CSI Controls RK Series User manual

RK Series™

Serious Products for Serious Contractors!

Float Systems Manual

Page 2

RK Series™

Table of Contents

About the RK Series Float Systems....................................................Page 4

Float System Installation Instructions...............................................Pages 5-7

Step 1: Installing the Floats

Step 2: Installing the Controller

Typical Float System Installation Diagram

Understanding the Float System........................................................Page 8

Subdoor Control Center

Float Indication Status Lights

Float System Features.........................................................................Pages 9 - 10

Hand Run Buttons

Blown Fuse Indicators

Audible Alarm Circuitry

Alternation and Lag Delay

Special Options

Redundant Off Float

Auxiliary Alarm Contact

RK “E Series”

DDCs and DIBs

Understanding the RK “E Series” Float System...............................Page 11

Subdoor Control Center

Hand-Off-Auto Switch

Digital Display Center (DDC)...............................................................Page 12 - 15

Installation

Display Menu

User Settings Menu

Level Control Options Menu

Time Dosing Options Menu

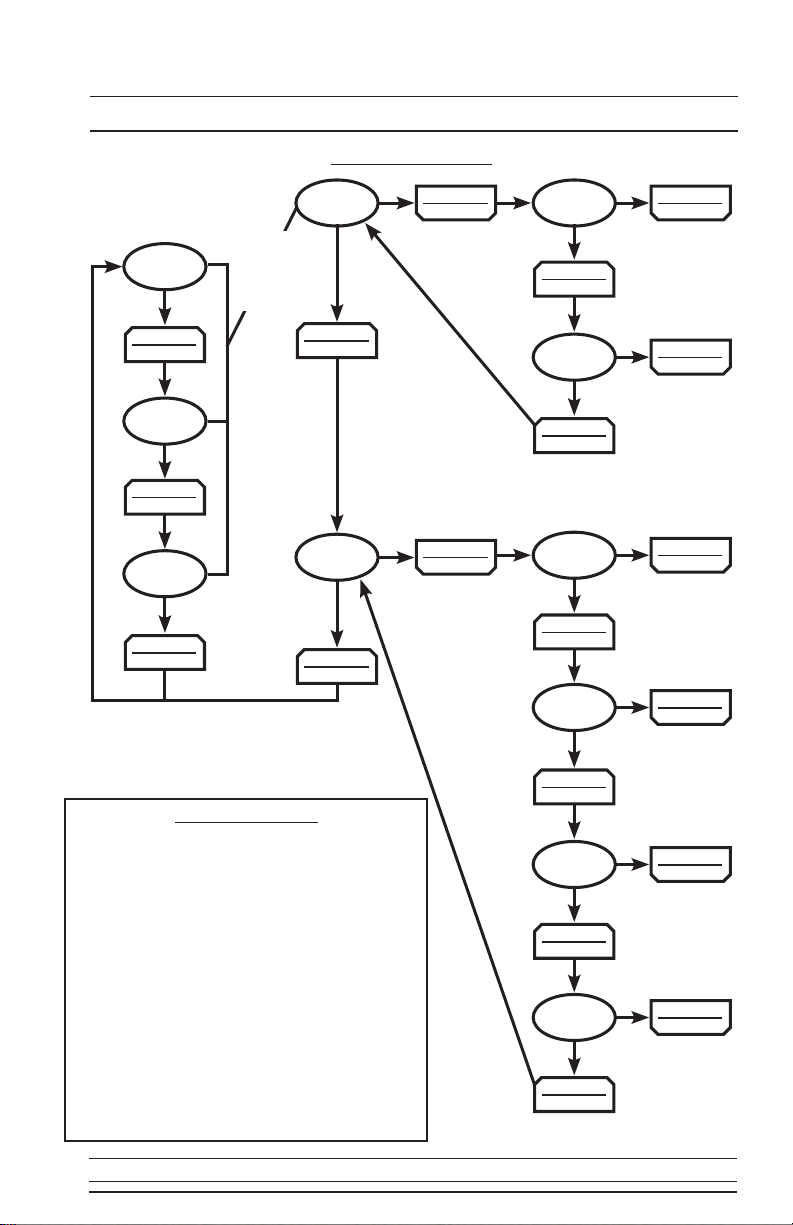

DDC Flow Chart

Page 3

Digital Interface Board (DIB)............................................................

Installation

Display Menu

User Settings Menu

Level Control Options Menu

Time Dosing Options Menu

Telemetry Menu

Alarm History Menu

Auxiliary Inputs

Flash Codes

FCC Information

DIB Flow Chart

Float System Troubleshooting..........................................................

Enclosure Dimensions........................................................................

Field Wiring Connections..................................................................

Terminal Strip With All Available Options

Determining Your RK Model Number

Float System Specifications..............................................................

