Cruisair SMXIIAB Owner's manual

SMX II Control Systems (DX)

English

❖

OWNER/OPERATOR

Revised: 1-17-05

L-2362

For Direct Expansion SMX II Control Systems using

SMXIIAB, SMXir or the new SMXht keypad/displays.

3❖❖

❖❖

❖English

L-2362

Table of Contents

SMX II Control Systems

• Introduction

Introduction ......................................................................... 4

SMX II Control Systems • Operation 5

The SMXIIAB & SMXir Keypad/Display .............................. 5

The SMXir Remote Control ................................................ 6

Basic Operation 7

Power On ............................................................................ 7

System Off .......................................................................... 7

Selecting Setpoint .............................................................. 7

Displaying Temperature ...................................................... 7

Cool Mode .......................................................................... 7

Heat Mode .......................................................................... 7

Automatic Switchover Mode ............................................... 7

Manual Fan Speed Control ................................................. 7

Automatic Fan Speed Control ............................................. 7

Adjusting Brightness ........................................................... 7

Using The Humidity Control Program ............................... 7

Anti-Ice Routine .................................................................. 8

Seawater Temperature ....................................................... 8

Programming the SMX II System 8

To Enter, Use and Exit the Programming Mode .................. 8

Compressor Time Delay ..................................................... 8

Fahrenheit/Celsius Display ................................................. 8

Compressor Restart Differential ......................................... 9

Fan Response Differential .................................................. 9

Low Fan Speed Adjustment ............................................... 9

High Fan Speed Adjustment ............................................... 9

Fan Mode ......................................................................... 10

AC Line Voltage Calibration .............................................. 10

Temperature Calibration ................................................... 10

Factory Memory Reset ..................................................... 10

Humidity Control Program 10

Programming the Dehumidification Time ......................... 11

Programming the Overall Time Period .............................. 11

Recommended Humidity Control Settings ........................ 11

SMXIIAB & SMXir Keypad/Display

Programming Summary Table ....................................... 12

Fault Shutdowns and Error Messages 12

Fault Codes ...................................................................... 12

High-Pressure Shutdown ................................................. 12

Low-Pressure Shutdown .................................................. 12

Low-Voltage Shutdown ..................................................... 13

Software Error .................................................................. 13

Determining Your Software

Version and Revision Level ............................................ 13

Initial Start Up 13

SMXht Keypad/Display Basic Operation &

Programmer's Guide 14

Basic Operation ................................................................ 14

Programming .................................................................... 14

Factory Memory Reset ..................................................... 15

Fault Code Displays.......................................................... 15

SMXht Keypad/Display Programming Summary Table ..... 15

SMX II Control Systems

• Troubleshooting

SMX II Quick Troubleshooting Guide ................................ 16

System Troubleshooting ................................................... 16

SMX II Control Systems

• Maintenance

Condensate Drains ........................................................... 17

Air Filters .......................................................................... 17

Seawater Connections ..................................................... 17

Seawater Pump ................................................................ 17

Seawater Strainer ............................................................. 17

Refrigerant Gas ................................................................ 17

Winterizing the System ..................................................... 17

Owner’s Warranty Periods 18

Limited Warranty Periods 20

Cruisair Worldwide Service Dealer Locator 21

Copyright 2004 Dometic Corporation, All Rights Reserved - Every precaution has been taken in the preparation of this manual to insure its accuracy. However, Dometic Corporation assumes

no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of this product and information contained herein.

4❖❖

❖❖

❖English

L-2362

Warning

This manual contains essential information concerning

the operation of your SMX II control system. It is very

important that you read and understand the contents of

this manual before using the equipment, and it should

be kept on the boat for future reference. If you have any

questions about the contents of this manual, contact

your local Cruisair dealer or the Dometic Service

Department for assistance.

Introduction

The term “SMX II” refers to the overall product family of

keypad/display controls and to the power/logic circuit board

located in the a/c unit’s electrical box. There are three

different keypad/displays that can operate an SMX II control

system.

The three different keypad/displays are:

•SMXIIAB (previously known as SMX II) - rectangular in

shape and larger than the other two, this was the standard

for many years. (See

The SMXIIAB & SMXir Keypad/

Display

section.)

•SMXir - newer and smaller than the SMXIIAB, this contol

has a hinged cover and an optional remote control. (See

The SMXIIAB & SMXir Keypad/Display

section.)

•SMXht - the newest “High Technology” keypad/display,

this European style control fits into a decorative bezel and

has many new features. (See

SMXht Keypad/Display

Basic Operation & Programmer’s Guide

section)

If you have the new SMXht, familiarize yourself in general

with the operation and programming sections of this manual,

but go to the SMXht Keypad/Display Basic Operation &

Programmer's Guide section for specific information on that

control.

If you have an SMX Net control system, refer to the SMX Net

Control Systems (DX) Installation and Operation manual.

