Table of Contents

Safety Guide ···································································································· 1

Precautions in Operation ···················································································· 8

International Standards Compliances ··································································· 11

Name for Each Parts and Their Functions ·····························································12

About SCON-LC Type·······················································································18

Actuator Axes··································································································20

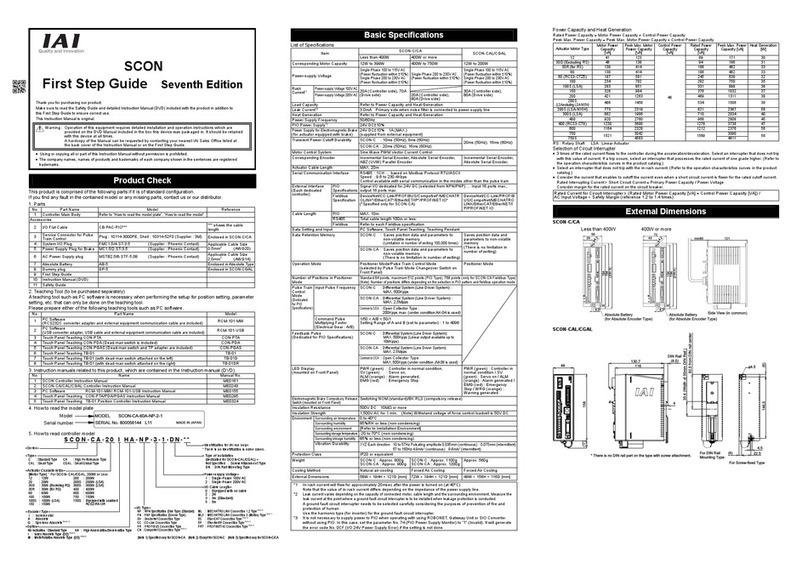

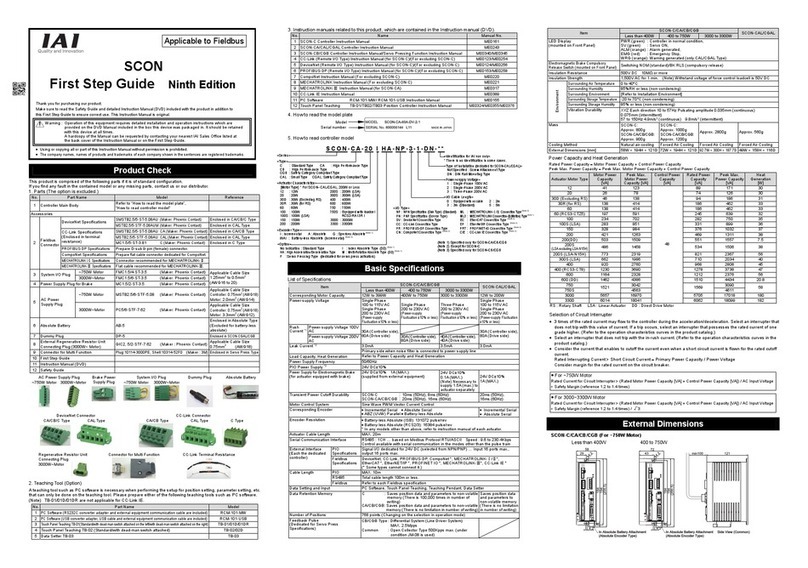

Chapter 1 Specifications Check ······································································· 21

