This manual covers the operational aspects of the D-2 JF-WA1 Hydro-

Light

Sensor. D-2

continuously strives to meet the full expectations of our customers and we welcome

comments on the structure, content and the ability of this manual to answer your

questions regarding our product. If you have any suggestions or comments, please

that future versions of this instrument may have additional commands, and the function

of the commands shown in this document may vary from the present operation.

TABLE OF CONTENTS

Notes for User:

.......................................................................................................................... 3

1.0 GENERAL DESCRIPTION.................................................................................................... 5

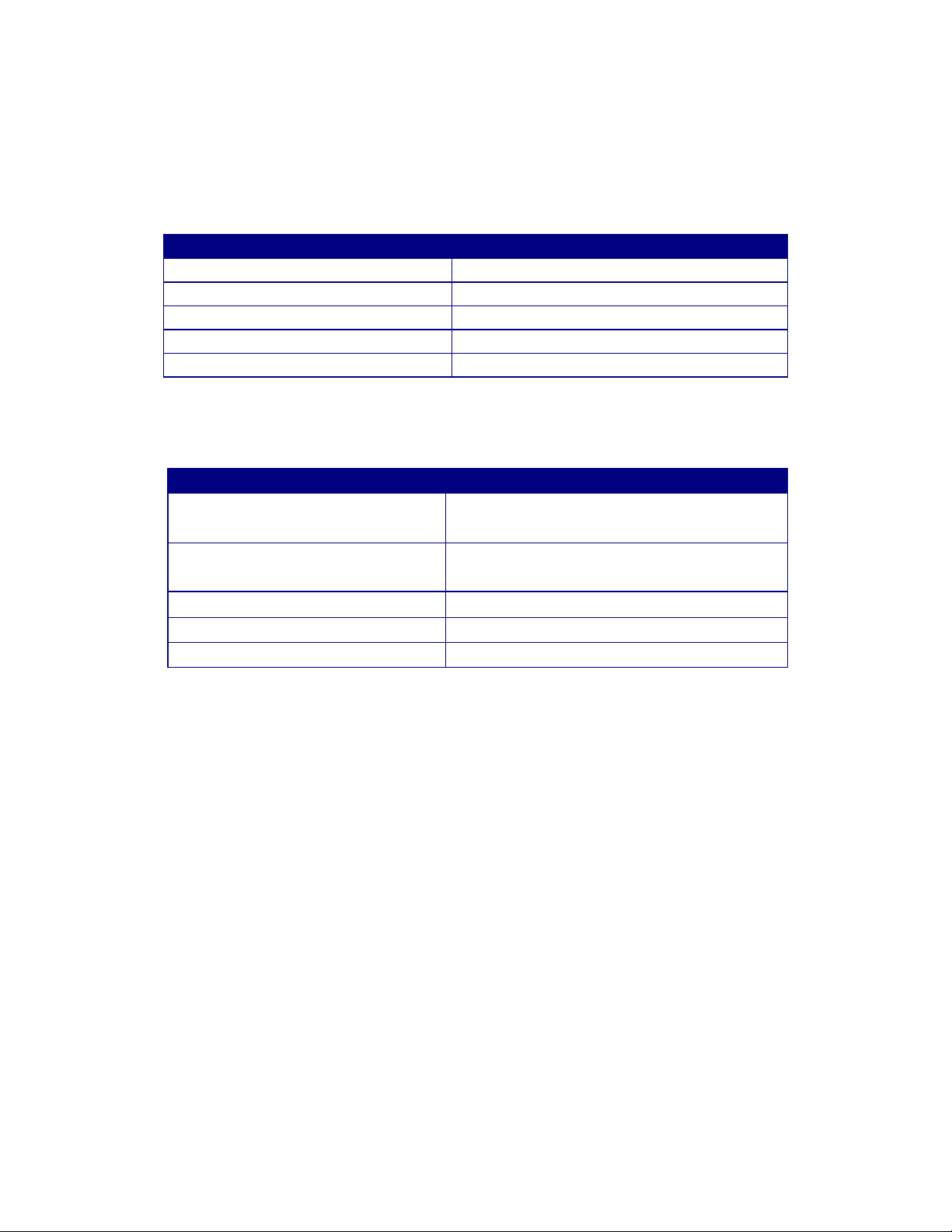

2.0 SPECIFICATIONS ................................................................................................................. 6

3.0 USAGE..................................................................................................................................... 6

4.0 THEORY OF OPERATION.................................................................................................... 7

Figure 1.....................................................................................................................................................8

5.0 OPERATION INSTRUCTIONS............................................................................................. 9

Figure 2...................................................................................................................................................10

Figure 3...................................................................................................................................................10

Figure 4...................................................................................................................................................10

6.0 FIELD VERIFICATION PROCEDURE............................................................................. 11

7.0 USB SERIAL DATA INTERFACE...................................................................................... 11

7.1 Port Settings.....................................................................................................................................12

7.2 Command Structure........................................................................................................................12

7.3 Continuous Data..............................................................................................................................13

7.4 Configuration/Calibration Constants............................................................................................13

7.5 Calibration Mode ............................................................................................................................13

8.0 CALIBRATION ..................................................................................................................... 13

8.1 Calibration Interval ........................................................................................................................13

8.2 Verification Tests.............................................................................................................................13

9.0 MAINTENANCE................................................................................................................... 14

APPENDIX A: LIMITED WARRANTY.................................................................................... 14

APPENDIX B: Serial Port Command List................................................................................. 16