Pages 16 - 22

Pages 23 - 24

Page 25

Page 26

Page 27

RK Series™

The Control Panel

Page 4

About the RK Series Float Systems

The RK Series float system is an innovative approach to today’s level

control requirements and offers many of the most requested items as

standard features such as lockable latches, a flashing red alarm light, an

electronic horn, and the innovative "Touch-To-Silence" pad all in a NEMA 4X

enclosure. Through the use of a standard subdoor and raised backpanel, the

RK Series is able to house common control panel features such as circuit

breakers, start components, contactors, and a terminal strip. The RK Series

also offers an exclusive control circuit board with float indication lights

conveniently located on the subdoor that allow the user to see the status of

each float.

Available in : Simplex or Duplex

Single Phase to Three Phase

Floats

-3 for simplex

-4 for duplex

Standard Float Systems Include:

RK Series™

Page 5

Float System Installation Instructions

Step 1: Installing the Floats

Installation Using the 2” PVC Mounting Bracket

Install the PVC mounting bracket to the side of the

tank and suspend a length of 2” PVC pipe from the

bracket. This allows the installer to mount the floats

the same as they would to the discharge pipe.

Installation Using the Float Mounting Bracket

Mount the bracket to the side of the tank and then

install the floats and weights into the cord snubbers.

Warning: 1. Do not install a float switch in direct line of incoming liquid

2. Make sure you leave at least 3.5 inches of tether length

between the actual float and the clamping device to allow

the float to tip properly.

The installer can tie wrap the floats to the pump discharge pipe at the

appropriate levels using a heavy duty tie wrap or a clamp designed for that

purpose.

Basic Float Installation

Warning: In critical applications where a failure could cause property

damage, a separate backup high water alarm should be used.

RK Series™

Page 6

Step 2: Installing the Controller

1. Determine a mounting location for the panel.

2. Determine the location of the conduit(s) coming into the panel.

3. Drill holes in the panel for conduit entry.

4. Mount the panel using the provided mounting feet.

5. Bring the float wires and power wires into the panel through the

conduit.

6. Wire the panel according to the schematic included in the panel.

7. Check installation by turning power on and manually tipping the

floats or running up the water level to test for proper installation.

8. Test the unit periodically to ensure proper operation.

Float System Installation Instructions

RK Series™

Page 7

Float System Installation Instructions

Typical Float System Installation Diagram

RK Series™

Note: Care should be taken to ensure

that sewage gases are not allowed

to enter the control panel by using

an approved gas sealing means!

(Damage caused by sewage gas is

not covered by warranty).

Page 8

Understanding the Float System

Subdoor Control Center

Float indication lights show the status of the floats in the basin. If a float

is tipped closed, the corresponding LED will be lit. If the floats tip out of

sequence it will cause the float indication lights to show an error. If a higher

float comes on before the next lowest float, the LED of the lower float will

flash indicating a problem. For example, if the “Lead Pump On” float hangs up

and the water level comes down to the “Pumps Off” float level, the “Pumps

Off” float will tip down. The “Pumps Off” LED will then flash while the “Lead

Pump On” LED remains on. However, the error indication will be automatically

cleared next time the floats sequence in the proper order. Another example

would occur when the “Pumps Off” float fails to close when it tips up. When

the “Lead Pump On” float tips up, the “Pumps Off” LED will then flash while

the “Lead Pump On” LED remains on. Even though the error indication is the

same there could be two causes for the error. The first cause being a hung up

float, and the second cause being a float failure. These lights help to assist in

troubleshooting float errors and station problems.

Float Indication Status Lights

If you need any additional help please call the factory for technical

assistance: 1-800-746-6287

Control Circuit

Power Light

"High Level"

Light

"Lag Pump

On" Light

"Lead Pump

On" Light

Alarm Light

"Pumps Off"

Light

Pump Run Lights

Hand Run

Pushbuttons

Test/Silence

Pushbutton

Alarm Circuit

Power Light

RK Series™

Page 9

Float System Features

Hand Run Buttons

RK panels include push-to-run (HAND) pushbuttons for the motor starters

output and a push-to-test (TEST) pushbutton for the alarm output accessible

on the subdoor. The push-to-run (HAND) pushbuttons toggle their respective

outputs off and on each time pushed under normal operation. However, to

protect the pumps should the sump go below the "Pump(s) Off" float, the

HAND pushbuttons revert to momentary contact and must be held down

to maintain its respective output on. This is a safety feature that keeps the

pumps from running dry.

Audible Alarm Circuitry

RK panels come standard with an audible piezo alarm (95 db +/-) and the

exclusive side mounted “Touch-To-Silence” pad (patents pending). With this

feature the user is able to silence the audible by simply touching the decal on

the side of the enclosure.

Blown Fuse Indicators

These lights are located above the fuses on the subdoor. If a fuse is blown,

the indicator above the blown fuse will light up and the power light on the

subdoor control center for that circuit will be off. However, if the power light

is off and the blown fuse light is not lit then that circuit is not getting any

power.

Alternation and Lag Delay (Duplex Controllers Only)

On the duplex controller the float indications are labeled "Lead Pump" and

"Lag Pump" because there is a built in alternator in the controller. The

alternator cycles which pump is the lead pump after each pump run cycle.

