Crystal Water CW-A1004 User manual

CRYSTAL WATER

Installation Guide

CW-A1004 Slimline Reverse Osmosis System

Contents

SECTION

PAGE

Features

1

Specifications

2

Water Treatment Process and Electrical Diagram

3

Product and Accessories

4

Functional Schematic Diagram

5

Installation Instructions

6

First Use Instructions

8

Cartridge Replacement

9

Troubleshooting

10

Precautions for Use

11

Commissioning Checklist

12

Warnings

13

1 | P a g e

Features

•Easily Installed with the use of an Arco Conekta Mini Stop Water Diverter

•Can be easily connected to an existing Flick Mixer Tap (other fittings may be

required) or the Standard Tap provided.

•Purifies Standard Municipal Water Supplies

•Automatically Shuts off Water when a Leak is Detected.

•Runs 110-240V AC Power (Power Supply included)

•Automatically Flushes system

•Built in TDS Meter

•Built in Independent Filter Monitors

2 | P a g e

Specifications

Slimline Reverse Osmosis System

•Feed Water Quality

oMunicipal Tap Water

•Voltage and Frequency

o100-240V, 50/60 Hz

•Power Input

o96 Watts

•Purified Water Flow

o1.2 Lt per minute

•Feed Water Temperature

o5-45 ºC

•Feed Water TDS

o~250 ppm

•Feed Water Chlorine Level

o~0.2ppm

•Rejection:

o90-99%

•Feed Water Pressure

o100-400 kpa

•Electric Shock Resistance

oType II

3 | P a g e

Water Treatment Process and Electrical Diagram

Technological Process

Electrical Diagram

4 | P a g e

Product and Accessories

5 | P a g e

Functional Schematic Diagram

6 | P a g e

Installation Instructions

1. Attach Inlet Water Supply

a. Locate and Close the Cold-Water Angle Stop Valve Under your kitchen sink. Open

the Cold-Water line one your existing Tap to release the water pressure.

b. Unscrew and disconnect the braided tubing on the threaded end of the Angle

Stop Valve.

c. Attach the Solenoid Valve to the Arco Mini Stop Valve. Attach the ½” Push-fit

Fitting to the End of the Stop Valve.

d. Attach the Arco Conekta Mini Stop Valve to the existing Cold-Water Angle Stop

Valve.

e. Attach the Braided tubing to the top of the Arco Conekta Mini Stop Valve.

f. Close the Side Valve on the Arco Conekta Mini Stop Valve and open the Cold-

Water Angle Stop Valve to return water service to the Kitchen Sink. Check for

Leaks.

g. Measure length of tubing needed to connect the Diverted water to the Inlet of the

System. Allow adequate tubing to avoid sharp turns.

h. Cut at a 90-Degree angle using a sharp knife.

i. Attach one end of the tubing to the Water Diverter Fitting.

j. Measure approximately 30-50mm away from the Water Diverter Fitting along the

tubing.

k. Cut at a 90-Degree angle using a sharp knife.

l. Attach the Water Diverter Tube to the Bottom of the PLV Check Valve and the

Remaining Tube to bother the outlet of the PLV Check Valve and the Inlet of the

System.

2. Install Supplied Tap

a. Place Cover Plate on top of the counter for the placement of the Tap.

b. Mark on the counter for drilling the hole for the tap. Ensure the is adequate room

both on top and underneath the counter/sink top for the locking nut, round plate

and push fit fitting installation.

c. Drill hole into the counter/sink top for the shaft of the Tap to go through. Clean

any potential burrs or knicks around the hole.

d. Place the small rubber Washer, Chrome Cover plate and large Rubber Washer (in

that order) on the shaft of the faucet. Insert shaft into the hole on the

counter/sink top.

e. Place Round Plastic Plate and Locking Washer on under the counter/sink side of

the faucet shaft. Tighten with the Locking Nut supplied on the shaft and ensure

the tap handle is pointing in the desired direction.

f. Attach the remaining Push-fit fitting onto the bottom of the shaft of the tap.

