labels should be replaced when they are no longer legible. You should contact The

Crosby Group for replacement labels.

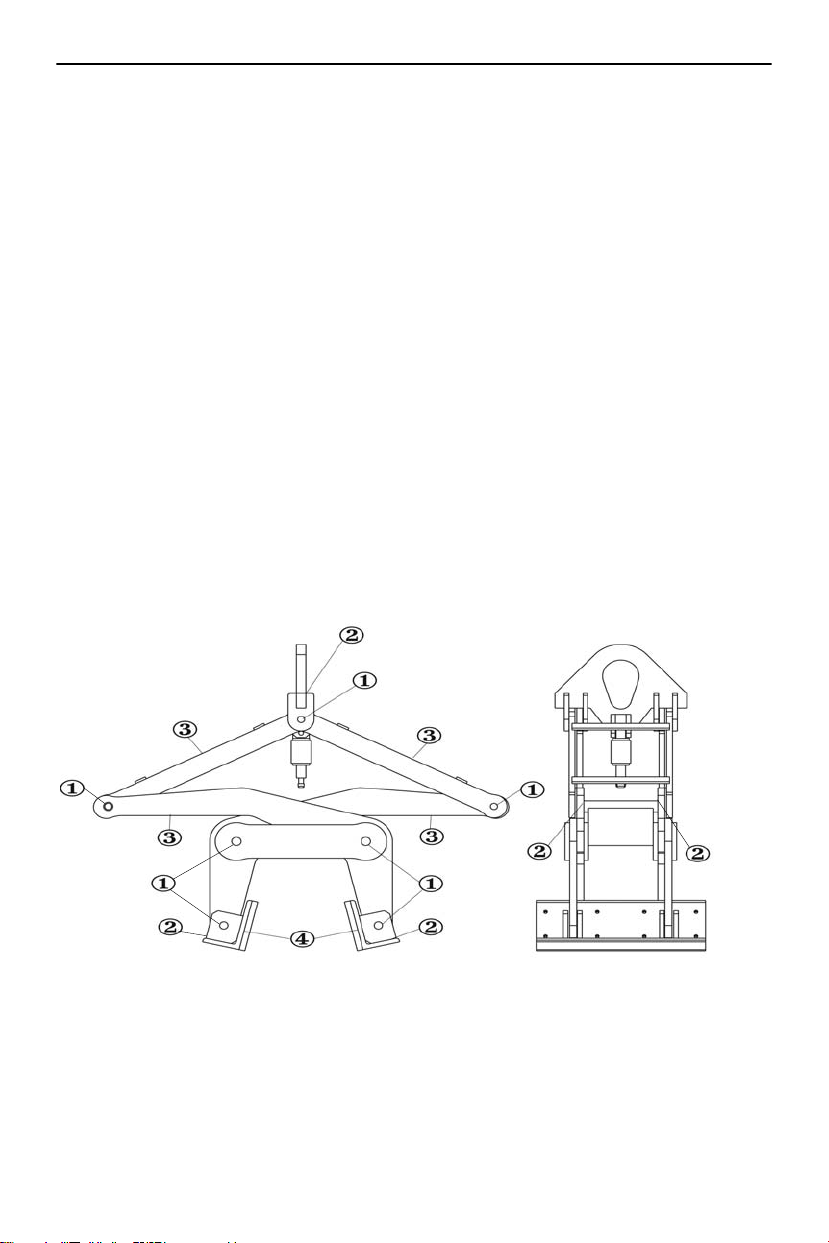

• Inspect pin welds for cracks or signs of failure. (1)

• Inspect all load carrying welds for cracks or signs of failure. (2)

• Inspect metal arms and linkage to determine if they are bent or warped (3)

• Grip pads must be securely bolted onto the barrier grab and be free from wear.

Replace with genuine Crosby Clamp-Co polyurethane grip pads. (4)

• If provided with hardened steel pads, rather than polyurethane, check for wear and

replace if worn. Replace with genuine Crosby Clamp-Co hardened steel grip pads.

• Lubricate index pin assembly, load pins and moving parts with oil can or spray at least

once a week.

INSPECTION AND LUBRICATION POINTS

Do not attempt to repair a damaged clamp by welding or with unauthorized replacement

parts. We recommend returning the clamp to the manufacturer when repairs are required.

Barrier_Grab_Clamp_manual.fm Page 6 Thursday, May 28, 2009 3:10 PM

Copyright© 2009 The Crosby Group 7

All Rights Reserved

INSPECTION AND MAINTENANCE CHECK LIST

• Is any part of the equipment distorted?

• Are any cracks visible, or is extensive corrosion evident?

• Is there wear evident at suspension points, shackles, master link, pivots, pins, bolts,

threads, or other moving and / or load bearing parts?

• Are the Working Load Limit, Serial Numbers and Warning labels legible?

• Have all inspections and maintenance been regularly recorded?

• Does the Crosby Clamp-Co product carry its original Identification Plate and Warning

Information?