The non-adjustable delay causes the lag pump to wait ten seconds before

turning on after the lead pump has turned on. This is useful during a power

outage when the liquid level may reach the lag pump setting. The lead

pump will turn on when power is restored and the lag pump will turn on ten

seconds later.

RK Series™

Page 10

Float System Features

Redundant Off Float

The redundant off float option reassures that the pump(s) will not run dry. If

your panel has this option the terminal strip will include numbers 7 & 8. To

use the redundant off option, connect a normally open float switch to these

terminals, otherwise install a jumper across terminals 7 & 8 if you do not

wish to use this feature. When the float is in the open position the pumps will

not be able to run except by using the hand run push buttons in momentary

contact mode.

Note: “Hand Run Buttons” (page 8) describes momentary contact mode.

Special Options

Auxiliary Alarm Contact

If your panel has the Auxiliary Alarm Contact option then the terminal strip

will include the numbers 17 & 18. This option offers a dry contact that closes

during a high level alarm condition then opens when the alarm goes away or

when the panel is silenced.

DDCs and DIBS

Every RK Series panel has a removable faceplate on the subdoor to add

either a Digital Display Center (DDC) or a Digital Interface Board (DIB).

Upgrading to one of these display options allows the user to access more

features.

DDC Operation Manual - Page 11

DIB Operation Manual - Page 15

RK “E Series”

The RK “E Series” offers basic features including 3-float operation (simplex

only), "Touch-To-Silence" pad, an audible alarm, and flashing alarm light in a

NEMA 4X enclosure. It is an economical solution for your pump control needs.

Understanding the

“E Series” Float System -Page 10

RK Series™

Page 11

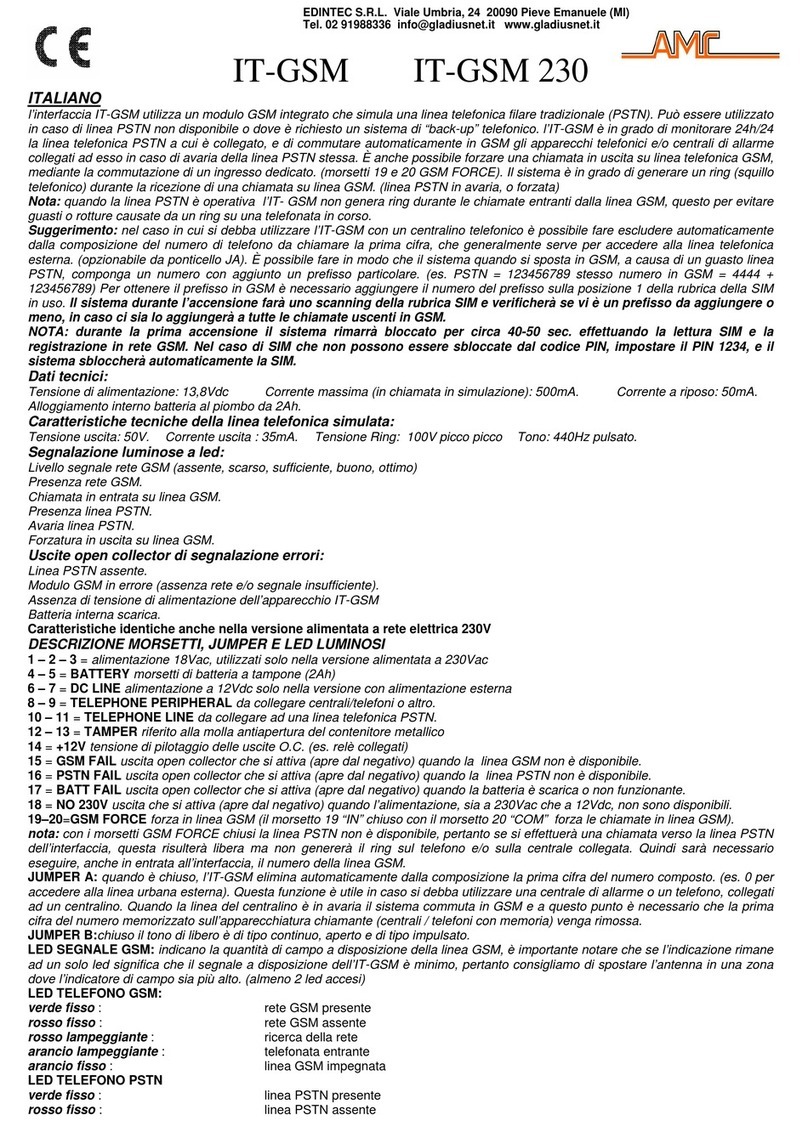

Understanding the “E Series” Float System

Pump Run

Light

Test/Silence

Pushbutton

Power Light

User Safe Fuse

Hand-Off-Auto

Switch

Hand-Off-Auto Switch

The Hand-Off-Auto switch is located on the front of the subdoor for control

of the pump state. In the “Auto” position, the level control circuit will control

the pump. In the “Hand” position, the pump will be turned on, and in the “Off”

position the pump will be disabled from running.

