Crown Micro X-3.6KW-M User manual

USER MANUAL

X-3.6KW-M / X-5.6KW-M

Hybrid Inverter

With MPPT Solar Charger

Version: 1.0

1

Table Of Contents

ABOUT THIS MANUAL ......................................................................................................................................2

Purpose............................................................................................................................................................2

Scope...............................................................................................................................................................2

SAFETY INSTRUCTIONS...................................................................................................................................2

INTRODUCTION .................................................................................................................................................3

Features...........................................................................................................................................................3

Basic System Architecture...............................................................................................................................3

Product Overview.............................................................................................................................................4

INSTALLATION...................................................................................................................................................5

Unpacking and Inspection................................................................................................................................5

Preparation ......................................................................................................................................................5

Mounting the Unit.............................................................................................................................................5

Battery Connection ..........................................................................................................................................6

AC Input/Output Connection............................................................................................................................7

PV Connection.................................................................................................................................................9

Final Assembly...............................................................................................................................................11

Communication Options.................................................................................................................................11

OPERATION......................................................................................................................................................12

Power ON/OFF ..............................................................................................................................................12

Operation and Display Panel.........................................................................................................................12

LCD Display Icons .........................................................................................................................................13

LCD Setting....................................................................................................................................................16

Display Setting...............................................................................................................................................24

Operating Mode Description..........................................................................................................................27

Battery Equalization Description....................................................................................................................30

Fault Reference Code....................................................................................................................................32

Warning Indicator...........................................................................................................................................33

CLEARANCE AND MAINTENANCE FOR ANTI-DUST KIT............................................................................34

Overview........................................................................................................................................................34

Clearance and Maintenance..........................................................................................................................34

SPECIFICATIONS.............................................................................................................................................35

Table 1 Line Mode Specifications ...................................................................................................................35

Table 2 Inverter Mode Specifications .............................................................................................................36

Table 3 Charge Mode Specifications ..............................................................................................................37

Table 4 General Specifications .......................................................................................................................37

TROUBLE SHOOTING.....................................................................................................................................38

Appendix I: Approximate Back-up Time Table .............................................................................................39

Appendix II: The Wi-Fi Operation Guide........................................................................................................40

2

ABOUT THIS MANUAL

Purpose

This manual describes the assembly, installation, operation and troubleshooting of this unit. Please read

this manual carefully before installations and operations. Keep this manual for future reference.

Scope

This manual provides safety and installation guidelines as well as information on tools and wiring.

SAFETY INSTRUCTIONS

WARNING: This chapter contains important safety and operating instructions. Read and

keep this manual for future reference.

1. Before using the unit, read all instructions and cautionary markings on the unit, the batteries and all

appropriate sections of this manual.

2. CAUTION --To reduce risk of injury, charge only deep-cycle lead acid type rechargeable batteries.

Other types of batteries may burst, causing personal injury and damage.

3. Do not disassemble the unit. Take it to a qualified service center when service or repair is required.

Incorrect re-assembly may result in a risk of electric shock or fire.

4. To reduce risk of electric shock, disconnect all wirings before attempting any maintenance or cleaning.

Turning off the unit will not reduce this risk.

5. CAUTION –Only qualified personnel can install this device with battery.

6. NEVER charge a frozen battery.

7. For optimum operation of this inverter/charger, please follow required spec to select appropriate cable

size. It’s very important to correctly operate this inverter/charger.

8. Be very cautious when working with metal tools on or around batteries. A potential risk exists to drop

a tool to spark or short circuit batteries or other electrical parts and could cause an explosion.

9. Please strictly follow installation procedure when you want to disconnect AC or DC terminals. Please

refer to INSTALLATION section of this manual for the details.

10. One piece of 150A fuse is provided as over-current protection for the battery supply.

11. GROUNDING INSTRUCTIONS -This inverter/charger should be connected to a permanent grounded

wiring system. Be sure to comply with local requirements and regulation to install this inverter.

12. NEVER cause AC output and DC input short circuited. Do NOT connect to the mains when DC input

short circuits.

13. Warning!! Only qualified service persons are able to service this device. If errors still persist after

following troubleshooting table, please send this inverter/charger back to local dealer or service center

for maintenance.

14. WARNING: Because this inverter is non-isolated, only three types of PV modules are acceptable:

single crystalline, poly crystalline with class A-rated and CIGS modules. To avoid any malfunction, do

not connect any PV modules with possible current leakage to the inverter. For example, grounded PV

modules will cause current leakage to the inverter. When using CIGS modules, please be sure NO

grounding.

15. CAUTION: It’s requested to use PV junction box with surge protection. Otherwise, it will cause

damage on inverter when lightning occurs on PV modules.

3

INTRODUCTION

This is a multi-function inverter/charger, combining functions of inverter, solar charger and battery charger to

offer uninterruptible power support with portable size. Its comprehensive LCD display offers user-configurable

and easy-accessible button operation such as battery charging current, AC/solar charger priority, and

acceptable input voltage based on different applications.

Features

Pure sine wave inverter

Inverter running without battery

Configurable input voltage range for home appliances and personal computers via LCD setting