SMX II Control Systems • Introduction

5❖❖

❖❖

❖English

L-2362 Operation

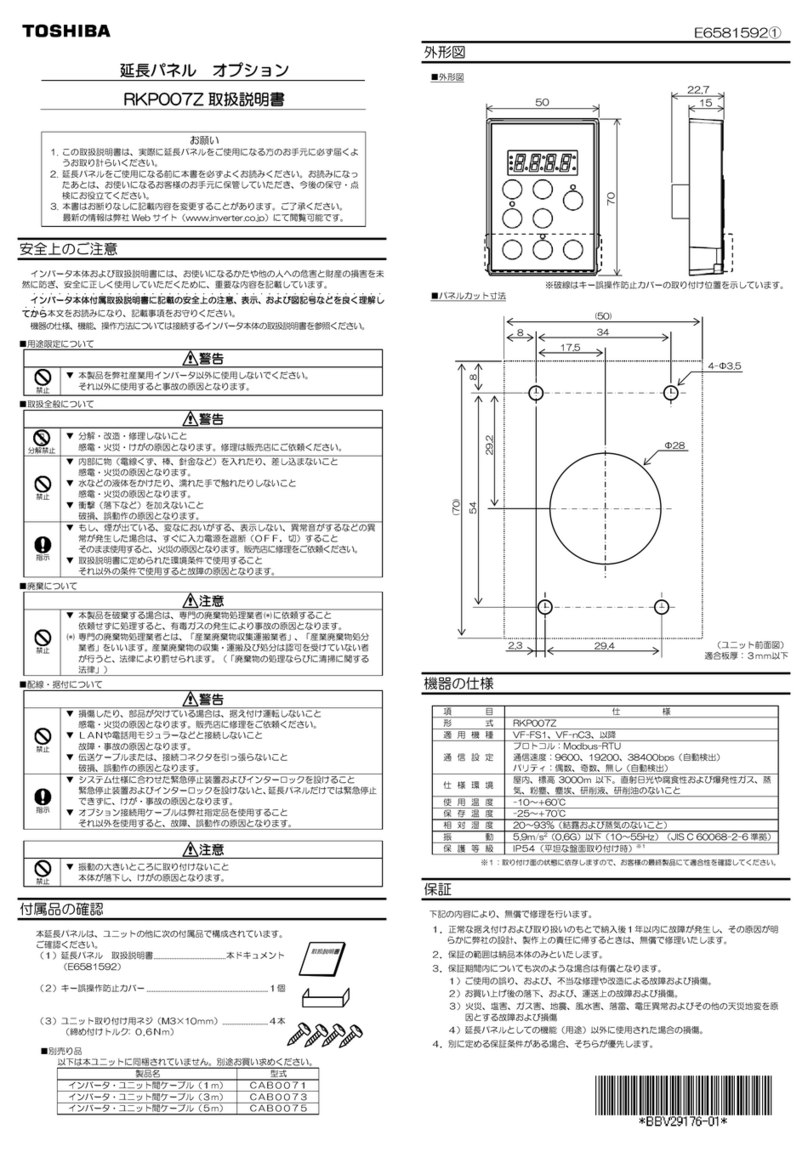

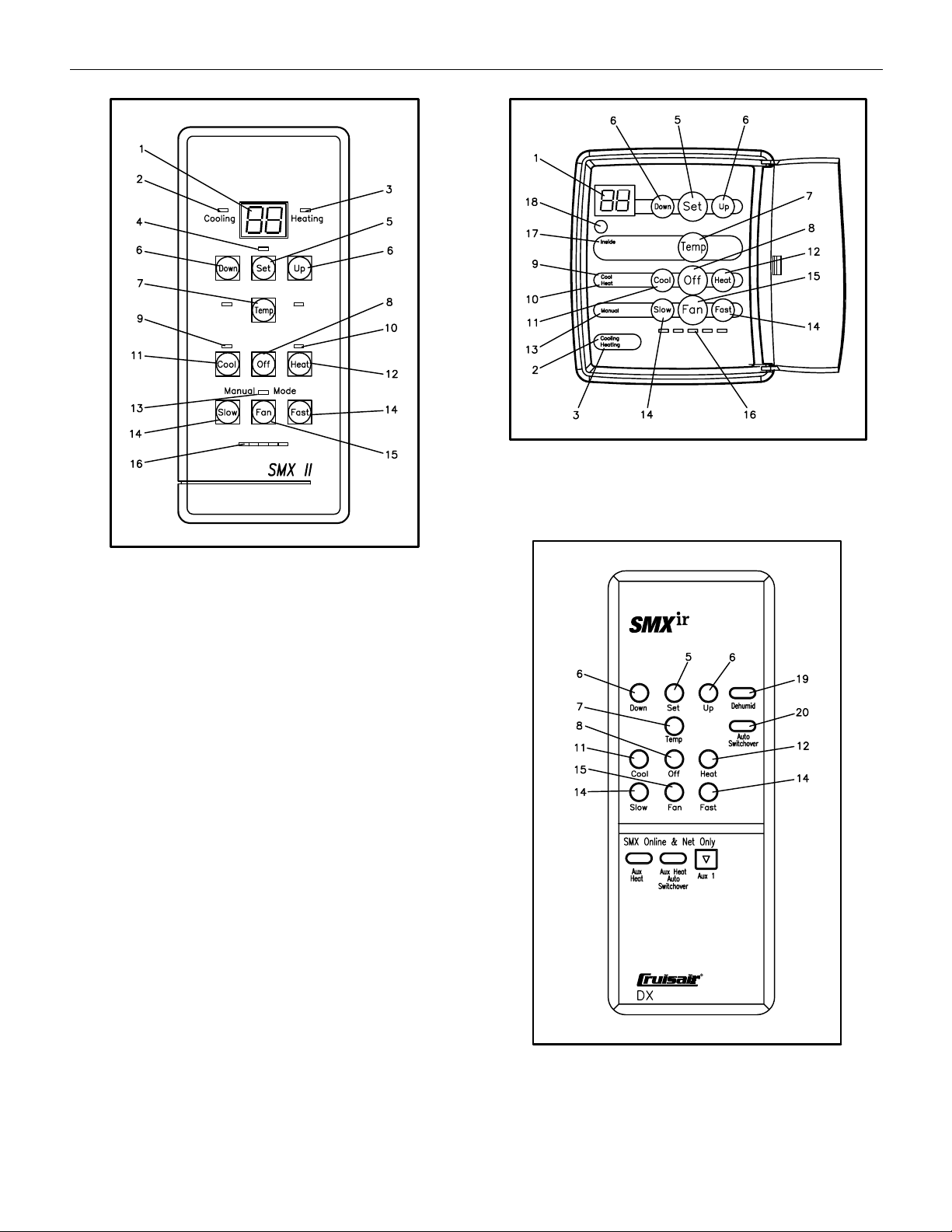

The SMXIIAB & SMXir Keypad/Display

The SMXIIAB and SMXir keypad/displays are designed for

user-friendly, logical operation. The button (or key) arrange-

ments on the SMXIIAB and the SMXir are similar, and these

keys perform the same respective functions. See next page

for keypad/display diagrams.

1. Data Display

Large LED readout which diplays the current setpoint,

temperatures, programmed values and error messages.

2. Cooling Indicator

Lights when compressor is running in Cool Mode.

3. Heating Indicator

Lights when compressor is running in Heat Mode.

4. Setpoint Indicator (SMXIIAB Display Only)

Lights when setpoint is displayed. Off when inside

temperature is displayed.

5. Set Key

Press the Set key to display your currently selected

setpoint (the temperature you wish to maintain in the

cabin). The Set key also is used to dim the Data Display.

6. Up and Down Keys

Press Up or Down to raise or lower the setpoint. Press

and hold keys for large changes. Note: if inside tempera-

ture is displayed, touching the Up or Down key will cause

the setpoint to be displayed.

7. Temp Key

Press once to display inside temperature. Press Temp

twice, and the display will alternate between inside

temperature and setpoint. Press again to return to inside

temperature only.

Hint

You can display temperature in degrees Fahrenheit or Celsius.

8. Off Key

Turns system off. Note that the Data Display remains on.

You can continue to adjust setpoint, display temperature

readings and activate the manual fan to circulate air

while the system is in the Off Mode.

9. Cool Mode Indicator

Lights when you press the Cool key to select the Cool

Mode.

10. Heat Mode Indicator

Lights when you press the Heat key to select the Heat

Mode.

11. Cool Key

Turns the system on in the Cool Mode.

12. Heat Key

Turns the system on in the Heat Mode.

Hint

Press both Heat and Cool at the same time, and the system

will automatically switch between Cooling and Heat Mode.

When in this Automatic Switchover Mode, both the Cool and

Heat indicators are lit.

13. Manual Fan Mode Indicator

Lights when fan is running in Manual Fan Mode.

14. Slow and Fast Keys

Control fan speed when the fan is in the Manual Fan

Mode. Pressing Slow or Fast key when in Automatic Fan

Mode will change the system into Manual Fan Mode.

15. Fan Key

Selects Manual or Automatic Fan Mode. Press once for

manual control. Press Fan again to select automatic fan

speed control. In this mode, the fan speed is controlled

by the microprocessor as a function of the difference

between setpoint and inside temperature. See the Fan

Response Differential programming section.

16. Fan Speed Indicators

Row of five small LEDs below Fan key that indicate the

current fan speed.

17. Inside Temperature Indicator (SMXir Display Only)

When illuminated, inside temperature is displayed. When

light is off, setpoint is displayed.

18. IR Receiver (SMXir Display Only)

Infrared remote receiver.

19. Dehumid Key (Remote Control Only)

Changes system into the Humidity Control Program.

20. Auto Switchover Key (Remote Control Only)

Places the system into Automatic Switchover Mode, so it

will change from cooling to heating as needed.

Definitions

LED - Light Emitting Diode. An indicator light used to denote

mode or operating status.

Setpoint - The desired room temperture that is set by pro-

gramming the SMX control.

IR - Infrared

SMX II Control Systems • Operation

6❖❖

❖❖

❖English

L-2362 Operation

SMXIIAB Keypad/Display

SMXir Keypad/Display

SMXir Remote Control

The SMXir Remote Control

The SMXir remote control keypad has the familiar layout of

the ten button SMX keypad, and performs most of the same

functions. The remote cannot be used to change program

settings. Programming must be done at the keypad/display.

In addition to the standard keys, the SMXir remote also has

two one-touch buttons that allow easy access to the humidity

control program and the Automatic Switchover Mode.

The remote has three buttons that are not used on SMX II

systems. The Aux Heat, Aux Heat Auto Switchover, and the

Aux 1 buttons are for SMX Net systems only.

The SMXir remote control must be pointed at the SMXir

keypad/display, which has the IR remote receiver. The

remote will not work if the SMXir keypad/display has the

optional full coverage door and the door is closed.

7❖❖

❖❖

❖English

L-2362 Operation

Basic Operation

Power On

When AC power is applied to the system at the circuit

breaker, the SMX II microprocessor performs a self-check

and retrieves the last operating configuration from perma-

nent memory. This process takes about four seconds, after

which the system will begin operating just as it had been

when power was last turned off.

System Off

Press the Off key to turn the system off. Note that the Data

Display remains energized even when the system is off. The

fan can be turned on manually when the system is in the Off

Mode.

Note

The SMX II has built-in protection against sudden power in-

terruptions. The system automatically stores the current op-

erating configuration in permanent memory every time any

changes are made. (The new operation mode must be in

affect for 30 seconds before it is saved into permanent

memory.) When AC power is lost, the SMX II system retains

these settings, and when AC power is restored it resumes

operation using the same settings as before.

