CONTENTS

1. OVERVIEW ....................................................................... 1

2. HARDWARE INSTALLATION ....................................... 3

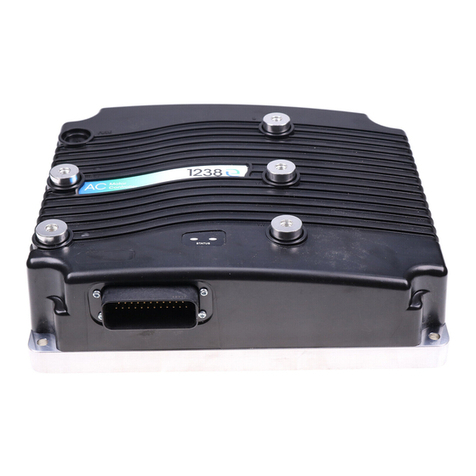

Controller .................................................................... 3

Throttle ........................................................................ 5

Other Hardware ........................................................... 8

Main contactor ................................................... 10

Forward/reverse contactors .................................. 11

Forward/reverse switches ..................................... 11

Keyswitch and interlocks ..................................... 11

Keyswitch relay ................................................... 11

Polarity protection diode ..................................... 12

Control wiring fuse ............................................. 12

Power wiring fuse ................................................ 12

3. WIRING ........................................................................... 13

Connections: Low Current......................................... 13

Connections: High Current ....................................... 13

Wiring: Typical Installation ....................................... 14

KSI wiring .......................................................... 15

Forward/reverse wiring ........................................ 16

Plug braking ................................................ 16

Freewheeling ................................................ 16

Throttle wiring ................................................... 17

Standard potbox wiring ............................... 17

Pots for twist-grip throttles .......................... 18

Electronic throttle wiring ............................. 19

Reduced speed operation ............................. 20

Throttle ramp shaping ................................. 21

Installation Checkout ................................................. 22

CONTENTS