CTB Chore-Time Setup guide

Extension Hopper

for

Model 55, 75, 75 Stainless, 75 Plus,

75 Plus Stainless, 90, & HMC

FLEX-AUGER Feed Delivery Systems

For additional parts and information, contact your nearest Chore-Time distributor or representative.

Find your nearest distributor at: www.choretime.com/contacts

MA709HAugust 2019

Installation and Operators Manual

Installation and Operators Manual

Contents

Topic Page

MA709H 2

Limited Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety and General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Follow Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Decal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DANGER: Moving Auger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DANGER: Electrical Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Support Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Planning the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Straight Line Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Right Hand Turn Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Left Hand Turn Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

(Single Phase, 230 V, 50/60Hz, w/o Motor Starters) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

(Single Phase, 230 V, 50/60Hz, w/ Motor Starters) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

(Three Phase, 220/380/415/460 V, 50/60 Hz, w/ Motor Starters) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Extension Hopper Limited Warranty

3

MA709H

LIMITED WARRANTY

Chore-Time Group, a division of CTB, Inc. (“Chore-Time”) warrants new CHORE-TIME CHORE-TIME FLEX-AUGER

System Parts and Components manufactured by Chore-Time to be free from defects in material or workmanship under

normal usage and conditions, for One (1) year from the date of installation by the original purchaser (“Warranty”). Chore-

Time provides for an extension of the aforementioned Warranty period (“Extended Warranty Period”) with respect to

certain Product parts. If such a defect is determined by Chore-Time to exist within the applicable period, Chore-Time will, at

its option, (a) repair the Product or Component Part free of charge, F.O.B. the factory of manufacture or (b) replace the

Product or Component Part free of charge, F.O.B. the factory of manufacture. This Warranty is not transferable, and applies

only to the original purchaser of the Product.

CONDITIONS AND LIMITATIONS

THIS WARRANTY CONSTITUTES CHORE-TIME’S ENTIRE AND SOLE WARRANTY AND CHORE-TIME

EXPRESSLY DISCLAIMS ANY AND ALL OTHER WARRANTIES, INCLUDING, BUT NOT LIMITED TO,

EXPRESS AND IMPLIED WARRANTIES, INCLUDING, WITHOUT LIMITATION, WARRANTIES AS TO

MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES. CHORE-TIME shall not be liable for any direct,

indirect, incidental, consequential or special damages which any purchaser may suffer or claim to suffer as a result of any

defect in the Product. Consequential or Special Damages as used herein include, but are not limited to, lost or damaged

products or goods, costs of transportation, lost sales, lost orders, lost income, increased overhead, labor and incidental costs,

and operational inefficiencies. Some jurisdictions prohibit limitations on implied warranties and/or the exclusion or

limitation of such damages, so these limitations and exclusions may not apply to you. This warranty gives the original

purchaser specific legal rights. You may also have other rights based upon your specific jurisdiction.

Compliance with federal, state and local rules which apply to the location, installation and use of the Product are the

responsibility of the original purchaser, and CHORE-TIME shall not be liable for any damages which may result from non-

compliance with such rules.

The following circumstances shall render this Warranty void:

· Modifications made to the Product not specifically delineated in the Product manual.

· Product not installed and/or operated in accordance with the instructions published by the CHORE-TIME.

· All components of the Product are not original equipment supplied by CHORE-TIME.

· Product was not purchased from and/or installed by a CHORE-TIME authorized distributor or certified

representative.

· Product experienced malfunction or failure resulting from misuse, abuse, mismanagement, negligence, alteration,

accident, or lack of proper maintenance, or from lightning strikes, electrical power surges or interruption of

electricity.

· Product experienced corrosion, material deterioration and/or equipment malfunction caused by or consistent with

the application of chemicals, minerals, sediments or other foreign elements.

· Product was used for any purpose other than for the care of poultry and livestock.

·

The Warranty and Extended Warranty may only be modified in writing by an officer of CHORE-TIME. CHORE-TIME

shall have no obligation or responsibility for any representations or warranties made by or on behalf of any distributor,

dealer, agent or certified representative.

