Momentary: When the actuator is depressed the

operator shall start up and continue to operate until the

appropriate limit switch is activated or a STOP button is

depressed.

IF MOMENTARY CONTROLS ARE USED CONSULT

FACTORY BEFORE PROCEEDING.

Step1:

With the mechanical disconnect disengaged and the

door free to move by hand, turn the power ON. Depress

"Open" push button. Does the Relay in the control box

labeled "O" light? If YES, proceed to step (2), if NO,

TURN POWER OFF and check the wiring from the

"OPEN" activation switch to the control box.

Step 2:

Is the operator rotating the proper direction to open the

door? If NO, turn off power to the operator control box.

Switch the motor wires typically labeled M1 & M2 or A1

& A2, located at the bottom of the control box. Turn the

power back on and check for proper rotation.

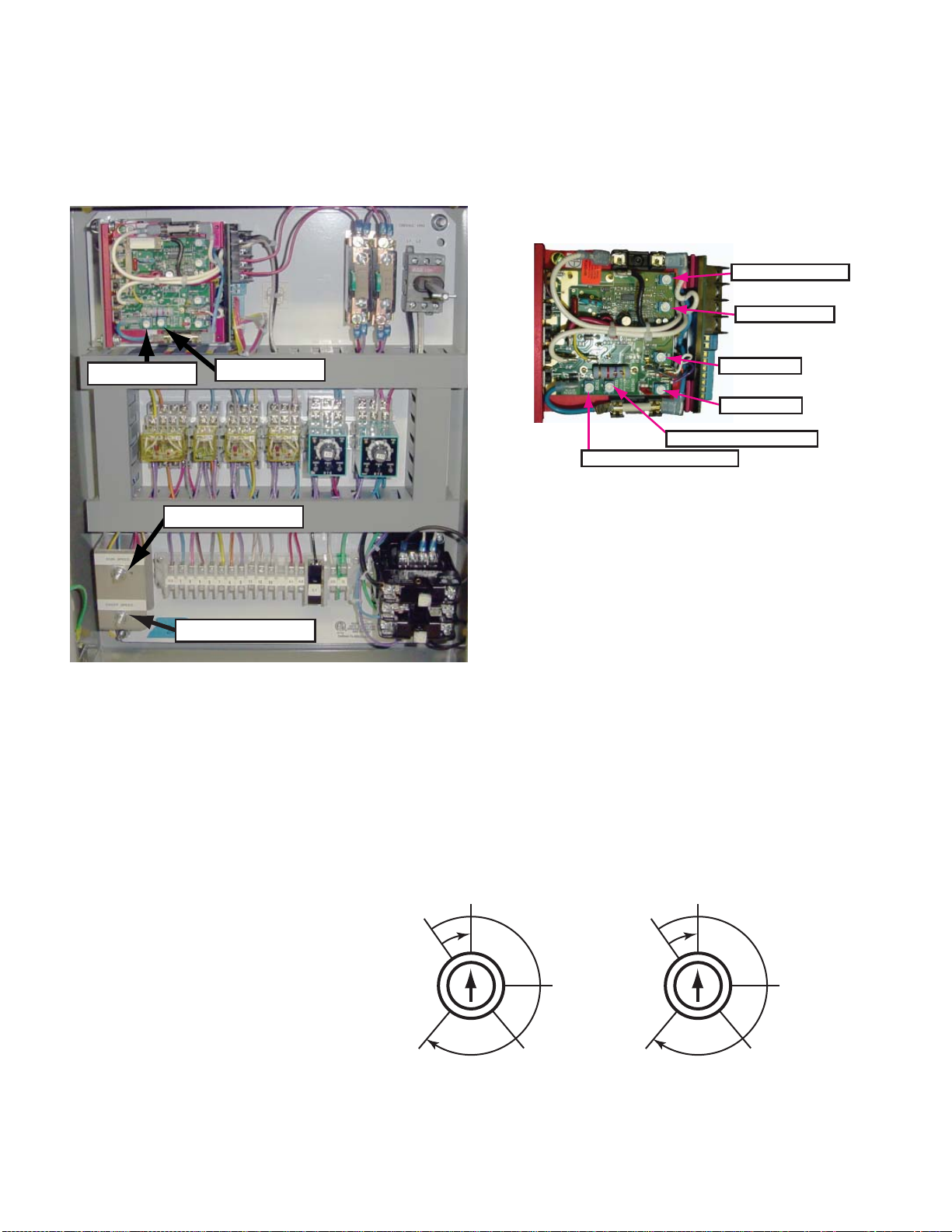

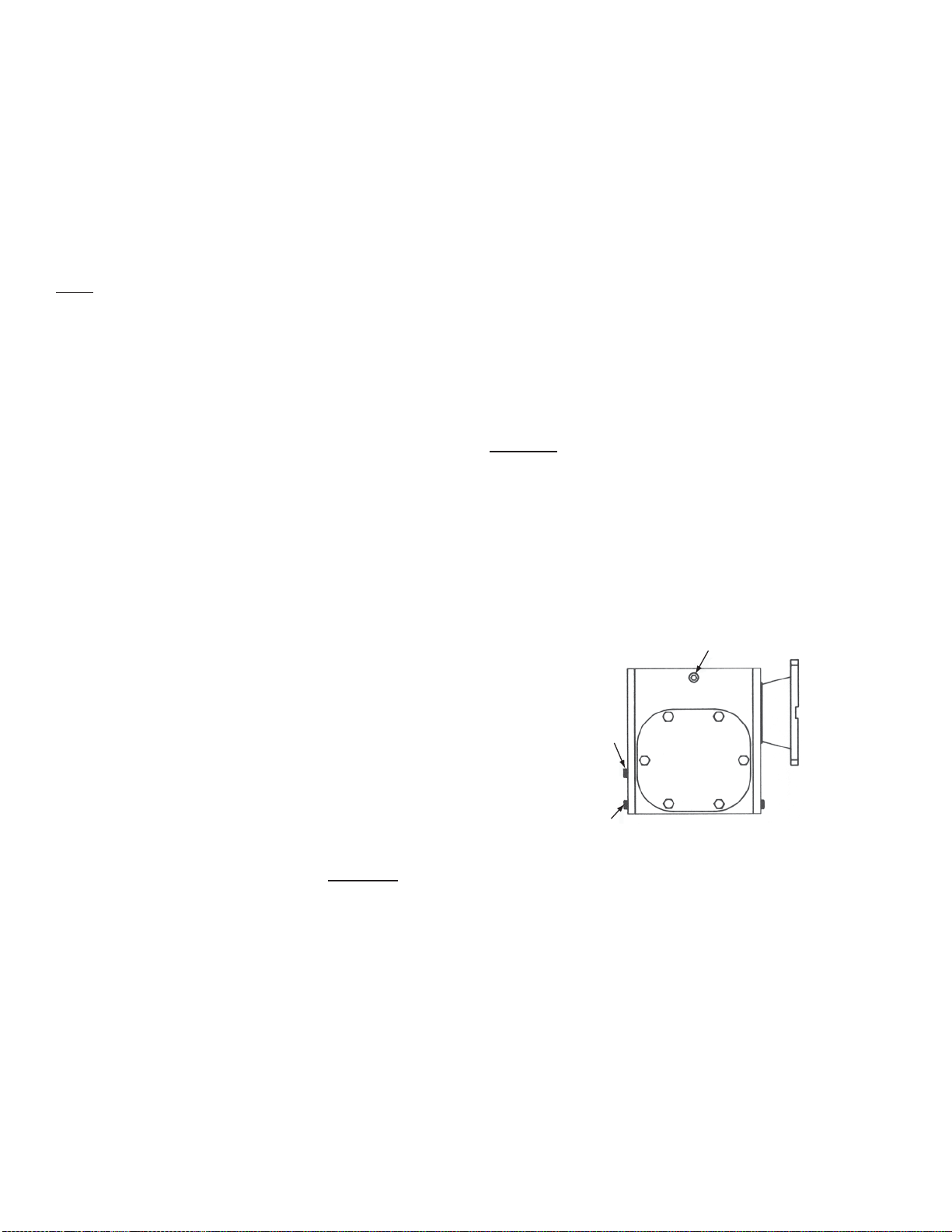

F. PRELIMINARY ROTARY LIMIT SWITCH

ADJUSTMENT

(1) DESCRIPTION: The rotary limit switch is designed

to accurately control the end limits of the door travel

provided by the electric operator as well as the activation

point and duration of the creep mode. The limit switch

input shaft drives a set of planetary gears which in

turn drives a set of nylon cams (See Figure 2). Each

precision limit switch unit is actuated by its individual

nylon cam. The cam rotate as the operator travels the

door back and forth. The cam contact the electrical

snap switches to either stop the travel of the operator or

initiate the creep modes. The limit switch has 4 switches.

(a) LSO = Limit Switch Open

