Crystal Clean 1684 User manual

1

MANUAL - 1684 SPRAY GUN CLEANER REVISED 2019-06

REV 2019-06

MODEL 1684

AUTOMATIC SPRAY GUN CLEANER

Heritage-Crystal Clean, LLC

2175 Point Blvd. Ste 375

Elgin, IL 60123

Tel. 1-877-938-7948

USER

MANUAL

2

MANUAL - 1684 SPRAY GUN CLEANER REVISED 2019-06

INTRODUCTION

Every machine is tested for compliance with Quality Assurance standards. Follow the directions in this manual

under SETUP, OPERATION and MAINTENANCE in order to operate this machine safely and effectively. Not

following these instruction can lead to malfunction or damage to the machine. Ensure that this manual is readily

available for the operator at all times. If you have any questions about the operation of this machine, call Heritage-

Crystal Clean Service Engineer at 1-877-938-7948.

COMMON FEATURES

• Cleans pressure pots up to 8" high and one spray gun in one cycle.

• Automatic Wash, Air Flush, Solvent Rinse to clean spray gun and pressure pot.

• Flow-through Brush for manual wash.

• Spigot for manual rinse.

• Stainless steel inlet filter, located at the end of the suction hose, prevents debris from reaching the pump and

wash pail.

• 14 Cleaning Jets with swirl action.

• Shipping Size and Weight: 38" W x 26" D x 68" H, 185 LBS 84 KG.

CAUTIONS AND WARNINGS

• Always disconnect this machine from air supply before performing maintenance.

•Make sure all ground wires are connected and that unit itself is grounded properly.

SAFETY EQUIPMENT

• Wear safety eye ware and protective clothing.

• Wear deluxe extended length neoprene gloves; SAS PN 6588 or Thicksters PN 6602-20 through 6605-20.

SETUP

DELIVERY INSPECTION

• Inspect the shipping carton for any sign of transport damage. Carefully remove the unit from the shipping carton

and check the unit for damage. Report any transport damage immediately to the carrier and to Heritage-Crystal

Clean. Initiate a freight claim with the carrier.

LOCATION

Position the unit in a ventilated area at least 6 " from the back wall.

3

MANUAL - 1684 SPRAY GUN CLEANER REVISED 2019-06

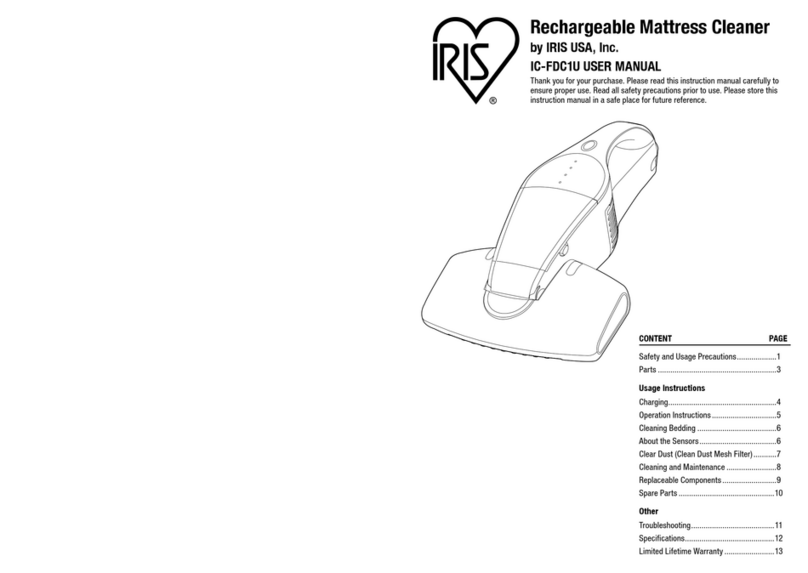

HCC75W

Stainless steel inlet

filter located on end

of suction hose

Note 1: The wash and

Rinse pails are provided by

Heritage-Crystal Clean. The

stainless steel inlet filter,

located at the end of the

suction hose, prevents debris

from reaching the pump and

wash tank. The procedure to

clean the filter is described

in the Section, MONTHLY

MAINTENANCE.

Suction Hose

Drain Valve (inside)

Wash Pail

See Note 1 below Nozzle Brush

Spigot

Brush

Drain Hose

Suction Hose and Brush

hose for Wash tank

Automatiic Tank

Manual Tank

Hood

Wash Pail

Blow Gun

Clean Pail

Vent Control

Timer

Air Rinse

Clean Rinse

HCC75W

Rinse Pump and Suction Hose

for Spigot.