Limited Warranty

Effective: April 2014

Safety and General Information Extension Hopper

4MA709H

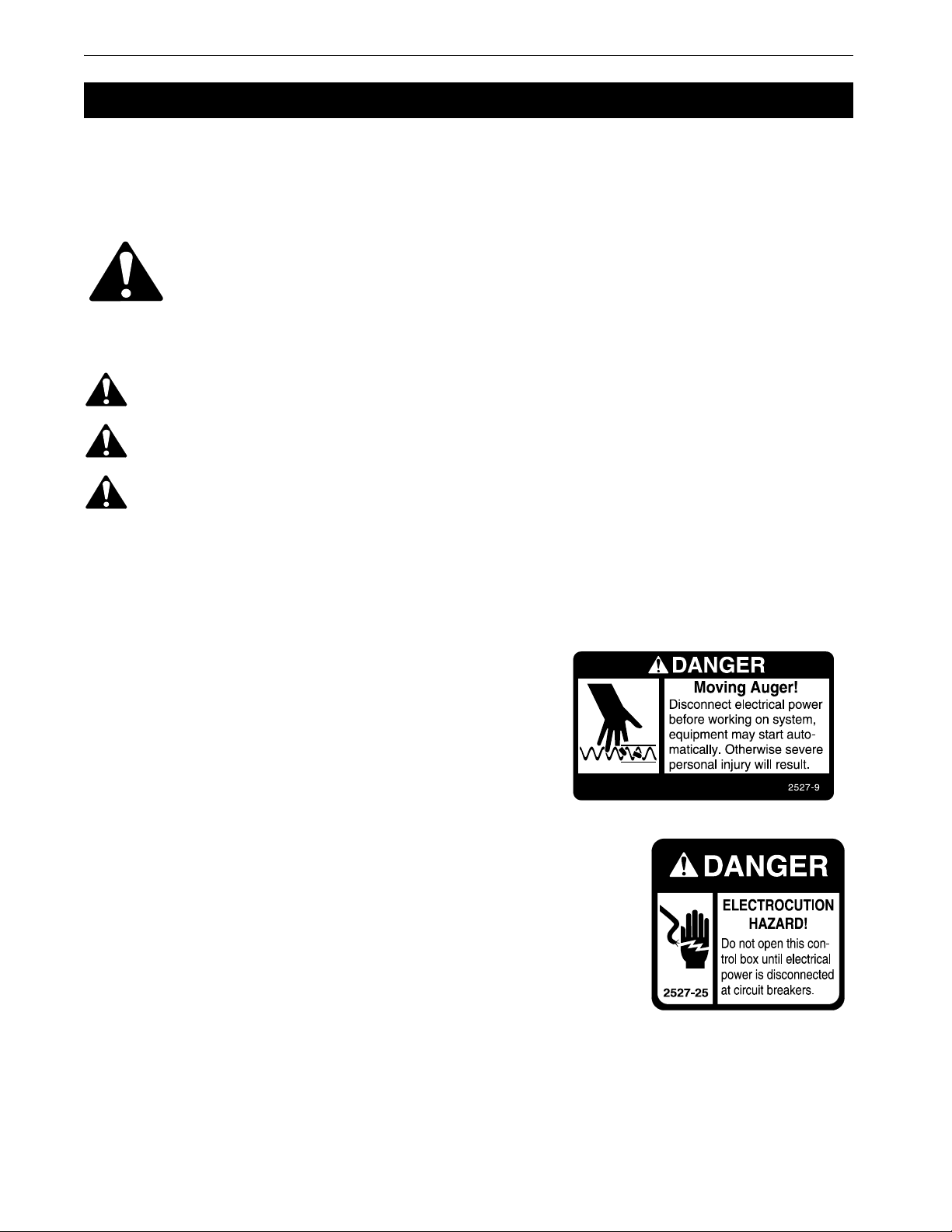

Caution, Warning and Danger Decals have been placed on the equipment to warn of potentially dangerous

situations. Care should be taken to keep this information intact and easy to read at all times. Replace missing or

damaged safety decals immediately.

Safety–Alert Symbol

This is a safety–alert symbol. When you see this symbol on your equipment, be alert to the potential

for personal injury. This equipment is designed to be installed and operated as safely as

possible...however, hazards do exist.

Understanding Signal Words

Signal words are used in conjunction with the safety–alert symbol to identify the severity of the warning.

DANGER indicates an imminently hazardous situation which, if not avoided, WILL result in death or

serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, COULD result in death or

serious injury.

CAUTION indicates a hazardous situation which, if not avoided, MAY result in minor or moderate

injury.