Tighten to ensure the internal seal is on the base of the tap.

7 | P a g e

3. Attach Filtered Water to Sink Tap

Measure length of tubing needed to connect the Outlet of the Filter Head to the Tap

connector fitting. Cut and insert each end of the tubing into the fittings.

4. Install the Drain Clamp

a. Select a location for the drain clamp above the “S”Trap but not more than

40mm above the normal water level or the best location is on the transfer

pipe between twin bowl sinks if you have one.

b. Position the drain outlet clamp on the drainpipe. Allow adequate space for

drilling. Tighten clamp with the “Tightening Screw.”

c. Using the opening in the drain outlet clamp, drill a ¼” hole in the drainpipe.

d. Clean debris from the clamp.

e. Attach the Red pipe, to the Drain Outlet on the System and to the Drain Clamp.

Allow for adequate tubing to prevent kinks.

NOTE: Locate the drain connection away from the garbage disposal to prevent potential

contamination and system fouling.

8 | P a g e

First Use Instructions

1.

a. Connect RO System with the Power Adapter.

b. Connect to power outlet in your wall.

c. Check the power light indicator on the power supply is illuminated.

d. Once the system is powered on, a buzzer will ring 3 TIMES.

e. Machine will flush for 90 seconds and the flushing icon on the system will

flash.

2. The RO System will begin to make water and the on-board computer will show the

real time TDS of both the incoming and outgoing of the Purified water, Cartridge Life

Span, and the power indicator light. All icons will turn off when system is not in use.

3. The water storage icon will flash, and the buzzer will ring 10 TIMES if there is

insufficient or low water pressure. The System will flush for 5 seconds after having

enough water or water pressure.

4. The System will stop purifying water, will flash all the icons, the buzzer will ring 30

TIMES after 6 hours of continuous operation or if a leak has been detected.

NOTE: Under normal operation, please draw off water for 10-15 minutes to flush cartridges

when it is first used.