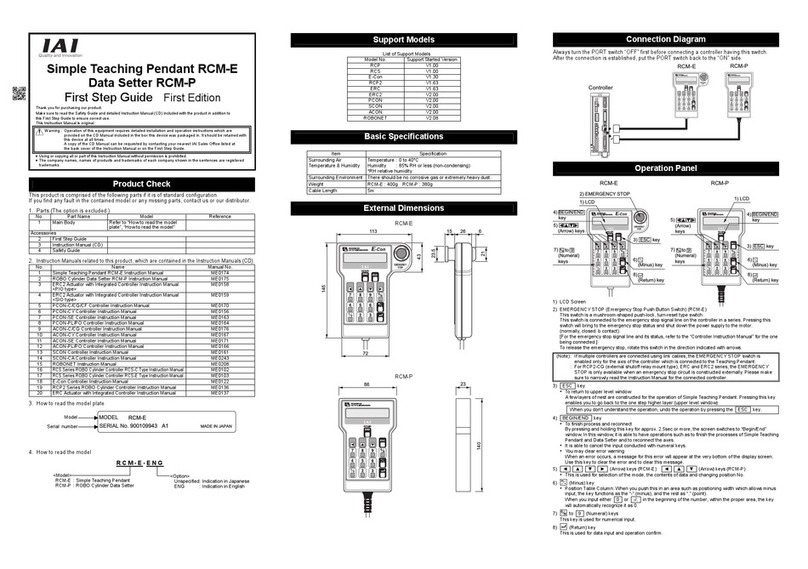

1.1 Product Check································································································· 21

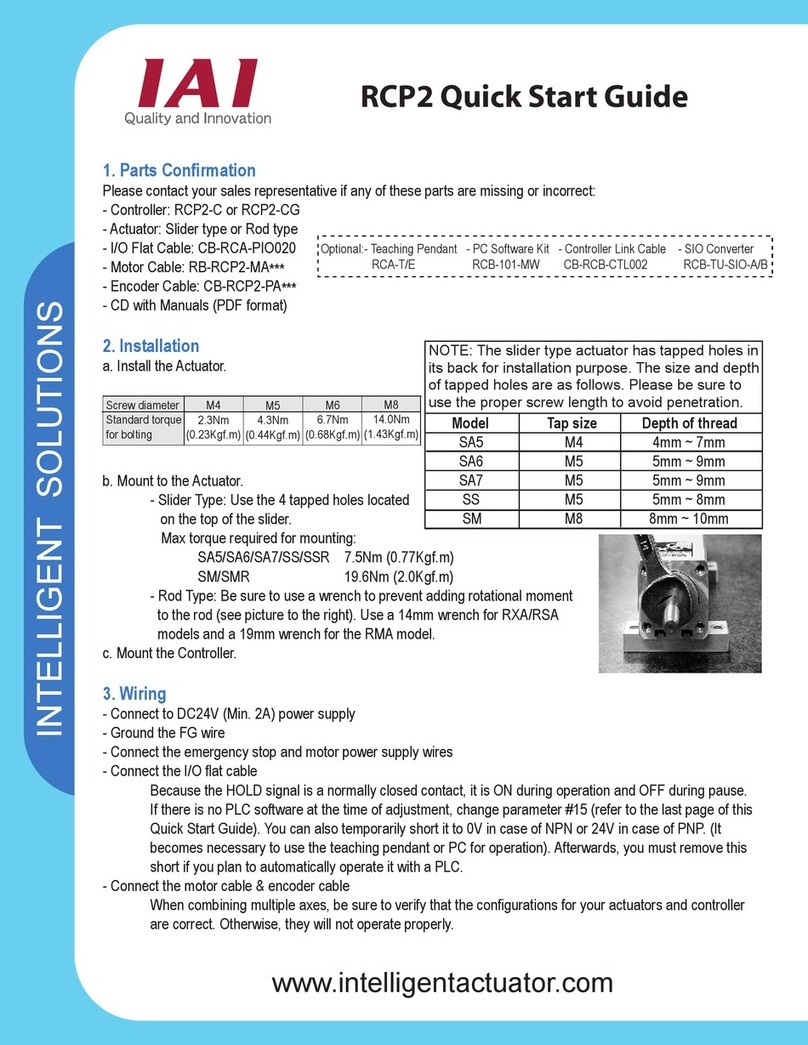

1.1.1 Parts ······································································································· 21

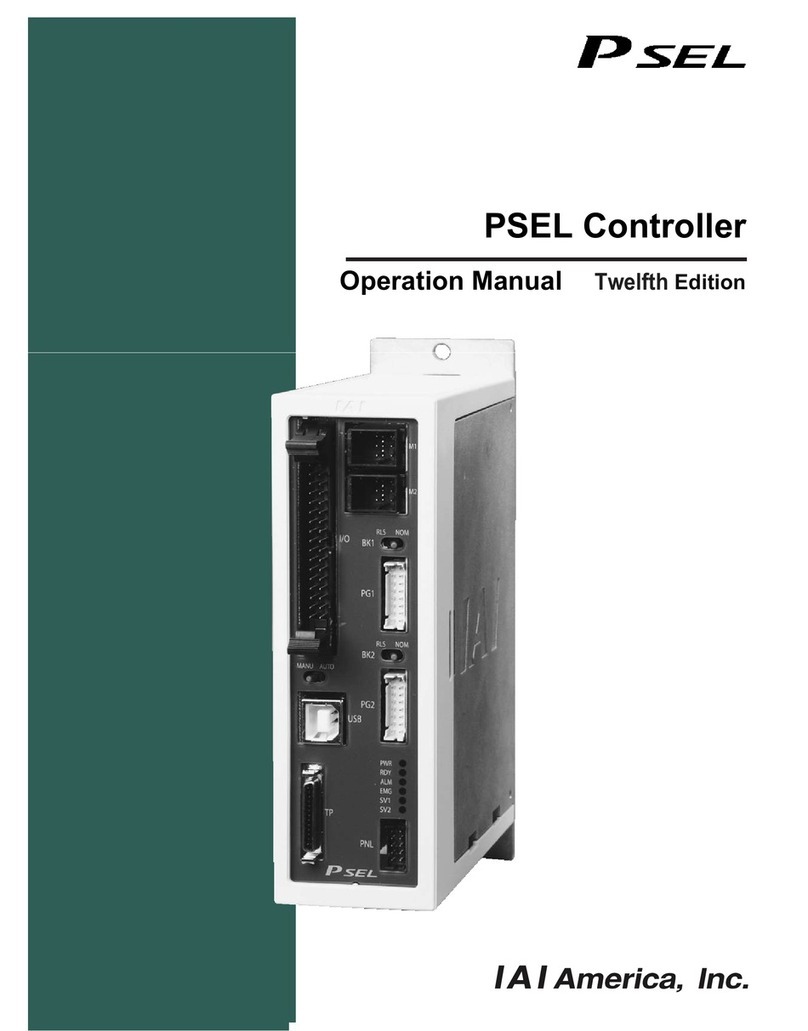

1.1.2 Teaching Tool ···························································································· 23

1.1.3 Instruction Manuals Related to this Product, which are Contained in the Instruction

Manual (DVD) ··························································································· 23

1.1.4 How to Read the Model Plate ······································································· 23

1.1.5 How to Read the Model ··············································································· 24

1.2 List of Basic Specifications ················································································· 25

1.2.1 Specification List ························································································ 25

1.2.2 Item for the Power Capacity and Heating Value ················································ 27

1.2.3 Selection of Circuit Breaker ·········································································· 27

1.2.4 Selection of Leakage Breaker ······································································· 27

1.3 External Dimensions ························································································· 28

1.3.1 SCON-CB/CGB/LC/LCG less than 400W ······················································ 28

1.3.2 SCON-CB/CGB/LC/LCG 400W to 750W ······················································· 28

1.3.3 SCON-CB/CGB/LC/LCG 3000W to 3300W···················································· 29

1.4 External Interface Specifications ·········································································· 30

1.4.1 Standard Input Output Interface Specification (Multi-Function Connector) ··············· 30

1.4.2 Input Output Interface Specification dedicated for PIO Type································· 31

1.4.3 Filedbus Type Specifications········································································· 32

1.5 Options ·········································································································· 35