Follow Safety Instructions

Carefully read all safety messages in this manual and on your equipment safety signs. Follow recommended

precautions and safe operating practices.

Keep safety signs in good condition. Replace missing or damaged safety signs.

Decal Descriptions

DANGER: Moving Auger

This decal is placed on the End Cap Weldment and Clean-out

cover. Severe personal injury will result, if the electrical

power is not disconnected, prior to servicing the equipment.

DANGER: Electrical Hazard

Disconnect electrical power before inspecting or servicing equipment unless

maintenance instructions specifically state otherwise.

Ground all electrical equipment for safety.

All electrical wiring must be done by a qualified electrician in accordance with

local and national electric codes.

Ground all non-current carrying metal parts to guard against electrical shock.

Electrical disconnects and over current protection are not supplied with the

equipment.

Safety and General Information

Extension Hopper Support Information

5

MA709H

The Chore-Time Extension Hopper is designed to lengthen a Feeding system in a Livestock feeding application.

Using this equipment for any other purpose or in a way not within the operating recommendations specified in this

manual will void the warranty and may cause personal injury.

This manual is designed to provide comprehensive planning, installation, operation, and parts listing information.

The Table of Contents provides a convenient overview of the information in this manual. The Table of Contents

also specifies which pages contain information for the sales personnel, installer, and consumer (end user).

Refer to Chore-Time Model 55/75/75 Stainless/75 Plus/75 Plus Stainless/90/HMC Installation Manual for

additional installation, operation, and parts listing information.

IMPORTANT: CE stands for certified Europe. It is a standard

which equipment must meet or exceed in ordered to be sold in

Europe. CE provides a benchmark for safety and manufacturing

issues. CE is required only on equipment sold in Europe.

Chore-Time Equipment recognizes CE Mark and pursues

compliance in all applicable products. Fill in the CE-Mark serial

number in the blank space provided for future reference.

Support Information

(CE-mark serial number)

Distributor’s Name___________________________________________________

Distributor’s Address ________________________________________________

Distributor’s Phone _______________________ Date of Purchase ___________

Installer’s Name _____________________________________________________

Installer’s Address___________________________________________________

Installer’s Phone ________________________Date of Installation ___________

System Specifications________________________________________________

Please fill in the following information about your Product.

Keep this manual in a clean, dry place for future reference.

Introduction Extension Hopper

6MA709H

The extended length Model 55, 75, 75 Stainless, 75 Plus, 75 Plus Stainless, 90, & HMC FLEX-AUGER Feed

Delivery Systems are used to increase the total length of the system in applications where this is required.

The Model 75 Plus/SS System offers Extension Hopper Kits in both Galvanized Steel and Stainless Steel

Construction.

The Extension Boot Kits may be used with

Model 55: 1/3, and 1/2 H.P. Power Units.

Model 75/Stainless, 90, and HMC: 1/2, 3/4, and 1 H.P. Power Units.