• If the identification plate has been damaged or removed, the clamp shall be taken out

of service and arrangements made to replace the identification plate.

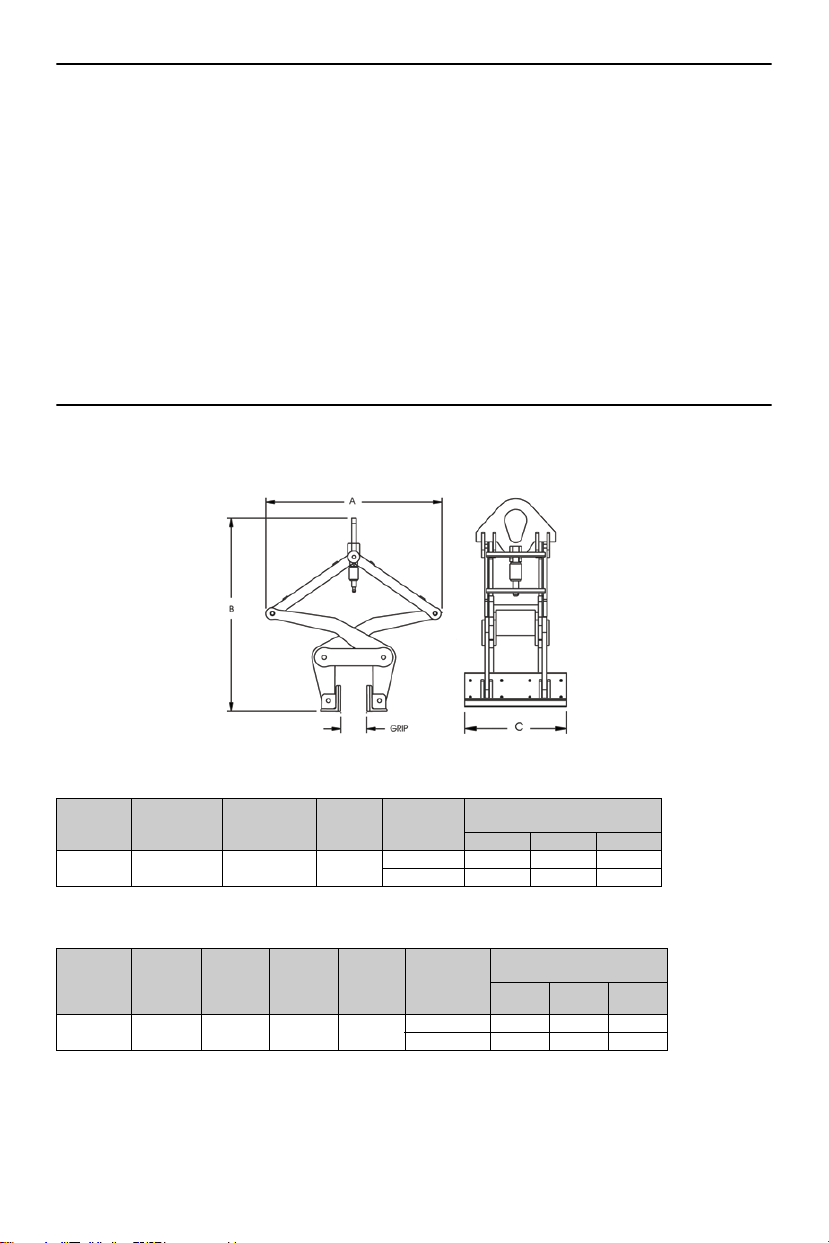

BARRIER GRAB MODEL BG 9000

Concrete barriers selected to lift must be within the limits of recommended Grip Width and

Working Load Limit as shown in Figure 2.

Figure 2

Barrier Grab - Imperial

Barrier Grab - Metric

The above information is for standard size clamp models. For special clamp models not

located in table, please refer to I.D. tag affixed to product for proper Working Load Limit

and size limitations.

Model

No.

CCBG-150

Stock

No.

Working

Load Limit

(Tons)

Weight

Each

(lbs.)

Grip

Width

(in.)

Dimensions

(in.)

A B C

BG-9000 2734009 4.5 290 6 (min.) 40.88 44.88 18.00

12 (max.) 44.00 36.75 18.00

Type

Model

No.

CCBG-

150

Stock

No.

Working

Load

Limit

(t)

Weight

Each

(kg.)

Grip

Width

(mm)

Dimensions

(mm)

A B C

Barrier

Grab BG-9000 2734009 4.08 132 152 (min.) 1038 1140 457

305 (max.) 1118 934 457

Barrier_Grab_Clamp_manual.fm Page 7 Thursday, May 28, 2009 3:10 PM

Copyright® 2009 The Crosby Group, Inc.

All Rights Reserved

P.O. Box 3128 Tulsa, Oklahoma 74101

(918) 834-4611

www.thecrosbygroup.com

stock # 9999277

Barrier_Grab_Clamp_manual.fm Page 8 Thursday, May 28, 2009 3:10 PM

Table of contents

Other Crosby Industrial Equipment manuals