4

MANUAL - 1684 SPRAY GUN CLEANER REVISED 2019-06

Ring Terminal

QTY

ACCESSORIES PART NO.

1MANUAL

1TRIGGER CLAMP & PLUG KIT, SET OF 2 140-2340

1 AIR BLOW GUN (INSTALL ON RIGHT SIDE OF UNIT) 102-7010

1 VENT AND HOOD DOOR SUPPORT 780-3723

1 CLEANING KIT FOR SPRAY GUN KIT-GCTOOLS

1 3" DIAMETER VENT HOSE / CLAMP 780-524/112-

261

NOZZLE EXTENSIONS:

1FOR DISPOSABLE CUP SYSTEMS. MAY ALSO BE USED TO CLEAN CONVEN-

TIONAL CUP SYSTEMS. 110-430PPS

1FOR CONVENTIONAL CUP SYSTEMS WITH SMALLER OPENINGS IN THE

NECK. 110-430

1FOR DISPOSABLE CUP SYSTEMS INCLUDING MANY PPS2 ADAPTORS 110-430PPS2

1NOZZLE EXTENSION, FOR USE IF CONVERTING TO A 2 GUN CLEANER 110-356

ACCESSORIES:

See below.

AIR SUPPLY

• Connect a male 1/4" NPT air supply plug (not supplied) into the female Air Inlet on the unit.

• Connect the female air supply hose to the plug. The air supply hose must be at least 3/8" inside diameter.

The air supply pressure must be at least 85 PSI and the supply air must be free from contaminants

such as water, dust, rust, tar and grease. If the air supply is not clean and dry, install a moisture filter.

The operation and longevity of the pump and other components depends on the presence of clean and

dry supply air.

• To prevent damage to the Diaphragm Pump an internal Air Pressure Regulator has been installed to limit the

air pressure to 85 PSI. Do not install a second air pressure regulator or use a pressure set below 85 PSI.

GROUNDING

• Connect the green ground wire at the back of the unit to a ground in the building using the ring terminal on

the ground wire.

Note: The pump and metal tube that inserts into each pail are grounded.

