8 — Troubleshooting

Notes

Rev 3-97

@ Crown

indicators you perform a visual inspection of your amplifier racks until you find

the point where one amplifier has its Data LED on and the next one in the loop

is not lit. When you find this point you have located the break.

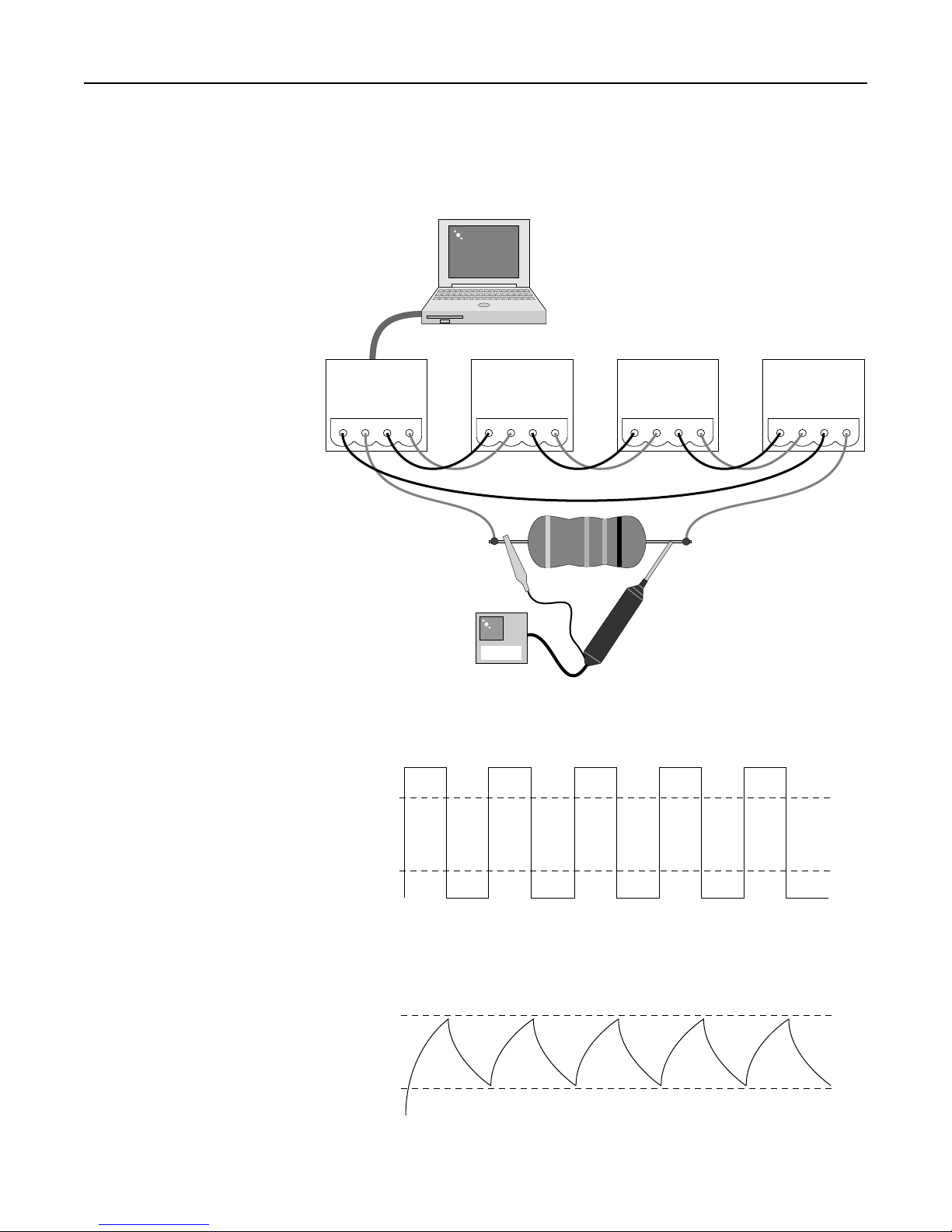

Expected Crown Bus Voltages

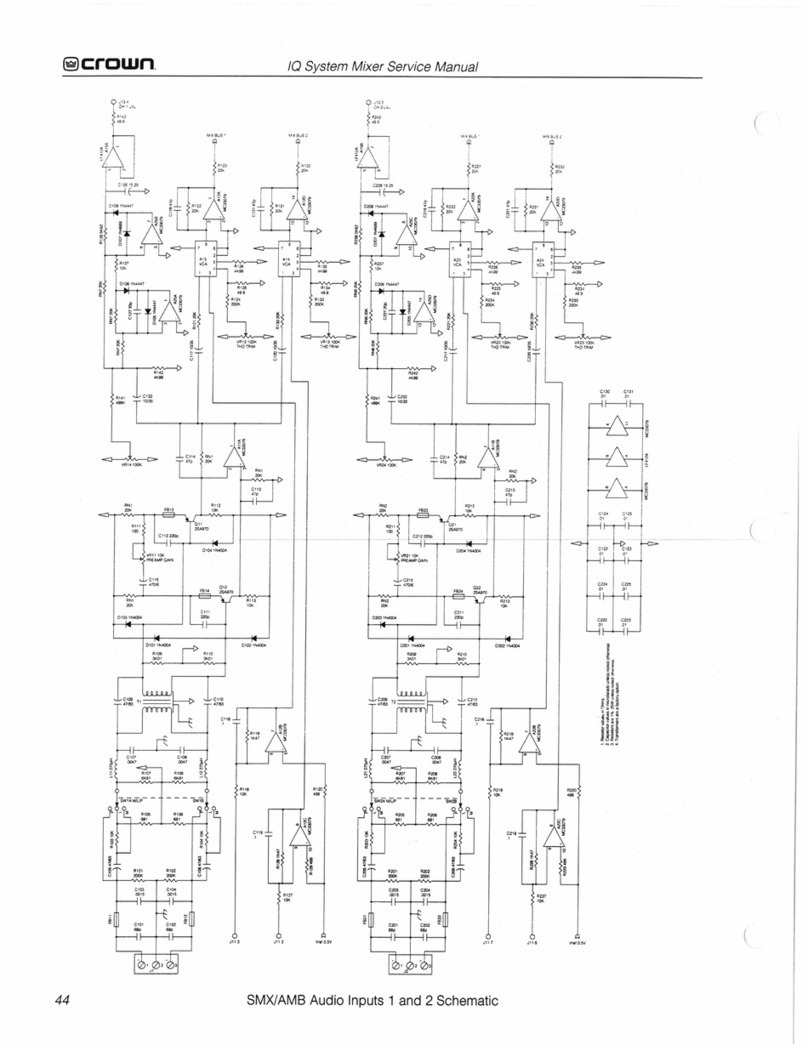

Another way of checking for a Crown Bus wiring problem is to use a DC voltage

meter and check the voltage across the positive and negative lines of the Crown

Bus cable. Figures 1 through 4 demon-

strate the various voltages you might see

under various loop wiring conditions.

If the cable is connected properly, as

shown in Figure 1, between two compo-

nents with good continuity,

proper polarity, and both of the

componentsarepoweredupand

operating you should expect to

see approximately 2.5 VDC

across the positive and negative

Crown Bus wires.

If polarity of the Crown Bus is

reversed you will see a voltage

drop corresponding to the drop

across a diode, or about 0.7

VDC. Figure 2 shows measure-

ments being taken at the point in

the loop where the cable is re-

versed.

If you have no voltage drop at all

the problem may be an open in

one of the wires between the

