8

SYSTEM OPERATION

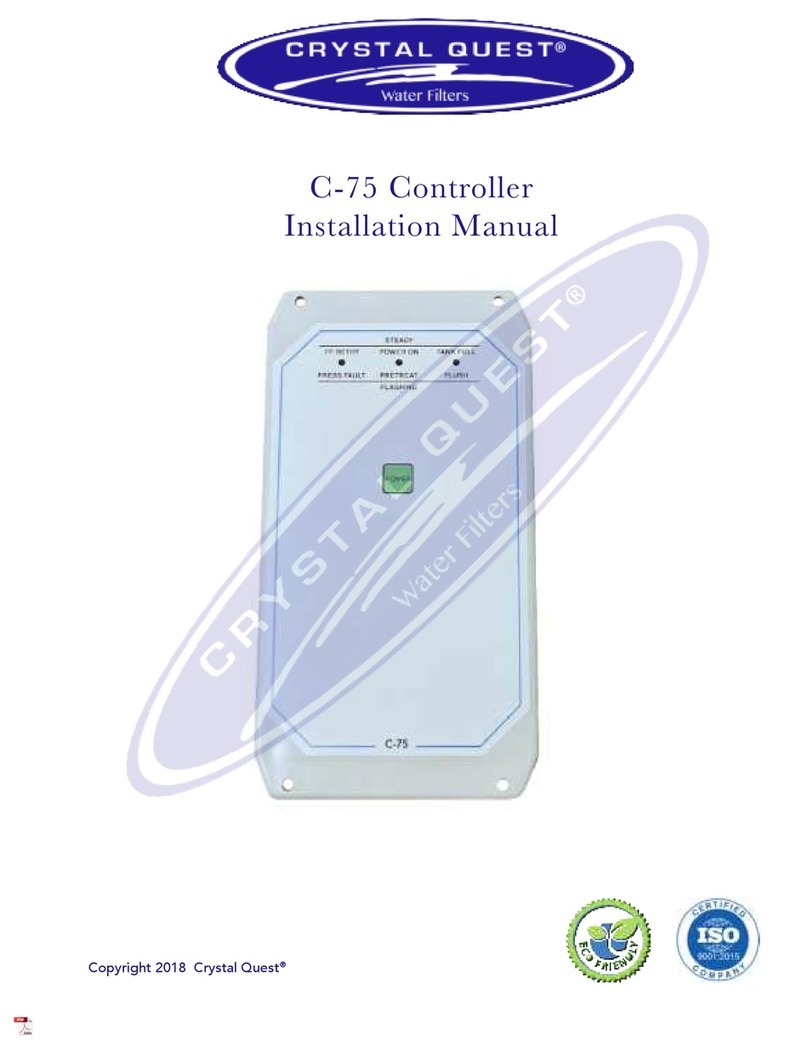

PF Auto Reset / PR Retry

With J8 in the A position, the power must be cycled using the Power key to clear a pressure fault shut down.

A PF auto reset function is enabled by placing J8 in the B position. When a pressure fault occurs with the PF

auto reset enabled, the controller will automatically reset after a 60 minute delay and the controller will start. If

the pressure fault has cleared, the controller will continue to run. If the pressure fault condition is still active, the

controller will again shut down for the pressure fault condition and the auto reset cycle will repeat. During the

auto reset delay, the water quality display will show PF and the status lamp will be off.

A PF retry function is enabled by placing J8 in the C position. When a pressure fault occurs with the PF retry

enabled, the controller will shut down for 30 seconds and then attempt to restart. If the pressure fault is still

active, the controller will shut down for 5 minutes and then attempt to restart. If the pressure fault is still

active, the controller will shut down for 30 minutes and attempt to restart. If the pressure fault is still active,

the controller will lockout for the pressure fault. During the retry delays, the water quality display will show

PF and the status lamp will be a steady red. If during one of the retries, the controller is able to start and run

continuously for 10 seconds, the retry function is reset. If a pressure fault occurs, the PF retry cycle will repeat

from the beginning.

When J8 is in the D position, both the PF auto reset AND the PF retry functions are enabled. If a pressure fault

condition occurs, the PF retry function will operate as described above. If the retry function locks out, the PF

auto reset function will operate as described above. The PF retry and PF auto reset functions will continue.

Tank Full

If the tank full input is active for 5 seconds, the controller will shut down for a tank full condition. The water

quality display will show FUL. When the tank full condition clears, the unit will restart after the selected restart

delay. The delay is selected with J9. With J9 in the A position, the restart delay is 2 seconds. With J9 in the B

position, the restart delay is 15 minutes. Position A is normally used with tank level switches that have a large

span. During the restart time, the status lamp will ash green.

Pretreat Lockout

If the pretreat lockout input is active for 2 seconds, the controller will shut down for a pretreat lockout condition.

The water quality display will show PL. When the pretreat lockout condition clears, the unit will restart.

Membrane Flush

A ush function can be enabled using J11 and J12. When a ush is initiated, the ush valve will operate and the

ush will last 5 minutes. The ush can occur when a tank full condition occurs or every 24 hours, depending on

the jumper settings. The inlet valve can be open or closed and the RO pump can be on or off, depending on the

jumper settings.