Contents

1. Product introduction .........................................................................................................................5

2. Safety Caution .................................................................................................................................6

3. Directions for use...............................................................................................................................7

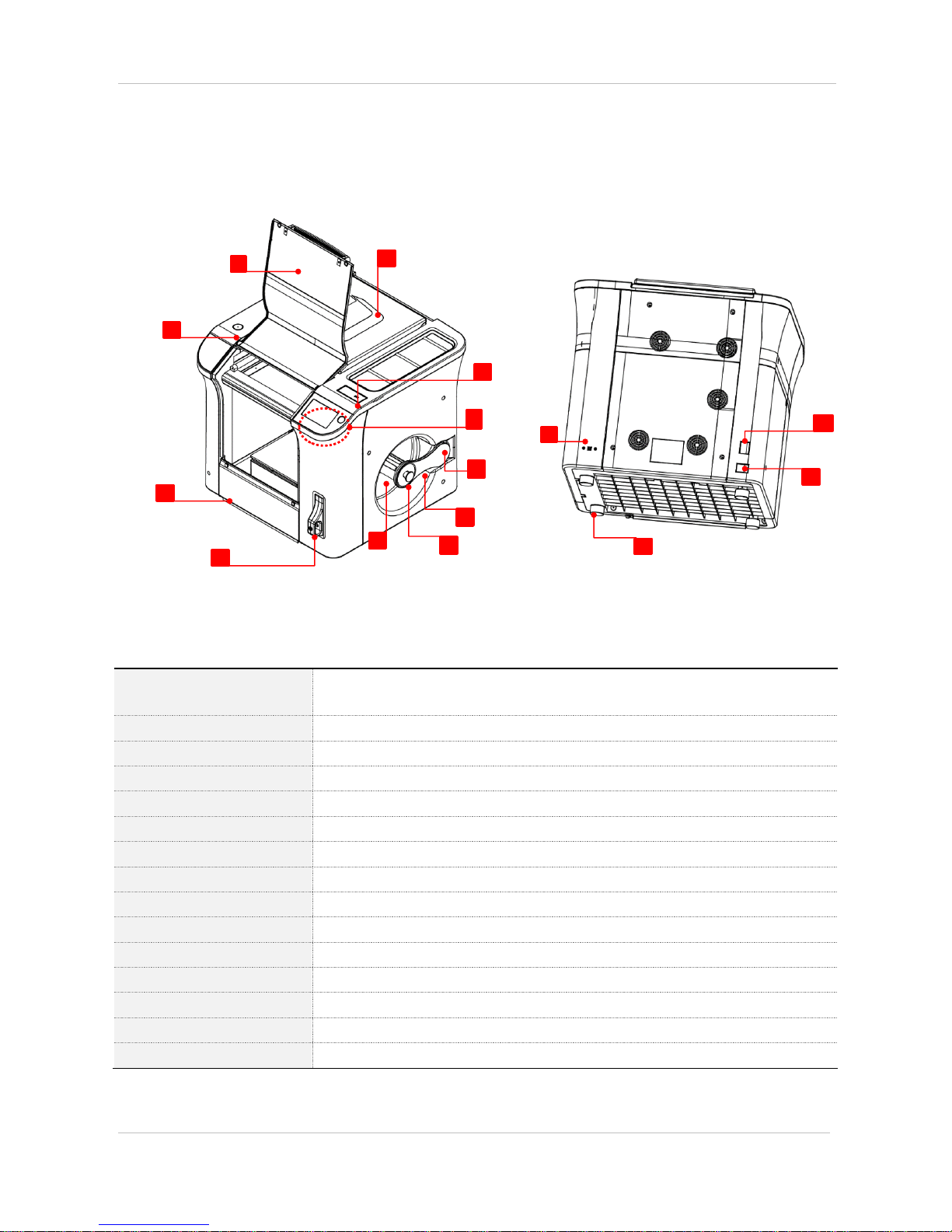

4. Product component and parts name .................................................................................................9

4-1. Product components ...................................................................................................................................... 9

4-2. Product parts name...................................................................................................................................... 10

5. Installation and printing preparation .................................................................................................12

5-1. Unpacking .................................................................................................................................................. 12

5-2. Filter installation ......................................................................................................................................... 13

5-3. Filament installation .................................................................................................................................... 14

5-4. Printer power ON ........................................................................................................................................ 15

6. Printer use.......................................................................................................................................16

6-1. LCD control panel......................................................................................................................................... 16

6-2. LCD main screen ......................................................................................................................................... 17

7. Filament replacement (Loading / Unloading) ..................................................................................18

7-1. Filament Loading ........................................................................................................................................ 17

7-2. Filament Unloading ..................................................................................................................................... 21

7-3. Filament replacement using ‘Pause’............................................................................................................. 22

8. Test model printing ........................................................................................................................23

8-1. First printing .................................................................................................................................................. 23

8-2. Printing with USB memory ............................................................................................................................ 23

9. Network...........................................................................................................................................24

9-1.USB cable connection between PC and printer ............................................................................................. 25

9-2.WIFI connection ........................................................................................................................................... 25

9-3. Cubicreator3 WIFI connection....................................................................................................................... 29