Configurable battery charging current based on applications via LCD setting

Configurable AC/Solar Charger priority via LCD setting

Compatible to mains voltage or generator power

Auto restart while AC is recovering

Overload/ Over temperature/ short circuit protection

Smart battery charger design for optimized battery performance

Cold start function

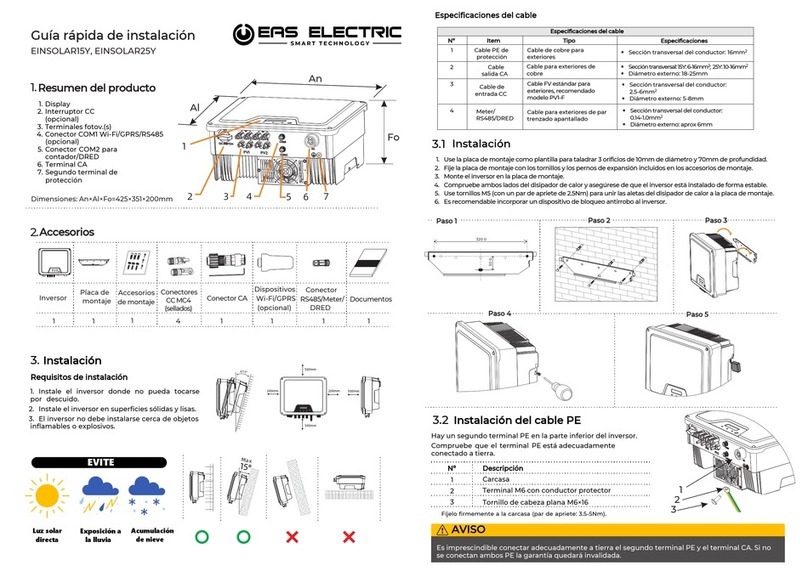

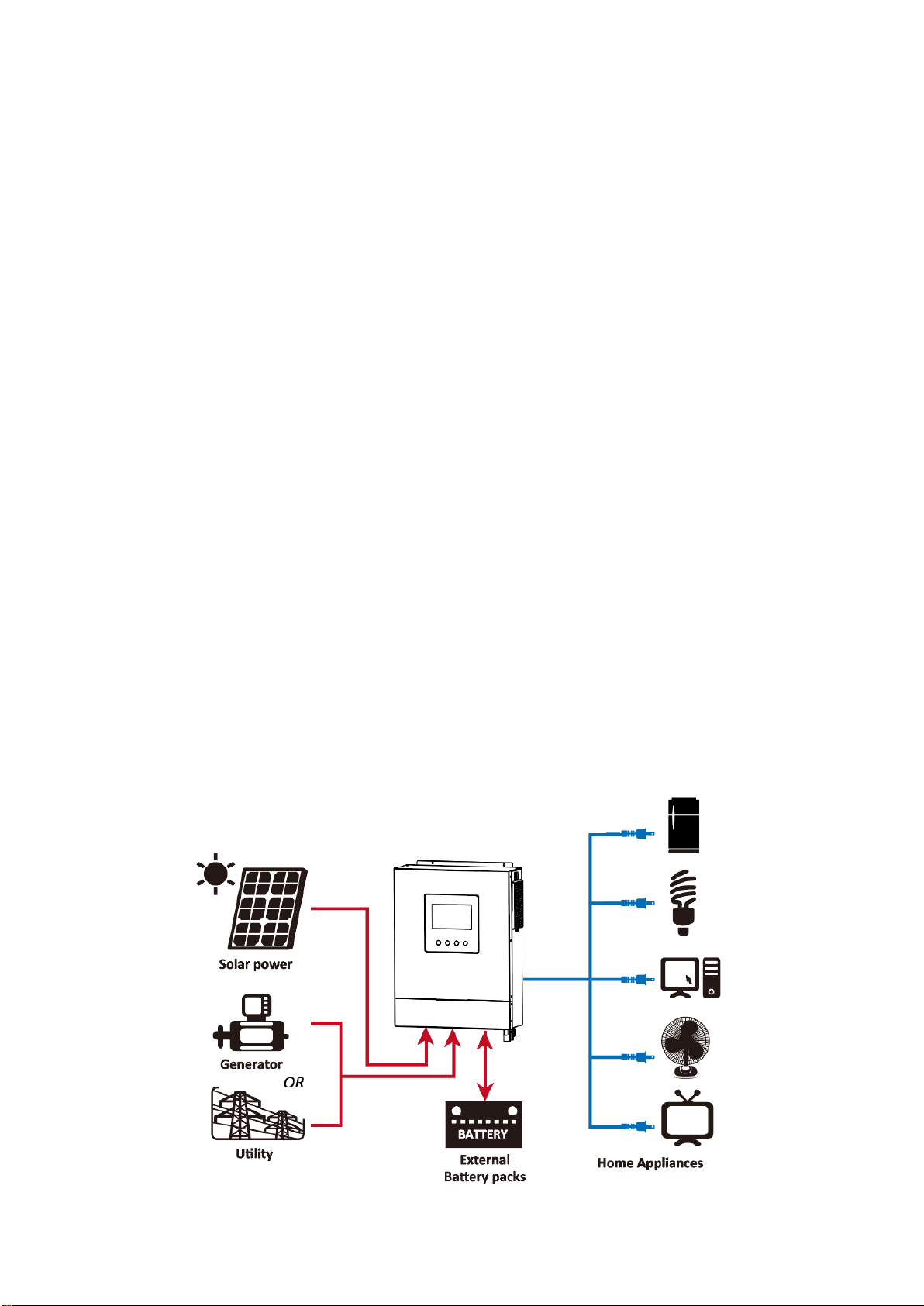

Basic System Architecture

The following illustration shows basic application for this inverter/charger. It also includes following devices to

have a complete running system:

Generator or Utility.

PV modules

Consult with your system integrator for other possible system architectures depending on your requirements.

This inverter can power all kinds of appliances in home or office environment, including motor-type appliances

such as tube light, fan, refrigerator and air conditioner.