Selecting Setpoint

Press the Set key and the current setpoint will be displayed.

Press the Up or Down key to change the setpoint.

Displaying Temperature

To display cabin temperature, press the Temp key. Press Temp

twice for an alternating display of inside temperature and

setpoint. Press again to return to inside temperature only.

Cool Mode

Press the Cool key to select Cool Mode. The Cooling Indicator

will light to show that you have selected the Cool Mode.

The Cooling Indicator will be lit whenever the system is in the

Cool Mode and the compressor is running. When the

compressor cycles off, the Cooling Indicator turns off, but the

Cool Mode Indicator remains on.

Heat Mode

Press the Heat key to select Heat Mode. The Heating

Indicator will light to show that you have selected the Heat

Mode.

The Heating Indicator will be lit whenever the system is in the

Heat Mode and the compressor is running. When the

compressor cycles off, the Heating Indicator turns off, but the

Heat Mode Indicator remains on.

Automatic Switchover Mode

Press the Cool and Heat keys simultaneously for Automatic

Switchover between Cool and Heat Modes. Both Cooling

and Heating Indicators will light when the system is in the

Automatic Switchover Mode.

For the SMXir Remote Control only - Press the Auto

Switchover key to enter Automatic Switchover Mode.

Note that the Cooling or Heating Indicator will come on when

the compressor is running to show that the system is running

in the Cool or Heat Mode.

Manual Fan Speed Control

Press the Fan key to select Manual Fan Mode. The Manual

Fan Mode Indicator will light to show that it is in the Manual

Fan Mode. Then use the Slow and Fast keys to select the

desired fan speed.

Note that you can use manual fan control to circulate air

even when the system is in the Off Mode.

Automatic Fan Speed Control

Press the Fan key until the Manual Fan Indicator turns off.

The system is now in Automatic Fan Mode. As the cabin

temperture deviates from the setpoint temperture, the

system will automatically adjust the fan speed. The fan will

increase speed as the difference between the two tempera-

tures increases, and slow down as the cabin temperature

approaches setpoint. Once setpoint is achieved, the com-

pressor cycles off and the fan continues running on low

speed. See the Fan Response Differential programming

section.

Adjusting Brightness

Pressing the Set key repetitively will dim the LED display.

Keep pressing Set to return to full brightness.

Using The Humidity Control Program

When activated, the Humidity Control Program automatically

turns the air conditioning system on at timed intervals to

remove moisture from the air. The system is programmed at

the factory for average values. To change the factory

settings, see the Humidity Control Program section.

To start the Humidity Control Program:

• Press Off.

• Press Cool, Heat and Fan keys simultaneously.

For the SMXir Remote Control only

- Press the

“Dehumid” key to enter Humidity Control Program.

• The Data Display will flash “HU”, indicating that the

program is active.

• To halt the program, press any key. The “HU” message

will stop flashing.

8❖❖

❖❖

❖English

L-2362 Operation

Safety Note

Whenever the system is in the Humidity Control Program, all

of the system safeguard controls remain active. For example,

if the seawater flow fails or if line voltage falls below preset

limits, the system will automatically shut down. Or, if AC

power is interrupted, the system will automatically resume

operation in the Humidity Control Program when power is

restored.

Anti-Ice Routine

The SMX II control will occasionally shut down the compres-

sor in the Cool Mode to allow any ice that may have formed

on the evaporator coil to melt. The Anti-Ice Routine shutdown

will occur only when the inside cabin temperature falls below

70°F (21°C).

During the ten minute cycle period, the compressor will shut

off for 15 seconds for each degree below 70°F. For example,

if the inside temperature is 67°F, the compressor will shut off

for 45 seconds, and then run for nine minutes and 15

seconds, repeating on ten minute intervals.

Seawater Temperature

The basic principle behind an air conditioner is the move-

ment of heat. In an air conditioner, heat is removed from the

inside cabin air and transfered to the seawater. In reverse-

cycle heating, the refrigerant flow is reversed and heat is

extracted from the seawater and discharged into the living

space. The efficiency of the system operation depends on

both seawater and cabin temperatures.

In Cool Mode, the air conditioner will operate most efficiently

in seawater temperatures below 90°F (32°C). At higher

seawater temperatures, the unit will operate, but at a

reduced capacity. A high-pressure shutdown may occur at

higher seawater temperatures.

In Heat Mode, the opposite is true. As the seawater gets

colder, there is less heat available, and the heating efficiency

is reduced. Full heating capacity is obtained at approximately

55°F (13°C) seawater temperature. Performance drops to

about 50% of rated capacity in 40°F (4.4°C) water. Below

this, the system pressure can be so low that the unit will shut

down on low-pressure fault. This problem is compounded

when the cabin is also cold. See the Fault Shutdowns and

Error Messages section.

Warning

Do not operate your air conditioning unit in water that is

colder than 38°F (3.3°C). Doing so could lead to water

freezing in the condenser coil which can cause damage

to the unit.

Programming the SMX II System

SMX II control systems are programmed at the factory for

average values. Some of the programmable functions may

need to be adjusted to suit each individual application and

the operator’s personal preferences. (The SMXir Remote

Control can not be used to program the system.)

To Enter, Use and Exit the Programming Mode

• To enter the Programming Mode: Press Off, then press

Set. Successful entry into the Programming Mode is

indicated by the presence of a decimal point to the right of

the two displayed characters.

• See the following table and each individual program for

specific instructions on using each programmable

function. Press the keys indicated to select that particular

function.

• Once a programmable function has been selected, then

use the Up and Down keys to raise, lower or change its

setting.

• Press Off to exit the Programming Mode.

Compressor Time Delay

(Factory Default: 0 seconds)

This function is used when there is more than one unit on

the boat. To prevent electrical overload due to multiple

compressors starting simultaneously when turning on power

to the system, or when power is interrupted, each SMX II unit

should be programmed with a different Compressor Time

Delay.

Time delay can be set in one-second increments. On older

systems (before 8/98) the time delay is set in ten-second

increments, up to 70 seconds.

• Upon entering the Programming Mode, press the Down,

Set and Up keys simultaneously. The delay in seconds will

be displayed.

At initial power-up, you will see the countdown for each

compressor on the Data Display, if you are in the Temp

Mode. The countdown will not appear in the Set Mode.

Fahrenheit/Celsius Display

(Factory Default: Fahrenheit)

Temperature can be displayed in degrees Fahrenheit or

Celsius.

• Upon entering the Programming Mode, press the Down,

Temp and Up keys simultaneously.

Note

If you switch from Fahrenheit to Celsius for temperature dis-

plays, the Compressor Restart Differential will also operate

on degrees Celsius. Thus, the factory set Compressor Re-

start Differential will be 1.5° Celsius, which is too much. To

correct this, reset the differential value from 12 to 6. This will

provide a differential of 0.75° C, or about 1.4° F.

9❖❖

❖❖

❖English

L-2362 Operation

This will also affect the Fan Response Differential, which is

factory set at a value of 4, or 0.5° Fahrenheit. When chang-

ing from Fahrenheit to Celsius, you should reset the Fan Re-

sponse Differential from 4 to 2. This will provide a fan

differential of 0.25° C, or about 0.5° F.

Compressor Restart Differential

(Factory Default: 12 = 1.5°)

The Compressor Restart Differential is the temperature

change needed for the compressor to cycle on and off. The

factory setting of 1.5° Fahrenheit should be adequate for

most applications. Differential selections are available in

increments of 1/8°. Thus, to change the setting one degree,

you should add or subtract 8 (for 8-eighths). If the tempera-

ture display is changed from Fahrenheit to Celsius, then the

default should be changed from 12 to 6, which is about 0.75°

Celsius.

• Upon entering the Programming Mode, press the Slow

and Fan keys simultaneously. The Compressor Restart

Differential will be displayed.

Hint

Be careful not to set your compressor restart differential too

low, since it will cause the compressor to start and stop quite

often. This will place an undue load on your electrical system

and may shorten the life of the compressor.

Fan Response Differential

(Factory Default: 4 = 0.5°)

When the fan is in the Automatic Fan Mode, its speed is

governed by how much the room temperature differs from

the setpoint. The fan runs faster when the difference is

greater. As the room cools or warms, and the temperature

approaches setpoint, the fan slows down automatically. The

Fan Response Differential can be adjusted from 1/4° to 4°, in

1/8° increments. If the temperature display is changed from

Fahrenheit to Celsius, then the default should be changed

from 4 to 2, which is about 0.25° Celsius.

