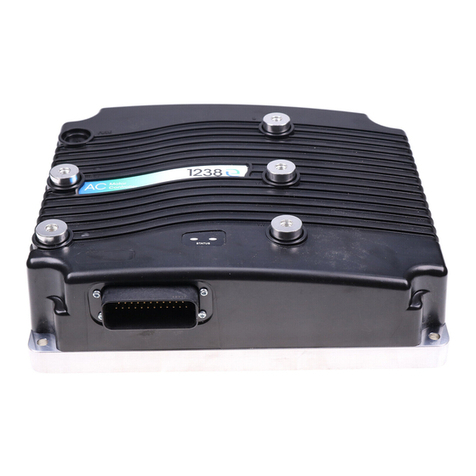

iv Curtis 1230 Manual, Rev. C

CONTENTS

Sequencing Parameters .......................................................30

Interlock Normally Open, Sequencing Delay,

SRO, HPD, Main Contactor Interlock Type,

Main Contactor Open Delay,

Main Contactor Check

Brake Parameters ................................................................32

Brake Fault Check, Brake Delay,

Brake Hold Voltage, Brake Driver Type,

Anti-Rollback Time

Emergency Reverse Parameters ..........................................33

Wiring Check, Speed, Direction Interlock,

Time Limit, Accel Rate, Switch Normally Closed

Motor & Control Parameters

Motor Parameters .............................................................35

Min Motor Voltage, Nominal Motor Voltage,

Nominal Motor Frequency, Max Motor Speed,

Number of Motor Poles, Encoder Pulses

Per Revolution, Swap Encoder Direction,

Failsafe Delay

Control Parameters ...........................................................36

P Gain, I Gain, Accel Slip, Regen Slip, Slip Boost,

Pull-Out Slip, Accel Slip Voltage, Regen Slip Voltage,

Accel Comp, Regen Comp, Regen Voltage Offset

System Parameters

Battery Parameters .............................................................38

Full Battery Voltage, Empty Battery Voltage,

BDI Reset Battery Voltage, Battery Recharge Level,

Low Voltage Level

Hourmeter Parameters .......................................................39

Enable Total Service Hours,

Enable Drive Service Hours, Adjust Hours,

Set Total Hours, Set Drive Hours,

Total Service Hours, Drive Service Hours,

Total Disable Hours, Drive Disable Hours,

Drive Disable Speed, Service Total Expired,

Service Drive Expired