Figure 1 Hybrid Power System

4

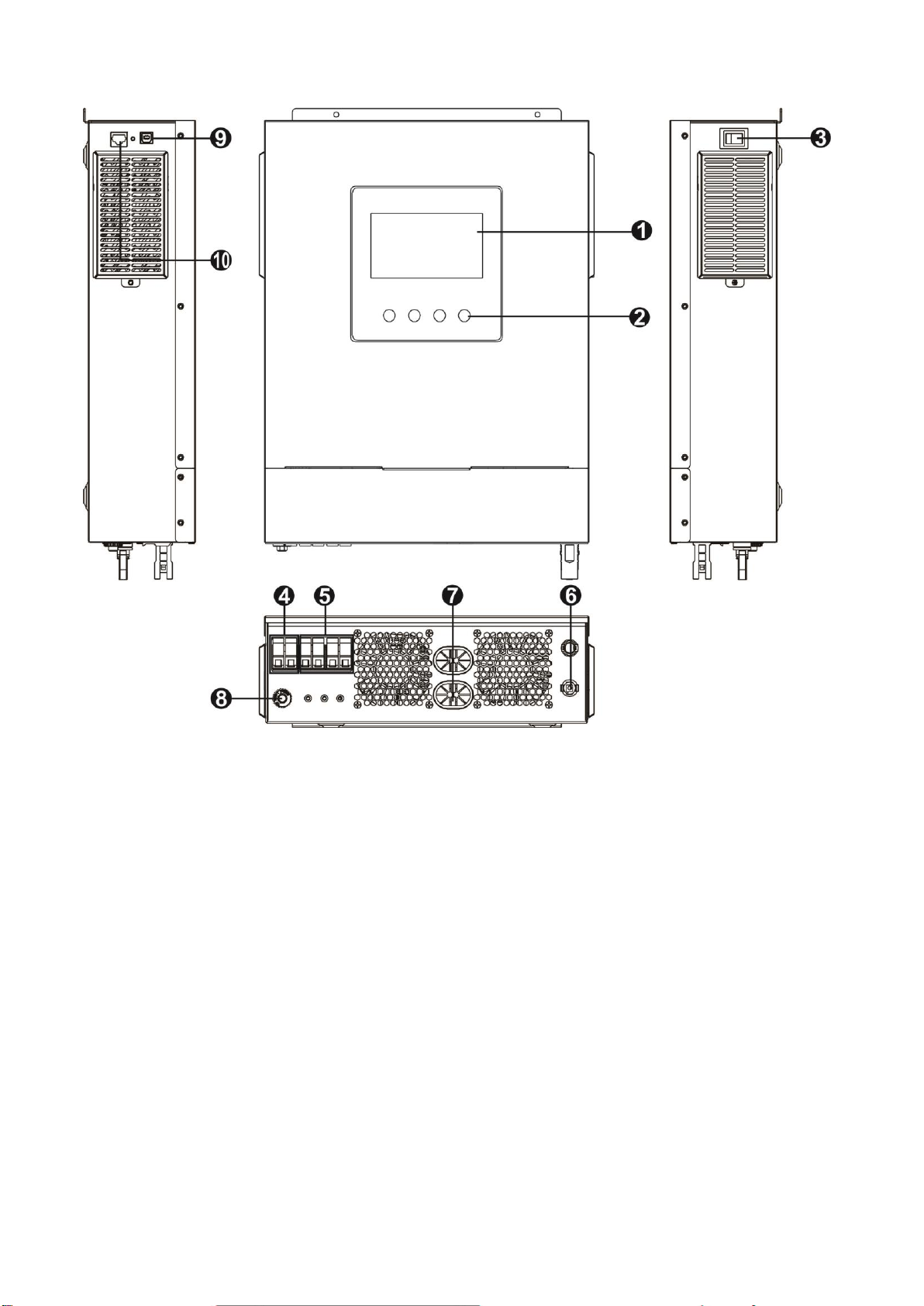

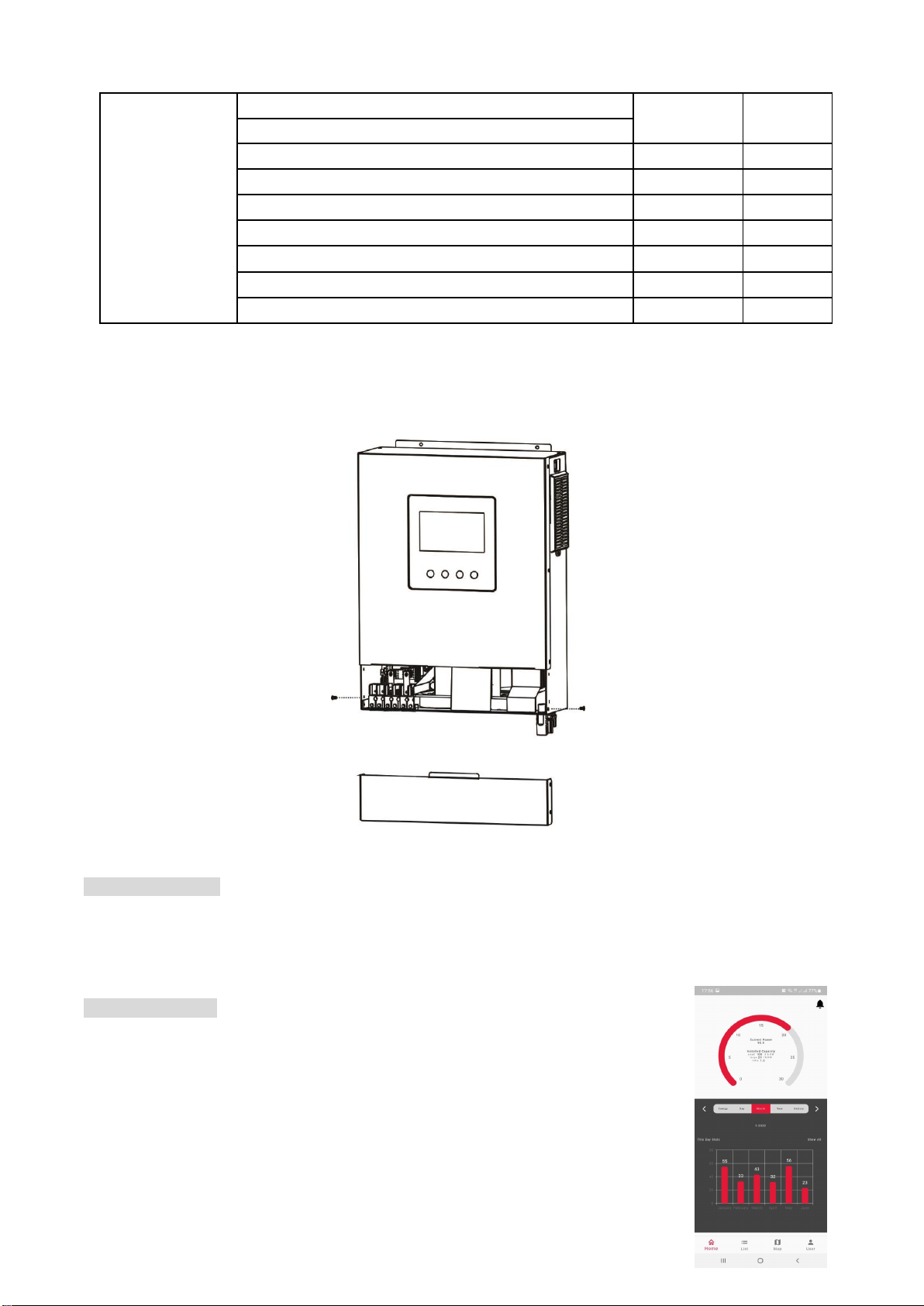

Product Overview

1. LCD display

2. Function keys

3. Power on/off switch

4. AC input

5. AC output

6. PV input

7. Battery input

8. Circuit breaker

9. USB communication port

10. RS-232 communication port

5

INSTALLATION

Unpacking and Inspection

Before installation, please inspect the unit. Be sure that nothing inside the package is damaged. You should

have received the following items inside of package:

The unit x 1

User manual x 1

Communication cable x 1

Software CD x 1

DC Fuse x 1

PV connectors x 1 set

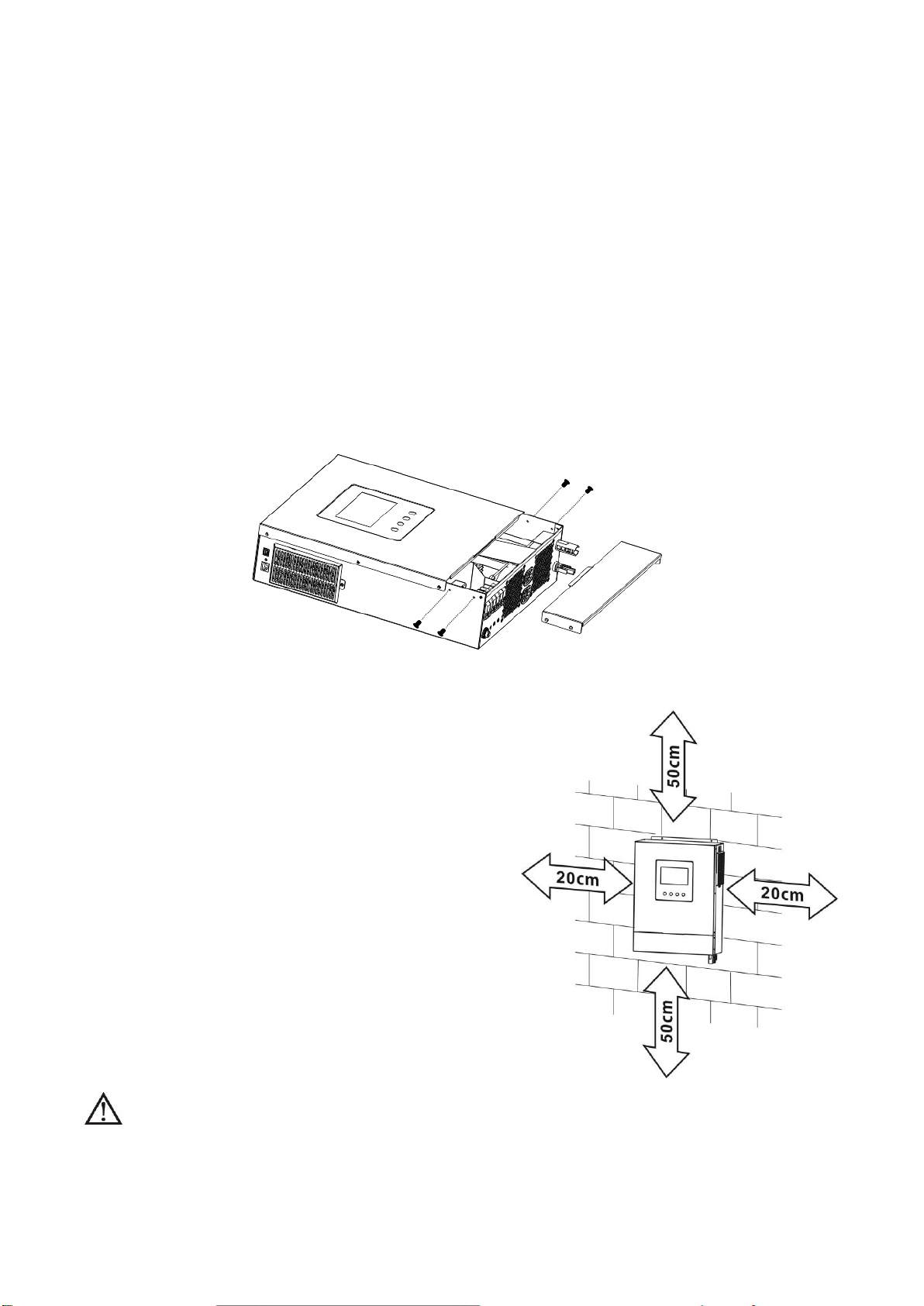

Preparation

Before connecting all wirings, please take off bottom cover by removing four screws as shown below.

Mounting the Unit

Consider the following points before selecting where to install:

Do not mount the inverter on flammable construction

materials.

Mount on a solid surface

Install this inverter at eye level in order to allow the LCD

display to be read at all times.

For proper air circulation to dissipate heat, allow a

clearance of approx. 20 cm to the side and approx. 50 cm

above and below the unit.

The ambient temperature should be between 0°C and

55°C to ensure optimal operation.

The recommended installation position is to be adhered

to the wall vertically.

Be sure to keep other objects and surfaces as shown in

the diagram to guarantee sufficient heat dissipation

and to have enough space for removing wires.

SUITABLE FOR MOUNTING ON CONCRETE OR OTHER NON-COMBUSTIBLE SURFACE ONLY.