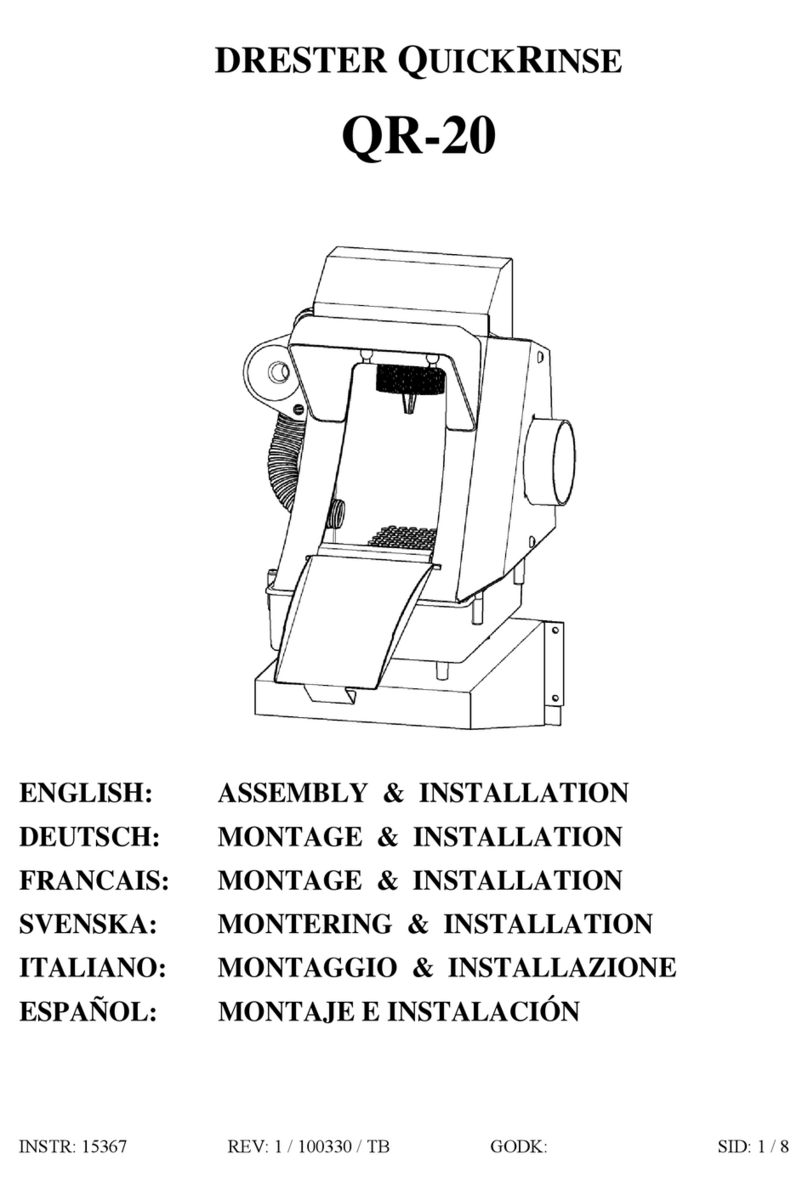

INSTALLATION OF VENT AND HOOD SUPPORT

5

MANUAL - 1684 SPRAY GUN CLEANER REVISED 2019-06

• The vent kit is located in a box in the cabinet.

Locate the hole for the vent on the underside

of the top of the cabinet. See photo to the

right and below, left.

• Push the vent through the hole and install one

screw in the front screw hole. Hold the

vent in place if necessary and reach on top

of the cabinet to install a wing nut onto the

screw. See the photo in the lower left below.

• Install the 3 other screws and wing nuts

in a similar way. To not tighten the wing nuts.

• Connect blue airline located near the vent on the inside of

the sink to the vent. See photo on right.

• Place the Hood Support between the wing nut

and the top of the cabinet. Tighten the 4 wing

nuts. See the photo below right.

OPTION - CONVERTING THE TANK TO A 2 SPRAY GUN CLEANER

• The post of the Rotating Jets can be replaced with a

nozzle from the accesssory kit, part 110-356 (see

drawings of replacement parts) to convert the tank to

a 2 spray gun cleaner.

• To remove the post of the Rotating Jets you will need 2

spanners. One spanner grips the nut (not seen) below

the post of the Rotating Jets and one spanner

grips the nut at the bottom of the post of the

Rotating Jets. Hold the spanner on the nut below

the post of the Rotating Jets steady and turn

anti-clockwise the nut of the post of the Rotating Jets.

• Install the Nozzle Extension, 110-356.

Vent

Vent Location

Air Line

Vent

Wing Nut Top of

Cabinet

Hood

Support

Hood Support

Vent at Top of Cabinet

Rotating Jets

Wash Tank

6

MANUAL - 1684 SPRAY GUN CLEANER REVISED 2019-06

PAIL SETUP

• Remove the cabinet door.

• Heritage-Crystal Clean provides a wash pail and a clean pail. The wash pail has 3 gallons of solvent and the

clean rinse pail has 5 gallons of solvent. Place the wash pail on the left side in front of the cabinet and the

rinse pail on the right side.

• Close the drain valve (horizontal position) to stop solvent dripping from the cleaning tank. See photo of the

Drain Valve below.

• Insert the black convoluted drain hose into the back hole of the wash pail. See photo below. Insert the suction

hose and brush hose into the front hole of the wash pail. See the photo of the unit below. Open the drain

valve (veritcal position) located inside the cabinet. See photo below. Place the wash pail in the left side of the

cabinet.

• The rinse pump is the stainless steel tube located in the bottom of the cabinet. Insert the rinse pump and tube

for the spigot into the opening and place the 5 gallon pail of solvent in the cabinet on the right side.

Check to ensure the Drain Valve is in the open position (handle in vertical position)

The stainless steel inlet filter is located at the end of the

suction hose and prevents debris from reaching the pump

and wash tank. See the photo of the filter at right. Clean the

filter monthly. The procedure to clean the filter is

described in the Section, MONTHLY MAINTENANCE.

Drain Valve - Open Drain Valve - Closed

Wash Pail

Stainless Steel Filter

Stainless Steel Filter

Drain Hose

Suction Hose

for Wash tank

Drain Valve

Rinse Pail

Rinse Pump

and hose for

Spigot

Wash Pail

Suction Tube for

Wash tank

7

MANUAL - 1684 SPRAY GUN CLEANER REVISED 2019-06

ALUMINUM VENT HOSE

Stretch the 3" diameter aluminum vent hose. Use the clamp to attach this vent hose to the solid vent tube at the top of

the cabinet of the 1684. The other end of the vent hose is connected to the venting system.