Note 1: When there is a fuse blown condition on a RK “E Series”

controller the “blown fuse indicator” will light and the “power

light” will continue to be dimly lit.

Blown Fuse

Indicator

Alarm Light

If you need any additional help please call the factory for technical

assistance: 1-800-746-6287

Subdoor Control Center

Note 2: Since the "E Series" is an economical version of the float

system, it does not support certain features. Features not

available in the “E Series” panels are Alternation (simplex

control only), Hand Run Buttons, Float Status Lights, Redundant

Off Float Option, and the Auxiliary Alarm Contact option.

RK Series™

Page 12

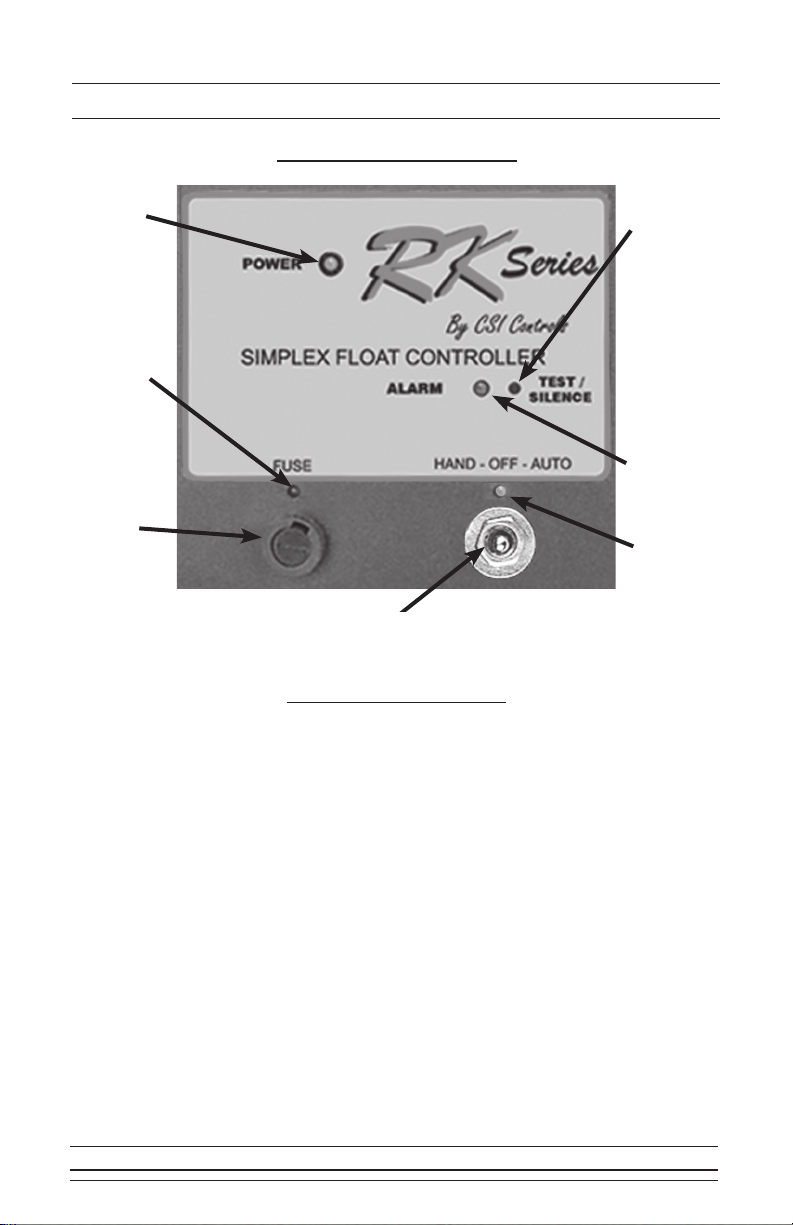

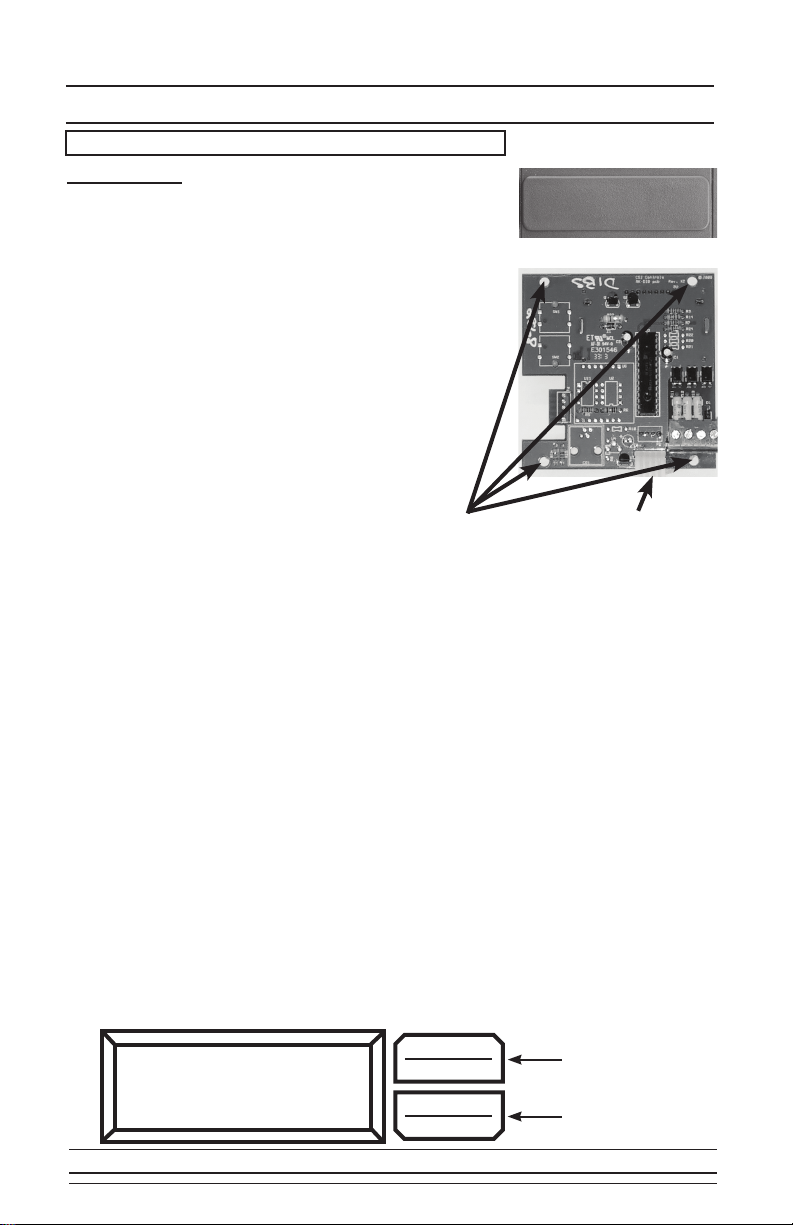

Digital Display Center (DDC)

Installation

To install the DDC, remove the faceplate from above the

control center on the subdoor and insert the DDC module

from the back of the subdoor. Next, screw in the four

corner screws. With the power off, attach the ribbon from

the DDC module to the control board. After everything is

installed, turn the power on. It may take up to 10 seconds

for the circuit board to complete the program update.

Once the circuit board has completed the program

update, normal operation will begin.

Note: RKE boards cannot update through the DDC.

Display Menu

Press Menu/Enter Button to change between menu

fields

Et. # - (Elapsed Time, # is Pump number (1 or 2)):

Reads out the total elapsed run time of the corresponding pump.

Press Set/Change button to alternate between

hours and minutes & seconds

CC.# - (Cycle Counter, # is Pump number (1 or 2)):

Reads out the number of cycles the corresponding pump has

run. (Max Value: 9999)

F1tr - (Field 1 Timer, Time Dose DDCs only):

Reads out the remaining time in the current time cycle. If the

