5

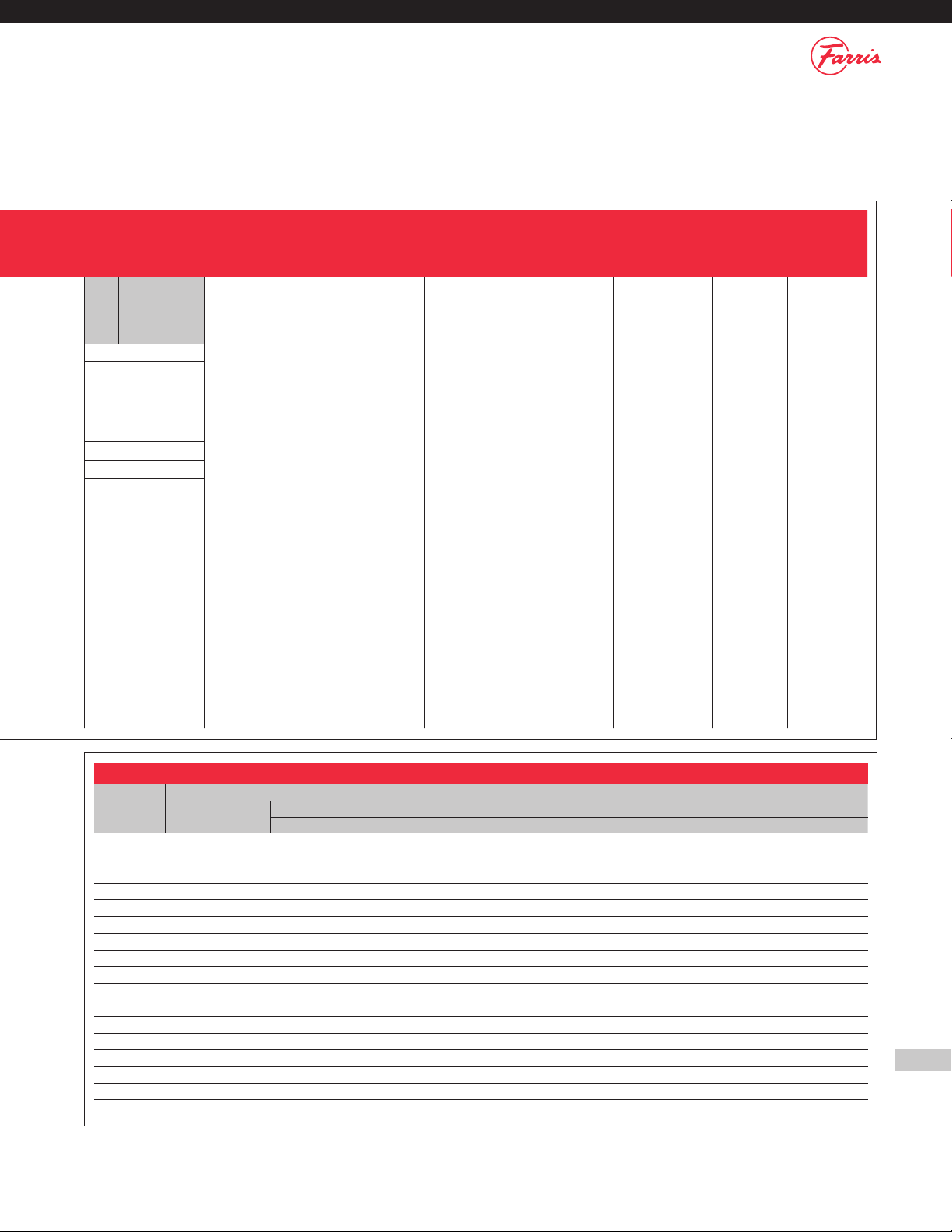

Familiarity with Farris valve type and serial numbering systems will greatly

benefit anyone using this manual or any other Farris literature. The ability

to recognize certain valve types and construction features along with

identifying serial numbers will assist correct maintenance procedures and

spare part selection/ordering. All Farris valve nameplates contain a specific

valve type number and serial number unique to that particular valve. See

Figure 1.2 on page 6 for an example of a typical 2600 Series nameplate.