This limit shuts off the electric operator when the

door reaches the full open position.

(b) LSC = Limit Switch Close

This limit shuts off the operator when the door

has reaches the full closed position.

(c) LSCO = Limit Switch Creep Open

This limit activates the creep mode during the

end of open cycle. When the limit switch is

actuated the door travels in the open direction at

a reduced speed.

(d) LSCC = Limit Switch Creep Close

This limit activates the creep mode during the

closing cycle. When this limit switch is actuated

the door travels in the closed direction at a

reduced speed.

To adjust each individual limit switch, turn the screw

adjustment for each specific limit switch. Note that

depending upon the handing of the operator the cams

travel from either the clockwise or counterclockwise

direction to activate the appropriate snap switches.

(2) PREPARATION FOR ADJUSTMENT:

(a) Disconnect the Electrical Power Supply to the

Operator Control Box.

(b) Unscrew limit switch cover and expose assembly.

(3) ROUGH ADJUSTMENT:

(a) Manually slide the door in the open direction

and note the direction the LSO cam lobe is

traveling. Clockwise or counterclockwise?

(b) Manually slide the door to approximately 6" from

the full open position.

(c) Adjust the LSO cam adjuster until the cam

contacts the electrical snap switch from the

same direction and you hear it click.

(d) Manually slide the door towards the closed

direction and back towards the open direction.

The snap switch should click when the door gets

approx. 6" from the full open position.