6

Install the unit by screwing two screws. It’s recommended to use M4 or M5 screws.

Battery Connection

CAUTION: For safety operation and regulation compliance, it’s requested to install a separate DC over-current

protector or disconnection device between battery and the inverter. It may not be necessary to have a

disconnection device in some applications, however, it’s still recommended to have over-current protection

installed. Please refer to typical amperage as required.

WARNING! All wiring must be performed by a qualified personnel.

WARNING! It’s very important for system safety and efficient operation to use

appropriate cable for battery connection. To reduce risk of injury, please use the

proper recommended cable and terminal size as below.

Recommended battery cable and terminal size:

Model

Typical

Amperage

Wire Size

Cable

mm2

Ring Terminal

Torque

Value

Dimensions

D (mm)

L (mm)

X-3.6KW-M

167A

2*4AWG

25

8.4

33.2

5 Nm

X-5.6KW-M

129.6A

1*2AWG

38

8.4

39.2

2*4AWG

25

8.4

33.2

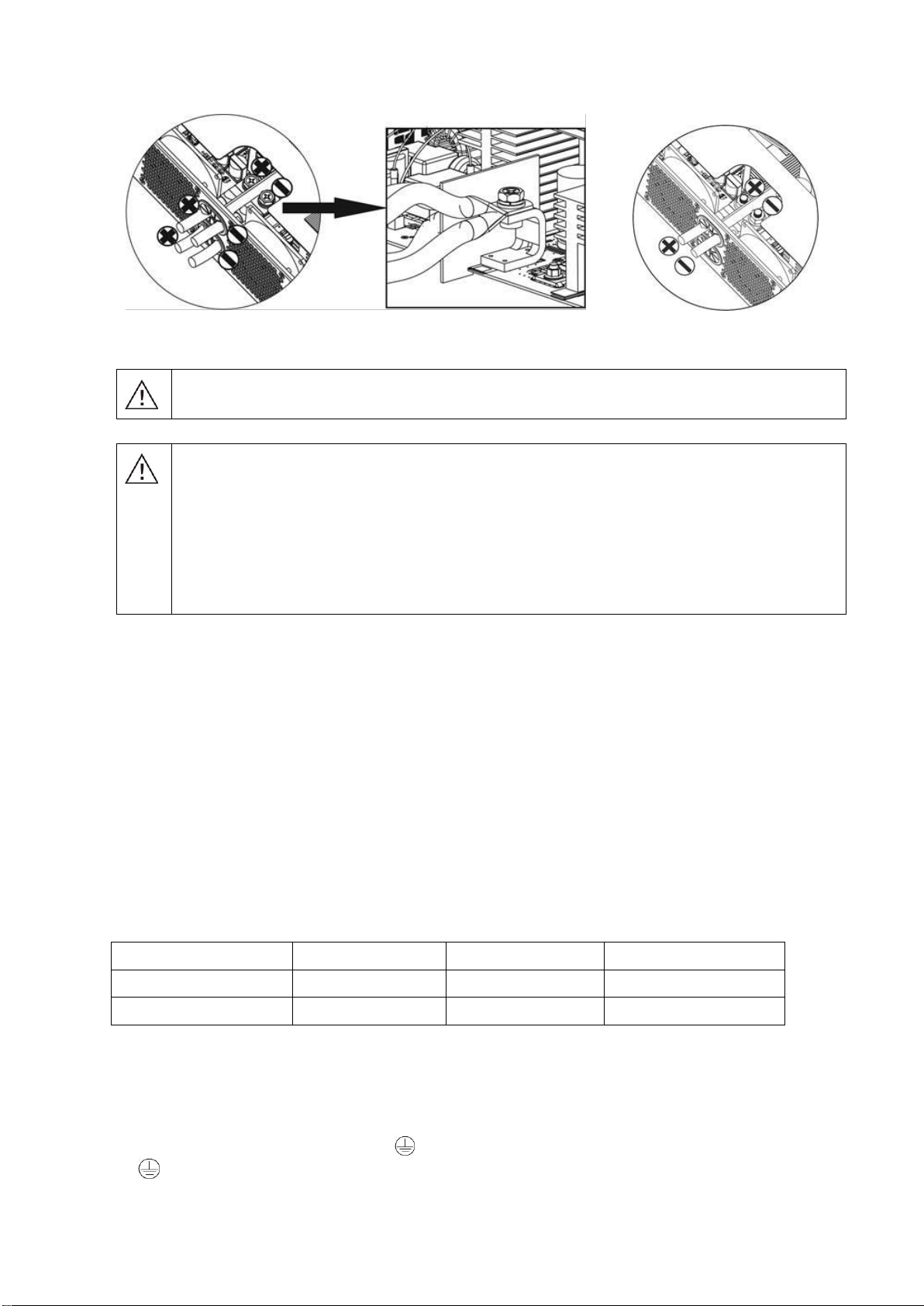

Please follow below steps to implement battery connection:

1. 3.6KW model supports 24VDC system and 5.6KW model supports 48VDC system. Connect all battery packs

as below chart. It is recommend to connect minimum of 100Ah capacity battery for 3.6KW model and

200Ah capacity battery for 5.6KW model.

2. Prepare four battery wires for 3.6KW model and two or four battery wires for 5.6KW model depending on

cable size (refer to recommended cable size table). Apply ring terminals to your battery wires and secure it

to the battery terminal block with the bolts properly tightened. Refer to battery cable size for torque value.

Ring terminal:

7

Make sure polarity at both the battery and the inverter is correctly connected and ring terminals are

secured to the battery terminals.

X-3.6KW-M/ X-5.6KW-M X-5.6KW-M

WARNING: Shock Hazard

Installation must be performed with care due to high battery voltage in series.

CAUTION!! Do not place anything between the flat part of the inverter terminal and the ring

terminal. Otherwise, overheating may occur.

CAUTION!! Do not apply anti-oxidant substance on the terminals before terminals are

connected tightly.

CAUTION!! Before making the final DC connection or closing DC breaker/disconnector, be sure

positive (+) must be connected to positive (+) and negative (-) must be connected to negative

(-).