Serial Numbering System

Each Farris pressure relief valve is assigned a unique serial number. This

serial number is assigned by the factory and remains part of the factory

records. Providing this serial number to the factory will assist in the

identification of the construction and metallurgy of the valve in question.

The following outline will give general guidelines on the serial numbering

system used on 2600 Series valves.

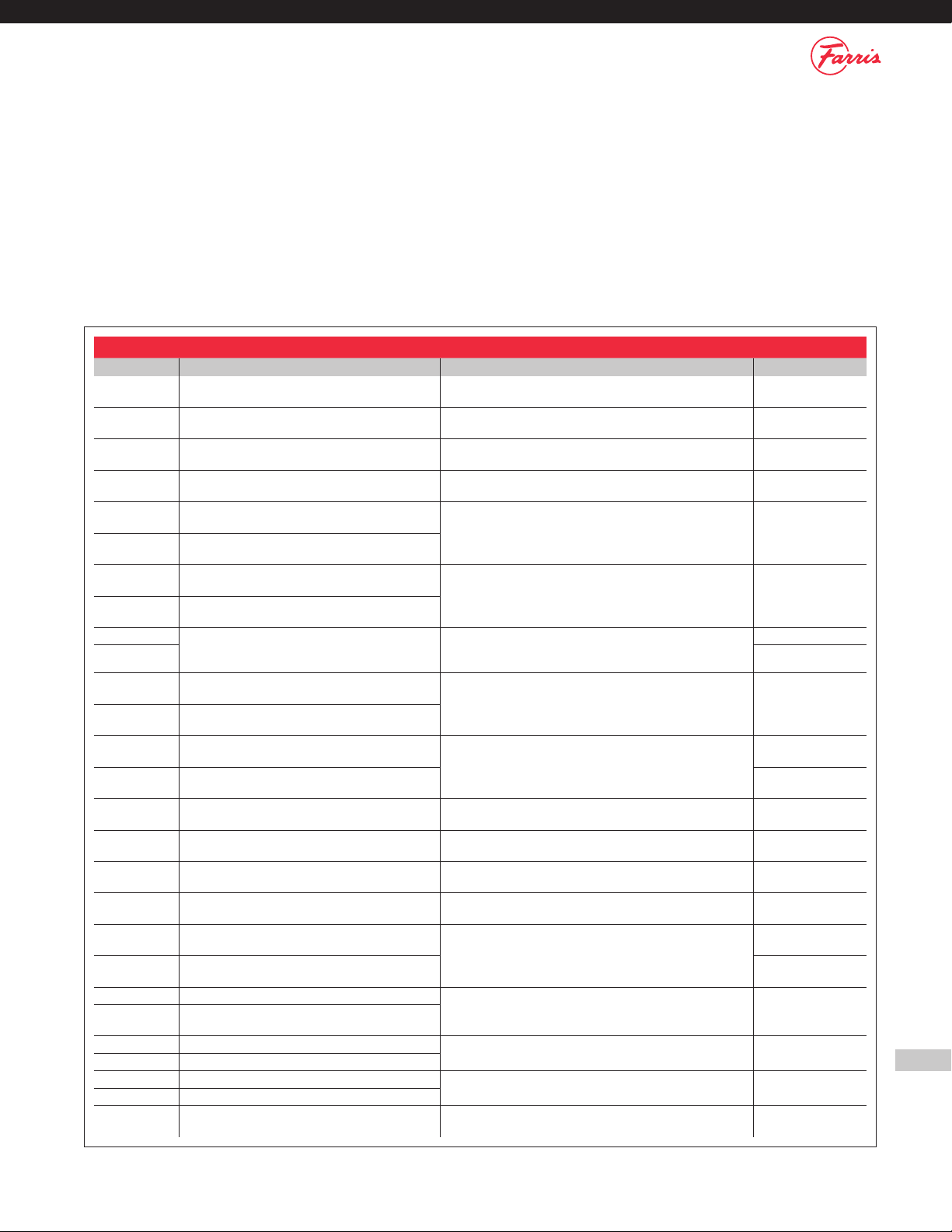