(e) Position the door approx. 12" from the full open

position.

(f) Turn the LSCO cam adjusting screw until the cam

contacts the electrical snap switch from the same

direction as the LSO switch and you hear it click.

Note: This cam is longer and the operator shall

only travel in closed creep mode while this cam is

depressing the snap switch.

(g) Repeat Step (d). The LSCO the snap switch

should click when the door gets approx. 12" from

the full open position.

(h) Manually slide the door to approximately 6" from

the full closed position.

(i) Turn the LSC cam adjusting screw until the cam

contacts the electrical snap switch from

the opposite direction and you hear it click.

(j) Manually slide the door towards the open

direction and back towards the closed direction.

The snap switch should click when the door gets

approx. 6" from the full closed position.

(k) Position the door approx. 12" from the fully

closed position.

(l) Turn the LSCO cam adjusting screw until the cam

contacts the electrical snap switch from the same

direction as the LSC switch and you hear it click.

Note: This cam is longer and the operator shall

only travel in open creep mode while the cam is

depressing the snap switch.

(m) Repeat step (j) LSCO the snap switch should

click when the door gets approx. 12" from the full

open position.

(n) Move the door back and forth noting that the

proper snap switches are being contacted from

the proper direction at the proper time.

Crown Industrial Operators • 213 Michelle Ct. • So. San Francisco, Ca 94080-6202

Phone: (650) 952-5150 • Fax: (650) 873-1495

G-2001 3