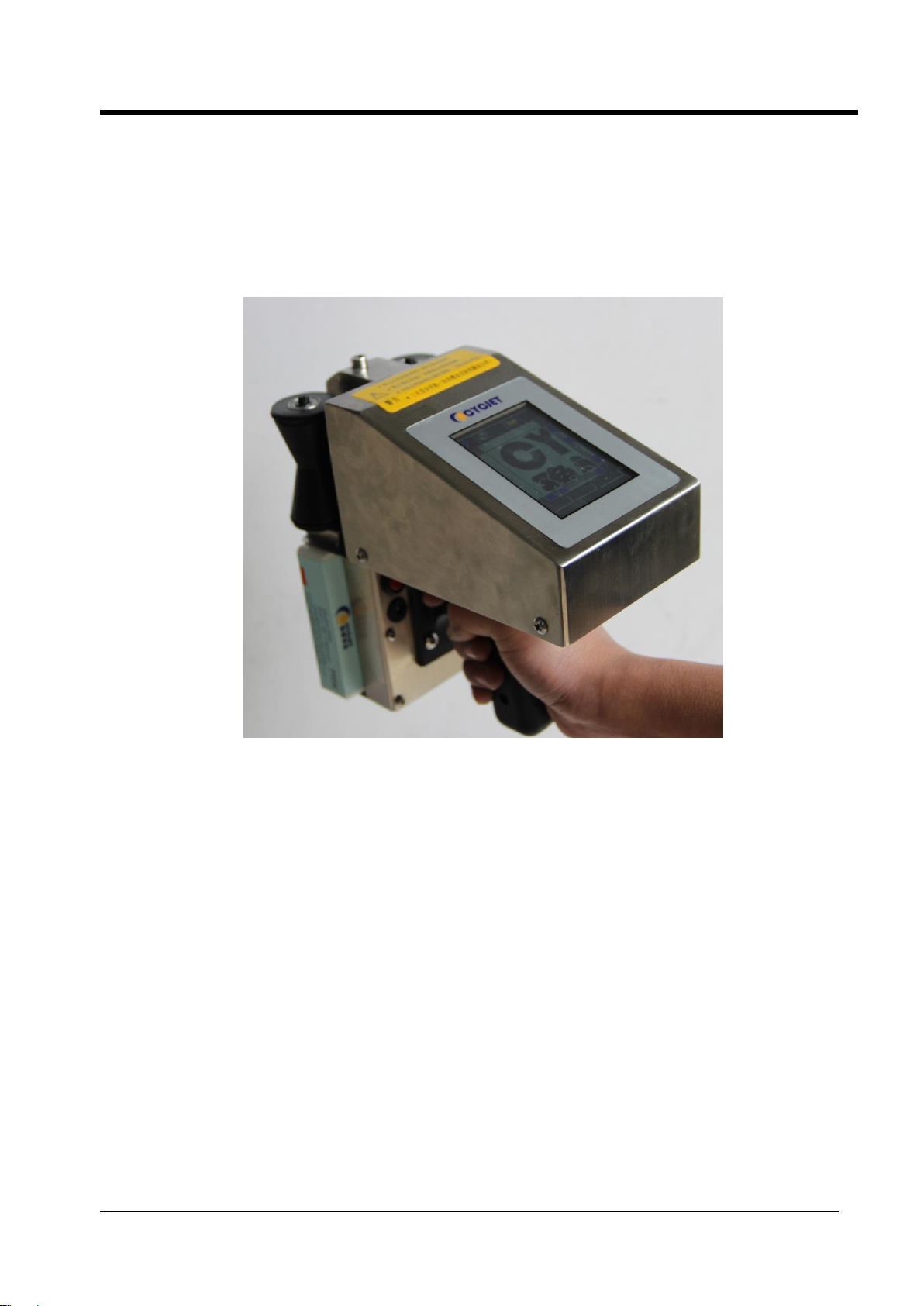

Manual of ALT382

Safety Instructions

Personal Safety

Some inks & cleaners are harmful, please installing & running machine in well ventilated conditions.

Some inks& cleaners are flammable, keep away from all sources of heat and ignition.

Fire-extinguisher shall be equipped with nearby the machine.

Wear safety glasses, gloves and masks when using inks & cleaners.

In the condition of inhalation and eye contact, please flush thoroughly with water and seek medical aid

immediately.

Turn the power off before maintenance.

Forbid to disassemble machine without our technician’s instruction. The ink-jet printer must be

properly grounded. When connecting electricity, the cabinet is powered with high voltage to risk life.

Only trained technicians are authorized to carry out installation, maintenance or repair.

Machine Safety

Loading Requirement

1、Ink-jet printer shall be packaged in standard container which filled with anti-vibration materials.

2、Purge the inside and outside of printhead and plug up the ink inlet. The printhead shall be covered by

cap and packed by anti-vibration film to prevent from scratch.

3、Just left an empty cartridge in Ink system before loading.

The warranty claims will not be accepted in the following situations:.

1、Printhead or inks system damages caused by using unauthorized inks and cleaners.

2、Printhead or inks system damages caused by replacing different types of consumable randomly. Such

as replaced oil-base inks into solvent-base inks, the two types of ink will cause chemical reaction to

damage machine.

3、Damages caused by running in unsuitable environments or electrical requirements.

4、Damages caused by non-approved disassembling and assembling.

5、The permanent damages caused by not performing schedules maintenance, or printhead scratching.

6、Damages caused by incorrect operation of non-approved people .

7、Damages caused by the Force Majeure.

Environmental Protection

Dispose of the waste inks & cleaners shall be in accordance with Local Authority Regulation. The wastes

are not allowed into the sewer system.