• Do not place the Pneumac Controller in direct sunlight.

• The Pneumac Controller must be stored and operated within

designed operang condions specified in this manual.

Operang the Pneumac Controller outside these

ranges may cause damage to the device which could

result in premature failure.

• The Pneumac Controller must be used with specified operang

wall currents. All other alternave power sources

and currents may result in irreparable damage to

the system and possible hazardous event to the

paent or caregiver.

• Equipment may be hazardous if misused.

• Modificaon of the device voids warranty and

may compromise intended funcon. Service should

be performed exclusively by the manufacturer or

manufacturer’s representave.

• If Pneumac Controller is damaged during the shipping process,

please contact the manufacturer for appropriate acon.

• If Pneumac Controller is dropped during use with noceable

damage, please remove from service and contact the manufacturer

for appropriate acon.

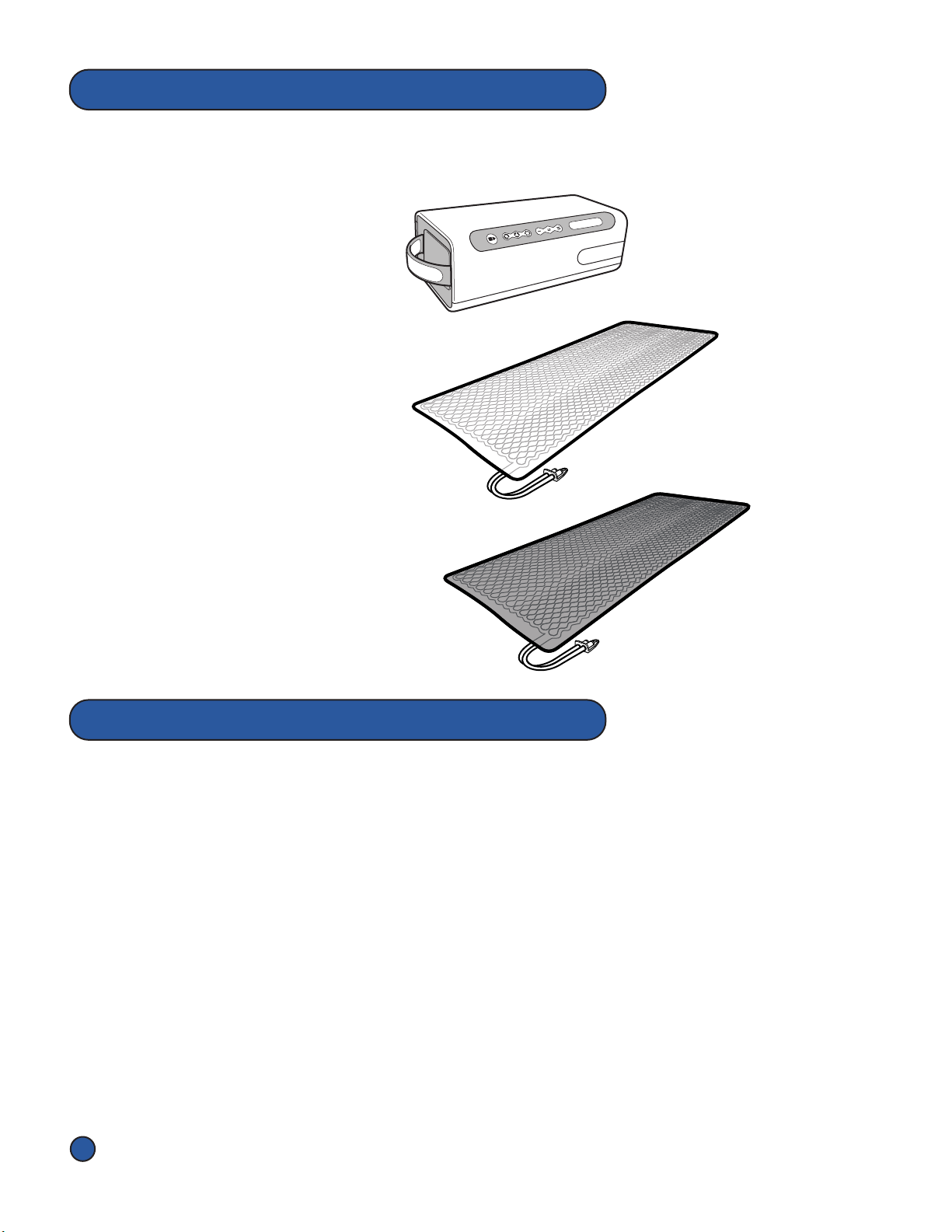

• Do not transport or carry the Pneumac Controller with an

Overlay aached.