output of the upstream device

and the point of measurement

as shown in Figure 3. It could

alsobeashortbetween the posi-

tive and negative wires or a

shortedopto-isolatoratthedown-

stream input device, as shown in

Figure 4. Another possibility

would be the upstream device

may not be powered up. If cable

continuity is proven good and

the component is turned on and

plugged in the problem may be

a failure of the current driver

circuitry.

A high voltage condition (10 to

15 VDC) occurs when there is an

open between the point of mea-

surement and the downstream

input device, as shown in Figure

3. The open may be in the Crown

OUT IN

+–+–

SMX 1

OUT IN

+–+–

SMX 2

OUT IN

+–+–

SMX 3

OUT IN

+–+–

SMX 4

0.7 VDC

+

–

Loop polarity is reversed between SMX 2

and SMX 3. Break Detect reports "Break

Before SMX 2" because SMX 2 senses loss

of input continuity and sends break report

with component ID. Meter reads diode

voltage drop due to input optic isolator.

0.7 VDC

+

–

OUT IN

+–+–

SMX 1

OUT IN

+–+–

SMX 2

OUT IN

+–+–

SMX 3

OUT IN

+–+–

SMX 4

2.5 VDC

+

–

Loop is OK. Expected voltage is

approximately 2.5 VDC at each

input and output.

Figure 1. Loop Voltage Check

Figure 2. Loop Voltage Check With Cable Polarity Reversed