The fan speed range is divided by the SMX II microproces-

sor into five equal increments. If the Fan Response Differen-

tial is set at 1/2°, then the fan speed will change 20% for

each 1/2° of temperature deviation from setpoint. Lowering

the fan speed differential will cause the fan to change speed

more frequently as temperature changes. Raising the fan

speed differential will result in slower fan speed changes for

a given temperature change. The factory setting of 1/2°

Fahrenheit is good for most applications, but you may wish to

try a slightly higher setting in your salon and a lower setting

in your stateroom.

• Upon entering the Programming Mode, press the Cool

and Slow keys simultaneously. The differential will be

displayed in increments of 1/8°.

Note

If the Compressor Restart and the Fan Response Differentials

are both set to the factroy default, or a comparable range, and

the Automatic Fan Mode is on, then the fan will not run at high

speed unless the cabin temperature rises 2.5° Fahrenheit

above setpoint.

Note

On SMX II systems built before 8/98, press Slow, Fan and Fast

simultaneously to adjust Fan Response Differential.

Low Fan Speed Adjustment

(Factory Default: 38)

You can adjust the lowest fan speed to suit individual

preferences. For instance, you may wish to decrease the low

fan speed setting in your stateroom to minimize fan noise.

• Upon entering the Programming Mode, press the Down

and Set keys simultaneously. The current low speed

reference number will be displayed (factory set

at 38).

Hint

You should normally keep the low fan speed at the highest

possible setting, consistent with a comfortable noise level, for

most efficient operation of your system. Running the fan

speed too slow may have an adverse affect on the system

and may cause the evaporator coil to freeze.

High Fan Speed Adjustment

(Factory Default: 60)

A blower will often reach its highest speed at a voltage lower

than full line voltage. For example, at a line voltage of 120V,

the blower might reach its fastest speed at 110V. At higher

voltages, the bower speed will not increase significantly.

The High Fan Speed Adjustment allows you to set the

maximum high speed voltage to the threshold of the blower

high-speed response. SMX II devides the fan speed voltage

steps into five equal increments (between the low speed and

high speed adjustments). Accurately setting the High and

Low Fan Speed Adjustments can help ensure that each fan

speed increment step results in a noticeable change of fan

speed.

• Upon entering the Programming Mode, press the Set and

Slow keys simultaneously. The current high-speed

reference number will be displayed (factory default is 60).

• While listening to the fan noise level, use the Up key to

raise the displayed value past the point that you can hear

an increase in the fan noise level.

• Press the Down key to lower the voltage until you hear a

drop in fan speed, then raise that number up by 2 or 3 to

ensure that it is set at the highest speed.

10 ❖❖

❖❖

❖English

L-2362 Operation

Fan Mode

(Factory Default: Continuous)

You can select continuous or intermittent fan operation.

Select “C” and the fan will run continuously while the system

is on. Select “I” for intermittent operation and the fan will

cycle on and off with the compressor.

• Upon entering the Programming Mode, press the Down,

Fan and Up keys simultaneously.

Hint

If you select intermittent fan operation, you should relocate the

thermistor from the return air grill to a cabin wall where it can

best sense the average room temperature. Check with your

dealer or call the Cruisair Applications Department for more

information.

AC Line Voltage Calibration

The SMX II control assembly has a built-in voltmeter that

senses AC line voltage. The microprocessor automatically

responds to sustained low-voltage conditions by shutting

down the air conditioning system to prevent compressor

damage. At installation, the SMX II voltmeter should be

calibrated to line voltage within +/- 1%. To check or re-

calibrate AC line voltage:

• Upon entering the Programming Mode, press the Down

and Up keys simultaneously. Line voltage will be displayed

in as the last two digits of the voltage. On 115V systems,

95V appears as “95”, 100V as “00”, and 120V as “20”. On

230V systems the last two digits of 1/2 of line voltage will

be displayed, therefore, 190V will appear as “95”, 200V as

“00”, and 230V as “15”.

• To check accuracy or to calibrate, turn off all on-board AC

loads and measure the line voltage with an accurate

voltmeter.

Temperature Calibration

The temperature sensor should be within one or two degrees

of actual room temperature. To check or re-calibrate the

sensor:

• Upon entering the Programming Mode, press the Set and

Up keys simultaneously. The sensed temperature will be

displayed.

• Place an accurate thermometer beside the sensor and

compare the temperatures.

Factory Memory Reset

Use Factory Memory Reset to restore all programmed

functions to the factory default settings.

To restore programmed functions to the default factory

settings:

• Press the Off, Set and Fan keys simultaneously.

• Press the Set key.

• After a delay, the memory will be reset from stored values.

After another delay, the display will come back on nor-

mally.

Humidity Control Program

The Humidity Control Program automatically operates the air

conditioning system for a programmed time period to help

control humidity in the boat. This dehumidification feature

works in three stages:

1) The fan comes on at high speed to circulate air for ten

minutes.

2) The fan then drops to low speed, and the compressor

cycles on in the Cool Mode to dehumidify.

3) After the dehumidification cycle, the system turns off. The

process repeats according to the programmed time period.

The compressor time delay setting will govern when the

dehumidification cycle starts. Every one-second of compres-

sor delay equals a six-minute advance into the dehumidifica-

tion cycle.

The factory default settings are:

Precirculation cycle ......................... 10 min.

Dehumidification cycle .................... 30 min.

Overall time period ........................... 12 hours

The factory settings are adequate for most moderate

climates and boats. For very humid climates, shorten the

overall time period and extend the dehumidification time. In

dry climates, select longer a overall time period between

cycles and a shorter dehumidification time. The

precirculation cycle time should not be changed.

11 ❖❖

❖❖

❖English

L-2362 Operation

Programming the Dehumidification Time

(Factory Default: 30 minutes)

The dehumidification time determines how long the com-

pressor runs in the Dehumidification Mode. You can select

10, 20, 30, 40, 50 or 60 minutes. Select a longer dehumidifi-

cation time in climates with high humidity.

• Upon entering the Programming Mode, press the Temp

and Set keys simultaneously. The display will show the

dehumidification time period in minutes.

Programming the Overall Time Period

Factory Default: 12 hours)

The overall time period determines how often the system

performs the dehumidification process. You can select

intervals of 2, 4, 6, 8, 10, 12, 14 or 16 hours. Chose a shorter

time period in climates with high humidity.

• Upon entering the Programming Mode, press the Temp

and Up keys simultaneously. The display will show the

overall time period in hours.

Recommended Humidity Control Settings

12 ❖❖

❖❖

❖English

L-2362 Operation

Fault Code Meaning Result

LO / AC Operating voltage remained Shutdown

(or 200V) below 100V for three minutes

for 230V system)

HI / PS* Head pressure above 425 PSI Shutdown

LO / PS* Suction Pressure below 30 PSI Shutdown

PE Program error in software Shutdown

* Note: The “PS” in the high-pressure and low-pressure

fault warning should not be confused as “P5” on the SMX II

LED Data Display.

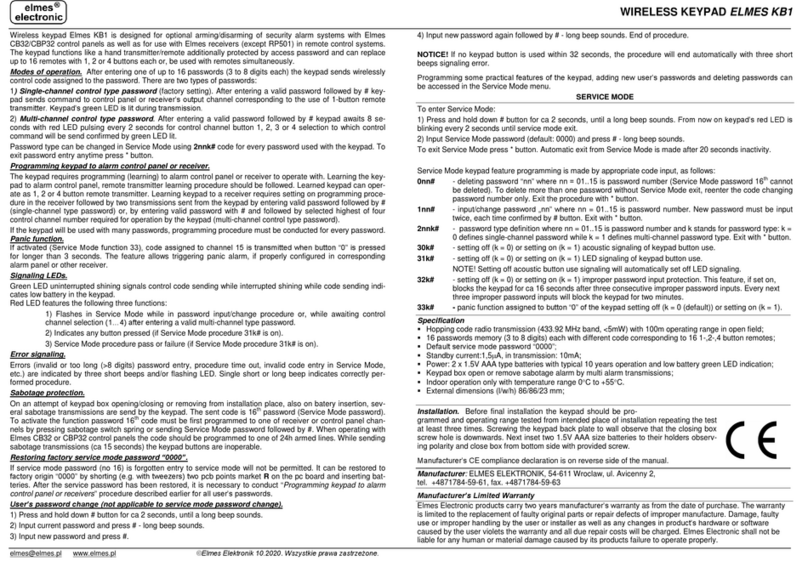

SMXIIAB & SMXir Keypad/Display Programming Summary Table

Fault Shutdowns and Error Messages

The SMX II control contains built-in safeguards designed to

protect your air conditioning system. These are described

below.