CLEANING SPRAY GUNS AND CUPS

Pour paint waste from the paint channel of the spray gun into a waste drum.

• Remove digital air gauge if so equipped.

• Loosen the air cap of the spray gun two full turns.

• Lock the trigger in the open position with the Trigger Lock Spring.

See photos below.

INSTALLING SPRAY GUNS IN TANK

•Center the pressure pot on the Rotating Jets in the middle of the tank. Maximum height 8". See the photo below.

• Place the spray gun on the nozzle extension with the cap facing the corner. See photo below.

Remove

Gauge

Trigger Lock Spring Trigger Lock Spring

On Spray Gun

PLACING SPRAY GUN

ON PUSH ON NOZZLE

EXTENSION

Location for Push On

Nozzle Extension for

second spray gun

Air Plug

WASH TANK

Rotating Jets, Center

the pressure pot over

the Rotating Jets

8

MANUAL - 1684 SPRAY GUN CLEANER REVISED 2019-06

DIFFERENT TYPES OF SPRAY GUNS

ON NOZZLE EXTENSION

TRAY TO HOLD NOZZLE EXTENSIONS

(left side of tank)

9

MANUAL - 1684 SPRAY GUN CLEANER REVISED 2019-06

PREVENT SOLVENT FROM ENTERING THE AIR PASSAGE OF THE SPRAY GUN

• Insert the plastic plug into the air fitting as in the photo at right.

• Positive air will flow through the passage way during cleaning.

• If you disconnect the air plug from the spray gun attach

the knurled nut to the air passageway of the spray gun. The nurled nut

is located on the chain with the trigger lock spring.

Cleaning Cycle:

• Close the lid of the spray tank and turn the "Auto Wash Timer" clockwise. See photo below. The maximum time

is 5 minutes.

• Push and hold the "Air Rinse" button for about 5 seconds to evacuate the wash liquid and air rinse the spray

guns. See photo below.

• Press and hold the "Clean Rinse" button for about 5 seconds to send 100 cc of clean liquid through the jets to

rinse the spray guns. See photo below.

• Press the air rinse button for 5 seconds.

MANUAL WASH

• Use the brush to manually clean the outside of the spray gun. See the photo below. The brush is located on

the wall of the right side of the tank. Step on the foot pedal to activate water flow from the wash pail. See the

photo on page 3 for the location of the brush and foot pedal.

• Rinse the spray gun or pressure pot using the spigot. Step on the foot pedal to activate solvent flow from the

clean solvent pail. See the photo on page 3 for the location of the nozzle and foot pedal.

Auto Wash Timer

Air Rinse

Air Plug inserted into the Air

Passage way of the spray gun

Clean Rinse

Vent Control

10

MANUAL - 1684 SPRAY GUN CLEANER REVISED 2019-06

DRAIN VALVE -

CLOSED POSITION

SUCTION PIPE WITH

INLET FILTER

MAINTENANCE

• Clean the stainless steel inlet filter each month.

Procedure:

Follow step 1 and step 2 below under REPLACING SOLVENT.

Lift the suction pipe from the wash pail, (see the left photo below) unscrew the stainless steel filter from the nut,

by hand, and clean it with clean solvent. See the right photo below.

Remove Suction Pipe and Filter Clean Filter

REPLACING SOLVENT

1) Remove the clean pail (right side) from the cabinet and then remove the rinse pump and tube for the spigot from

the clean pail.

2) Close the drain valve (left photo below). Remove the drain hose and suction pipes from the wash pail and take the

pail out of the cabinet. See middle and left photo below.

3) Replace the pail of wash solvent with a fresh pail of wash solvent. The replacement pail contains 3 gallons of

clean wash solvent. Top up the clean water pail to 5 gallons. Return the pails to the cabinet.

4) Open the drain ball valve (verticle position)

WASH AND

CLEAN RINSE PAIL

Suction Tube

Wash Pail

Inlet Filter

Clean Rinse Pail

11

MANUAL - 1684 SPRAY GUN CLEANER REVISED 2019-06

TROUBLE SHOOTING

PROBLEM REASON CORRECTIVE ACTION

PUMP MAKES PUMPING

SOUND BUT LIQUID DOES

NOT FLOW THROUGH THE

JETS.