Model 75 Plus/Stainless: 3/4, 1, and 1-1/2 H.P. Power Units

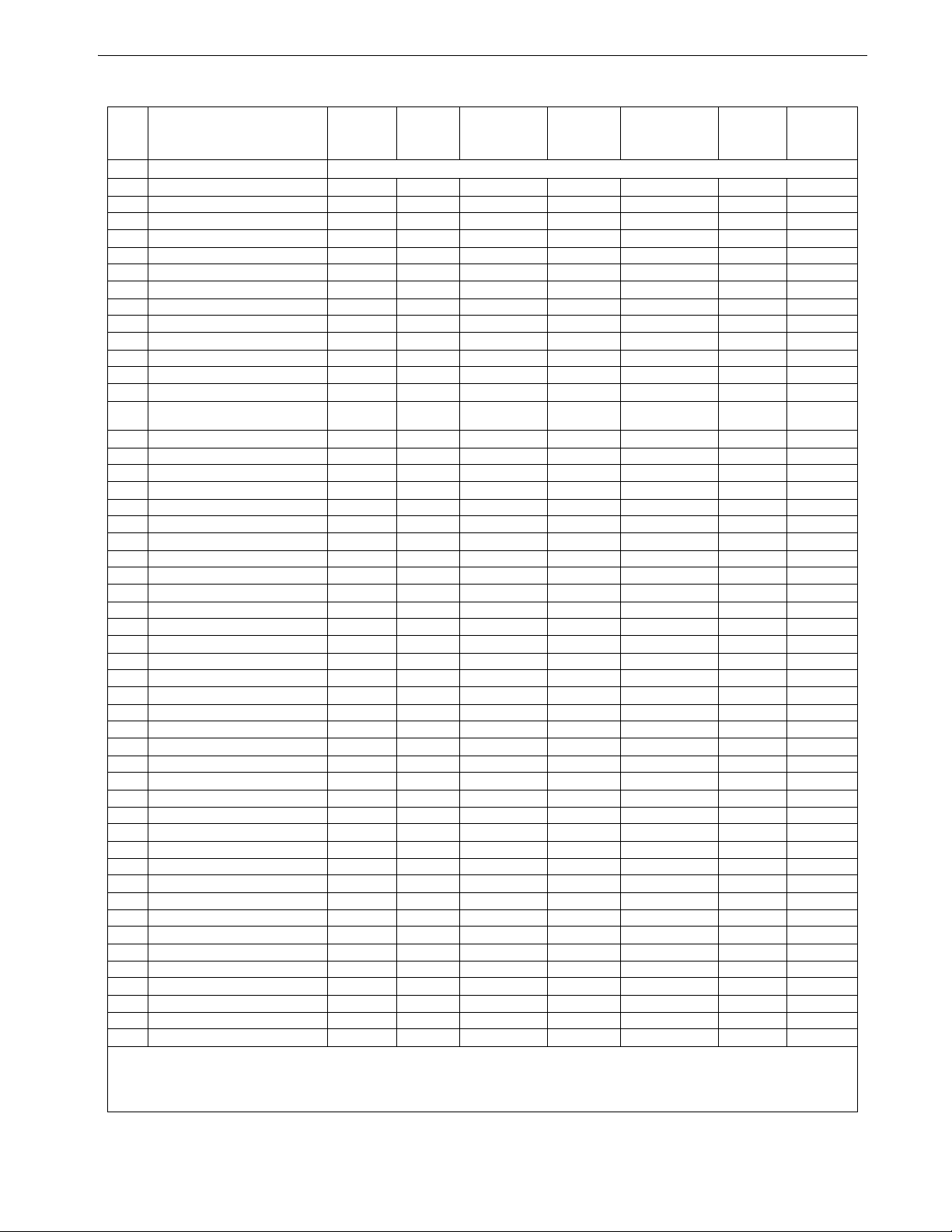

Maximum lengths for the standard system and Extended Length Systems with various power unit are shown in

the chart below.

Maximum length recommendations for standard systems include use of two 45 degree elbows. No elbows are

included in the recommendations for maximum length of extension systems. If additional elbows are required,

decrease the length recommendations by 30 feet (9 m) for each additional 90 degree turn.

Introduction

Model 55 Model 75/SS Model 75/SS

Plus Model 90 Model HMC

Motor

Size

Max.

Standard

Max.

Extension

Max.

Standard

Max.

Extension

Max.

Standard

Max.

Extension

Max.

Standard

Max.

Extension

Max.

Standard

Max.

Extension

1/3 H.P. 150 Feet

(46 M)

185 Feet

(56 M)

n//a n/a n/a n/a n/a n/a n/a n/a

1/2 H.P. 250 Feet

(76 M)

285 Feet

(87 M)

80 Feet

(24 M)

125 Feet

(38 M)

n/a n/a 30 Feet

(9 M)

65 Feet

(20 M)

30 Feet

(9 M)

55 Feet

(17 M)

3/4 H.P. n/a n/a 150 Feet

(46 M)

185 Feet

(56 M)

80 Feet

(24 M)

125 Feet

(38 M)

90 Feet

(27 M)

125 Feet

(38 M)

90 Feet

(27 M)

105 Feet

(32 M)

1 H.P. n/a n/a 200 Feet

(61 M)

245 Feet

(75 M)

150 Feet

(46 M)

185 Feet

(56 M)

150 Feet

(46 M)

185 Feet

(56 M)

150 Feet

(46 M)

185 Feet

(56 M)

1-1/2 H.P. n/a n/a n/a n/a 300 Feet

(91 M)

