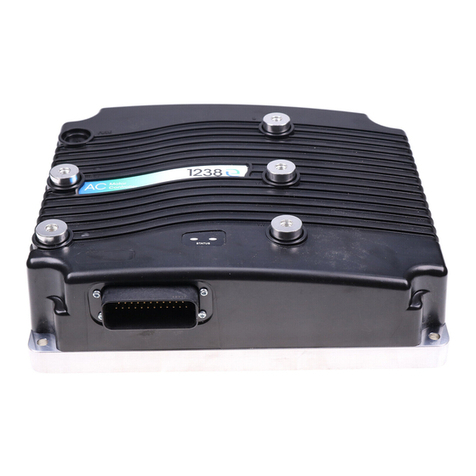

Curtis AC F4-A Motor Controller – August 2020

pg. iv

TABLE OF CONTENTS cont’d

5: SYSTEM MONITOR........................................................................................................................ 116

6: COMMISSIONING .......................................................................................................................... 127

INITIAL SETUP ............................................................................................................................ 127

TO BEGIN ............................................................................................................................. 128

CONTROL MODE SELECTION ................................................................................................ 128

PARAMETER SETTINGS – METHOD OVERVIEW...................................................................... 128

AC TRACTION MOTOR SETUP GUIDE..................................................................................... 129

CONTROLLER SETUP GUIDE ................................................................................................. 131

TRACTION THROTTLE SETUP................................................................................................ 133

VOLTAGE THROTTLE ............................................................................................................. 136

AUTOMATED ACIM (MOTOR) CHARACTERIZATION PROCEDURE ................................................... 142

TRACTION SYSTEMS................................................................................................................... 143

TUNING GUIDE............................................................................................................................ 147

SELECTING THE CONTROL MODE ......................................................................................... 147

0 − SPEED MODE EXPRESS TUNING..................................................................................... 147

1 − SPEED MODE TUNING .................................................................................................... 148

OTHER PARAMETER TUNING................................................................................................. 149

SETTING UP THE HYDRAULIC SYSTEM ........................................................................................ 150

HYDRAULIC LIFT AND LOWER COMMAND INPUTS....................................................................... 150

LIFT & LOWER SWITCH INPUTS ............................................................................................ 151

LIFT SWITCH INPUT, WITH A PROPORTIONAL LOWERING VALVE............................................. 153

7: DIAGNOSTICS AND TROUBLESHOOTING........................................................................................ 155

THE DIAGNOSTICS PROCESS ...................................................................................................... 155

TROUBLESHOOTING CHART INDEX.............................................................................................. 160

FAULT ACTIONS .......................................................................................................................... 164

8: MAINTENANCE ............................................................................................................................. 183

CLEANING................................................................................................................................... 183

FAULT HISTORY........................................................................................................................... 183