3. Serial and Type Numbering Systems

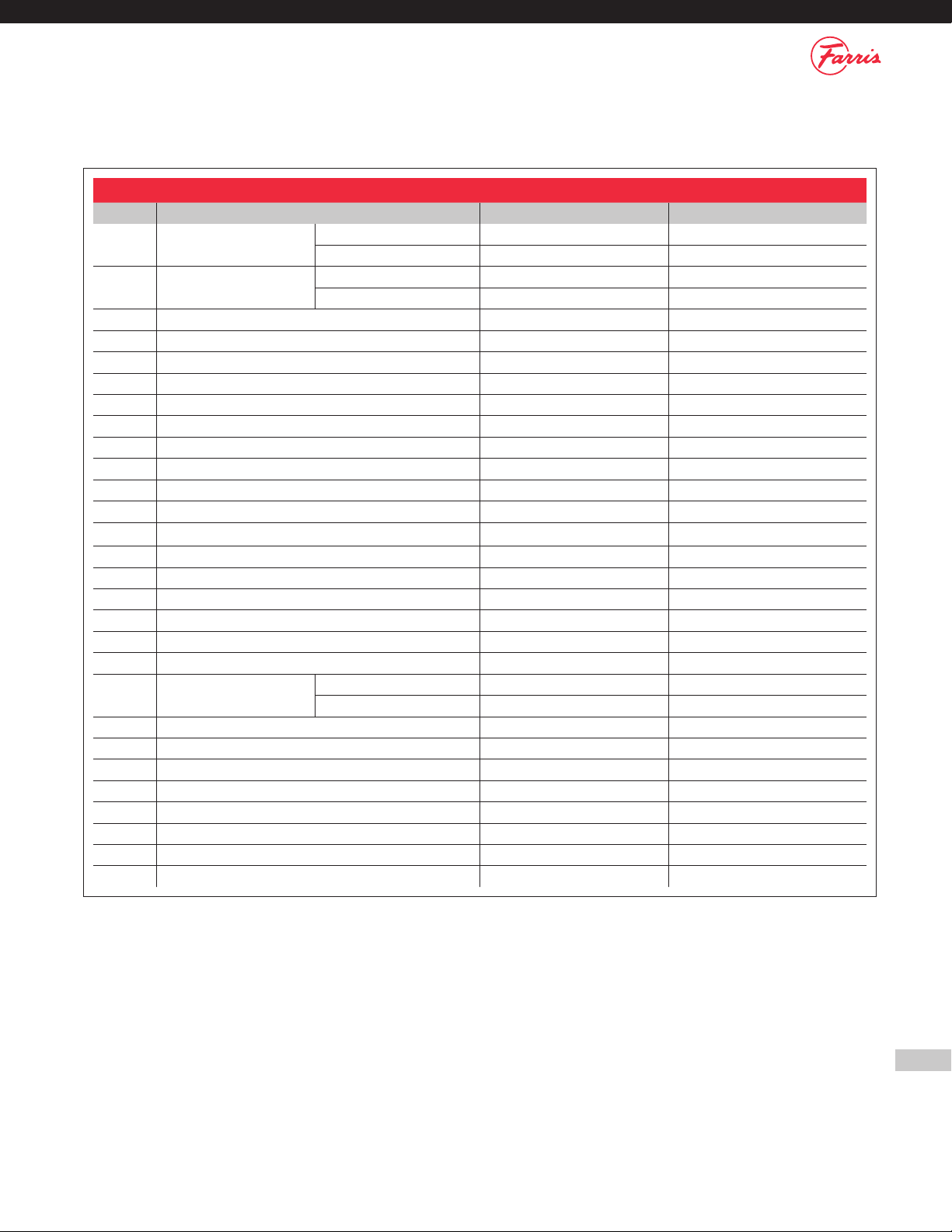

Serial Suffix Summary For 2600 Maintenance Manual

Serial # Suffix Valve Type Description Production Dates

-A15/H 2600L BalanSeal “O” Ring Seat Design

(Liquid Service)

Improved “G” orifice (150# & 300# Class only)

and “F” orifice designs.

2006 - present (G)

2011 - present (F)

-A14/H 2600L Conventional “O” Ring Seat Design

(Liquid Service)

Improved “G” orifice (150# & 300# Class only)

and “F” orifice designs.