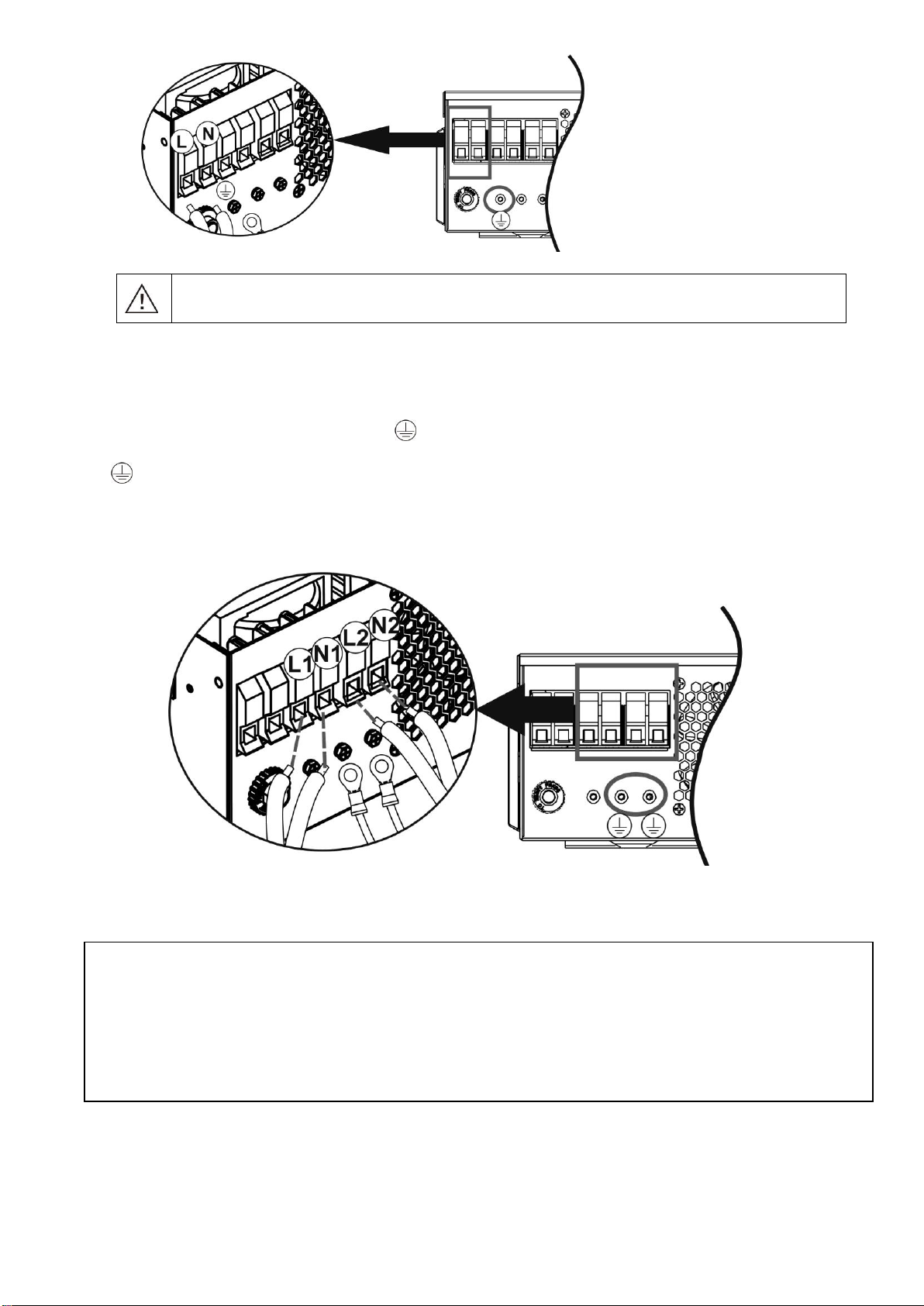

AC Input/Output Connection

CAUTION!! Before connecting to AC input power source, please install a separate AC breaker between

inverter and AC input power source. This will ensure the inverter can be securely disconnected during

maintenance and fully protected from over current of AC input. The recommended spec of AC breaker is 32A

for 3.6KW and 50A for 5.6KW.

CAUTION!! There are two terminal blocks with “IN” and “OUT” markings. Please do NOT mis-connect input

and output connectors.

WARNING! All wiring must be performed by a qualified personnel.

WARNING! It's very important for system safety and efficient operation to use appropriate cable for AC input

connection. To reduce risk of injury, please use the proper recommended cable size as below.

Suggested cable requirement for AC wires

Model

Gauge

Cable (mm2)

Torque Value

X-3.6KW-M

12 AWG

4

1.2 Nm

X-5.6KW-M

10 AWG

6

1.2 Nm

Please follow below steps to implement AC input/output connection:

1. Before making AC input/output connection, be sure to open DC protector or disconnector first.

2. Remove insulation sleeve 10mm for six conductors. And shorten phase L and neutral conductor N 3 mm.

3. Insert AC input wires according to polarities indicated on terminal block and tighten the terminal screws. Be

sure to connect PE protective conductor ( ) first.

→Ground (yellow-green)

L→LINE (brown or black)

N→Neutral (blue)

8

WARNING:

Be sure that AC power source is disconnected before attempting to hardwire it to the unit.

4. This inverter is equipped with dual-output. There are four terminals (L1/N1, L2/N2) available on output port.

It’s set up through LCD program or monitoring software to turn on and off the second output. Refer to “LCD

setting” section for the details.

Insert AC output wires according to polarities indicated on terminal block and tighten terminal screws. Be

sure to connect PE protective conductor ( ) first.

→Ground (yellow-green)

L1→LINE (brown or black)

N1→Neutral (blue)

L2→LINE (brown or black)

N2→Neutral (blue)

5. Make sure the wires are securely connected.

CAUTION: Appliances such as air conditioner are required at least 2~3 minutes to restart because it’s required

to have enough time to balance refrigerant gas inside of circuits. If a power shortage occurs and recovers in a

short time, it will cause damage to your connected appliances. To prevent this kind of damage, please check

manufacturer of air conditioner if it’s equipped with time-delay function before installation. Otherwise, this

inverter/charger will trig overload fault and cut off output to protect your appliance but sometimes it still causes

internal damage to the air conditioner.

9

PV Connection

CAUTION: Before connecting to PV modules, please install separately DC circuit breakers between inverter

and PV modules.

NOTE1: Please use 600VDC/30A circuit breaker.

NOTE2: The overvoltage category of the PV input is II.

Please follow the steps below to implement PV module connection:

Step 1: Check the input voltage of PV array modules. This system is applied with two strings of PV array. Please

make sure that the maximum current load of each PV input connector is 18A.

Step 2: Disconnect the circuit breaker and switch off the DC switch.

Step 3: Assemble provided PV connectors with PV modules by the following steps.

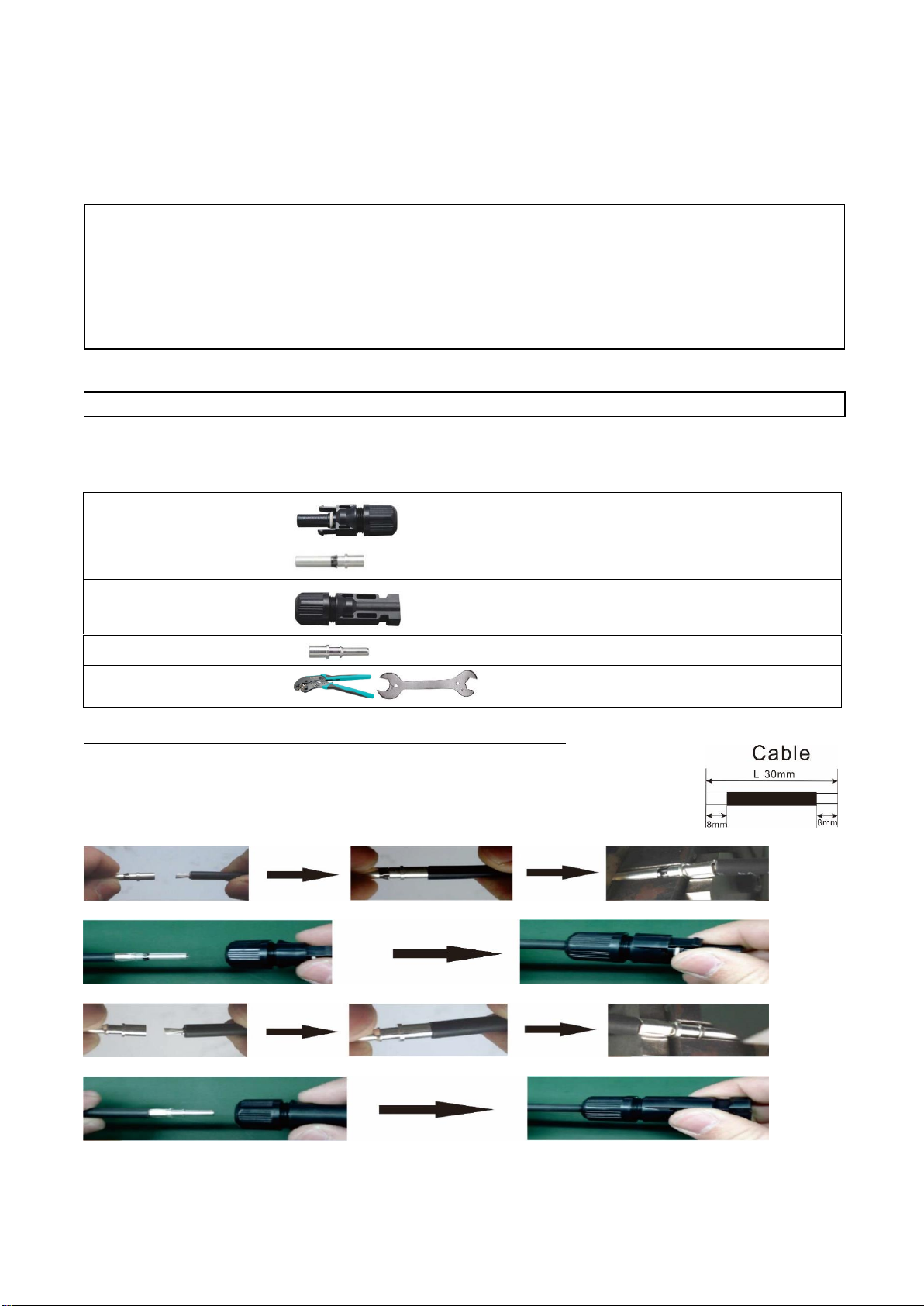

Components for PV connectors and Tools:

Female connector housing

Female terminal

Male connector housing

Male terminal

Crimping tool and spanner

Prepare the cable and follow the connector assembly process:

Insert striped cable into female terminal and crimp female terminal as shown below.