Drain valve closed Open drain valve (put in vertical posi-

tion), if not already open

Liquid level too low Check wash liquid level. Add liquid if

less than1/2 full.

Debris in pump or suction and

output hose

Follow Procedure 1, “Blocked Fluid

Passage in Diaphragm pump” in the

next section.

WASH PUMP MAKES HISS-

ING SOUND AND LIQUID

DOES NOT FLOW.

Water or contaminants in air line

of pump.

Follow Procedure 2. “Blocked Air Pas-

sage in Diaphragm Pump” in the next

section.

BRUSH PUMP DOES NOT

MAKE A NOISE AND LIQ-

UID DOES NOT FLOW WITH

PEDAL DEPRESSED

Foot pedal switch not function-

ing

Inspect foot switch for free travel, and

lubricate with gun oil. If switch will

not travel freely, replace with PN 155-

400BF2

WASH PUMP DOES NOT STOP

UNLESS TIMER IS TURNED

BY HAND OR AIR IS SHUT

OFF. WASH PUMP DOES NOT

START.

Defective Timer Replace Timer. (115-200K)

TIMER KNOB SPINS BACK

WHEN TURNED Defective Timer Replace Timer. (115-200K)

INSIDE WALL OF TANK IS

COATED WITH PAINT EVEN

THOUGH OPERATOR MAIN-

TAINS TANK

Liquid lacks cleaning strength. Use new solvent and/or better solvent

or, for water cleaning, add Aqua-Kleen.

GUNS NOT CLEAN, PUMP

WORKING, LIQUID FLOW IS

NORMAL

Trigger not locked in open posi-

tion Use Trigger Lock Spring. (120-350)

Spray gun is not properly in-

stalled on to nozzle Re-install with proper adapter

Liquid lacks cleaning strength. Use new solvent and/or better solvent

or, for water cleaning, add Aqua-Kleen.

Low pressure in air supply Increase air pressure to a minimum of

85 PSI.

Plugged jets.

Remove and clean by blowing air

through the jets. If not successful,

replace the jets or, if still not success-

ful, replace the whole Delivery Tube

Assembly.

12

MANUAL - 1684 SPRAY GUN CLEANER REVISED 2019-06

TROUBLESHOOTING PROCEDURES

PROCEDURE 1

The 5" diaphragm pump, UDP5TA, powers the wash tank and a UDP2TAB pump powers the brush and spigot.

5" Diaphragm Pump, UDP5TA for Wash Tank:

• If the pump sounds like it is working but liquid does not flow into the wash tank, clear the fluid passage as

follows:

Remove the suction tube from the wash pail and blow air at 85 PSI into the Inlet Solvent Hose (see

diagram below and the Flow Diagram). Turn the timer.

• Repeat these steps several times. If this procedure does not help, disconnect the output hose at the

combination valve. See the flow diagram. Point the end of the output hose into the wash pail. Activate the

pump. If liquid does not flow through the output hose replace the pump. If liquid does flow remove the

blockage in the delivery tubes or jets.

PROBLEM REASON CORRECTIVE ACTION

GUNS NOT CLEAN, WASH

SOLVENT IS MILKY WHITE

Wash solvent is contaminated

with water Replace cleaning agent

SOLVENT APPEARS RED OR

ORANGE

Water in solvent is corroding the

metal pail.

Replace or recycle wash solvent. Use

HDPE pail approved for use with sol-

vent.

DEPRESSING CLEAN RINSE

BUTTON DOES NOT PROVIDE

CLEAN LIQUID

Rinse pump is leaking Replace rinse pump. (URP100S-F)

CLEAN RINSE LIQUID IS

DIRTY

Replace Combination Valve. (UVB-

400KIT)

13

MANUAL - 1684 SPRAY GUN CLEANER REVISED 2019-06

UDP2TA:

• Remove the suction tube from the pail and blow air at 85 PSI

into the INLET Sovent Hose. Step on the foot pedal to activate

the pump for the brush. This procedure may have to be repeated

several times. If this procedure does not help, disconnect the

output hose at the tank wall. See the flow diagram. Point the

end of the output hose into the wash pail. Activate the pump

by steping on the foot pedal. If liquid does not flow through

the output hose replace the pump. If liquid does flow clear the

blockage upstream. The warranty on the diaphragm pump is two

years from date of purchase.