pump(s) are running then it indicates the time remaining until the

pump(s) shut off. If the pump(s) are off then it indicates time

remaining until the pump(s) are enabled to run again.

Installation Screws

Back of DDC Module

Connecting Ribbon

Menu/Enter

Button

Set/Change

Button

dEPH MENU

ENTER

SET

CHANGE

Make sure power is OFF before installing DDC!

RK Series™

Removable Face Plate

Installation Screws

Page 13

Digital Display Center (DDC)

User Settings Menu

Press and hold Menu/Enter Button for 3 seconds while in the Display Menu to

enter into this menu. Press the Menu/Enter Button to change between menu fields.

LCOP - (Level Control Options Menu):

Press Set/Change button to enter into this submenu.

tDOP - (Time Dosing Options Menu, Time Dose DDCs only):

Press Set/Change button to enter into this submenu.

Level Control Options Menu

LSS - (Lead Selection Setting, Duplex Panels Only):

Display will alternate showing “LSS” and the current value.

Press Set/Change button to change this field.

Possible Settings:

0 = Alternate Between Pumps

1 = Pump #1 Always is Lead Pump

2 = Pump #2 Always is Lead Pump

r CC - (Reset Cycle Counter(s))

Display will alternate showing “r CC” and the value “0.”

Press Set/Change button to change this field.

Possible Settings:

0 = Do Not Reset Cycle Counter(s)

1 = Reset Cycle Counter(s) to 0

RK Series™

Page 14

Digital Display Center (DDC)

F1t1 - (Field 1 Time 1 (Pump Enable Time Setting))

Display will alternate showing “F1t1” and the current value. Time shown

is in [Minutes : Seconds] (Maximum time setting is 99:59)

Press Set/Change button to change this field.

F1t2 - (Field 1 Time 2 (Pump Disable Time Setting))

Display will alternate showing “F1t2” and the current value. Time shown

is in [Hours : Minutes] (Maximum time setting is 99:59)

Press Set/Change button to change this field.