9 | P a g e

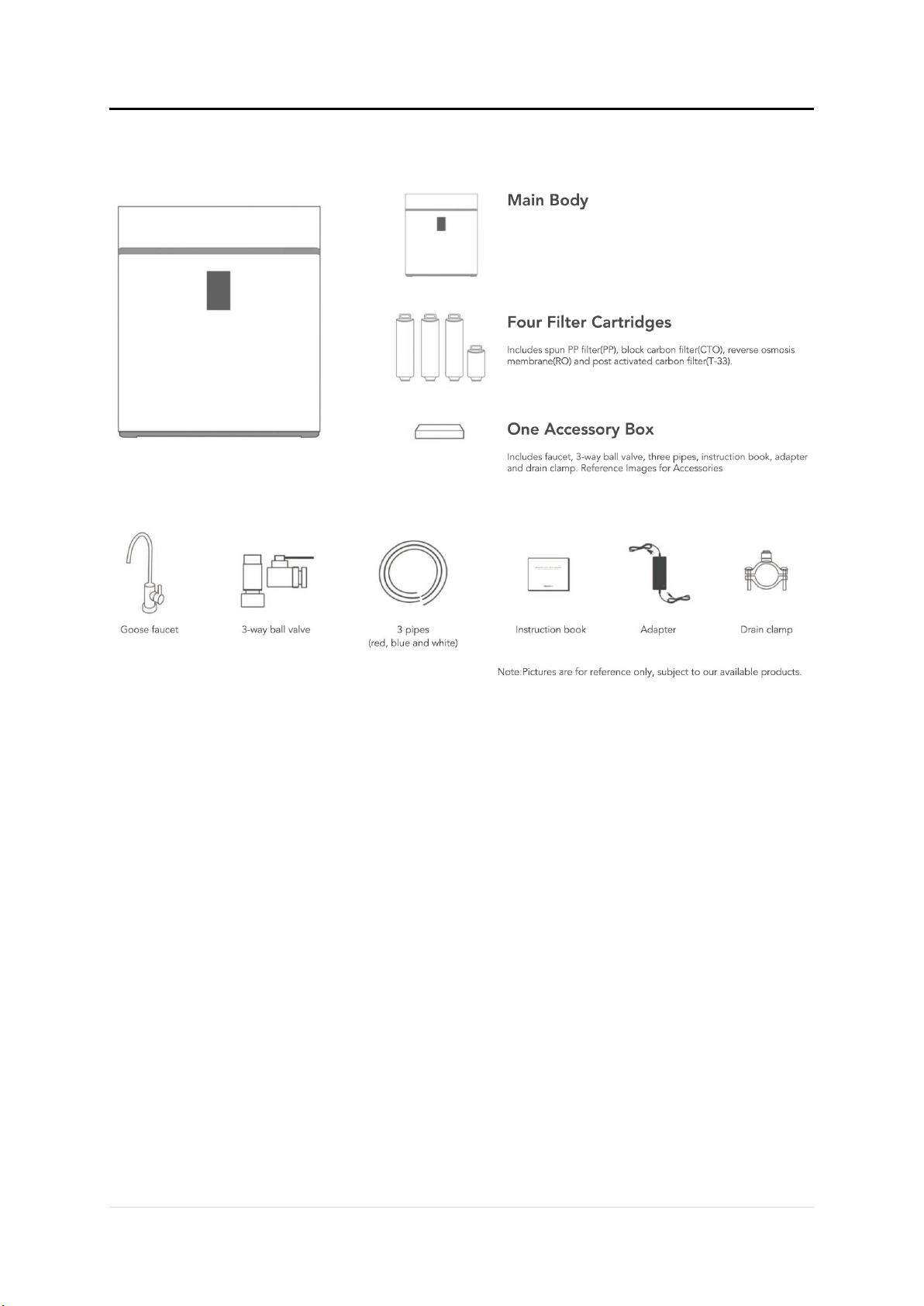

Cartridge Replacement

10 | P a g e

Troubleshooting

Trouble

Cause

Solution

Water pump is out of

service and the system

does not work

Insufficient feed water

pressure

Increase feed water

pressure

No power or power failure

Power on

High pressure switch is

out of order

Replace High Pressure

Switch

Pump is block and power

adapter fuse is burned

out

Replace Power adapter

and repair water pump

High TDS Value

TDS of feed water is too

high, or system has not

been used for a long

period of time

Open the tap to draw

water off the purified

water for 10-15 minutes

Cartridge lifespan is over

Replace cartridge

Water pump works but

system does not work

RO membrane is Blocked

Replace RO Membrane

Water Pump pressure

loss

Repair water pump

Flush Solenoid valve is

damaged

Replace flush Solenoid

Valve

Constantly running water

in downtime

Inlet water solenoid valve

damaged

Replace fee water

Solenoid Valve

Cannot stop working

when a pressure tank is

full or repetitive starting

High pressure switch is

damaged

Repair or replace High

Pressure Switch

Check valve is Damaged

Replace Check Valve

11 | P a g e

Precautions for Use

ATTENTION

1. Flush and replace cartridge regularly.

2. Do not disassemble parts randomly as it may cause leakage or damage.

3. Do not use power supply with unsupported voltage.

4. Please disconnect power and turn off Main feed water Valve if the system will not be

used for long periods of time.

5. Do not store or explore in an environment of 0 ºC or below.

6. Handle with care when discharging, moving, and installing.

REMINDER

1. If any “Water Hammering”occurs on the system, Crystal Water will NOT take

responsibility or consequences regarding any damage of malfunctions caused.

2. Please disconnect power and turn off water to the system at once in case troubles

occur and ask professional staff to repair.

3. Professional staff are advised to replace cartridges only. For any other faults, a

Technician may be required, or postage of the system may be required for repair.

