July 2016

P 2

da Vinci

Jr.2.0 Mix

The purpose of this user manual is to help users understand and use the da Vinci Jr. 2.0 Mix 3D printer correctly. It contains

the operating instructions, maintenance information and application skills of the da Vinci Jr. 2.0 Mix 3D printer. To learn

more about the latest news of the da Vinci Jr. 2.0 Mix 3D printer, please contact local dealers or visit the ofcial website of

XYZprinting: http://www.xyzprinting.com

Trademarks

All trademarks and registered trademarks are the property of their respective owners.

Print History

New editions of this manual incorporate new and changed material different from previous editions. Minor corrections and

updates may be incorporated into reprints of the current edition without releasing additional announcements or documenta-

tion regarding the updated version. The User Manual is for user reference only. If you need to obtain the latest information,

you are welcomed to visit the XYZprinting website: www.xyzprinting.com

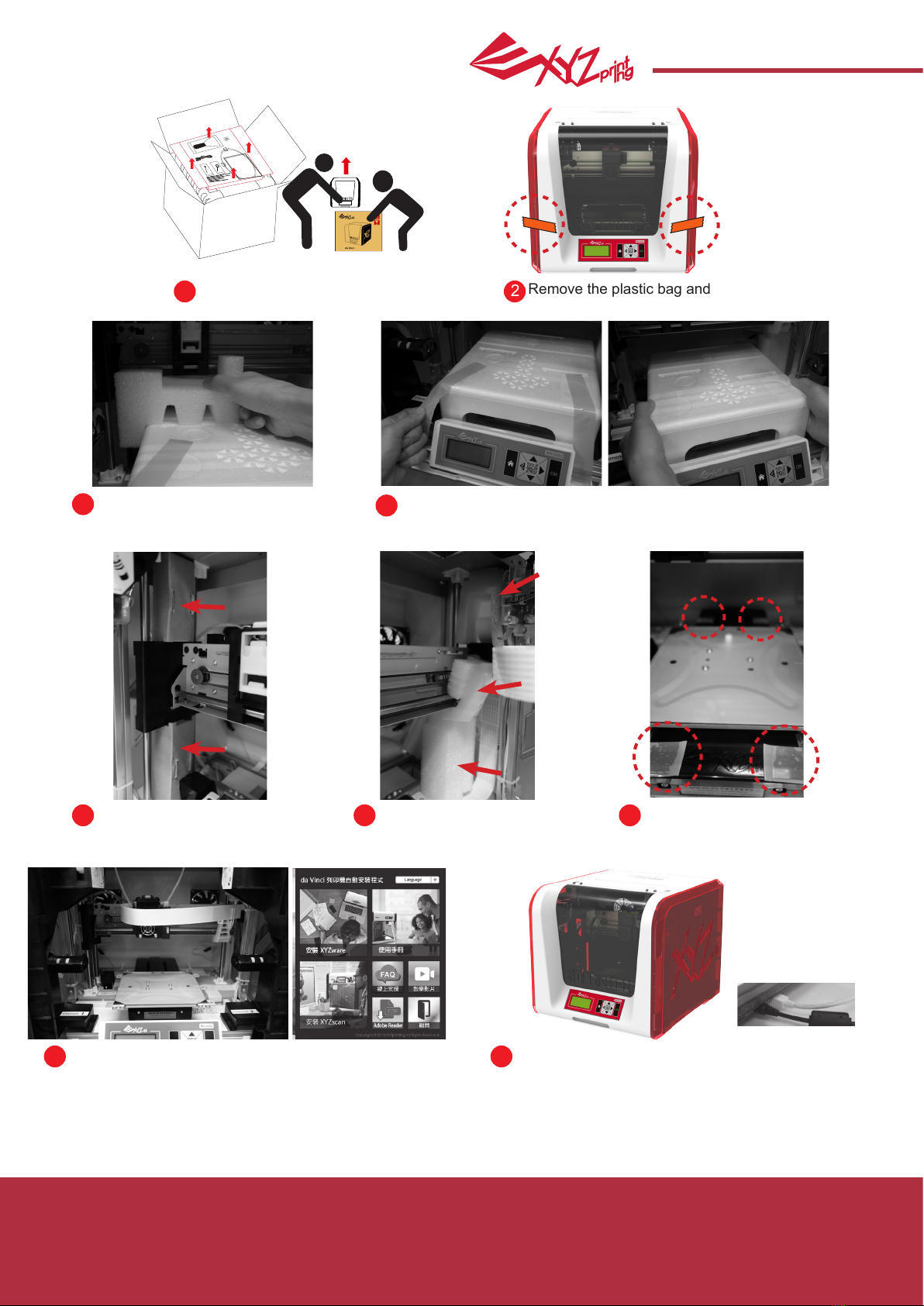

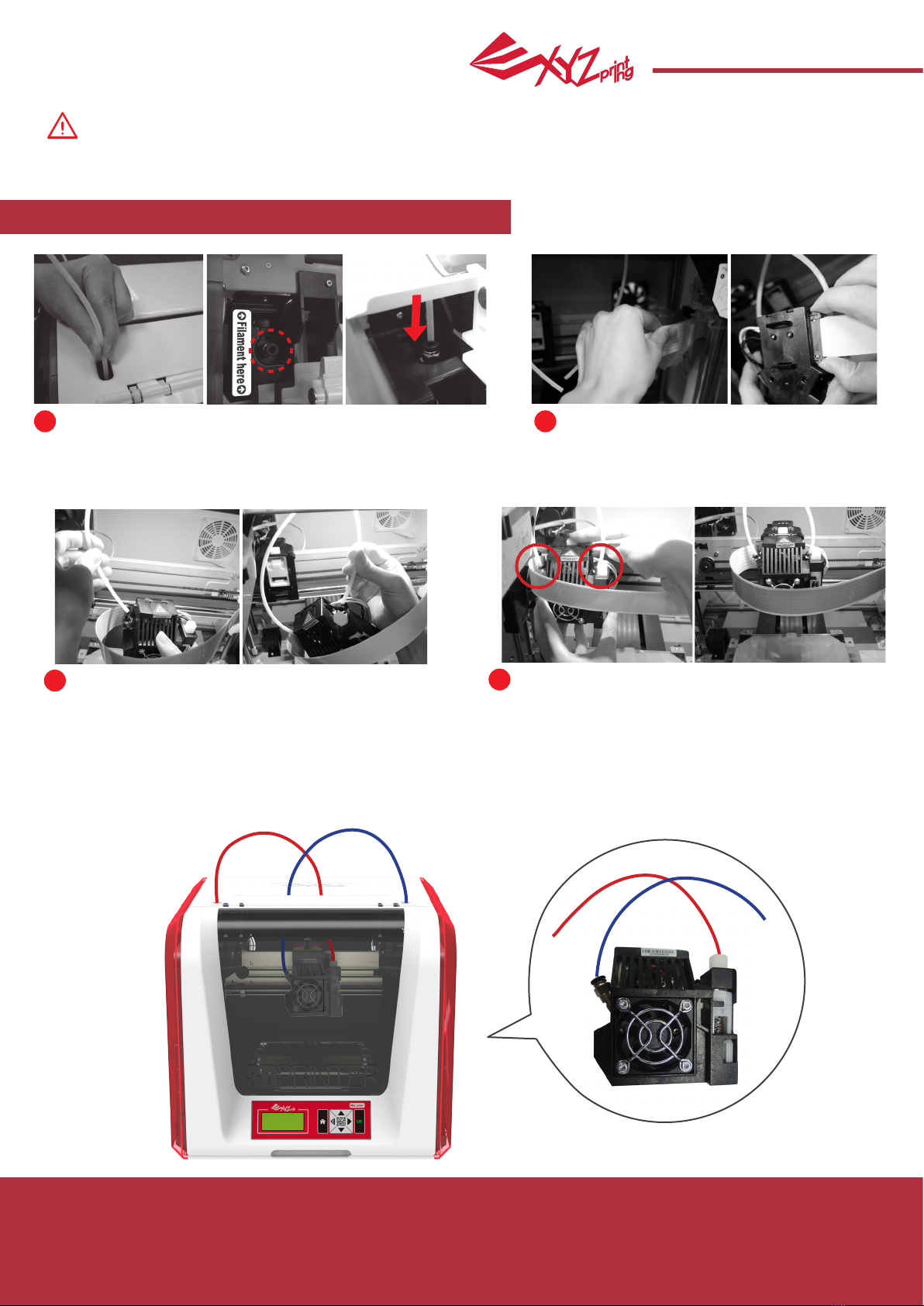

Before using this printer, please first remove

the xed materials from the printing module and

printing bed. Switching on the printer's power

without removing these fixed materials may

damage the machine.