Hint

Your system must be equipped with a high-pressure switch

and low-pressure switch for the high- and low-pressure shut-

down to operate. You should check with your dealer to make

sure these important protective devices are installed properly.

Fault Codes

If an operational failure occurs, the display will flash one of

the following fault code messages. Fault code displays are

cancelled by pressing the Off key.

High-Pressure Shutdown

In the Cool Mode, if head pressure rises above 400-425 PSI

(28-30 kg/cm

2

) (usually caused by loss of cooling water flow,

refrigerant gas overcharge or a fouled condenser) the SMX II

will attempt three restarts, then shut down the entire system.

The display will alternately flash “HI/PS”. This is a sustained

shutdown, and even when the pressure lowers after shut-

down, the system will remain off until reset by pressing the

Off key.

In the Heat Mode, a rise in head pressure above the set limit

(usually caused by poor airflow or incorrect charge) will

cause the compressor to cycle off for two minutes, allowing

the heat in the coil to dissipate. This prepares the system for

recycling in the Heat Mode. The compressor will then

continue to cycle, based on input from the high-pressure

switch, until the cabin temperature reaches setpoint, after

which compressor cycling is automatically restored to normal

operation.

Low-Pressure Shutdown

When installed, the optional low-pressure switch is moni-

tored by the SMX II control. The low-pressure switch opens

when the suction pressure drops below 30 PSI (2.11 kg/

cm

2

), and resets at 45 PSI (3.16 kg/cm

2

). The low-pressure

fault routine operates differently in the Cool and Heat Modes.

Cool Mode:

When the low-pressure switch first opens, the unit will run for

two minutes, then shut down for 50 seconds. It will do this

four times. If the switch has not closed, the unit will shut

Programmable Function Keystroke Combination Factory Setting Range

Compressor Time Delay Down & Set & Up 0 0 to 70 sec.

Fahrenheit/Celsius Display Down & Temp & Up F F or C

Compressor Restart Differential Slow & Fan 12 4 to 24

Fan Response Differential Cool & Slow 4 2 to 8

(Slow & Fan & Fast Before 8/98)

Low Fan Speed Adjustment Down & Set 38 2 to 57

High Fan Speed Adjustment Set & Slow 60 41 to 99

Fan Mode Down & Fan & Up C C or I

AC Line Voltage Calibration Down & Up - ± 1%

Temperature Calibration Set & Up - ± 1%

Factory Memory Reset Off & Set & Fan, then Set

HU Precirculation Temp & Down 10 Min. 10 Min.

HU Dehumidification Temp & Set 30 Min.

HU Overall Time Period Temp & Up 12 Hrs.

See Humidity

Control Program

Note: See the SMXht section for progamming that keypad/display.

13 ❖❖

❖❖

❖English

L-2362 Operation

Likewise, the self-diagnostic routine runs continuously

whenever the SMX II system is on. If a system fault is

detected, the system shuts down, and the “PE” error

message appears.

If this message occurs, contact your nearest Cruisair dealer,

or call the Factory Service Department for assistance.

Please read the next paragraph before calling.

Determining Your Software

Version and Revision Level

Prior to calling a dealer or the factory for service assistance,

it’s helpful to know the software version and revision level for

the SMX II system. To display this information:

• Press Off, then Set.

• Then press the Cool and Down keys simultaneously. The

display will show the version number.

• Press Up once. The display will show the revision level

number.

down for 15 minutes, and alternately flash “LO/PS” on the

display. After 15 minutes of shut down, the cycle stats again

in which the unit runs for two minutes and then shuts down

for 50 seconds.

If, after 18 attempted compressor starts, the low-pressure

switch does not stay closed, the unit will go into a sustained

shutdown and flash “LO/PS”.

If the low-pressure switch closes at any time before the

sustained shutdown, the unit will then operate normally.

Heat Mode:

If the low-pressure switch opens, the fan will automatically

change to low speed to try and raise system pressure. It will run

for 11 minutes in this mode. Note that the fan speed can not be

adjusted at this time. Any attempt to raise fan speed will result in

“LO/PS” being flashed, while the unit continues to run.

After 11 minutes, the unit will run for two minutes, then shut

down for 50 seconds. It will do this four times. If the switch

has not closed, the unit will shut down for 15 minutes, and

flash “LO/PS” on the display. After 15 minutes of shut down,

the cycle stats again in which the unit runs for two minutes

and then shuts down for 50 seconds.

If, after 18 attempted compressor starts, the low-pressure

switch does not stay closed, the unit will go into a sustained

shutdown and flash “LO/PS”.

If the low-pressure switch closes at any time before the

sustained shutdown, the unit will then operate normally.

Low-Voltage Shutdown

The low-voltage protection feature is always active. If AC line

voltage drops and remains below the limit, 100 volts for a

115V system or 200 volts for a 230V system, for more than

three minutes, the SMX II shuts down the entire system. The

display will flash “LO/AC”. This is a sustained shutdown, and

the system will not resume operation even if the line voltage

rises to normal levels. To reset, press the Off key.

Hint

For the low-voltage shutdown function to work properly, the

SMX internal voltmeter should be calibrated. This should be

done when the system is installed. To check or recalibrate

line voltage, see the AC Line Voltage Calibration section.

Software Error

Whenever power is applied to the SMX II, the microproces-

sor goes through an automatic self-check and software

loading process. If all is well, the SMX II loads the most

recent operating configuration from its internal memory, and

turns on normally. If a program fault is found during the self-

check, the error message “PE” (Program Error) will be

displayed.

Initial Start Up

The following instructions apply to both self-contained and

remote condensing systems.

1. Open the seacock (seawater inlet valve).

2. Turn on the circuit breaker for the air conditioner. If a

pump relay is installed, the breaker for the pump must

also be turned on.

3. Set the system for cooling or heating at the SMX II

keypad, and adjust temperature setting so the unit will

turn on.

4. Verify that water is flowing from the overboard discharge.

If more than one unit is installed, then check all such

discharges.

5. Allow unit to run for ten minutes at high fan speed.

Check the temperature differential between discharge

and return air by placing an accurate thermometer in

front of the discharge grill and then in front of the return

air grill.

In the Cool Mode, the difference between the discharge

and return should be 15 - 20°F (8.3 - 11.1°C), with

normal ambient air and water temperatures. In the Heat

Mode the differential can be as high as 25°F (13.9°C).