Insert assembled cable into female connector housing as shown below.

Insert striped cable into male terminal and crimp male terminal as shown below.

Insert assembled cable into male connector housing as shown below.

CAUTION: Exceeding the maximum input voltage can destroy the unit!! Check the system before wire connection.

WARNING: Because this inverter is non-isolated, only three types of PV modules are acceptable: single

crystalline and poly crystalline with class A-rated and CIGS modules.

To avoid any malfunction, do not connect any PV modules with possible current leakage to the inverter. For

example, grounded PV modules will cause current leakage to the inverter. When using CIGS modules, please

be sure NO grounding.

CAUTION: It’s required to use PV junction box with surge protection. Otherwise, it will cause damage on

inverter when lightning occurs on PV modules.

Strip one cable 8 mm on both end sides and be careful NOT to nick conductors.

10

Then, use spanner to screw pressure dome tightly to female connector and male connector as shown below.

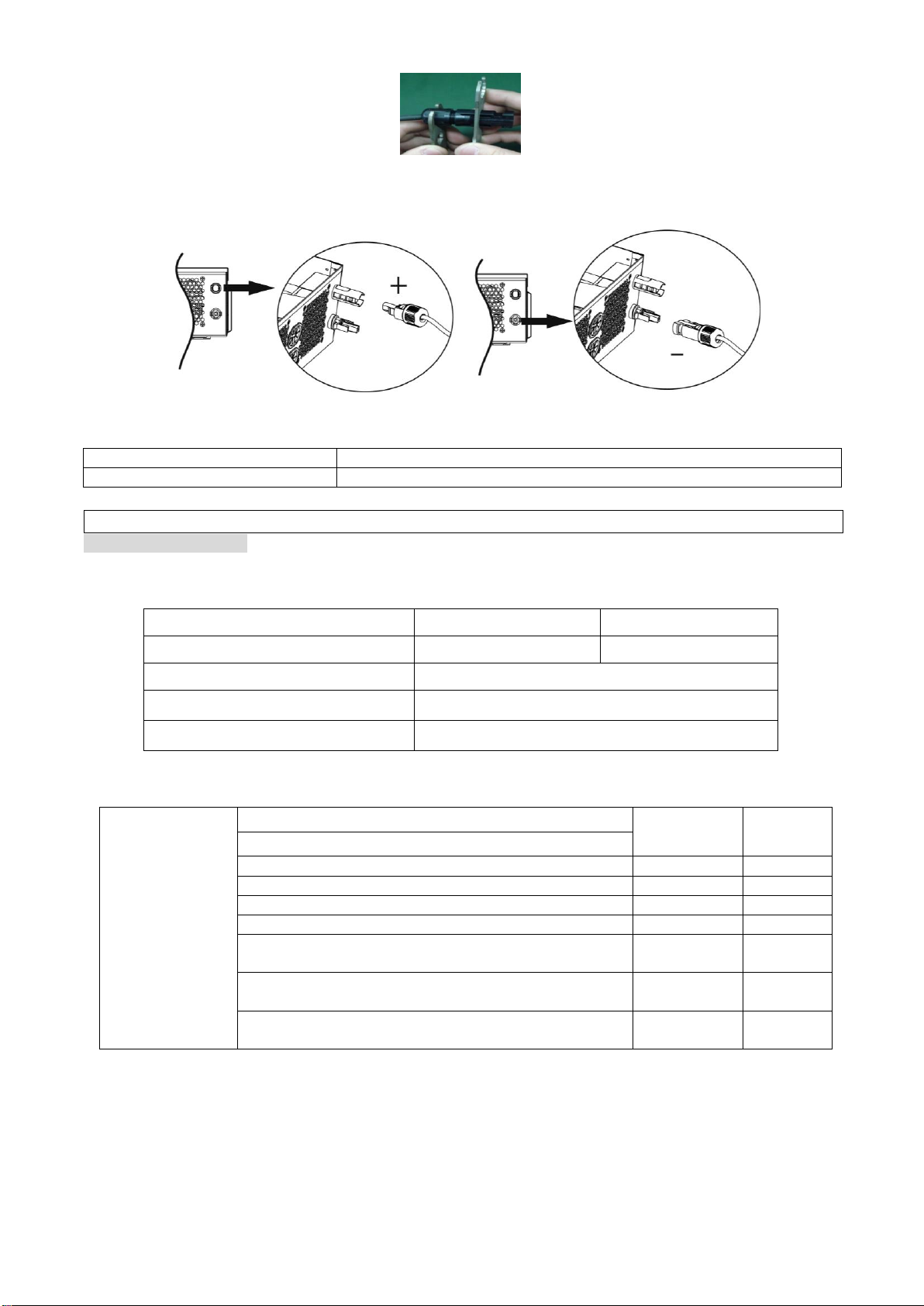

Step 4: Check correct polarity of connection cable from PV modules and PV input connectors. Then, connect

positive pole (+) of connection cable to positive pole (+) of PV input connector. Connect negative pole (-) of

connection cable to negative pole (-) of PV input connector.

WARNING! For safety and efficiency, it's very important to use appropriate cables for PV module connection.

To reduce risk of injury, please use the proper cable size as recommended below.

Conductor cross-section (mm2)

AWG no.

4~6

10~12

PV Module Selection:

When selecting proper PV modules, please be sure to consider below parameters:

1. Open circuit Voltage (Voc) of PV modules not exceeds max. PV array open circuit voltage of inverter.

2. Open circuit Voltage (Voc) of PV modules should be higher than min. Start-up Voltage.

INVERTER MODEL

X-3.6KW-M

X-5.6KW-M

Max. PV Array Power

4000W

6000W

Max. PV Array Open Circuit Voltage

500Vdc

PV Array MPPT Voltage Range

120Vdc~450Vdc

Start-up Voltage

150Vdc +/- 10Vdc

Take 250Wp PV module as an example. After considering above two parameters, the recommended module

configurations are listed as below table.

Solar Panel Spec.

(reference)

- 250Wp

- Vmp: 30.1Vdc

- Imp: 8.3A

- Voc: 37.7Vdc

- Isc: 8.4A

- Cells: 60

SOLAR INPUT

Q'ty of panels

Total input

power

Min in series: 6 pcs, max. in series: 12 pcs.

6 pcs in series

6 pcs

1500W

8 pcs in series

8 pcs

2000W

12 pcs in series

12 pcs

3000W

8 pieces in series and 2 sets in parallel

16 pcs

4000W

10 pieces in series and 2 sets in parallel (only for 5.6KVA

model)

20 pcs

5000W

11 pieces in series and 2 sets in parallel

(only for 5.6KVA model)

22 pcs

5500W

12 pieces in series and 2 sets in parallel

(only for 5.6KVA model)

24 pcs

6000W

CAUTION: Never directly touch the terminals of inverter. It might cause lethal electric shock.

11

Take the 555Wp PV module as an example. After considering above two parameters, the recommended

module configurations are listed in the table below.

Solar Panel Spec.