2006 - present (G)

2011 - present (F)

-A15/G 2600L BalanSeal Metal Seat Design (Liquid Service) Improved “G” orifice (150# & 300# Class only)

and “F” orifice designs.

2006 - present (G)

2011 - present (F)

-A14/G 2600L Conventional Metal Seat Design

(Liquid Service)

Improved “G” orifice (150# & 300# Class only)

and “F” orifice designs.

2006 - present (G)

2011 - present (F)

-A15/M 2600L BalanSeal Design - “O” Ring

(air, steam, vapor & liquid services) Modified “D” through “K” orifice “O” ring seat design that replaced

original A14 & A15 “O” ring seat design.

Starts at Serial #’s above 300000.

July 1993 - present

-A14/M 2600L Conventional Design - “O” Ring

(air, steam, vapor & liquid services)

-A15 2600L BalanSeal Design

(air, steam, vapor & liquid services) Full nozzle valves conforming to API Standard 526 with ASME

Section VIII certification for liquid service.

Air & steam certification added in 2005.

1985 - present

-A14 2600L Conventional Design

(air, steam, vapor & liquid services)

-A13 2600 & 2600L BalanSeal Piston Design -

All design variations and Services

2600 & 2600L Balanced Piston version of standard 2600

BalanSeal Design. Use of serial suffix changed from A12 to A13

for consistency of numbering system.

Nov. 1997 - present

-A12 1978 - Nov. 1997

-A11/R 2600 BalanSeal Design - “O” Ring

(air, steam, & vapor services) Modified “D” through “K” orifice “O” ring seat design that replaced

the modified A10/M & A11/M “O” ring seat design.

Starts at Serial #’s above 312123.

August 1996 - present

-A10/R 2600 Conventional Design - “O” Ring

(air, steam, & vapor services)

A11/N 2600 & 2600L BalanSeal Design

(air, steam, vapor & liquid services) Special version of 2600 series built to military specifications with

MIL Spec. flanges and semi-nozzle construction

2000 - present

A10/N 2600 & 2600L Conventional Design

(air, steam, vapor & liquid services) 2000 - present

A11/H 2600 BalanSeal “O” Ring Seat Design

(air, steam, & vapor services)

Improved “G” orifice (150# & 300# Class only)

and “F” orifice designs.

2006 - present (G)

2011 - present (F)

A10/H 2600 Conventional “O” Ring Seat Design

(air, steam, & vapor services)

Improved “G” orifice (150# & 300# Class only)

and “F” orifice designs.

2006 - present (G)

2011 - present (F)

A11/G 2600 BalanSeal Metal Seat Design

(air, steam, & vapor services)

Improved “G” orifice (150# & 300# Class only)

and “F” orifice designs.

2006 - present (G)

2011 - present (F)

A10/G 2600 Conventional Metal Seat Design

(air, steam, & vapor services)

Improved “G” orifice (150# & 300# Class only)

and “F” orifice designs.

2006 - present (G)

2011 - present (F)

-A11/M 2600 BalanSeal Design - “O” Ring

(air, steam, & vapor services) Modified “D” through “K” orifice “O” ring seat design that replaced

original A10 & A11 “O” ring seat design.

Starts at Serial #’s above 300000.

July 1993 - July 1996

-A10/M 2600 Conventional Design - “O” Ring

(air, steam, & vapor services) July 1993 - July 1996

-A11 2600 BalanSeal Design (air, steam, & vapor services) Full nozzle valves conforming to API Standard 526 with nozzles

revised to incorporate ASME 0.9 capacity reduction factor. 1976 - present

-A10 2600 Conventional Design

(air, steam, & vapor services)

-A9 BalanSeal Bellows Design Full nozzle valves conforming to API Standard 526. 1959 - 1976

-A8 Conventional Design

-A3, A5, & A7 BalanSeal Bellows Design Includes both 2605 & 2675 Series 1955 - 1967

-A2, A4, & A6 Conventional Design

-A Full nozzle valves, conventional and

BalanSeal bellows types.

Serial suffix covers all types of construction including Conventional,

FarriSeal, BalanSeal, enclosed and exposed spring designs. 1943 - 1955

Note: Valves covered by serial number suffixes in RED are for obsolete designs.