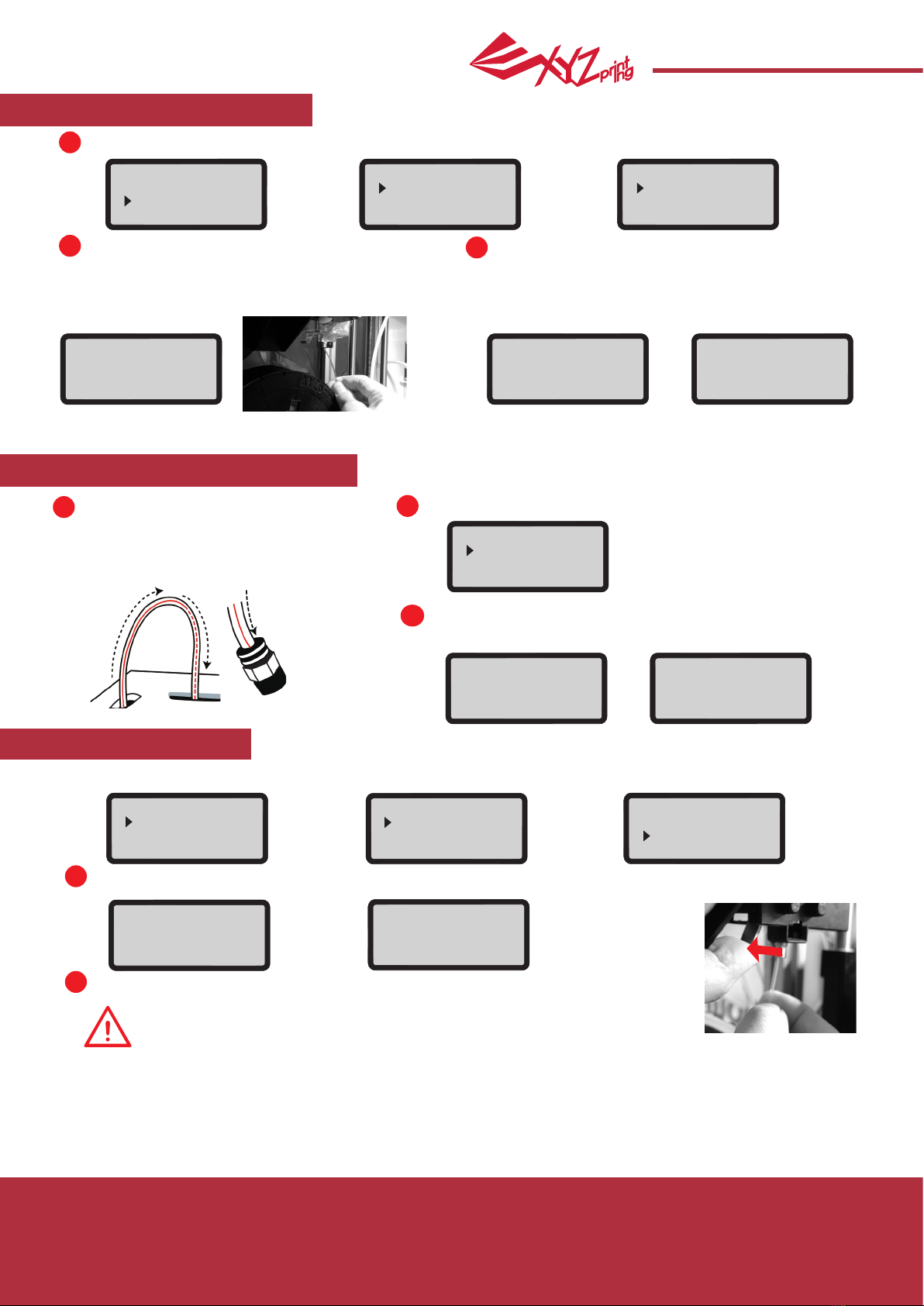

Registration via XYZware before your rst print

is strongly recommended. When registered with

XYZprinting, you will receive latest technical

supports and updates. To register, simply click

"Register Now" to begin.

You may use XYZware to initiate manual updates to the printer

rmware and software. When using the printer for the rst time,

we recommend connecting to the Internet and performing manual

update once to obtain the latest resources.

The optimal room temperature for printing is 15-26 ◦C (60-78 ◦F).

Printing quality may be affected if room temperature is higher or

lower.