ALOr - (Alarm / Override Function):

Display will alternate showing “ALOr” and the current value.

Press Set/Change button to change this field.

Possible Settings, Simplex:

(What the High Level input will do)

0 = Override the Pump Disable Timer and Alarm with selected

Time Delay (see HLtd setting). A warning will sound and

flash the alarm light to indicate the panel is in Override

mode. This can be silenced. It will be cleared after the

Disable Timer times out.

1 = Only Override the Pump Disable Timer without any alarms.

2 = Only Sound High Level Alarm without any delays.

Possible Settings, Duplex:

(What the Lag (override) input will do)

0 = Override Pump Disable Timer. A warning will sound and

flash the alarm light to indicate the panel is in Override

mode. This can be silenced. It will be cleared after the

Disable timer times out.

1 = Override the Pump Disable Timer. No warning will sound.

2 = Override function is disabled. Lag float input is ignored.

HLtd - (High Level Time Delay, Simplex Panels Only):

Display will alternate showing “HLtd” and the current value. The High

Level Alarm will delay according to the set time. If the fluid level is

above the High Level input for this length of time without interruption,

the alarm will begin to sound. Time shown is in [Minutes : Seconds]

(Maximum time setting is 99:59)

Press Set/Change button to change this field.

Time Dosing Options Menu

RK Series™

Page 15

Digital Display Center (DDC)

DDC Flow Chart

Digital Display Key

Et.# - Elapsed Run Time of Corresponding Pump

CC.# - Number of Cycles the Corresponding

Pump Has Run

F1tr - Field 1 Timer (Time Dose DDCs Only)

LCOP - Level Control Options Menu

tDOP - Time Dosing Options Menu (Time Dose

DDCs Only)

LSS - Lead Selection Setting (Duplex Panels

Only)

rCC - Reset Cycle Counters

F1t1 - Field 1 Time 1 (Pump Enable Setting)

[MIN:SEC]

F1t2 - Field 1 Time 2 (Pump Disable Setting)

[HR:MIN]

HLtd - High Level Delay (Simplex Panels Only)

[MIN:SEC]