14 ❖❖

❖❖

❖English

L-2362 Operation

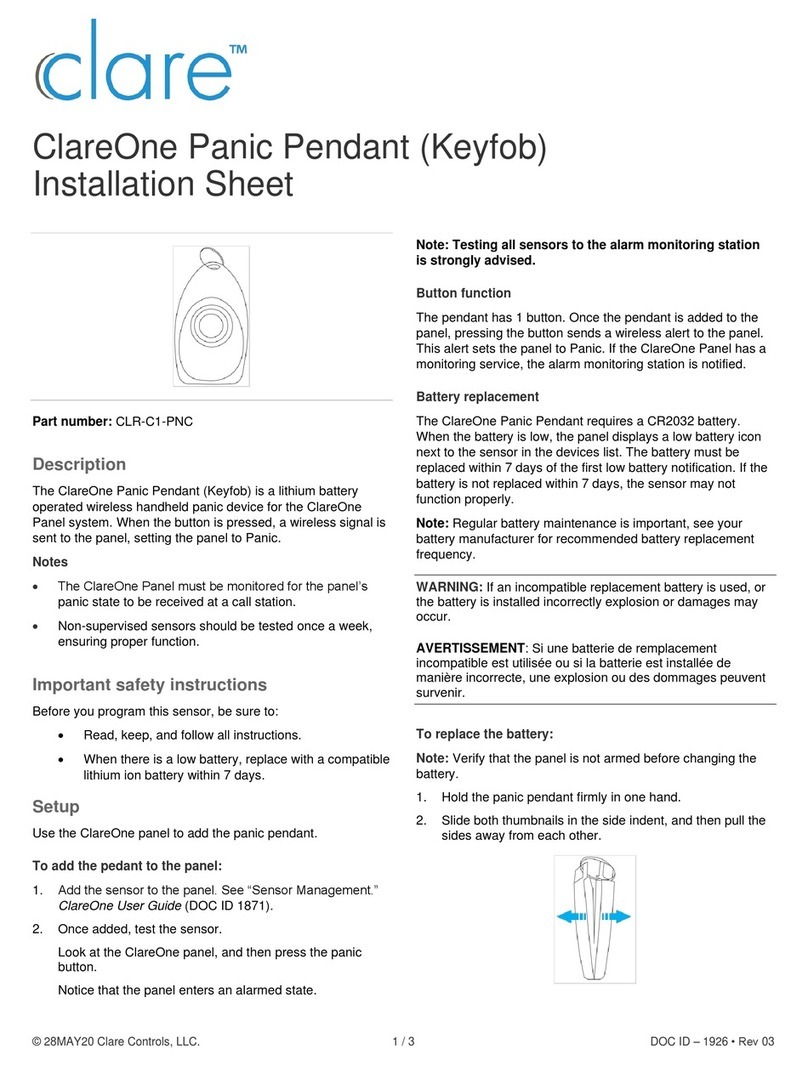

SMXht Keypad/Display Basic Operation

& Programmer's Guide

This section deals specifically with the new SMXht keypad/

display. Much of this keypad/display’s operation and

programming is similar to the older SMXIIAB & SMXir.

General operation and programming is covered in more

detail in the previous sections of this manual, and that

information should be reviewed prior to operating the new

SMXht. The following pages are specific to the new keypad/

display.

Basic Operation

Turning the System On:

Press the POWER or MODE keys to turn the system on. In

three seconds, the system will start operating in whatever

mode it was running prior to the last shut down. Press the

MODE key prior to three seconds (while the display is

flashing) to change mode before system starts, or any time

to change the mode while the system is on. The modes

available are: Cool, Heat Auto Switchover (automatically

switches from Cool to Heat Mode), or Dehumidification

Mode. A solid dot will light up next to the words COOL or

HEAT when the compressor is on and running in that mode.

Selecting the Setpoint:

Press the Up or Down Arrow keys to adjust the setpoint

(press and hold keys to scroll); wait three seconds after

powering up system. The word SET will appear in the display

while setpoint is being adjusted. The setpoint range is 55-

99°F (10-40°C). After selecting the desired setpoint tempera-

ture, if no buttons are pressed for three seconds, the display

will automatically revert back to showing the inside cabin

temperature. Inside cabin temperature is continuously

displayed.

Adjusting the Fan Speed:

The Fan key is used to adjust the fan speed while in Manual

Fan Speed Mode and to switch from Manual to Automatic

Fan Speed Modes. The fan may be run manually whether the

system is on or off. The word MANUAL appears in the

display while in that mode. Automatic Fan Speed Mode may

be operated only when the system is on. Fan behavior also

depends on how the Fan Mode function is programmed - “C”

for continuous or “I” for intermittent running with the compres-

sor (see

SMXht Keypad/Display Programming Summary

Table

).

Dimming the Display:

Press the MODE and Up Arrow keys simultaneously and

repeatedly to select the display brightness setting.

Backlight Mode:

While in the Sleep Mode (backlight is off, see function #20)

press any button to light the display, and then operate as

usual.

Important Memory Function:

After changing modes, programming settings, setpoint, etc.,

wait at least 30 seconds before turning off main power

supply in order for new settings to be maintained in memory.

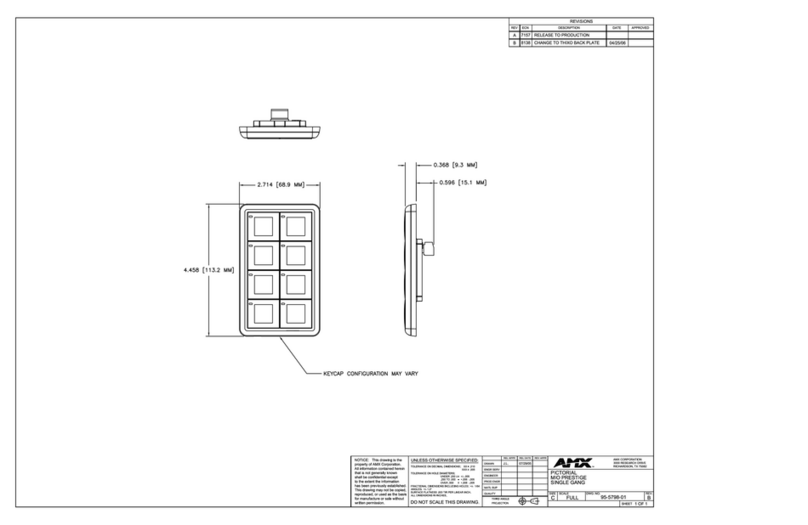

Programming

SMXht must be in the Off Mode prior to entering Program-

ming Mode; pressing the POWER key turns the display off or

on. Once in the Off Mode, then:

1. Simultaneously press and hold the MODE and Down

Arrow keys for three seconds. The word “PROG” will flash

in the display while the buttons are being held. Success-

ful entry into the Programming Mode is indicated when

the word “PROG” stops flashing, and a flashing “1”

appears in the display.

2. Use the Up or Down Arrow keys to scroll until the desired

program Function Number is displayed. (See

SMXht

Keypad/Display Programming Summary Table

.)

3. Press the MODE key to enter the desired function. The

current value and the word “PROG” will be displayed.

4. Use the Up or Down Arrow keys to change the value of

that program.

5. Press the POWER key to save the new settings, exit the

Programming Mode, and return to the Off Mode.

Note: If SMXht is programmed for displaying °C (rather than

the factory setting °F), then functions 3 & 4 should be

adjusted. For function 3, the factory setting of 12 (or 1.5°F)

should be changed to 7 (7/8 = 0.8°C). For function 4, the

factory setting of 4 (or 0.5°F) should be changed to 2 (2/8 =

0.3°C). For these functions, 1°F (or 8) = 0.6°C (or 5).

SMXht Keypad/Display (shown here with bezel, which is sold

separately).

15 ❖❖

❖❖

❖English

L-2362 Operation

Factory Memory Reset

To restore all programming functions to the Factory Setting,

first switch to Off Mode and then simultaneously press and

hold the POWER and MODE keys. Hold keys for three

seconds while “00” flashes in the display. Successful

memory reset is indicated by a “1” flashing back and forth

across the display; release keys. System returns to the Off

Mode.

NOTE: Performing a Factory Memory Reset will not change

the value of Function Numbers 21 & 22. Also note that

Function Number 2, which displays Fahrenheit or Celsius,

reverts back to °F each time.

Fault Code Displays

If an operational failure occurs, such as low voltage or high/

low pressure, a flashing fault code message will be dis-

played. Fault code displays are canceled by pressing the

POWER key. (See

Fault Code Summary Table

.)

SMXht Keypad/Display Programming Summary Table

Fault Code Summary Table

E

16 ❖❖

❖❖

❖English

L-2362 Troubleshooting

SMX II Quick Troubleshooting Guide

Problem: SMX display not on

Possible Solution:

1. Turn circuit breaker on

2. Check CX/CXP cable and connections

3. Replace keypad/display

4. Replace Power/Logic board

Problem: Erratic temperature display

Possible Solution:

1. Perform a Factory Memory Reset

2. Check temperature sensor, cable and connection

3. Ensure the temperature sensor is installed properly

4. Calibrate temperature

5. Replace Power/Logic board

Problem: Erratic system operation

Possible Solution:

1. Perform a Factory Memory Reset

2. Check CX/CXP cable and connections

3. Check temperature sensor, cable and connection

4. Replace keypad/display

5. Replace Power/Logic board

Warning

The Power/Logic board operates at 115VAC or 230VAC.

Make sure the power is off before removing the cover of

the Power/Logic box.

