1. INTRODUCTION

A. PURPOSE: This Crown Installation, Operation,

Maintenance and Parts Manual has been developed to

assist you in the installation, operation and maintenance

of your electric operator and thus enable you to utilize it

to its maximum eciency.

B. MODELS COVERED: The manual covers current

models 1502-1 & 1502-2 Operators.

C. APPLICATION: The Crown Industrial Model #1502

Swing Door Operators are intended for use on large

interior industrial doors operated by trained personnel.

D. DESCRIPTION:

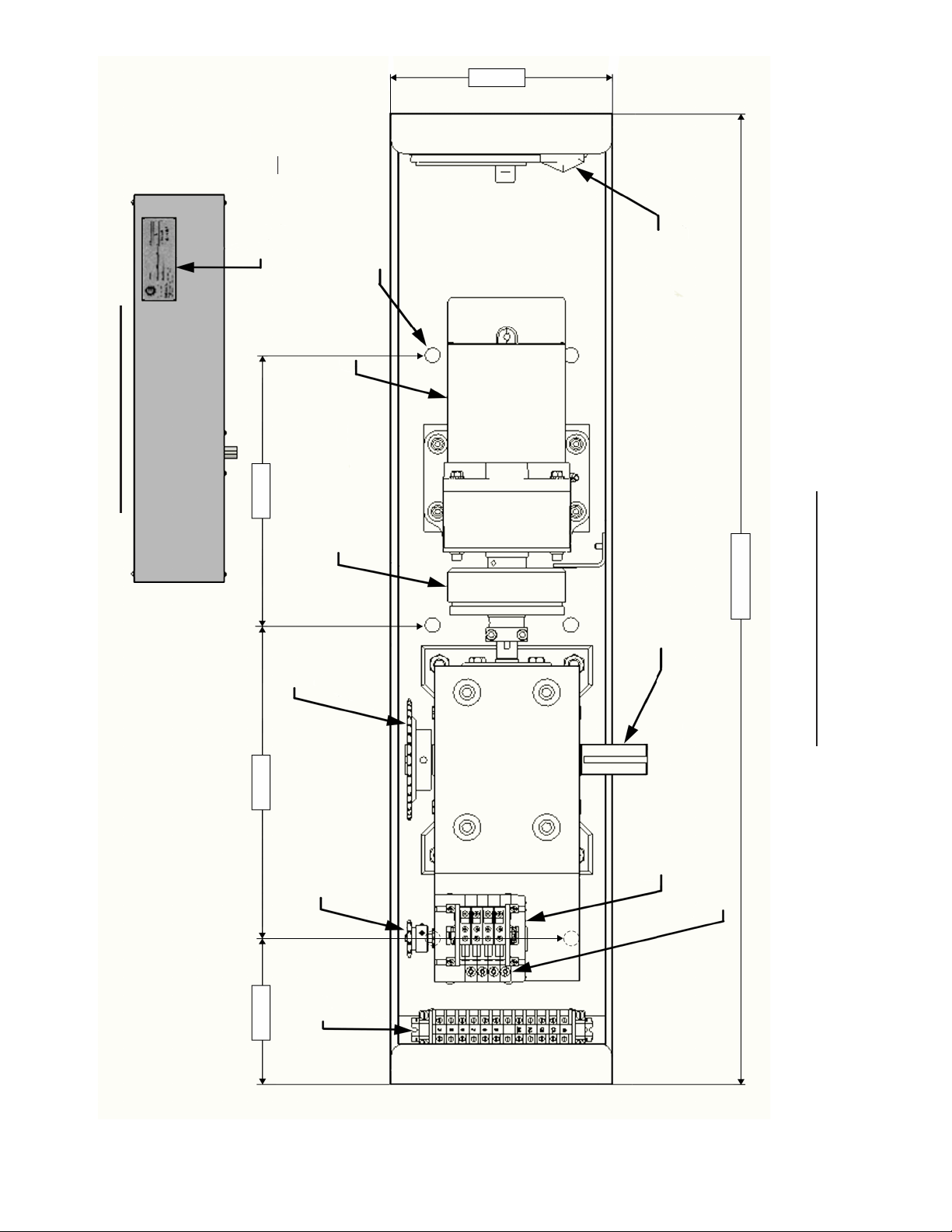

The model 1502 operator consists of a 90 volt, DC

permanent magnet gear motor, variable torque electric

clutch, right angle worm gear and internal limit switches.

The motor control is accomplished by means of an

electronic control package. The motor controls are

mounted in a remotely located control panel. The

operator shall mount above the door on the lintel of the

frame. Door connecting arms and door brackets are

included. The operator mounting frame and cover shall

be prime coated ready for nish painting in the eld. The

supply voltage should be 120 volt AC, single phase. The

control circuit will allow for two speed operation with the

run and creep speeds independently adjustable.

Figure 1. 1502 Left Hand Swing Door

Operator

2. INSTALLATION AND OPERATION

A. GENERAL

The Crown 1502 Electric Door Operator has been

designed primarily for commercial and industrial

installations where the operator has to withstand

constant hard use. To ensure correct installation

and proper operation of the operator and associated

hardware, the following instructions are given:

(1) SHIPMENT CHECK: Included with the installation

packet is a copy of the packing slip for the components

supplied with the order. Compare the components

received with the packing slip to insure that all

equipment is complete.

(2) REVIEW INSTALLATION DRAWINGS: The

installation drawings show the layout of the door,

template drilling for the door and jamb, and general

terms used to describe the components. Review the

drawings to familiarize yourself with the equipment.

(3) CHECK THE DOORS: Prior to installing the

operator, conrm the doors are properly hung. 95% of

all door operator trouble is caused by doors not swinging

free of the oor and lintel. It is also very important that

all hinge pins are properly aligned and there is no hinge

binding.

(4) PREPARING THE DOOR AND LINTEL:

The door operators are handed (left and right) and

are supplied as push or pull to open (Refer to Figure 2

Operator Handing). Ensure proper backing and support

are available in the lintel and the door to receive the

operator and connecting arm. Remove the electric

operator from crate. Choose the appropriate drilling

template. Prepare the lintel for the operator.

Figure 2. Operator Handing

RIGHT HAND PULL TO OPEN

#1502 OPERATOR #1502 OPERATOR

LEFT HAND PULL TO OPEN

HINGE

#1502 OPERATOR #1502 OPERATOR

RIGHT HAND PUSH TO OPEN LEFT HAND PUSH TO OPEN

HINGE

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495