• This device requires the use of a shielded Power Cord

for compliance with emissions limits. Do not operate

device without manufacturer supplied Power Cord.

• Do not use in an MRI environment.

• Turn Dabir System “OFF” during paent transfer and

before paent posioning.

• It is the responsibility of the caregiver to adequately secure and

protect the paent against paent falls.

4

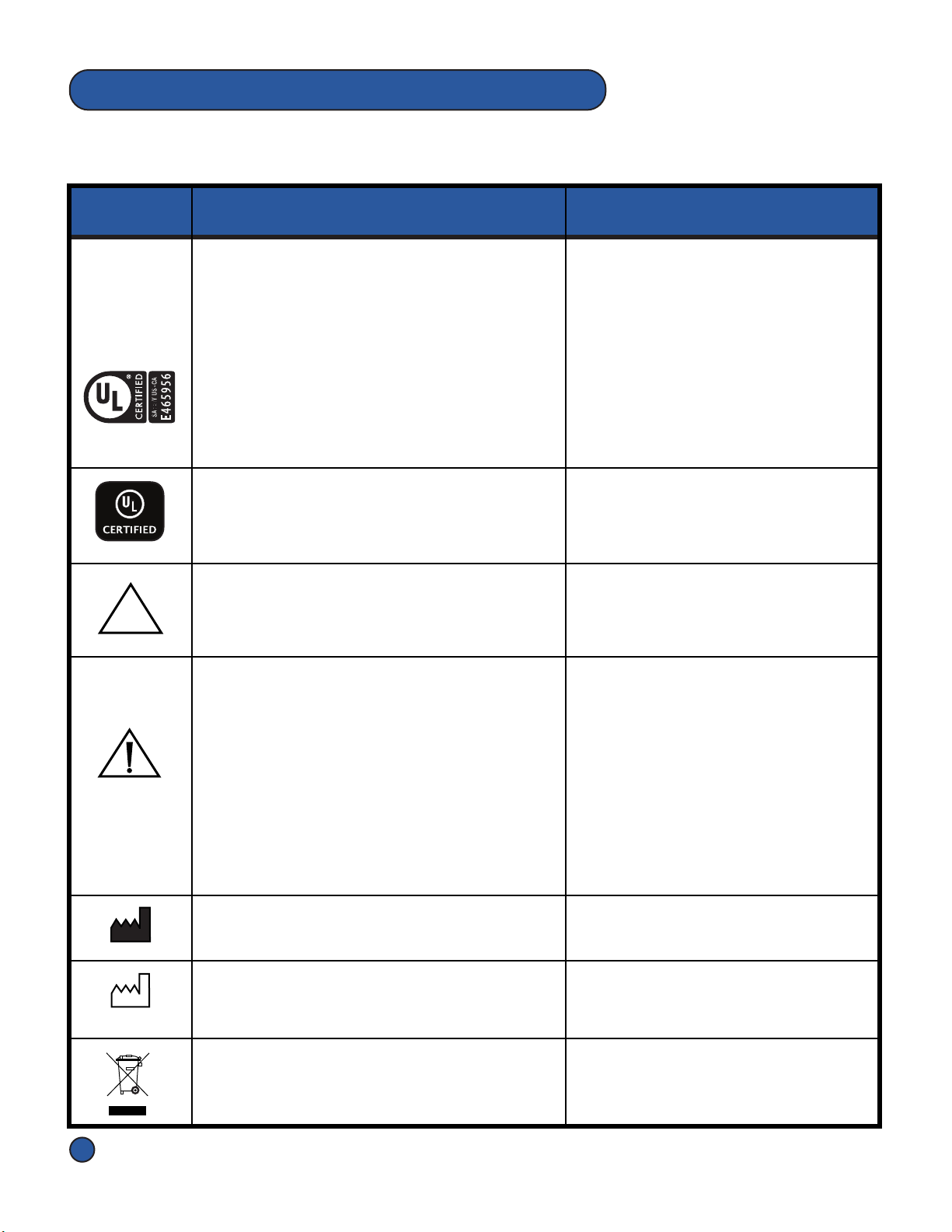

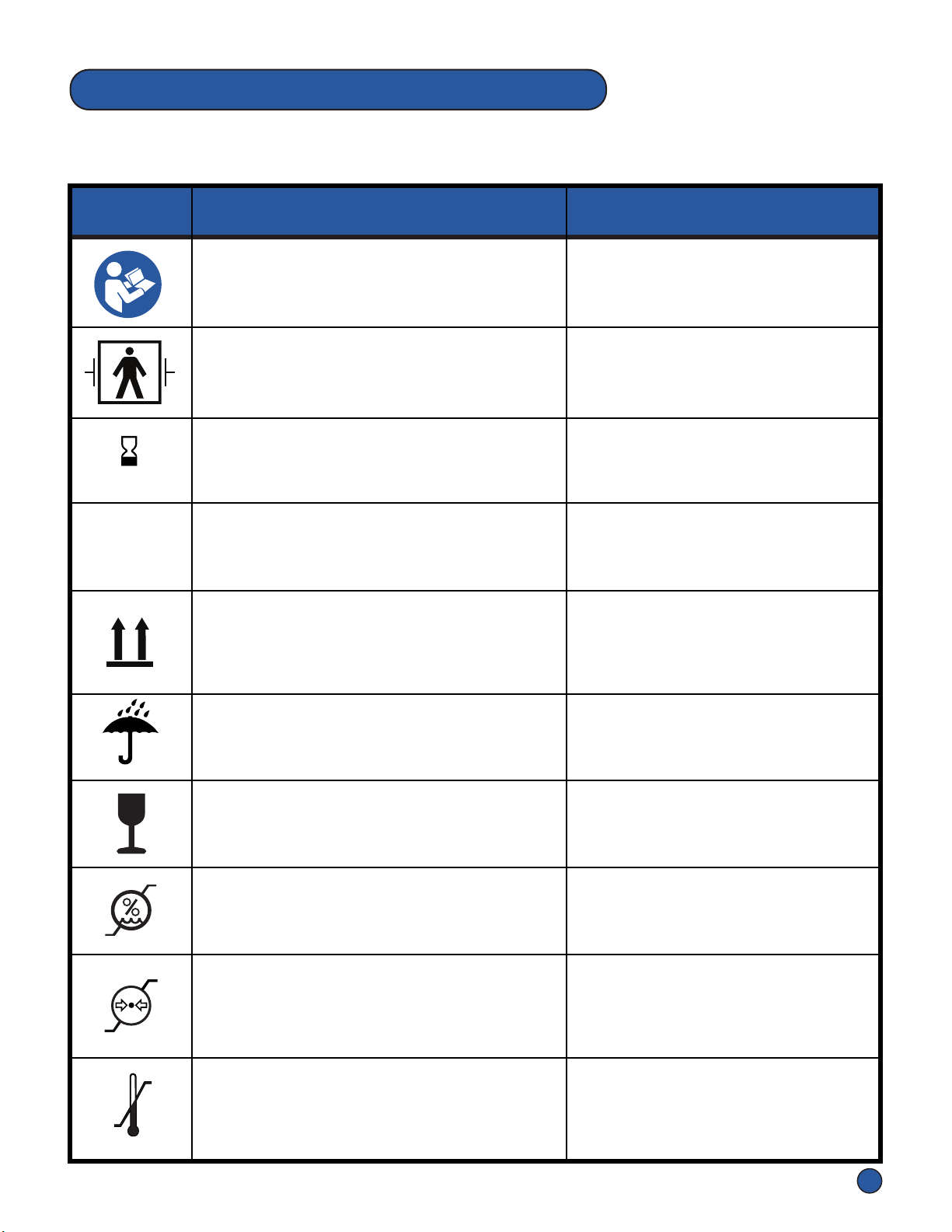

