OPERATIONS & SAFETY

HB-1030/HB-1430

SUPO 610

REV M

4

TABLE OF CONTENTS

SECTION 1 | SAFETY.........................................................................................................................................................6

1.1 | SAFETY SYMBOLS .....................................................................................................................................................6

1.2 | GENERAL RULES AND PRECAUTIONS..............................................................................................................6

1.3 | SAFETY FEATURES....................................................................................................................................................7

1.4 | SAFETY INDICATORS & INTERLOCKS.................................................................................................................7

1.5 | SAFETY CONTROLS.................................................................................................................................................8

1.6 | MAINTENANCE LOCK .............................................................................................................................................9

1.7 | SAFETY GUIDELINES................................................................................................................................................10

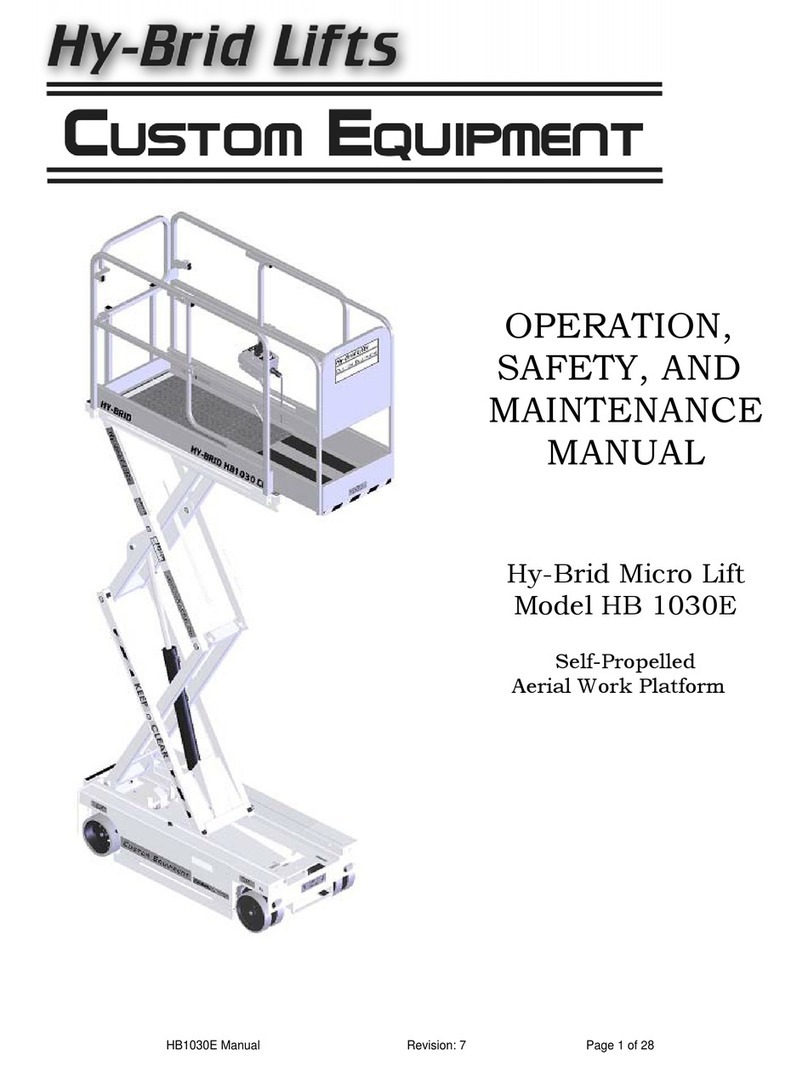

SECTION 2 | PRODUCT DESCRIPTION......................................................................................................................12

2.1 | GENERAL ....................................................................................................................................................................12

3.1 | DECAL DESCRIPTIONS...........................................................................................................................................15

4.1 | PRELIMINARY UNPACKING INSTRUCTIONS AND DEALER INSPECTION................................................17

4.2 | STORAGE ..................................................................................................................................................................17

4.3 | PREPARATION FOR TRANSPORT ........................................................................................................................17

SECTION 4 | TRANSPORT, HANDLING & STORAGE...............................................................................................17