(reference)

- 555Wp

- Imp: 17.32A

- Voc: 38.46Vdc

- Isc: 18.33A

- Cells: 110

SOLAR INPUT

Q'ty of panels

Total input

power

Min in series: 2 pcs, max. in series: 11 pcs.

2pcs in series

2 pcs

1110W

4pcs in series

4 pcs

2220W

6 pcs in series

6 pcs

3330W

7 pcs in series

7 pcs

3885W

8 pcs in series (only for X-5.6KW-M model)

8 pcs

4440W

10 pcs in series (only for X-5.6KW-M model)

10 pcs

5550W

11 pcs in series (only for X-5.6KW-M model)

11 pcs

6000W

Final Assembly

After connecting all wirings, please put bottom cover back by screwing two screws as shown below.

Communication Options

Serial Connection

Please use the supplied serial cable to connect between the inverter and your PC. Install the monitoring

software from the bundled CD and follow the on-screen instructions to complete your installation. For

detailed software operation, refer to the software user manual on the bundled CD.

Wi-Fi Connection

Wi-Fi module needs to be installed on the inverter for Wi-Fi Connection. Wi-Fi module

can enable wireless communication between inverters and monitoring platform. Simply

put this module connected to an inverter with communication cable and you may find

“Crown Monitor” app from the Apple® Store or Google® Play Store. All data loggers

and parameters are saved in iCloud. For quick installation and operation, please check

Appendix II.

Wi-Fi Module Installation

Please follow below steps to install Wi-Fi module:

12

Step 1: The module contains four strong magnetics backing and can be easily be placed on the side of the

inverter.

Step 2: Please use one RJ45 to RS-232 communication cable to connect an inverter and Wi-Fi module as

below chart.

OPERATION

Power ON/OFF

Side view of unit

Once the unit has been properly installed and the batteries are connected well, simply press On/Off switch

(located on the side of the unit) to turn on the unit.

Operation and Display Panel

The operation LCD panel, shown in the chart below, includes one RGB LED ring, four function keys and a LCD

display to indicate the operating status and input/output power information.

Function Keys

Function Key

Description

ESC

To exit the setting

Up

To last selection

Down

To next selection

Enter

To confirm/enter the selection in setting mode

Function keys

LCD display

13

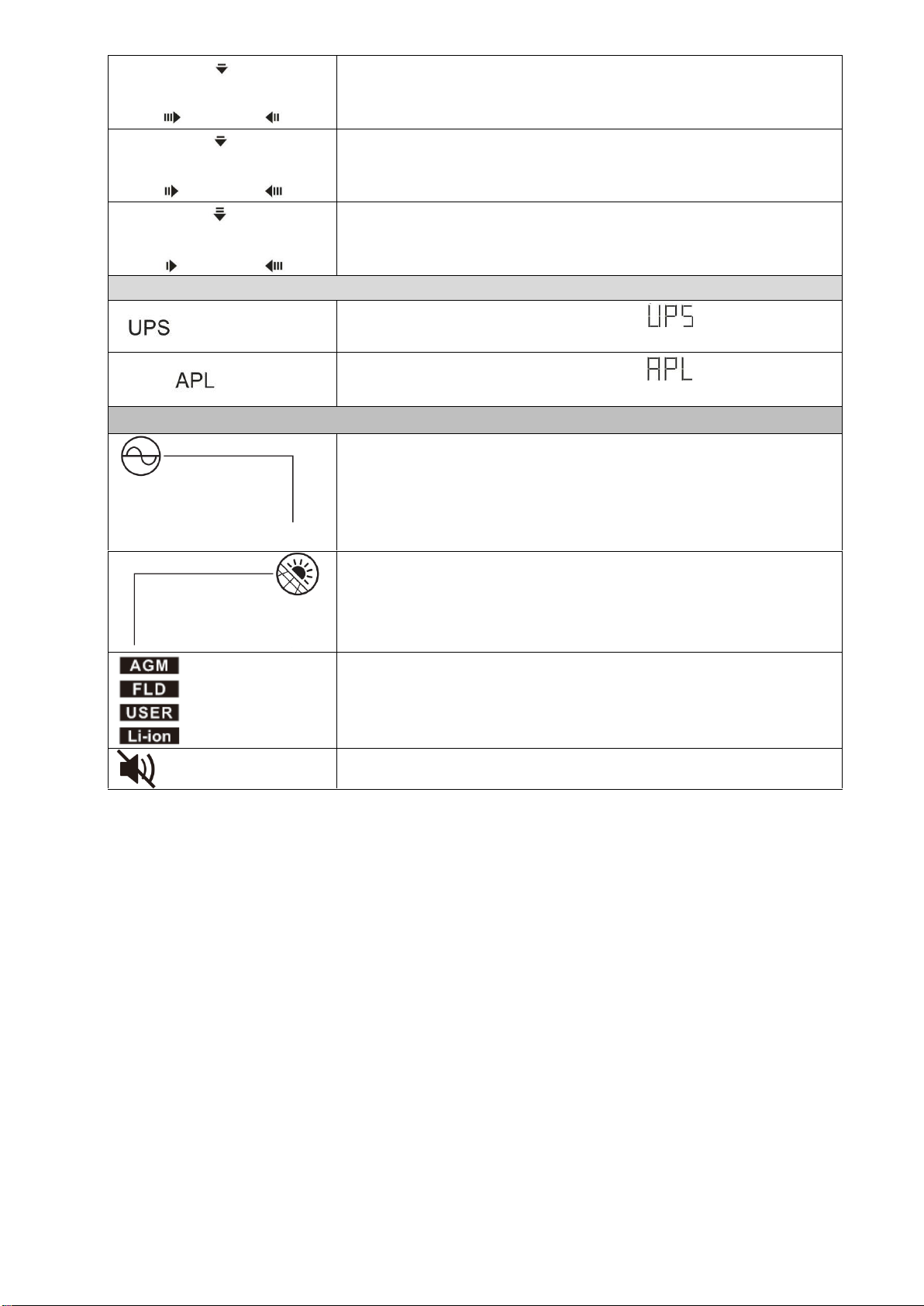

LCD Display Icons

Icon

Function description

Input Source Information

Indicates the AC input voltage and frequency.

Indicates the PV voltage, current and power.

Indicates the battery voltage, charging stage, configured battery

parameters, charging or discharging current.

Configuration Program and Fault Information

Indicates the setting programs.

Indicates the warning and fault codes.

Warning: flashing with warning code.

Fault: lighting with fault code.

Output Information

Indicate the output voltage, load in VA, and load in Watt and output

frequency.

The ICON flashing indicates the unit with AC output and setting

programs 60,61 different from default setting.