If you need more detailed technical support and program

resources, visit the website:

http://support.xyzprinting.com/global_en/Support

Before operating the printer, insert the SD card in the SD card port

to make sure that the printing program is able to run properly.

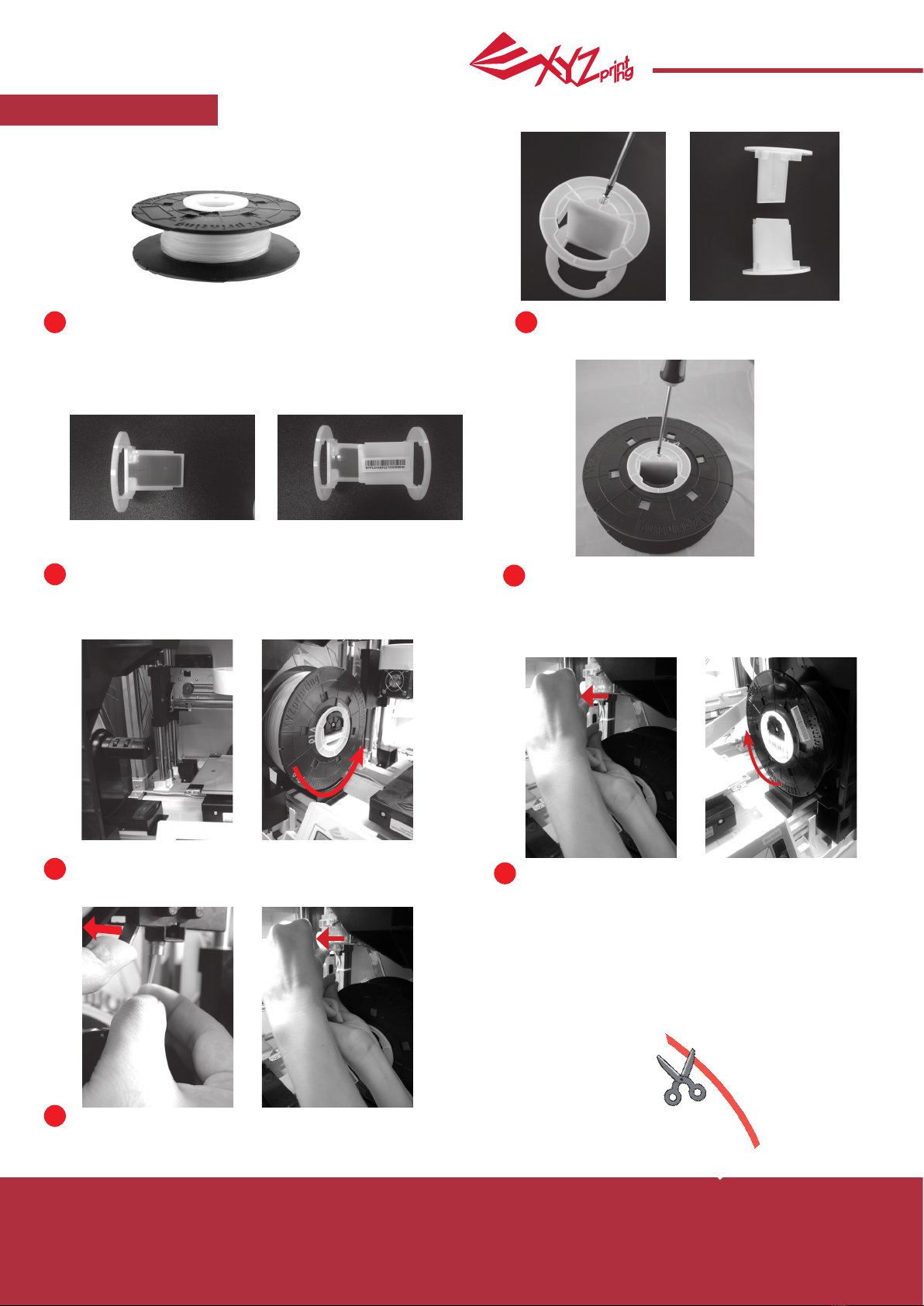

Before you start printing, please afx the bed tape on the print

bed. The bed tape may be removed after printing is complete. (Bed

tape can be reused.)

Before launching XYZware, connect the PC to with printer

using the USB cable. For a better user

experience, it is strongly advised to follow the proper

procedure for using the product.

Please carefully read the contents of the product

instruction manual before using this product.

2

3

4

5

5

1

6

7

8

8

3