PROCEDURE 2

Blocked Air Passage In Diaphragm Pump

If there is a steady hissing sound and the pump is not cycling, the

spool valve has stalled due to a blocked air passage. Follow the proce-

dure below to clear the blockage.

• Connect a blow gun to an 85 PSI source. Locate the blue hose that extends from the air exhaust port of

the diaphragm pump. Use a blow gun to blow air into the open end of this hose. Turn timer. If the proce-

dure is successful, the pump will start working. The procedure may have to be repeated several times. If

this procedure does not work, replace the pump.

•Cause: Contaminants in the air supply (water, oil, solid particles etc)

•Preventative Action: If necessary, install an Airline (Moisture) Filter.

PROCEDURE 3

Blocked Passage in Air Line

The components in the air line are the diaphragm pump, air valve, foot pedal, 3-way ball valve and regula-

tor. See the Flow Diagram and the section: Replacement Parts.

To troubleshoot a component:

1) Disconnect the air line to the component using the quick disconnect.

2) Step on foot pedal and check for presence of positive air pressure in the air line. If there is ample positive air

pressure, replace the component.

If air pressure is absent, there is a faulty component downstream. Reconnect the air line and check the operation

of the next component upstream by following steps 1 and 2 above.

14

MANUAL - 1684 SPRAY GUN CLEANER REVISED 2019-06

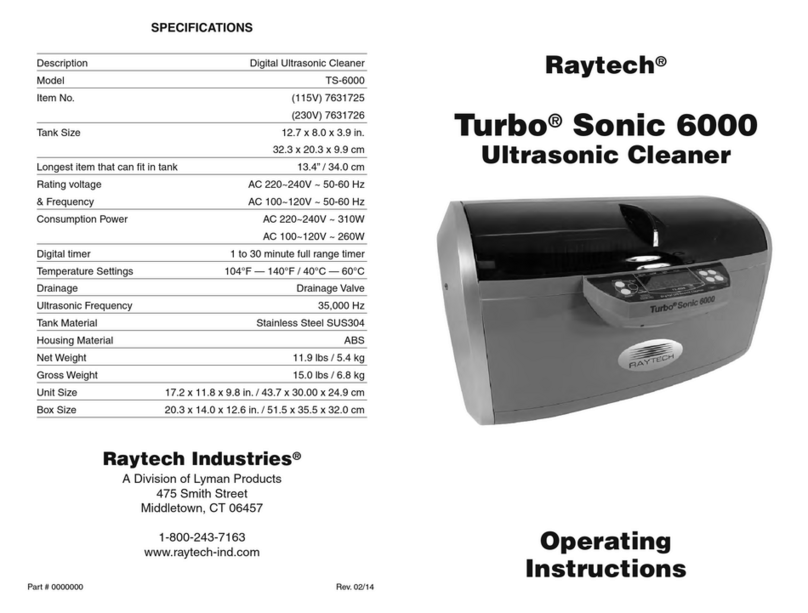

HCC75W FLOW DIAGRAM

Use the diagram to trace the flow of compressed air and liquid.

15

MANUAL - 1684 SPRAY GUN CLEANER REVISED 2019-06

REPLACEMENT PARTS

PART NO. ACCESSORIES

780-3723 VENT AND HOOD DOOR SUPPORT

140-2340 TRIGGER CLAMP & PLUG KIT, SET OF 2

780-3530 INSTALLED NOZZLE EXTENSION TO CLEAN DISPOSABLE CUPS

102-7010 AIR BLOW GUN (INSTALL ON RIGHT SIDE OF UNIT)

780-524/112-261 3" DIAMETER VENT HOSE AND CLAMP

ITEMS BELOW ARE SHOWN ON THE ATTACHED PAGE.

110-430PPS HOLES ALLOW LIQUID TO CLEAN DISPOSABLE CUP ADAPTOR. MAY ALSO BE USED

TO CLEAN CONVENTIONAL CUP SYSTEMS.

110-430 FOR CONVENTIONAL CUP SYSTEMS WITH SMALLER OPENINGS IN THE NECK.

110-430PPS2 FOR DISPOSABLE CUP SYSTEMS INCLUDING MANY PPS2 ADAPTORS

110-356 NOZZLE EXTENSION FOR CONVERTING TO A 2 SPRAY GUN CLEANER

780-2701F SPIGOT

115-200K TIMER AND VALVE ASSEMBLY

140-2341 TRIGGER CLAMP, CHAIN AND PLUG, SINGLE

100-835-6 GROUND WIRE,18AWG, GREEN, 1300MM,W. 1/4" RING TERMINAL.