Contact an authorized Cruisair servicing dealer if the

problem continues, or for replacement parts.

System Troubleshooting

Before you call for service, review this list. It may save you

time and expense. This list contains common occurrences

that are not a result of defective workmanship or materials. If

you need service after trying these procedures, call your

nearest Cruisair dealer.

Situation

The unit will not operate at all.

Problem/Solution

1. Blown fuse or tripped circuit breaker. Replace fuse with

time delay type or reset breaker. Check for correct sizing.

2. Low voltage to unit. Check shore power supply and

rating of electrical power cord to boat.

SMX II Control Systems • Troubleshooting

Situation

Air from the unit does not feel cool in the Cool Mode or warm

in the Heat Mode.

Problem/Solution

1. The selector switch is set for Fan only. Switch the system

into the Cool or Heating Mode.

2. The thermostat is set incorrectly. Set the thermostat for a

cooler or warmer setting.

3. Water flow is restricted. Clear restriction. Clean strainer.

Situation

The unit operates but the cabin fails to cool normally.

Problem/Solution

1. Dirty air filter. Clean lint screen or air filter.

2. The thermostat is set too high. Reset the thermostat to a

cooler setting.

3. The evaporator coil has iced. Turn the system to Fan only

for five minutes, then restart.

Situation

Compressor cycles on and off.

Problem/Solution

1. Dirty air filter. Clean lint screen or air filter.

2. Water flow restriction. Clear restriction. Clean strainer.

Situation

Water dripping inside cabin.

Problem/Solution

1. Condensate drain is clogged. Clean out drain holes.

2. Blockage in hose. Clear hose. Check downhill routing of

hose.

17 ❖❖

❖❖

❖English

L-2362 Maintenance

Condensate Drains

At least once every three months, check the condensate drains

for obstructions by pouring a quart of water rapidly into the

condensate pan. If it does not drain completely within 30

seconds, check the drain outlets for clogging. Remember that

many air conditioning units have two drains and hoses, one at

each end of the drain pan.

Air Filters

At least once a month, check the lint screen or filter behind

the return air grill or on the face of the cooling/heating unit

and clean if necessary.

Seawater Connections

Verify that all seawater connections are tight, and check for

water flow from each unit’s overboard discharge.

Seawater Pump

If the seawater pump has a plastic pump head, then the

impeller is made of either plastic or rubber, and should be

inspected after 300 hours of operation. Replace the impeller

if it is worn. Whereas, if the pumps head is made of bronze,

then the impeller is too, and regular maintenance is not

needed as often.

Seawater Strainer

Check the seawater strainer daily. Remove any debris.

Refrigerant Gas

The refrigerant gas used in the air conditioning system is

adequate for the life of the system. Routine “seasonal”

charging of the system is not typically necessary.

Winterizing the System

Close the seacock and remove the inlet water hose from the

air conditioner. Allow all water to drain from the system.

Loosen the screws on the pump head to allow the water to

drain from the pump. Drain and clean the seawater strainer.

SMX II Control Systems • Maintenance

18 ❖❖

❖❖

❖English

L-2362

Owner’s Warranty Periods

As hereinafter described, Dometic Corporation limits the duration of any implied warranty to the duration of the underlying

express warranty and also disclaims any liability for consequential or incidental damages arising from any application,

installation, use or malfunction of any warranted product.

Section I

What does the Limited Warranty cover?

Products manufactured by Dometic Corporation (Dometic)

are under limited warranty to be free from defects in work-

manship or materials under normal use and service with the

obligation of Dometic under this limited warranty being

limited to replacing or repairing any component(s) which

shall disclose defects within the time limits defined in

Section III and which, upon examination by Dometic, shall

appear to the satisfaction of Dometic to be defective or not

up to specifications.

This Limited Warranty is made in lieu of all other express

warranties, obligations, or liabilities on the part of

Dometic. In addition, Dometic shall not be responsible

for any incidental or consequential damages.

In those

instances in which a cash refund is made, such refund shall

effect the cancellation of the contract of sale without reserva-

tion of rights on the part of the purchaser. Such refund shall

constitute full and final satisfaction of all claims which

purchaser has or may have against Dometic due to any

actual or alleged breach of warranty, either express or

implied, including, without limitation, any implied

warranty of merchantability or fitness for a particular

purpose. Some states do not allow the exclusion or limita-

tion of incidental or consequential damages so the above

limitation may not apply to you. The terms and conditions of

this warranty shall be governed by the laws of the Common-

wealth of Virginia.

The Dealer is not an agent for Dometic except for the

purpose of administering the above warranty to the extent

herein provided, and Dometic does not authorize the dealer

or any other person to assume for Dometic any liability in

connection with such warranty, or any liability or expense

incurred in the replacement or repair of its products other

than those expressly authorized herein. Dometic shall not be

responsible for any liability or expense except as is specifi-

cally authorized and provided in this section.

Dometic reserves the right to improve its products through

changes in design or material without being obligated to

incorporate such changes in products of prior manufacture,

and to make changes at any time in design, materials, or

part of units of any one year's model, without obligation or

liability to owners of units of the same year's model of prior

manufacture.

This warranty gives you, the purchaser, specific legal rights,

and you may also have other rights which vary from state to

state. You also have implied warranty rights, including an

implied warranty of merchantability, which means that your

product must be fit for the ordinary purposes for which such

goods are used.

The duration of any implied warranty

rights is limited to the duration of the express warranty

as found in Section III.

Some states do not allow limitations

on how long an implied warranty lasts, so the above limita-

tion may not apply to you.

Section II

What does this Limited Warranty not cover?

This Warranty Shall Not Apply to:

1. Failures resulting from improper installation or use

contrary to instructions.

2. Failures resulting from abuse, misuse, accident, fire, or

submergence.

3. Any part manufactured by Dometic which shall have

been altered so as to impair its original characteristics.

4. Any parts which fail as a result of misuse, improper

application or improper installation.

5. Items not manufactured by Dometic, i.e., items which are

purchased from another manufacturer and supplied as

received by Dometic without alteration or modification

except as any part of an Dometic-manufactured unit or

component.

6. Components or parts used by or applied by the pur-

chaser as an integral part of products not manufactured

by Dometic.

7. Warranty does not cover damage to components that

comprise a Custom Wrapped Box Evaporator refrigera-

tion system (aka: catch boxes, fish boxes, etc.) when the

box is installed in such a way that the customer can

move it. These damages may include, but are not limited

to: crimped refrigerant linesets (copper tubing or flexible

linesets), refrigerant leaks, moisture ingression into the

refrigeration system, subsequent damage to condensing

unit from being operated with low refrigerant charge or

moisture in the system, broken refrigerant connections,

broken thermostat sensors, and/or broken constant

pressure valves.

Installation and application of Dometic components is not

warranted by Dometic because Dometic has no control or

authority over the selection, location, application, or installa-

tion of these components.

Section III

What is the period of coverage?

See the Limited Warranty Periods, document # L-0694, for

the period of coverage.

19 ❖❖

❖❖

❖English

L-2362

L-0123 Revised: 10-16-03

All Dometic components bear a data plate on which there

are model and serial numbers. The serial number is date

coded. To determine whether or not any Dometic component

is in warranty, proceed as follows:

1. Determine the manufacture date of the component from

the serial number on the data plate. If you are not familiar

with the date code, write or call the Dometic Customer

Service Department at (804)746-1313, to obtain the

manufacture date. The hours of the Customer Service

Department are 8:00 am - 5:00 pm (USA, Eastern Time

Zone) Monday through Friday excluding holidays.

2. It is possible that there might exist a considerable time

lag between the date a component is manufactured and

the date it is put in service. In such instances, the date of

manufacture could indicate that the item is out of

warranty. However, based on the date the equipment is

first put in service, the item may still be covered by the

Dometic warranty described in Section I. For proof of

date put in service, Dometic will require a copy of the bill

of sale of the Dometic equipment from the installer or

new boat dealer to the original owner.

Section IV

How do you get service? Please Read the follow-

ing Warranty Procedure.

WARRANTY PROCEDURE

If the failure of a Dometic component is determined to be

covered under the Dometic warranty and the time in service

is determined to be within the warranty time limit, the owner

has the following three options:

1. Preferred option: Have a Dometic authorized Servicing

Dealer perform the work needed. The customer should

call Dometic's Service Department for a recommenda-

tion as to the closest dealer. If the customer already

knows an authorized servicing dealer, the dealer should

be contacted directly.