345 Feet

(105 M)

n/a n/a n/a n/a

Extension Hopper Planning the Installation

7

MA709H

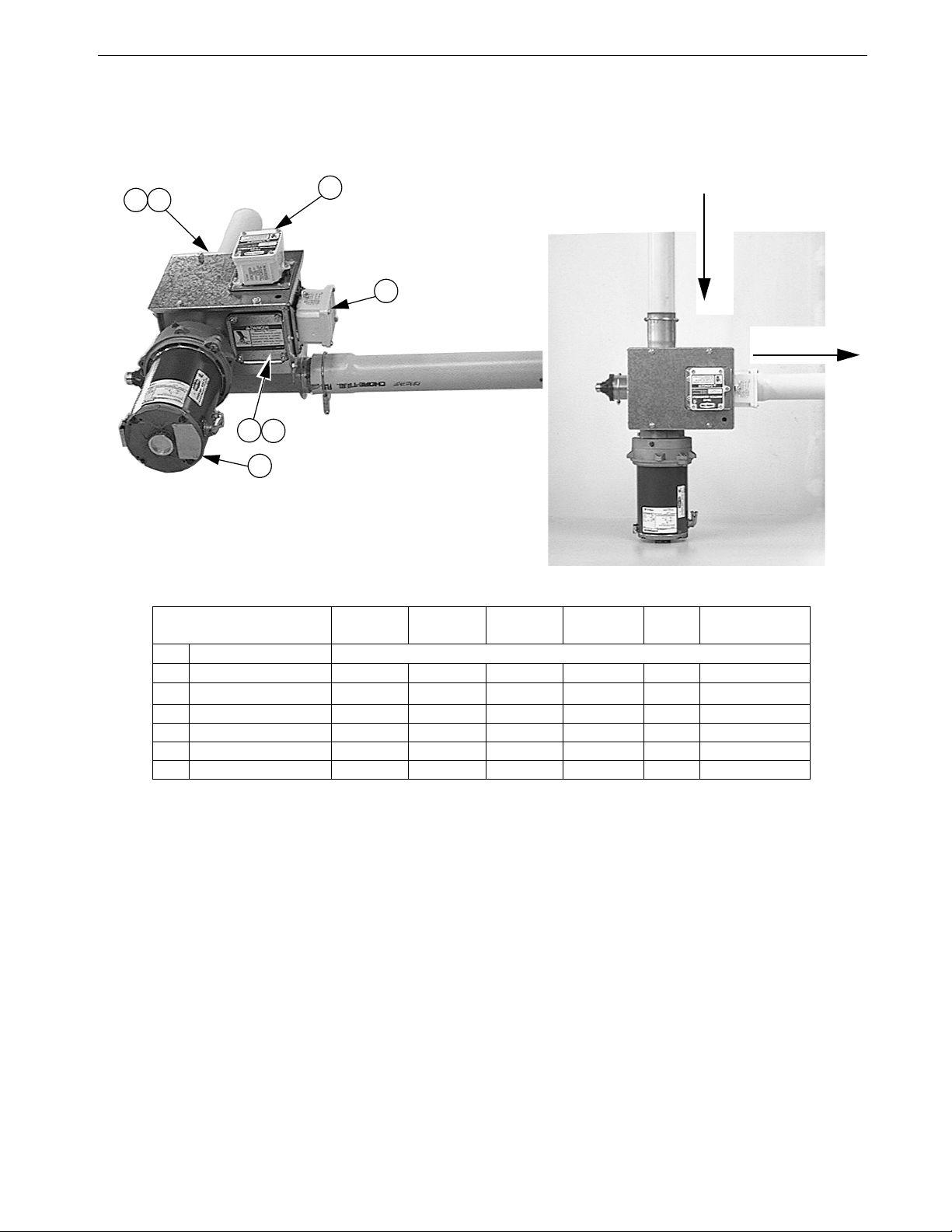

By moving the Window Plate, Cover Plate, Tube Anchor, Level Switch Assembly, and Power Unit, it is

possible to extend the system in a straight line or use the Extension Boot to replace elbows making a 90 degree

turn where that is convenient.

The Safety Switch should be located toward the outlet end of the boot on all applications.

Figure 1 through Figure 4 show that by moving several components to different locations the Extension Boot

may be used to turn right hand, left hand, or extend a straight line system.

Straight Line Application

Planning the Installation

Model 55 Model

90 & HMC Model 75 Model 75

Stainless

Model

75 Plus

Model

75 Plus Stainless

Key Description Part No.

