Custom Equipment HB-P830 Installation and operating instructions

Other Custom Equipment Scissor Lift manuals

Custom Equipment

Custom Equipment HY-BRID LIFTS PRO PS-1030 Programming manual

Custom Equipment

Custom Equipment HY-BRID LIFTS I HB-P4.5 Programming manual

Custom Equipment

Custom Equipment Hy-Brid Lifts III Series Programming manual

Custom Equipment

Custom Equipment HY-BRID LIFTS II Series Programming manual

Custom Equipment

Custom Equipment HY-BRID LIFTS II Series Use and care manual

Custom Equipment

Custom Equipment Hy-Brid Lifts HB-P830CE Programming manual

Custom Equipment

Custom Equipment Hy-Brid Lifts PUSH-AROUND Programming manual

Custom Equipment

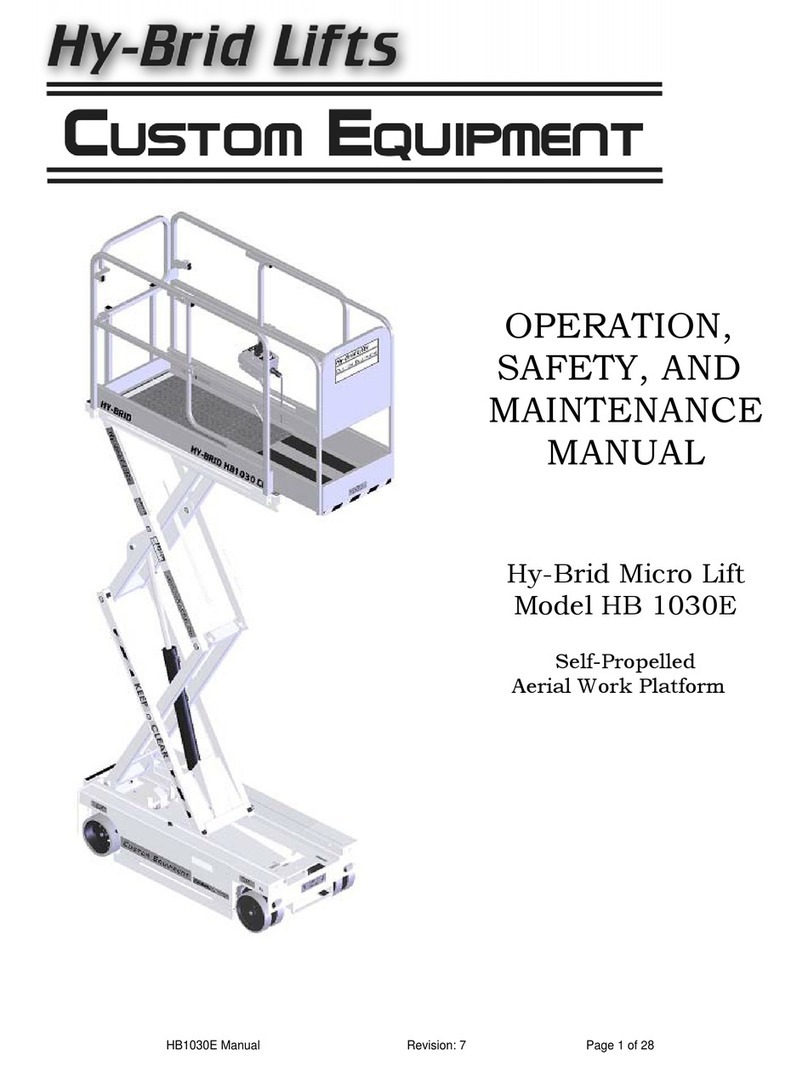

Custom Equipment Hy-Brid HB 1030E Use and care manual