4 | P a g e

Table of contents

1.

Service

........................................................................................................................................... 7

2.

Consequential damages

............................................................................................................. 7

3. Safety.............................................................................................................................................. 8

4. Residual risk................................................................................................................................ 10

5.

Intended use of the machine

................................................................................................... 11

6.

Personnel qualifications

.......................................................................................................... 11

6.1. Mounted and trailed equipment........................................................................................ 12

6.2. Fire safety regulations........................................................................................................ 13

6.3. Hydraulic system................................................................................................................. 13

7. Transportation on public roads................................................................................................. 14

8.

Warranty claims

......................................................................................................................... 14

9.

Danger to children

..................................................................................................................... 14

10. Warning pictograms ............................................................................................................... 15

10.1. Placement of warning pictograms................................................................................ 18

11.

Technical data

........................................................................................................................ 19

12.

Load calculation

..................................................................................................................... 21

13. Danger zone............................................................................................................................ 23

14. Use of fertilizers and treated seeds.................................................................................... 24

15. Identification plate................................................................................................................... 24

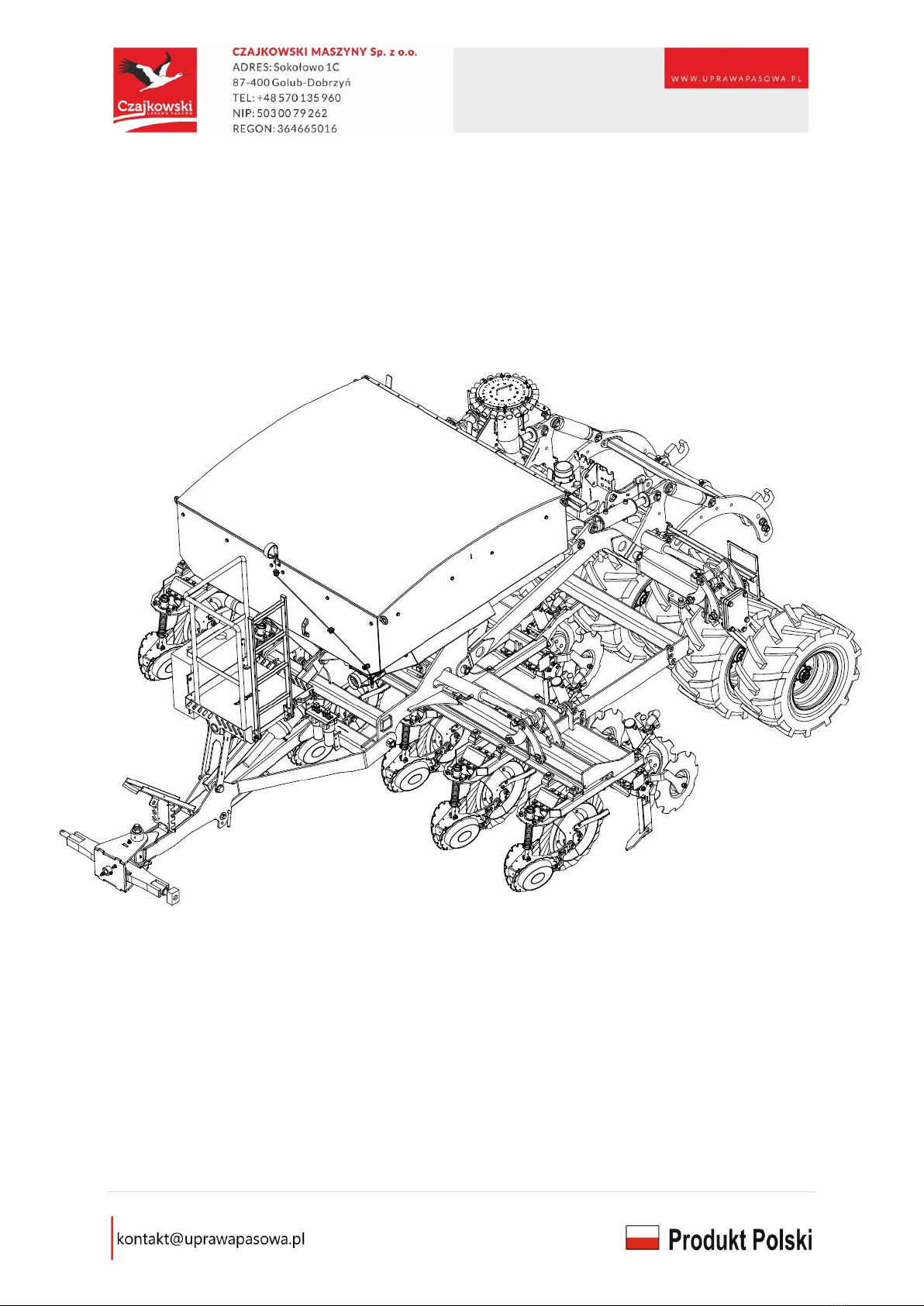

16. Description and design of the machine............................................................................... 25

16.1. Working sections............................................................................................................. 28

16.2. Design of the furrow opener.......................................................................................... 30

16.3. Types of chisels.............................................................................................................. 31

16.4. Tank.................................................................................................................................. 32

16.5. Setting the seed level sensor........................................................................................ 33

17. Spacing configurations for STK300 –individual seeding operations ............................. 34

17.1. 37,5 cm spacing for 8 frames of STK 300................................................................... 34

17.2. 45 cm spacing for 6 frames of STK 300...................................................................... 34

17.3. 75 cm spacing for 4 frames of STK 300...................................................................... 35

18. Spacing configurations for STK 300 PLUS - individual seeding operations.................. 35

18.1. 37,5 cm spacing for 8 frames of STK 300 PLUS....................................................... 35

18.1. 45 cm spacing for 6 frames of STK 300 PLUS.......................................................... 36

18.2. 75 cm spacing for 6 frames of STK 300 PLUS.......................................................... 36

19. Attaching and detaching the working sections................................................................... 37