1 Power Unit -- -- -- -- -- --

2 Level Switch Assembly 7840 7840 7840 7840SS 7840 7840SS

3 Incoming Tube Anchor 35531 5069 6518 6518SS 6518 6518SS

4 Seal 4873 4873 4873 4873 4873 4873

5 Cover Plate 4878 4878 4878 4878SS 4878 4878SS

6 Safety Switch Assembly 7840 7840 7840 7840SS 7840 7840SS

Figure 1.Side View of Straight Line Application

1

2

34

5

6

4

Figure 2.Side View of Straight Line Application (Arrows Indicating Feed Line)

Planning the Installation Extension Hopper

8MA709H

Right Hand Turn Application

Figure 3.Right Hand Turn Application

Model

55

Model

75

Model

90 & HMC

Model

75 Stainless

Model

75 Plus

Model

75 Plus Stainless

Key Description Part No.

1 Power Unit -- -- -- -- --

2 Window Plate 7842 7842 7842 7842SS 7842 7842SS

3 Window 7852 7852 7852 7852 7852 7852

4 Seal 4873 4873 4873 4873 4873 4873

5 Level Switch Ass’y 7840 7840 7840 7840SS 7840 7840SS

6 Incoming Tube Anchor 35531 6518 5069 6518SS 6518 6518SS

7 Safety Switch Ass’y 7840 7840 7840 7840SS 7840 7840SS

Feed Flow

Feed Flow

1

2

5

64

3

7

4

Extension Hopper Planning the Installation

9

MA709H

Left Hand Turn Application

The Power Unit will not mount beside the switch (as boot is shipped) for left hand turn applications. Left hand

turn applications will require moving the Level Switch to the Access Plate location over the outlet end of the boot

as shown in Figure 4.

Feed Flow

Feed Flow

Figure 4.Side View of a Left Hand Application

Model

55

Model

75

Model

90 &HMC

Model

75 Stainless

Model

75 Plus

Model

75 Plus Stainless

Key Description Part No.

1 Power Unit -- -- -- -- -- --

2 Seal 4873 4873 4873 4873 4873 4873

3 Level Switch Ass’y 7840 7840 7840 7840SS 7840 7840SS

4 Incoming Tube Anchor 35531 6518 5069 6518SS 6518 6518SS

5 Cover Plate 4878 4878 4878 4878SS 4878 4878SS

6 Safety Switch Ass’y 7840 7840 7840 7840SS 7840 7840SS

1

3

42

52

6

Installation Instructions Extension Hopper

10 MA709H

1.Attach the (incoming) Tube Anchor to the Extended Length Boot, using hardware supplied.

Place a Tube Clamp on the Tube Anchor.

2.Mount the Power Unit on the Boot, using 5/16-18 hardware supplied.

3.The Extension Hopper should be located near the center of the auger line to balance the load on the systems.

Suspend the Extension Hopper/Power Unit from the ceiling. The Extension Hopper, Power Unit, and feed

will weigh approximately 90 pounds (40.1 kg). Adequate support must be provided to prevent sagging at the

Extension Hopper location.

Support the Boot securely, using the “ears” on the Power Unit, chain and screw hooks to suspend the

Extension Hopper.

4.Install the incoming and outgoing auger tubes to the Tube Anchor and Boot Anchor on the Extension

Hopper.

5.Install the remaining fill system components as specified in the FLEX-AUGER Fill System Manual.

6.A full length Restrictor Tube is provided with the Extension Hopper. The Restrictor Tube may need to be

shortened to match the outgoing feed with the incoming feed. Refer to the instructions on shortening the

Restrictor in the FLEX-AUGER Fill System Manual.

7.Refer to the wiring diagrams for proper wiring information for the Extension Hopper.

Installation Instructions

Extension Hopper Part Numbers

15

MA709H

Model 55

Kit

40170

Model

75 Kit

7944

Model 75

Stainless Kit

7944SS

Model 75

Plus Kit

56471

Model 75 Plus

Stainless

56471SS

Model 90

Kit

7869

Model

HMC Kit

7849

Key Description Part No.