4. It is normal to hear vibrations when the system is producing water.

12 | P a g e

Commissioning Checklist

Water Diverter Installed onto Cold Line Water Supply.

In-line PLV Check Valve Installed before Filtration System.

Drain clamp is secured and fitted correctly.

Locking clips are installed on Push-Fit connections.

Inlet and outlet connections are properly fitted and well secured (if

applicable)

Tap Fitting Installed onto Threading

Water has been run for at least 10 to 15 minutes before use.

If any difficulties arise contact Crystal Water: Phone +61 8 6244 1300.

For information on our Filtration and Service Contracts please contact Crystal Water

Customer Service on +61 8 6244 1300 or service@crystalwaterperth.com.au.

13 | P a g e

Warnings

For continued safety of this appliance it must be installed, operated and maintained in accordance with the

manufacturer’s instructions. For correct operation of this appliance, it is essential to observe the instructions

as outlined in this booklet.

—Your unit should be installed by a suitably qualified tradesperson.

—For correct operation of this unit it is essential to observe the instructions as outlined in this booklet.

—Do not use this unit with water that is microbiologically unsafe or with water of unknown quality without

adequate disinfection before or after the system. Systems certified for cyst reduction may be used on disinfected

water that may contain filterable cysts.

—Use this unit only as directed in these instructions and relevant Crystal Water User Guides and only for its

designed purpose.

—Do not install unit if power cord is damaged.

—This unit is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety. Children should be supervised to ensure

that they do not play with the unit.

—This unit is designed for indoor installation only and must not be exposed to direct sunlight, rain and excessive

heat, cold, damp or dust.

—Do not store solvents or corrosive chemicals or other flammable items on or around this Unit.

—Any service or unit repairs must be performed by a trained and suitably qualified Technician.

—If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

—Packaging material including plastic bags must be kept out of reach of children and disposed of according to

local regulations.

14 | P a g e

Crystal Water

236 Fletcher Road, Karnup

Western Australia 6176, Australia

Telephone: +61 8 6244 1300

Email: service@crystalwaterperth.com.au

Crystalwaterperth.com.au

As Crystal Water has a policy of

continual improvement, all details are

subject to change without notice. All

goods are sold subject to our

published terms and conditions.

Table of contents

Other Crystal Water Water Filtration System manuals

Popular Water Filtration System manuals by other brands

NKT Photonics

NKT Photonics SUPERK SELECT Product guide

R.O. DRINKING WATER SYSTEM

R.O. DRINKING WATER SYSTEM T.F.C.-300 Installation, operation & service manual

Micronfilter

Micronfilter KALAMIT Series Use and maintenance manual

EWS

EWS UF3020 instruction manual

Newa Pond

Newa Pond PURO advance Instructions and guarantee

Hydro Action

Hydro Action AP Series owner's manual

BWT

BWT AQA drink Ho.Re.Ca. General instructions

Hayward

Hayward SWIMCLEAR C3030EURO owner's manual

Master Water Conditioning

Master Water Conditioning Clarifier MCA Series Installation and operation manual

Savio

Savio K5003 operating manual

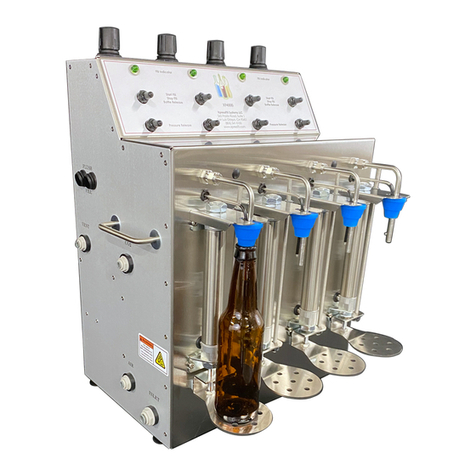

XpressFill

XpressFill XF4500 manual

Mitte Home

Mitte Home WK 9557 quick start guide