MENU

ENTER

MENU

ENTER

MENU

ENTER

MENU

ENTER

MENU

ENTER

MENU

ENTER

MENU

ENTER

MENU

ENTER

MENU

ENTER

MENU

ENTER

MENU

ENTER

SET

CHANGE

SET

CHANGE

Et. #

HLtd

ALOr

F1t2

r CC

LSS

tDOP

LCOP

F1tr

CC. #

SET

CHANGE

F1t1 SET

CHANGE

SET

CHANGE

SET

CHANGE

SET

CHANGE

SET

CHANGE

Press

& Hold

Menu/

Enter

Button

Push to Change

Field

Push to Change

Field

Push to Change

Field

Push to Change

Field

Push to Change

Field

Push to Change

Field

RK Series™

Page 16

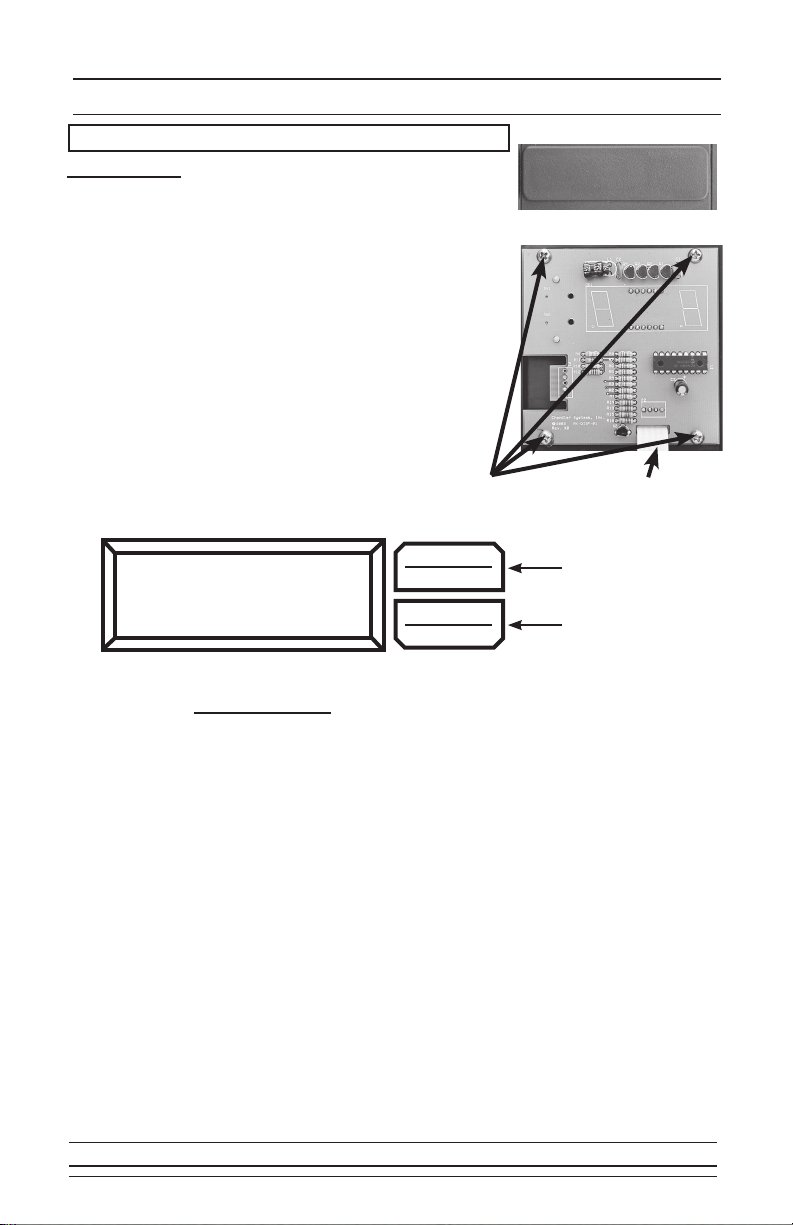

Digital Interface Board (DIB)

Installation

To install the DIB, remove the faceplate from above

the control center on the subdoor and insert the

DIB module from the back of the subdoor (be sure

to remove the protective film on the display before

installing). Next, screw in the four corner screws.

With the power off, attach the ribbon from the DIB

module to the control board. After everything is

installed, turn the power on. It may take up to 10

seconds for the circuit board to complete the program

update. Once the circuit board has completed the

program update, normal operation will begin. Once a

DIB has been installed, the panel will not work if the

DIB is removed.

Note: RKE boards are not compatible with the DIB.

Installation Screws

Back of DIB Module

Connecting Ribbon

Make sure power is OFF before installing DIB!

Menu Navigation

To advance to the next menu, press the “Menu/Enter” button. To go to the settings

menu from the display menu, push and hold “Menu/Enter” until you see the “Level

Cntrl Menu” appear on the LCD screen. When in the Settings Menu press “Menu/

Enter" to cycle through the fields, to select a submenu, press the “Set/Change”

button.

Editing Fields

To edit the setting currently being displayed on the screen, press the “Set/Change”

button. The value that is now being edited will begin to flash. To change this value,

press the “Set/Change” button. To move to the next edit digit, or to finish editing the

setting, press the “Menu/Enter” button.

Example

To Change Pump Alternation Features: (Duplex Systems Only)

From the Display Menu press and hold the “Menu/Enter” button until “Level Cntrl

Menu” appears on the LCD screen. Next press the “Set/Change” button to enter

into the Level Control submenu. The first field is “Lead Pump Set”. Press the “Set/

Change” button again to change this field. The field being edited will flash. Press the

“Set/Change” button to change the field and press the “Menu/Enter” button to accept

the setting.

Lead Pump Set

Alternate

Menu/Enter

Button

Set/Change

Button

MENU

ENTER

SET

CHANGE

RK Series™

Removable Face Plate

Page 17

Digital Interface Board (DIB)

Display Menu

Press Menu/Enter Button to change between menu fields.

Elapsed Time # - (# is Pump number (1 or 2)):

Reads out the total elapsed run time of the corresponding pump. (Max

Value 999999:59:59) Time shown is in the format of

[Hours:Minutes:Seconds]

Cycle Count # - (# is Pump number (1 or 2)):

Reads out the number of cycles the corresponding pump has run.

(Max Value: 999999)

Override Count - (Time Dose DIBs only):

Reads out the number of times the panel has gone into override mode.

(Max Value: 999999)

High Level Count :

Reads out the number of times the liquid level has reached high level.

(Max Value: 999999)

Field #1 Timer - (Time Dose DIBs only):

Reads out the remaining time in the current time cycle. If the pump(s)

are running then it indicates the time remaining until the pump(s) shut

off. If the pump(s) are off then it indicates time remaining until the

pump(s) may run again.

Active Alarm :

Reads out what alarm condition the panel is currently experiencing. If

there are no alarms, it will read “None.”

User Settings Menu

Press and hold Menu/Enter for 3 seconds while in the Display Menu to enter into

this menu. Press the Menu/Enter button to change between the following menu

fields.

Level Cntrl Menu - (Level Control Options Menu):

Press Set/Change button to enter into this submenu.

Time Dosing Menu - (Time Dosing Options Menu, Time Dose DIBs only):

Press Set/Change button to enter into this submenu.

Telemetry Menu - (Modem DIBs only):

Press Set/Change button to enter into this submenu.

Alarm History :

Press Set/Change button to enter into this submenu.

RK Series™

Page 18

Digital Interface Board (DIB)

Level Cntrl Menu - (Level Control Options Menu):

Lead Pump Set (Duplex Panels Only):

Press Set/Change button to change this field.

Possible Settings:

Alternate = Alternates which pump turns on at LEAD PUMP

input every time a pump runs.

Pump 1 is Lead = Pump #1 ALWAYS turns on at the LEAD PUMP

input and Pump #2 ALWAYS turns on at the LAG

PUMP input.

