INSTALLING DRAFT TOWER

1. Connect beer line connector to keg coupler.

2. Place rubber washer over draft arm mounting holes in cabinet.

3. Put beer line connector down through hole.

4. Secure draft arm with four screws.

5. Insert air hose in draft arm, being careful not to disturb insulation.

6. Remove top cover of draft arm and attach air hose clip to the insulating sleeve at the top of the draft arm. This will

assure that the hose remains in the proper place at all times, which will keep the beer faucet cold.

7. Replace top cover.

8. Screw the handle onto the beer faucet.

DRAIN INSTRUCTIONS

On beer dispensers, the drain is located at the front of the cabinet. On one door model, the unit drains into a bottle located

inside the cabinet.

To plumb in the drain, connect ½” PVC pipe to the barbed tting supplied with the unit.

If you would prefer to drain the beer inside the unit (for mobility or where a drain can’t be found):

•Use a screwdriver to remove the drain bracket

•Pull the drain hose so that it is inside the unit

•Attach a bottle to the drain hose inside the unit

•Plug the created hole at the bottom of the unit

PRESSURE

Dispensing pressures dier according to:

•The type of draft dispensing system

•The length of draft dispensing line

•The actual draft product

•The temperature of the draft product

•The pressurizing agent: Compressed air, CO2, or specially blended gasses

TAPPING

•Do not agitate the kegs unnecessarily

•If excessive agitation occurs, allow kegs to settle for 1-2 hours before tapping

•Prior to tapping the keg, ensure that all beer faucets in the serving location are in the o position

•Completely remove the dust cover from the keg

STORAGE & HANDLING

Draft beer should be treated as a food product. In most instances draft beer is not pasteurized. It is very important that you

store and handle it properly. Follow these steps to ensure the highest quality, safety, and consumer satisfaction:

•Draft beer should be immediately stored in a refrigerated cabinet

•Draft beer products have a recommended shelf life. If you have questions regarding the shelf life of any of your draft

products, please consult with your supplier or brewery representative.

•Kegs should be stored separately from food products. If your cooler is used to refrigerate draft and food products, it is

very important that the food not be stored near or on the kegs.

•Keg storage and dispensing areas should be kept clean to prevent any possibility of contaminating products.

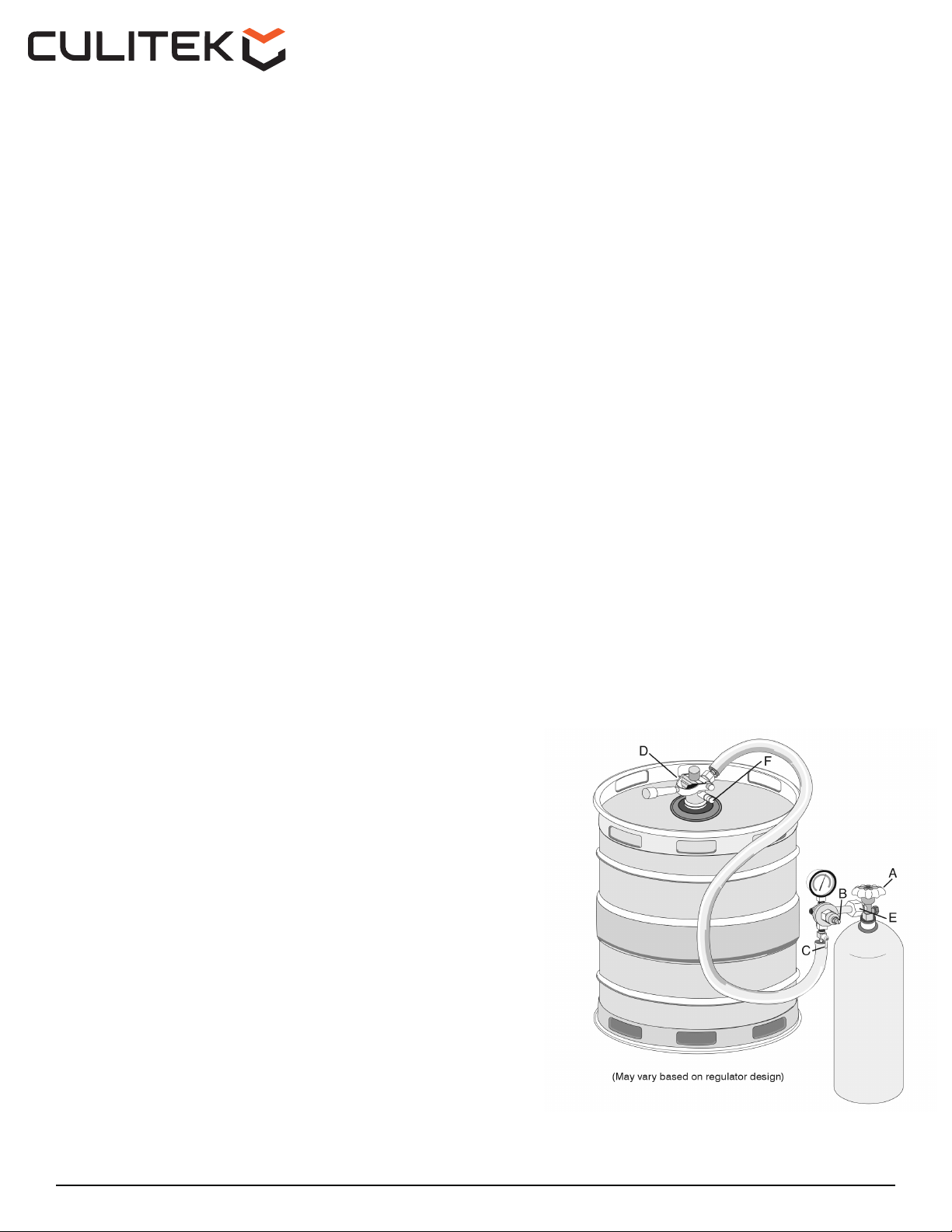

KNOCKOUT CO2 INSTALLATION

This is the recommended procedure for installing a remote CO2 container in your unit:

1. Remove black knockout plug with pliers.

2. Use drill with 1/2” bit to bore a whole straight back through wall into compressor compartment.

3. Snake CO2 line through hole, down and around, exiting behind rear caster underneath grill.

4. Seal hole around CO2 line with silicone sealer to prevent cold air leakage.

*Depending on setup and amount of kegs, a CO2 manifold may be needed.

NOTE: In one door models, the CO2 tank (up to 5 lbs in size) can be placed inside the cooler to maintain complete mobility.

CAUTION: CO2 tanks are potentially dangerous because of the pressure they contain. If you are unfamiliar with their use

or the use of a CO2 regulator, seek information from your local distributor or beverage supplier before proceeding.

Tools Needed:

• Pliers

• Power Drill

• Silicone Sealer

• 1/2” Drill Bit