1* Safety Cap -- 29702 29702 29702 29702 29702 29702

2 Tube Clamp Kit 29520 4141 4141 4141 4141 6721 6721

3* 5/8” Set Collar 1386 1386 1386 1386 1386 1386 1386

4 Tube Clamp Kit 35726 6515 6515 6515 6515 6721 6721

5* Bearing Cap Assembly -- 35440 35440 35440 35440 34830 34830

6*** Cover Assembly 7838 7838 7838SS 7838 7838SS 7838 7838

7* Universal Anchor Shaft -- 43281 43281 43281 43281 43281 43281

8* Clamp Spacer -- -- -- -- -- 5009 --

9* Clamp Pin -- 4702 4702 56409 56409 4702 4702

10* 5/16-18 x 1/2” Set Screw -- 5095 5095 5095 5095 5095 5095

11* 5/16-18 x 3/8” Set Screw -- 1174 1174 1174 1174 1174 1174

12* Anchor Weldment 39410 36393 36393 56387 56387 26048 36393

13 Cover Plate 4878 4878 4878SS 4878 4878SS 4878 4878

14**

***

Seal 4873 4873 4873 4873 4873 4873 4873

15*** Switch and Plate Assembly 7840 7840 7840SS 7840 7840SS 7840 7840

16*** Diaphragm Assembly 7900 7900 7900 7900 7900 7900 7900

17 Boot Body Weld. 40168 7878 7878SS 7878 7878SS 28881 28881

18 Window Plate 7842 7842 7842SS 7842 7842SS 7842 7842

19 Window 7852 7852 7852 7852 7852 7852 7852

20 Tube Anchor Weldment 35531 6518 6518SS 6518 6518SS 5069 5069

21 Access Panel Assembly 7928 7928 7928SS 7928 7928SS 7928 7928

22 Cannonball 3621 3531 3531 3531 3531 3531 3531

23** Switch Box Cover 6776 6776 6776 6776 6776 6776 6776

24** Gasket 6777 6777 6777 6777 6777 6777 6777

25** Switch Box 7841 7841 7841 7841 7841 7841 7841

26** Switch Mounting Plate 7908 7908 7908SS 7908 7908SS 7908 7908

27** Paddle 7896 7896 7896 7896 7896 7896 7896

28** 6-32 x 7/8” Pan Hd. Screw 1921 1921 1921 1921 1921 1921 1921

29** Compression Spring 6972 6972 6972 6972 6972 6972 6972

30** SPDT Actuator Switch 7114 7114 7114 7114 7114 7114 7114

31** Switch Insulation 1907-5 1907-5 1907-5 1907-5 1907-5 1907-5 1907-5

32** Switch Bracket 7068 7068 7068 7068 7068 7068 7068

33** 1/8 x 1” Rd Hd Rivet 8757 8757 8757 8757 8757 8757 8757

34 5/16-18 X 1/2 Socket Hd Screw -- 6850-3 6850-3 6850-3 6850-3 6850-3 6850-3

35 5/16-18 x 2-1/4 Socket Hd Screw -- 6850-4 6850-4 6850-4 6850-4 6850-4 6850-4

36 Anchor Block -- 7703 7703 7703 7703 7703 7703

37 Driver Weldment -- 7704 56390 56390 56390 7706 7704

*38 Auger Clamp (Model 55) 39205 -- -- -- -- -- --

*39 Anchor Bearing (Model 55) 39407 -- -- -- -- -- --

40 Cap (Model 55) 29523 -- -- -- -- -- --

41 Stub Tube (Model 55) 4163 -- -- -- -- -- --

*42 Socket Head Screw (Model 55) 6850-7 -- -- -- -- -- --

43 Tube Clamp Kit 29515 6515 6515 6515 6515 6721 6721

44 Auger Clamp Pin -- -- -- 56405 56405 -- --

45 5/16-18 x 1" Socket Hd Screw -- -- -- 6850-5 6850-5 -- --

46 5/16-18 Hex Lock Nut -- -- -- 2148 2148 -- --

47* .688 x 1.750 x .134 Washer 1484 -- -- -- -- -- --

48* 1/4-20 x 1.50 Sk. Hd Cap Screw 5083-8 -- -- -- -- -- --

49* Driver Tube 2920 -- -- -- -- -- --

50* Driver Block 4642 -- -- -- -- -- --

*These Anchor and Bearing Components may be ordered as complete Assemblies under the following Part Numbers:

Model 55 (39405), Model 75/SS (37347), Model 75 Plus/SS (56417), Model 90 (35345), Model HMC (37241)

**These Switch and Plate components may be ordered as an assembly under Chore-Time part number #7840/SS

***The #7839/SS Cover Assembly includes items 6, 14, 15, and 16 and the required hardware.

MADE TO WORK.