1.5.1 Regenerative Unit for Motors of up to 750W····················································· 35

1.5.2 Regenerative Unit for Motors of 3000W and above············································ 36

1.5.3 Brake Box: RCB-110-RA13-0········································································ 37

1.5.4 Load Cell·································································································· 38

1.5.5 Pulse Converter: JM-08 ··············································································· 39

1.6 Installation and Storage Environment···································································· 40

1.7 Noise Elimination and Mounting Method································································ 41

Chapter 2 Wiring ·························································································· 45

2.1 Servo Press Controller for Motors of up to 750W (PIO Control) ·································· 45

2.1.1 Wiring Diagram (Connection of Devices) ························································· 45

2.1.2 Wiring······································································································ 46

2.2 Wiring for Controller for Motors of up to 750W ························································ 59

2.2.1 Wiring for Power Supply Circuit ····································································· 59

2.2.2 Wiring of Emergency Stop Circuit (System I/O) ················································· 64

2.2.3 Connection of Actuator ················································································ 66

2.2.4 Connection of PIO······················································································ 68

2.2.5 Multi-function Connector ·············································································· 69

2.2.6 Connection of Regenerative Unit ··································································· 72

2.2.7 SIO Connector Connection··········································································· 74

2.3 Servo Press Controller for Motors of 3000W and above (PIO Control) ························· 75

2.3.1 Wiring Diagram (Connection of Devices) ························································· 75

2.3.2 Wiring······································································································ 76