4.5 | FORK LIFT POCKETS...............................................................................................................................................18

4.4 | LIFTING AND TIE-DOWN POINTS.......................................................................................................................18

SECTION 5 | OPERATION ..............................................................................................................................................19

5.1 | BEFORE YOU OPERATE..........................................................................................................................................19

5.2 | STARTUP/SHUT DOWN..........................................................................................................................................20

5.3 | DRIVING AND STEERING.......................................................................................................................................20

5.4 | ELEVATING AND LOWERING................................................................................................................................21

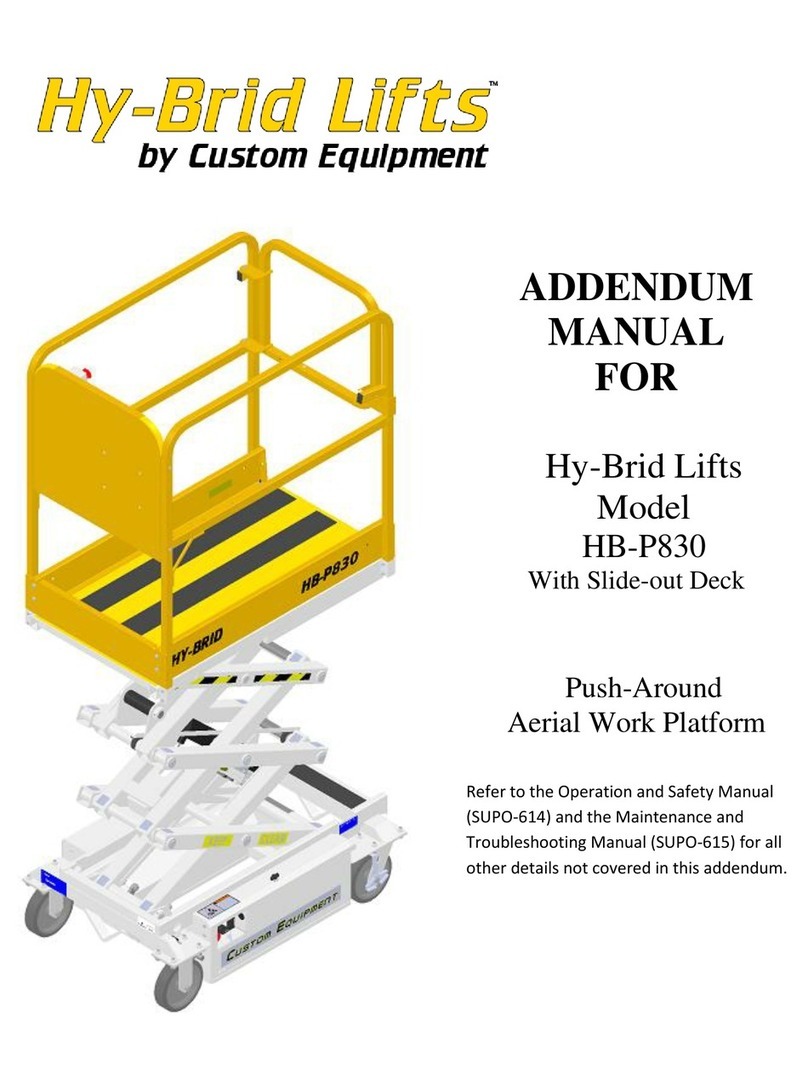

5.5 | EXTENDING THE PLATFORM ...............................................................................................................................21

5.5 | DAILY MAINTENANCE.............................................................................................................................................22

5.6 | CHARGING THE BATTERY.....................................................................................................................................22

5.7 | BATTERY DISPLAYS ..................................................................................................................................................23

SECTION 6 | INSPECTION CHECKLIST.......................................................................................................................25

SECTION 7 | ADDITIONAL RESOURCES.....................................................................................................................26

7.1 | GENERAL LIFT INFORMATION ..............................................................................................................................26

7.2 | TECHNICAL REFERENCES.....................................................................................................................................26

7.3 | PARTS DIAGRAMS.....................................................................................................................................................26