BUILT TO LAST.®

Revisions to this Manual

Page No. Description of Change ECO

Various Added 75 Stainless, 75 Plus,

and 75 Plus Stainless 34341

For additional parts and information, contact your nearest Chore-Time distributor or representative.

Find your nearest distributor at: www.choretime.com/contacts

Chore-Time Group, A division of CTB, Inc.

PO Box 2000

Milford, Indiana 46542-2000 USA

Phone (574) 658-4101 Fax (877) 730-8825

Email: choretime@choretime.com

Internet: www.choretime.com

Table of contents

Popular Industrial Equipment manuals by other brands

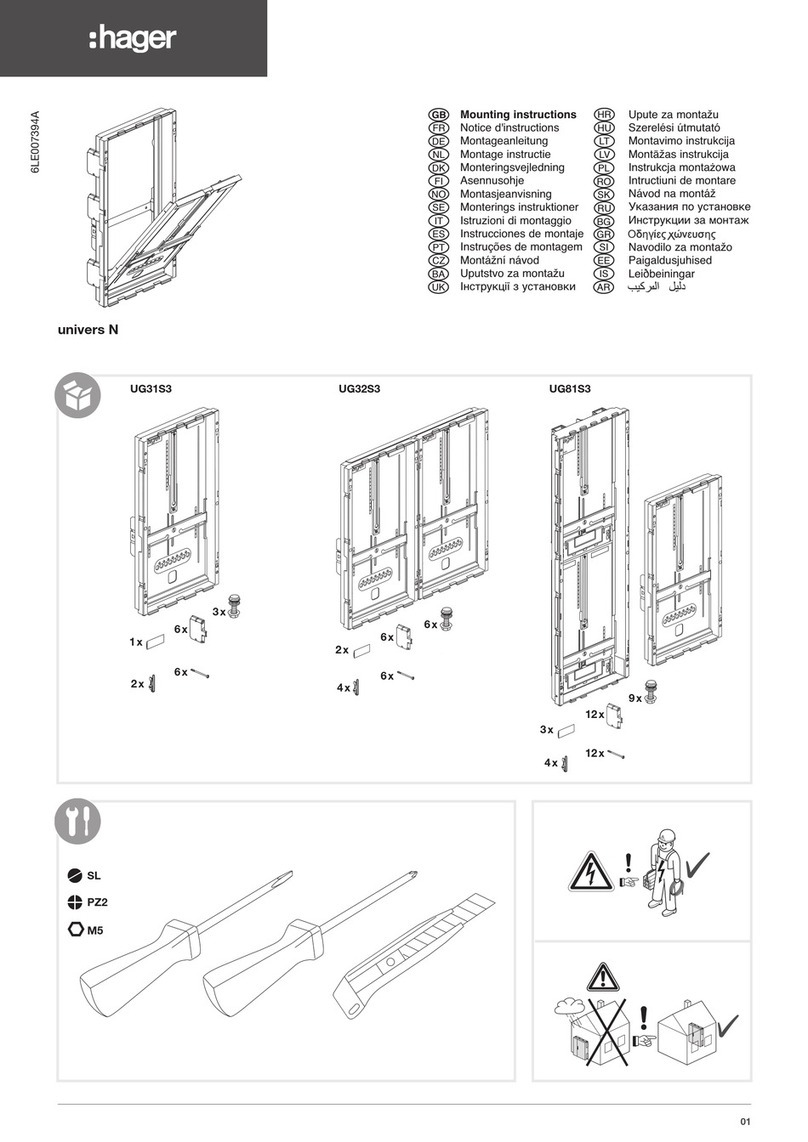

hager

hager univers N UG31S3 Mounting instructions

Branick

Branick 5500 Installation, Operation and Repair Parts Information

TUFFA TANKS

TUFFA TANKS 30000VBFS Installation, operation and servicing manual

GSi

GSi TopDry Autoflow 36 FT DIAMETER Construction manual

EAE

EAE E-LINEKX-III manual

ABB

ABB TPS 57D01 Operation manual