K Series Service Manual Rev A.

1-2 Introduction

©1999 Crown International, Inc.

1.3 Repair Strategy

The

Balanced Current Amplifier

technology rings in a

new era in Crown history. Taking full advantage of the

modular design approach used in the design of

K Se-

ries

amplifiers,weareable to offeramoduleexchange

programforthisproduct.The concept is that thePWA

(Printed Wire Assembly) as a whole is one compo-

nent, and when a part of the assembly is defective,

the whole assembly is defective. Exceptions are the

Control, Bridge, Display, and Line Filter PWAs. Those

PWAs may be repaired at the component level unless

there is sufficient damage or malfunction to warrant

PWA replacement.Non-PWAcomponentsarealsoex-

cluded from this program.

Under the module exchange program, defective

PWAs are returned to Crown for evaluation and re-

work. The reworked assemblies will then be stocked

in the Crown Parts Department to be sold as refur-

bished parts.

This strategy offers several advantages. One advan-

tage is less time spent in troubleshooting and repair-

ing the amplifier, thus resulting in greater customer

satisfaction. This strategy also allows Crown to col-

lect the necessary information from amplifier failures,

soimprovementscanbe made for even greater prod-

uct reliability.

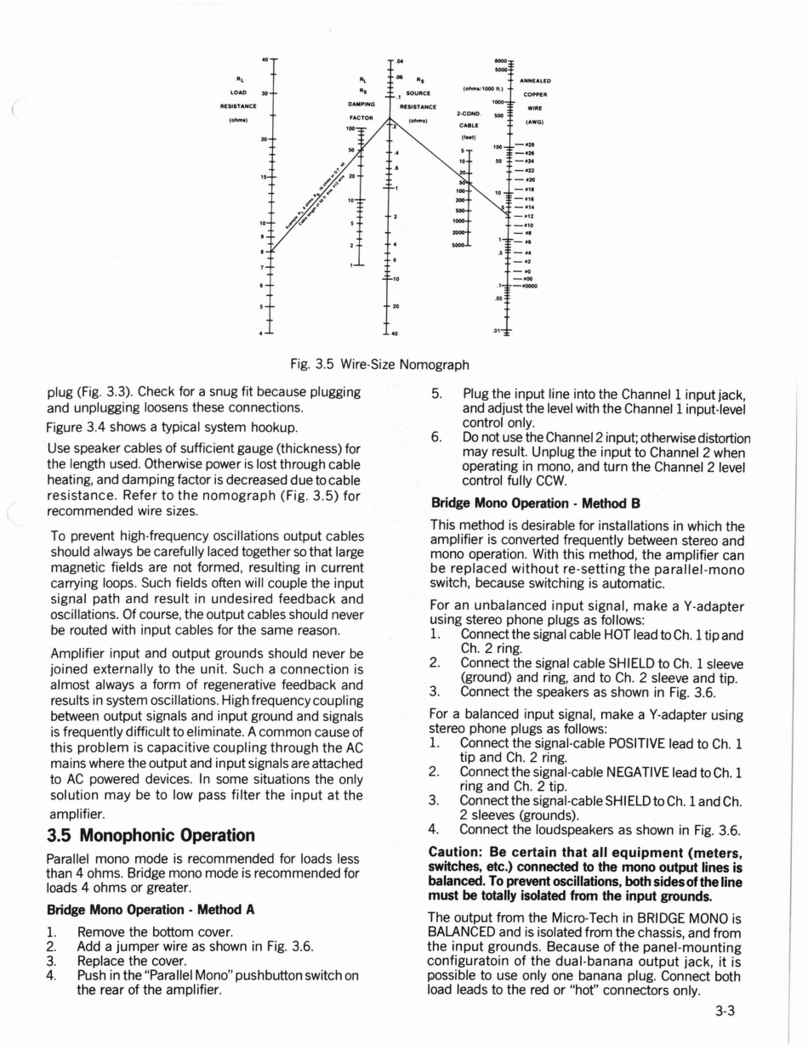

1.4 Service Procedure

Servicing a

Balanced Current Amplifier

requires cer-

tain steps to be followed. See Figure 1.2 for a flow

chart of these steps. It is important that the defective

PrintedWireAssemblies(PWAs)bereturnedtoCrown

forevaluationandrepair. Under the module exchange

program, warranty claims for PWA replacement will

not be honored unless the defective PWA accompa-

nies the warranty claim. In the event of a non-war-

ranty repair, rebuilt PWAs will be available at a lower

price than new PWAs, and a discount will be given if

the defective PWA is returned to Crown.

Each PWA purchased from the Crown parts depart-

ment will have a tag indicating that it is “Available for

Issue.” This tag will have two parts. The first part sim-

ply states that the PWA is ready for use. It also has

instructions for the PWA and the serial number of the

module. Once the new PWA is installed, this part is to

be discarded. The second part will be filled out by

the service technician. After it is filled out with data

such as the amplifier serial number and a description

of the failure, it will be attached to the failed PWA.

This part has three copies. The first is for the service

center to keep. Copies 2 and 3 will remain together

for use at Crown.

WARNING

Component-level troubleshooting and repair of

PWAs included in the module exchange program

should not be attempted without expressed autho-

rization from the Crown Audio Service Manager.

Such an attempt, without specialized training and

specialized test equipment,will likely result in sub-

stantial damage to the amplifier. Crown will not

authorize payment of warranty claims in such an

instance.