)

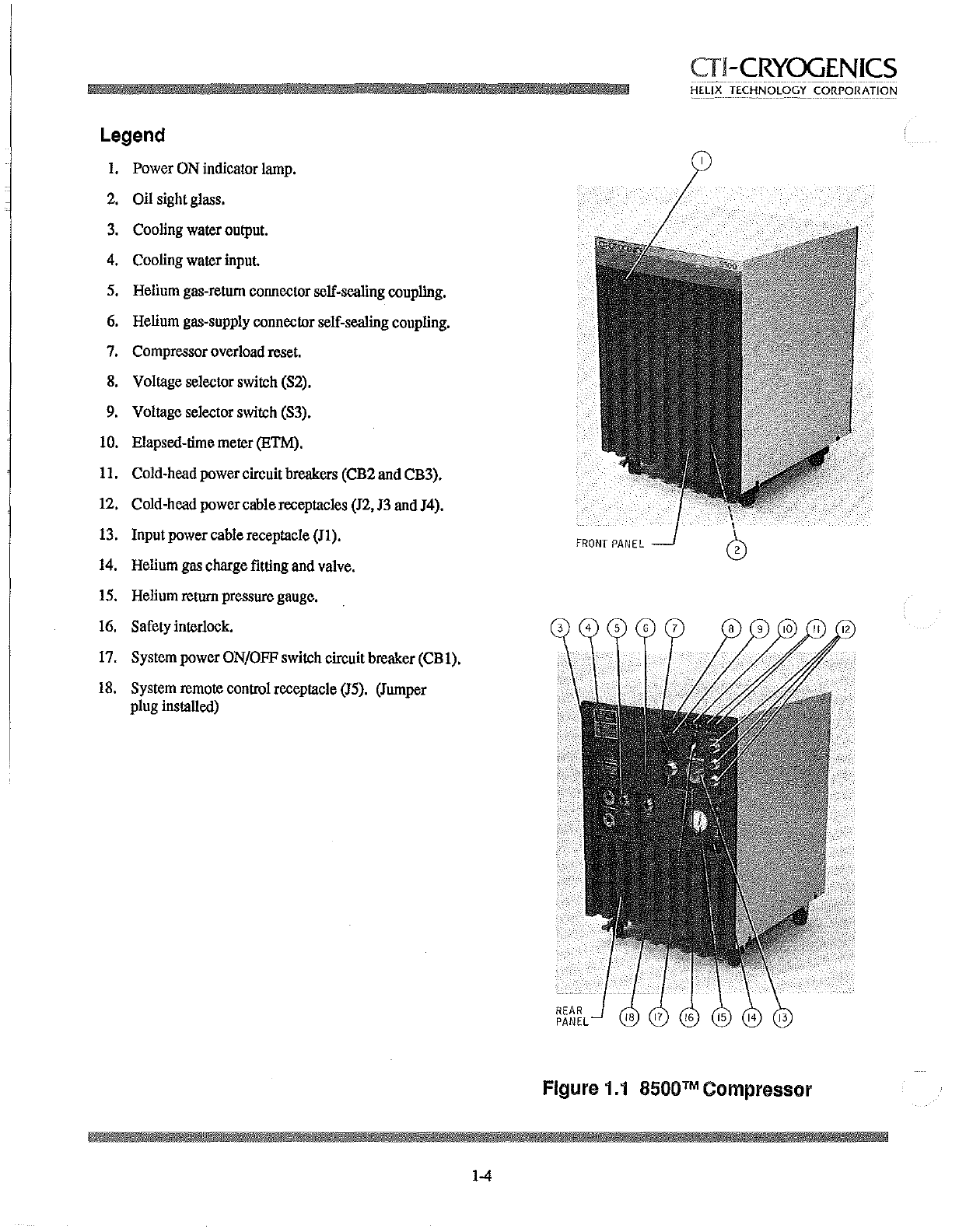

Illustrations

1.1

8500™

Compressor

. . . . • . . • . . • . • • .

1-4

3.1

Block

diagram

for

8500

Compressor

installation.

. • • . • . . . . . . •

3-1

3.2

Removing

compressor

pump

shipping

supports

. , , , , , , , , , , , , , , ,

3-2

3.3

Stripping

compressor

input-power

cable

insulation

. , , , , ,

..

, , , , , , , , ,

3-2

3.4

Input

power

cable

receptacle

plug

• • . . . • . • . . . • • • . • •

3-3

3.5

Wiring

diagram

for

compressor-

receptacle

plug.

. • . • . . • . . . . . • • . • .

3-3

3.6

Preparing

the

8500

Compressor

control

module

••..•.•..•.

3-5

3.7

8500

Compressor

installation

....•.••

, • . • • . . • . • • .

3-7

4.1

Disconnecting

the

adsorber

self-sealing

couplings

••

, , . . • . , , . . . .

4-1

4.2

Connecting

self-sealing

couplings

• , , , . . •

4-2

B.l Electrical

schematic

for

8500

Compressor,

P/N

8031351.

••.•.••.•..

B-3

C.

l

Components

in

the

electrical

control

module

of

8500

Compressor.

,

.••••..•.

C-3

D.

l

Flow

diagram

of

8500

Compressor

. . . • . . . . • . . . . . • . • . .

D-1

E.

l

Typical

multiple

cryopump

installation

with

8500

Compressor

• . . . • . . . . . . • •

E-1

F.

l

Remote

high-vacuum

pump

switching

schematic.

. . . . . . . • . • . • . .

F-2

v/vi

CTI-CRYOGENICS

HEifX--fEcHNOLciGY"

·c-OR"PORATJON

Tables

1.1

8500™

Compressor

Specifications. , , , , , ,

1-2

A.

l

Compressor

Troubleshooting

Procedures

•.....•.•.••.•..•...

A-2