Pump 2 is Lead = Pump #2 ALWAYS turns on at the LEAD PUMP

input and Pump #1 ALWAYS turns on at the LAG

PUMP input.

Reset Cyc Cnt # - This is the cycle count that can be viewed in the

Display Menu (Reset Cycle Counter to zero, # is pump number (1 or 2)

Possible Settings:

Do Not Reset = Cycle Counter will not reset

Reset Counter = Cycle Counter will reset to 0

Reset ETM # - This is the Elapsed time that can be viewed in the Display Menu

(Reset Elapsed Time to zero, # is pump number (1 or 2)

Press Set/Change button to change this field.

Possible Settings:

Reset Counter = Elapsed Time will reset to 0

Do Not Reset = Elapsed Time will not reset

RK Series™

Page 19

Digital Interface Board (DIB)

Time Dosing Options Menu (Time Dose Versions Only)

Pump 1 Time On - (Pump Enable Time Setting) This is the amount of time

the pump will be enabled to run once the level reaches the PUMP ON

(simplex) or LEAD PUMP ON (duplex) input. Note: If the level reaches the

PUMP OFF input before time expires, the pump will shut off and the Pump

Disable time will begin.

Time shown is in [Minutes:Seconds] (Maximum time setting is 99:59)

Press Set/Change button to change this field.

Pump 1 Time Off - (Pump Disable Time Setting) This is the amount of time

the pump must wait after it completes a run cycle before it may run again.

Note: If the level reaches the override (lag) input, the pump will begin to

run regardless of Pump Disable Time.

Time shown is in [Hours:Minutes] (Maximum time setting is 99:59)

To disable Time Dosing, set this field to 00:00.

Press Set/Change button to change this field.

Pump 1 Ovrrid On - (Pump Enable Time Setting for Override) This is the

amount of time the pump will be enabled to run once the level reaches the

override input at which time the system enters Override Time Dosing

mode.

Time shown is in [Minutes:Seconds] (Maximum time setting is 99:59)

Press Set/Change button to change this field.

Pump 1 Ovrrid Off - (Pump Disable Time Setting for Override) This is the

amount of time the pump must wait after it completes an Override run cycle

before it may run again. Note: The pump will continue to cycle in override

time dosing mode until the level is below the PUMP ON input when the

Override Pump Disable Time expires.

Time shown is in [Hours:Minutes] (Maximum time setting is 99:59)

Press Set/Change button to change this field.

Pump 2 Time On - (Pump Enable Time Setting)

See “Pump 1 Time On” Description

Time shown is in [Minutes:Seconds] (Maximum time setting is 99:59)

Press Set/Change button to change this field.

Pump 2 Time Off - (Pump Disable Time Setting)

See “Pump 1 Time Off” Description

Time shown is in [Hours:Minutes] (Maximum time setting is 99:59)

To disable Time Dosing, set this field to 00:00.

Press Set/Change button to change this field.

RK Series™

Page 20

Digital Interface Board (DIB)

Time Dosing Options Menu (Continued)

Pump 2 Ovrrid On - (Pump Enable Time Setting for Override)

See “Pump 1 Ovrrid On” Description

Time shown is in [Minutes:Seconds] (Maximum time setting is 99:59)

Press Set/Change button to change this field.

Pump 2 Ovrrid Off - (Pump Disable Time Setting for Override)

See “Pump 1 Ovrrid Off” Description

Time shown is in [Hours:Minutes] (Maximum time setting is 99:59)

Press Set/Change button to change this field.

Alarm/Override - This setting controls 3 functions of Time Dosing:

Override: When the basin level reaches the Override float (High Level

float on simplex, Lag float on duplex), the panel will override the

Off Timer, and run the pump(s) using the override On and Off times.

Override Warning: When an override occurs, the panel will sound an Override

Warning Alarm, to signal that an override event is occurring.

High Level Alarm: When the basin level reaches the High Level float, the

panel will sound a High Level Alarm, to signal that the liquid level is

much higher than expected.

Press Set/Change button to change this field.

Setting Override Override Warning High Level Alarm

Override w/ Alarms ON ON ON

Override-No Warning ON OFF ON

Overide-No Alarms ON OFF OFF

Alarm-No Override OFF OFF ON

High Level Delay - (High Level Time Delay, Simplex Panels Only):

The High Level Alarm will delay according to the set time. If the fluid level is

above the High Level float for this length of time without interruption the

alarm will begin to sound.

Time shown is in [Minutes:Seconds] (Maximum time setting is 99:59)

Press Set/Change button to change this field.

Number of Fields - (Duplex Panels Only):

The Time Dosing operation can be set up for “One Field” or “Two Fields.”

- When set to “Two Fields” each pump will be able to run as soon as its

corresponding Off Timer is complete. During override the two pumps

may run at the same time.

- When set to “One Field” each pump will only be able to run when the Off

Timer for both pumps is complete. The two pumps will never run at the

same time.

RK Series™

This manual suits for next models

1

Table of contents