100-8330 GROUND WIRE, GREEN,14 AWG X 4 FT LONG

780-2210 REMOVABLE BASKET, FOR HCC75W/HCC75PS

140-230 AIR PASSAGE PLUG WITH TUBE, NYLON

120-4200TDM DUAL TUBE + FILTER 104-4206, SINGLE, 30 MESH, 30MM DIA

780-75010F FOOT PEDAL WITH HINGE WELDMENT, FOR ALL EXCEPT IWJ 780-75010F 780-010F

115-400 RINSE VALVE ASSY,2WAY, HEAVY DUTY, M10 THREAD,

780-3940 FLOW CONTROL VALVE

144-390S SOLVENT BRUSH+ 6 MM COMP. FITTING + TUBE

102-7010 AIR BLOW GUN, 4" ASSEMBLY, PLASTIC, WITH 4FT TUBING

NYT4X6 SUPER SOFT NYLON TUBE, 4mm ID x 6mm OD,SEMI-CLEAR WHITE

UDP2TAB 2" DIAPHRAGM PUMP,TEFLON BALLS, BRASS BARBS

102-020PR PRESSURE REGULATOR ASSY, WHIP LINE

UDP5TA DUAL DIAPHRAGM PUMP, 4"

URP100S RINSE PUMP ASSY,SS,100CC,BOTTOM PORT

16

MANUAL - 1684 SPRAY GUN CLEANER REVISED 2019-06

6

8'37$%

8'37$

8566

7'0

$

.

336

336

)

1684

5(3/$&(0(173$576

1<7;

REPLACEMENT PARTS

17

MANUAL - 1684 SPRAY GUN CLEANER REVISED 2019-06

Full Product Warranty

These Heritage-Crystal Clean products have been engineered and manufactured to high performance standards.

Each unit has been subjected to detailed factory testing before shipment.

This product comes with a one-year full warranty from the date of purchase. Heritage-Crystal Clean Corporation

reserves the right to repair or replace the unit, free of charge, to the original purchaser if a part is found to be

defective in material or workmanship as determined by factory service personnel. The items listed below under

"Conditions of Warranty" as consumables are not covered.

Heritage-Crystal Clean reserves the right to direct the customer to ship the unit collect to the Heritage-Crystal

Clean factory or to an approved Service Center for repair using the Heritage-Crystal Clean Return Goods

Procedure or to repair the unit on-site. To prevent damage in transport, the purchaser must ship the unit in the

original packaging or use alternate adequate packaging. All units must be shipped clean and free of liquid.

Diaphragm Pump:

We are pleased to advise that the warranty on the diaphragm pump, the heart of the spray gun cleaner, comes

with a 2 year replacement warranty. If, in the unlikely event your diaphragm pump fails during the first two years

of service, call Heritage-Crystal Clean Service at 1-877-938-7948.We will send you a new pump free of charge

and arrange for the return of your original pump.

Conditions of Warranty:

As Heritage-Crystal Clean Corporation has no control over the working conditions or circumstances under which

the purchaser stores, handles or uses the product, Heritage-Crystal Clean makes no warranty or claim, either

expressed or implied with respect to this product's fitness for any purpose or the result to be obtained from its

use. This condition applies to the sale of all products and no representative or distributor of Heritage-Crystal

Clean Corporation has the authority to waive or change these conditions.

This warranty applies only to the original purchaser and does not apply if the unit has been misused, overloaded,

neglected, altered or used for any purpose other than those specified in the operating and installation instruc-

tions. Deterioration due to normal wear is not covered by this warranty. Damage due to accident, transportation,

fire, floods or acts of God is also not covered. Units whose serial numbers have been altered or removed are not

covered. The warranty is invalid if unauthorized chemicals as noted in the manual or liquids with acid content

are used in this unit. Unauthorized attempts at self-repair or alterations by the owner also invalidate this warranty.

Interior or exterior finishes are not covered by this warranty.

Consumable Items are not covered by this warranty (eg: gaskets, screens, bags, filters, nozzles and air jets).

This warranty replaces all other warranties expressed or implied by statute or otherwise.

To make a claim, call Heritage-Crystal Clean Service at 1-877-938-7948 and quote the serial number of the unit.

Table of contents