14

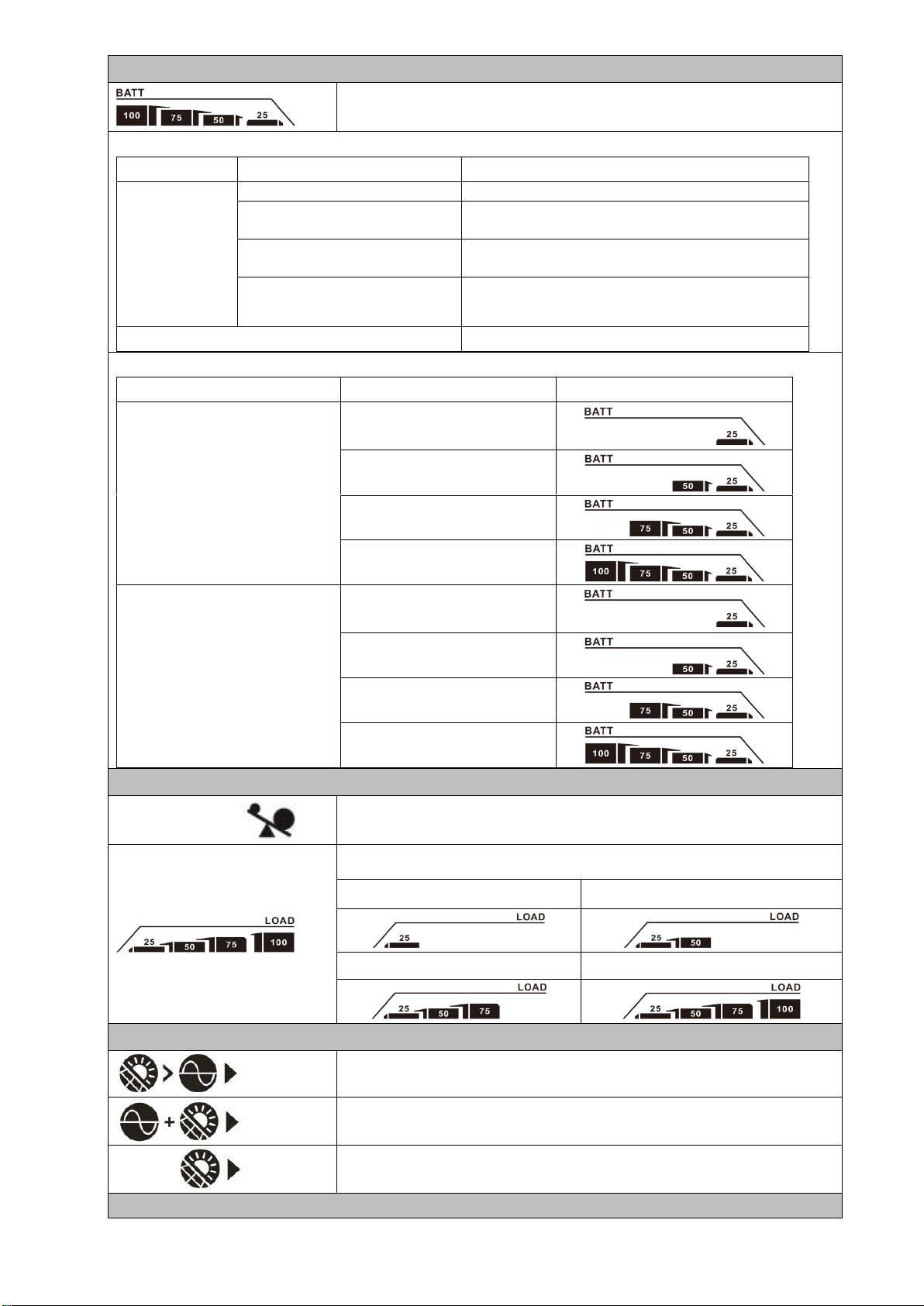

Battery Information

Indicates battery level by 0-24%, 25-49%, 50-74% and 75-100% in

battery mode and charging status in line mode.

When battery is charging, it will present battery charging status.

Status

Battery voltage

LCD Display

Constant

Current mode /

Constant

Voltage mode

<2V/cell

4 bars will flash in turns.

2 ~ 2.083V/cell

The right bar will be on and the other three bars

will flash in turns.

2.083 ~ 2.167V/cell

The right two bars will be on and the other two

bars will flash in turns.

> 2.167 V/cell

The right three bars will be on and the left bar

will flash.

Floating mode. Batteries are fully charged.

4 bars will be on.

In battery mode, it will present battery capacity.

Load Percentage

Battery Voltage

LCD Display

Load >50%

< 1.85V/cell

1.85V/cell ~ 1.933V/cell

1.933V/cell ~ 2.017V/cell

> 2.017V/cell

Load < 50%

< 1.892V/cell

1.892V/cell ~ 1.975V/cell

1.975V/cell ~ 2.058V/cell

> 2.058V/cell

Load Information

Indicates overload.

Indicates the load level by 0-24%, 25-49%, 50-74% and 75-100%.

0%~24%

25%~49%

50%~74%

75%~100%

Charger Source Priority Setting Display

Indicates setting program 16 “Charger source priority” is selected as

“Solar first”.

Indicates setting program 16 “Charger source priority” is selected as

“Solar and Utility”.

Indicates setting program 16 “Charger source priority” is selected as

“Solar only”.

Output source priority setting display

15

Indicates setting program 01 “Output source priority” is selected as

“Utility first”.

Indicates setting program 01 “Output source priority” is selected as

“Solar first”.

Indicates setting program 01 “Output source priority” is selected as

“SBU”.

AC Input Voltage Range Setting Display

Indicates setting program 03 is selected as “ ”. The acceptable AC

input voltage range will be within 170-280VAC.

Indicates setting program 03 is selected as “ ”. The acceptable AC

input voltage range will be within 90-280VAC.

Operation Status Information

Indicates unit connects to the mains.

Indicates unit connects to the PV panel.

Indicates battery type.

Indicates unit alarm is disabled.

16

LCD Setting

After pressing and holding ENTER button for 3 seconds, the unit will enter setting mode. Press “UP”or “DOWN”

button to select setting programs. And then, press “ENTER”button to confirm the selection or ESC button to

exit.

Setting Programs:

Program

Description

Selectable option

00

Exit setting mode

Escape

01

Output source priority:

To configure load power

source priority

Utility first (default)

Utility will provide power to the

loads as first priority.

Solar and battery energy will

provide power to the loads only

when utility power is not available.

Solar first

Solar energy provides power to

the loads as first priority.

If solar energy is not sufficient to

power all connected loads, Utility

energy will supply power to the

loads at the same time.

SBU priority

Solar energy provides power to

the loads as first priority.

If solar energy is not sufficient to

power all connected loads, battery

energy will supply power to the

loads at the same time.

Utility provides power to the loads

only when battery voltage drops

to either low-level warning voltage

or the setting point in program 12.

02

Maximum charging current:

To configure total charging

current for solar and utility

chargers.

(Max. charging current =

utility charging current +

solar charging current)

60A (default)

Setting range is from 10A to 100A.

Increment of each click is 10A.

17

03

AC input voltage range

Appliances (default)

If selected, acceptable AC input

voltage range will be within

90-280VAC.

UPS

If selected, acceptable AC input

voltage range will be within

170-280VAC.

05

Battery type

AGM (default)

Flooded

User-Defined

If “User-Defined”is selected,

battery charge voltage and low DC

cut-off voltage can be set up in

program 26, 27 and 29.

06

Auto restart when overload

occurs

Restart disable (default)

Restart enable

07

Auto restart when over

temperature occurs

Restart disable (default)

Restart enable

09

Output frequency

50Hz (default)

60Hz

18

10

Output voltage

220V

230V (default)

240V

11

Maximum utility charging

current

Note: If setting value in

program 02 is smaller than

that in program in 11, the

inverter will apply charging

current from program 02 for

utility charger.

30A (default)

Setting range is 2A, then from 10A

to 100A. Increment of each click is

10A.

12

Setting voltage point back

to utility source when

selecting “SBU” (SBU

priority) in program 01.

Available options in 3.6KW model:

23.0V (default)

Setting range is from 22V to

25.5V. Increment of each click is

0.5V.

Available options in 5.6KW model:

46V (default)

Setting range is from 44V to 51V.

Increment of each click is 1V.

13

Setting voltage point back

to battery mode when

selecting “SBU” (SBU

priority) in program 01.

Available options in 3.6KW model:

Battery fully charged

27V (default)

Setting range is from 24V to 29V. Increment of each click is 0.5V.

19

13

Setting voltage point back

to battery mode when

selecting “SBU” (SBU

priority) in program 01.

Available options in 5.6KW model:

Battery fully charged

54V (default)

Setting range is from 48V to 58V. Increment of each click is 1V.

16

Charger source priority:

To configure charger

source priority

Solar first

Solar energy will charge battery as

first priority.

Utility will charge battery only

when solar energy is not available.

Solar and Utility (default)

Solar energy and utility will charge

battery at the same time.

Only Solar

Solar energy will be the only

charger source no matter utility is

available or not.

If this inverter/charger is working in Battery mode, only solar

energy can charge battery. Solar energy will charge battery if it's

available and sufficient.

18

Alarm control

Alarm on (default)

Alarm off

This manual suits for next models

1

Table of contents

Other Crown Micro Inverter manuals