2. If the customer contacts Dometic's Service Department

for a Servicing Dealer and Dometic has no one in that

particular area, Dometic will authorize the use of a local

service company and Dometic will work with the local

company to assist in any way possible.

3. The customer may send his equipment back to the

factory to have the repair work done. Dometic will make

every effort to return the equipment to the customer

within a three week time period. If the claim represents a

legitimate warranty problem, Dometic will pay the freight

both ways. Dometic prefers option one and two, if at all

possible.

The customer may contact the Dometic Service Department

at (804) 746-1313.

WARNING

Dometic Corporation (Dometic) manufacturers of Cruisair, Grunert, Marine Air,

Sentry and Tundra Products, makes the following safety warnings concerning the

application, installation, use and care of its products. Although these warnings are

extensive, there may be specific hazards which may arise out of circumstances

which we have not outlined herein. Use this as a guide for developing an

awareness of potential hazards of all kinds. Such an awareness will be a key

factor in assuring your SAFETY and comfort.

ELECTRICITY - Many Dometic products operate on 115, 230 or 440 volt AC

power. Such voltages can be LETHAL; therefore, the chassis, cabinets, bases,

etc., on all components must be grounded together and connected to the vessel's

grounding system. Sparks can occur as switches, thermostats and relays open

and close in the normal operation of the equipment. Since this is the case,

ventilating blowers for the removal of hazardous fumes or vapors should be

operated at least 5 minutes before and during operation of any Dometic product or

group of Dometic products. All electrical connections must be covered and

protected so accidental contact cannot be made by persons using the equipment,

as such contact could be LETHAL.

ELECTROLYSIS - Electrical leakage of any component can cause electrolytic

deterioration (electrolysis) of thru-hull components which could result in leakage

serious enough to sink a vessel which could result in loss of life. All Dometic

components must be kept clean and dry and checked periodically for electrical

leakage. If any electrical leakage is detected, the component should be replaced

or the fault causing the leakage corrected before the component is put back into

service.

GAS - CRUISAIR, MARINE AIR, GRUNERT and TUNDRA components utilize R-22

(Chlorodifluoromethane), R134a refrigerant (Tetrafluoroethane), R-407C (which

contains Diflouromethane (HFC-32), Pentafluoroethane (HFC125), and 1.1.1.2 -

Tetrafluoroethane (HFC134a)), R404A (R125/R143a/R134 (44%/52%/4%)), or

R417a, which are non-toxic, non-flammable gases; however, these gases contain

no oxygen and will not support life. Refrigerant gas tends to settle in the lowest

areas of the compartment. If you experience a leak, evacuate all personnel, and

ventilate area. Do not allow open flames in the area of leaks because refrigerant

gas, when burned, decomposes into other potentially LETHAL gases. Refrigerant

components operate at high pressure and no servicing should be attempted

without gloves, long-sleeved clothing and eye protection. Liquid refrigerant gas

can cause severe frost burns to the skin and eyes.

VENTILATION - To cool or heat air, CRUISAIR, MARINE AIR and GRUNERT

components are designed to move air through a heat exchanger by a blower or

propeller fan. This design necessarily produces a suction on one side of the air

handling component and a pressure on the other side. Air handling components

must be installed so that the suction-pressure action does not: (1) pressurize an

area to the extent that structural failure occurs which could cause harm to

occupants or bystanders, or (2) cause a suction or low pressure in an area where

hydrogen gas from batteries, raw fuel vapor from fuel tanks, carbon monoxide

from operating propulsion engines, power generators or heaters, methane gas

from sewage holding tanks, or any other dangerous gas or vapor could exist. If an

air handling unit is installed in such a manner that allows potentially lethal gases

or vapors to be discharged by the air handling unit into the living space, this could

result in loss of life.

Maximum protection against the introduction of dangerous gases or vapors into

living spaces can be obtained by providing living spaces which are sealed from all

other spaces by use of airtight bulkheads and decks, etc., and through the

introduction of clean air into the living space. Bear in mind that the advent of air

conditioning, whether it be for cooling or for heating, naturally leads to the practice

of closing a living space tightly. Never close all windows and doors unless

auxiliary ventilating systems, which introduce clean outside air into the living

space, are used. Always leave enough window and door openings to provide

adequate ventilation in the event potentially lethal gases or fumes should escape

from any source.

CONDENSATE - All cooling units produce water condensate when operating on

the cooling cycle. This water must be drained from the cooling unit overboard. If

condensate is allowed to drip on a wooden structure, rotting or decay and

structural failure may occur which could result in loss of life. If condensate is

allowed to drip on electrical components, deterioration of the electrical compo-

nents could result in hazardous conditions. When an air conditioning system is in

operation, condensate drains may be subjected to negative pressure. Always

locate condensate drains as far as possible from points where engine waste and

other dangerous gases are exhausted so no such dangerous gases can be drawn

into the condensate drains.

Warning

Never sleep in a closed area on a boat when any equipment, which functions as a

result of the combustion of a volatile fuel, is in operation (such as engines,

generators, power plants, or oil-fired heaters, etc.). At any time, the exhaust

system of such devices could fail, resulting in a build-up of LETHAL gases within

the closed area.

20 ❖❖

❖❖

❖English

L-2362

* The box denotes the part of the warranty that pertains to this particular product.

Please read and keep this document with your important paperwork. Use it as a reference in the future. If you have any

questions, please contact the Dometic Corporation Service Department at (804)746-1313 for clarification.

Note: Any model or replacement part that has been installed due to a warranty failure will carry onlythe remainder of the

original warranty. All warranties begin when the customer takes possession of the equipment. The warranty is extended to all

owners of the equipment commencing the date the original owner takes possession of it. Proof of original purchase may be

required. Fuses and MOV’s are used as safety devices to protect Cruisair equipment against over-current conditions caused by

lightning or inductive switching environments. These are not covered under warranty. We reserve the right to change our

warranty policies and procedures as well as our warranty allowances without notice.

Cruisair Direct Expansion (DX)

and Modulating Systems

• New, complete system installation using any member of

the SMX family.

The warranty includes the pump.

2 year warranty including Parts and Labor

• New, complete system installation using an electro-

mechanical control (3-knob).

The warranty includes the pump.

1 year warranty including Parts and Labor

• New, complete model sold as a partial system retrofit to

an existing system.

Includes SMX family.

1 year warranty including Parts and Labor

Cruisair Tempered Water

• New, complete system installation using any member of

the SMX family.

2 year warranty including Parts and Labor

NOTE: Excludes pump which has a 1 year warranty

• New, complete model sold as a partial system retrofit to

an existing system.

Includes SMX family.

1 year warranty including Parts and Labor

Sentry Battery Chargers

• New SM and FR series installation.

2 year warranty including Parts and Labor

• New G-series installation.

1 year warranty including Parts and Labor

Refrigerators/Freezers/Fish Boxes

The below warranty periods do not apply to systems that are

installed as described in Section II, item #7, of the Owner’s

Limited Warranty, document # L-0123.

• New installation of entire system including condensing

unit, line sets, evaporator, etc.

1 year warranty including Parts and Labor

• New complete model sold as a partial system retrofit to an

existing Cruisair system.

1 year warranty including Parts and Labor

• New installation of condensing unit only, with line sets,

evaporators, etc. done by others i.e. not Cruisair pre-

charged line sets and evaporators.

1 year warranty including parts and labor on

mechanical and electrical parts of condensing unit

only.

Replacement Parts

• Replacement parts and components - example: A-509,

40401-30.

90 day warranty, Parts only

• Replacement Compressors for other than Tempered

Water Systems - example: R3101-16T, DX equipment -

installed in an existing Cruisair system or a competitor’s

system.

1 year warranty including Parts and Labor

• Replacement compressors for Tempered Water - example:

30130-36 installed in an existing Cruisair system.

1 year warranty including Parts and Labor

• A Tempered Water compressor - example: 30130-36

installed with competitor’s equipment.

90 day warranty, Parts only

Revised: 8-19-04 L-0694

Limited Warranty Periods

This manual suits for next models

2

Table of contents