Copyright Reserved HyVISION System Inc. 2 / 44

This document is a general purpose operation manual and is subject to change without notice when necessary

for product improvements. HyVISION System does not take the responsibility for loss caused by any error in the

document or provisions and use of this document.

Table of Contents

1. Safety Caution.....................................................................................................................................3

2. Directions for use ................................................................................................................................4

3. Introduction to Cubicon Single............................................................................................................5

4. Printer Parts and Accessories...........................................................................................................10

4.1. External Printer Parts..............................................................................................................10

4.2. Internal Printer Parts and Extruder .........................................................................................11

4.3. Accessories included with Package........................................................................................12

5. Installation.........................................................................................................................................13

5.1. Unpacking...............................................................................................................................13

5.2. Installation of Printer...............................................................................................................14

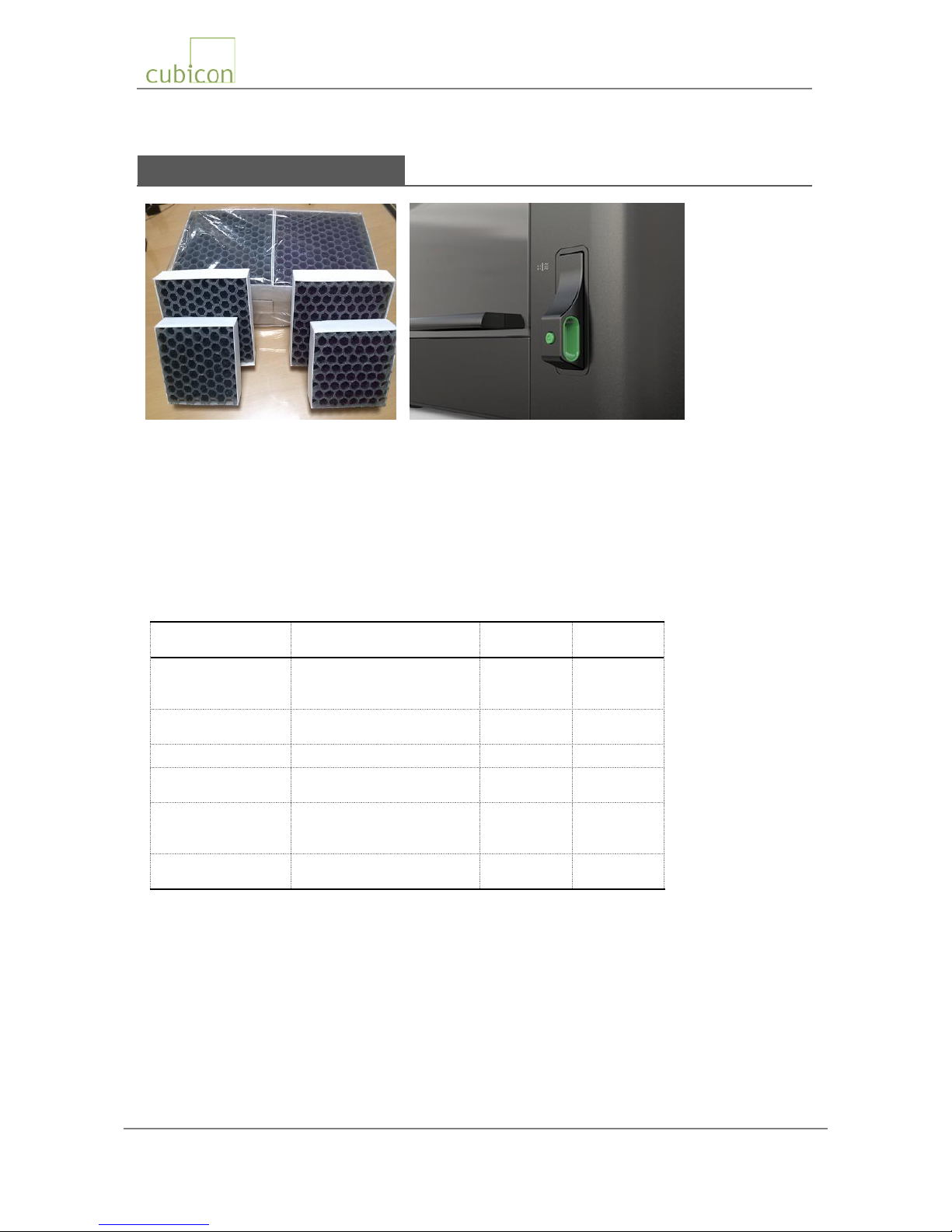

5.2.1. Mounting of Clean Filter ...............................................................................................14

5.2.2. Mounting of Filament Spool..........................................................................................15

5.2.3. Turning on Printer.........................................................................................................16

6. How to use printer.............................................................................................................................17

6.1. LCD and Operating Buttons....................................................................................................17

6.2. LCD Display of Status.............................................................................................................18

6.3. Functional Menu during Printer Standby ................................................................................19

6.4. Functional Menu during Printing.............................................................................................20

6.5. Caution and Notes on Using the Functional Menu.................................................................21

6.6. Replacing Filament (Loading/Unloading) ...............................................................................23

6.6.1. Loading Filament (Printer in Standby Mode)................................................................23

6.6.2. Unloading Filament (Printer in Standby Mode) ............................................................25

6.7. Separating Detachable Extruder (Mounting) ..........................................................................27

6.8. Cleaning Printer ......................................................................................................................29

6.8.1. Cleaning of Heating Bed...............................................................................................29

6.8.2. Cleaning of Detachable Extruder and Nozzle ..............................................................30

6.8.3. Replacement of Clean Filter.........................................................................................33

7. Printing..............................................................................................................................................34

7.1. Printing for the First Time........................................................................................................34

7.2. Printing after Replacing Filament............................................................................................37

7.3. Replacing Filament during Printing.........................................................................................38

7.4. Supplying Filament after Filament Runs Out during Printing .................................................39

8. Troubleshooting.................................................................................................................................40

9. Product Specifications.......................................................................................................................44

Symbols used in the operation manual