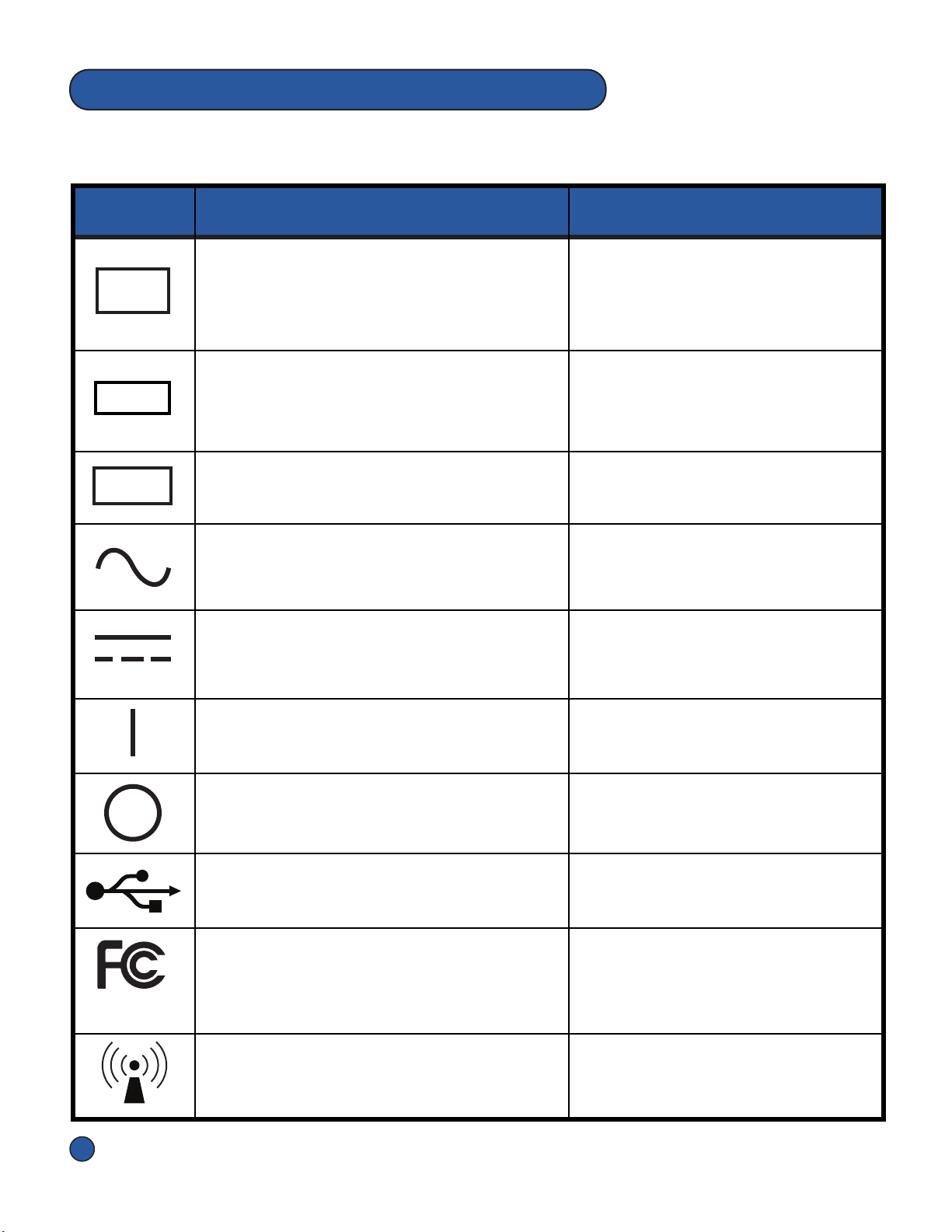

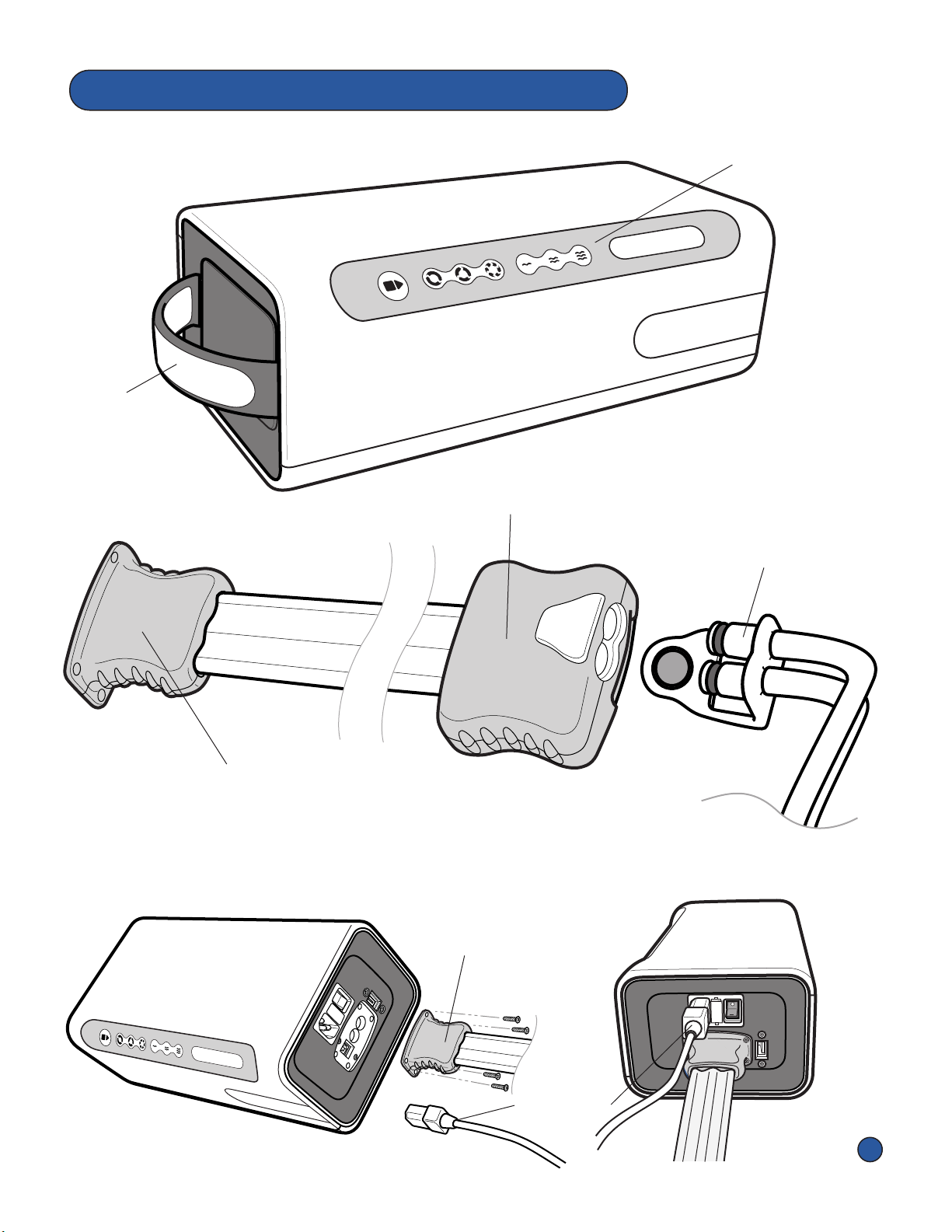

1.3 Labels and Descripons

UL Mark

ANSI/AAMI ES60601-1 AMD 1 (2012), "Medical

Electrical Equipment - Part 1:

General Requirements for Basic Safety and

Essenal Performance, Amendment 1.

CAN/CSA-C22.2 No. 60601-1 (2014), "Medical

Electrical Equipment - Part 1:

General Requirements for Basic Safety and

Essenal Performance

Label Descripon Applicaon

Pneumac Controller label

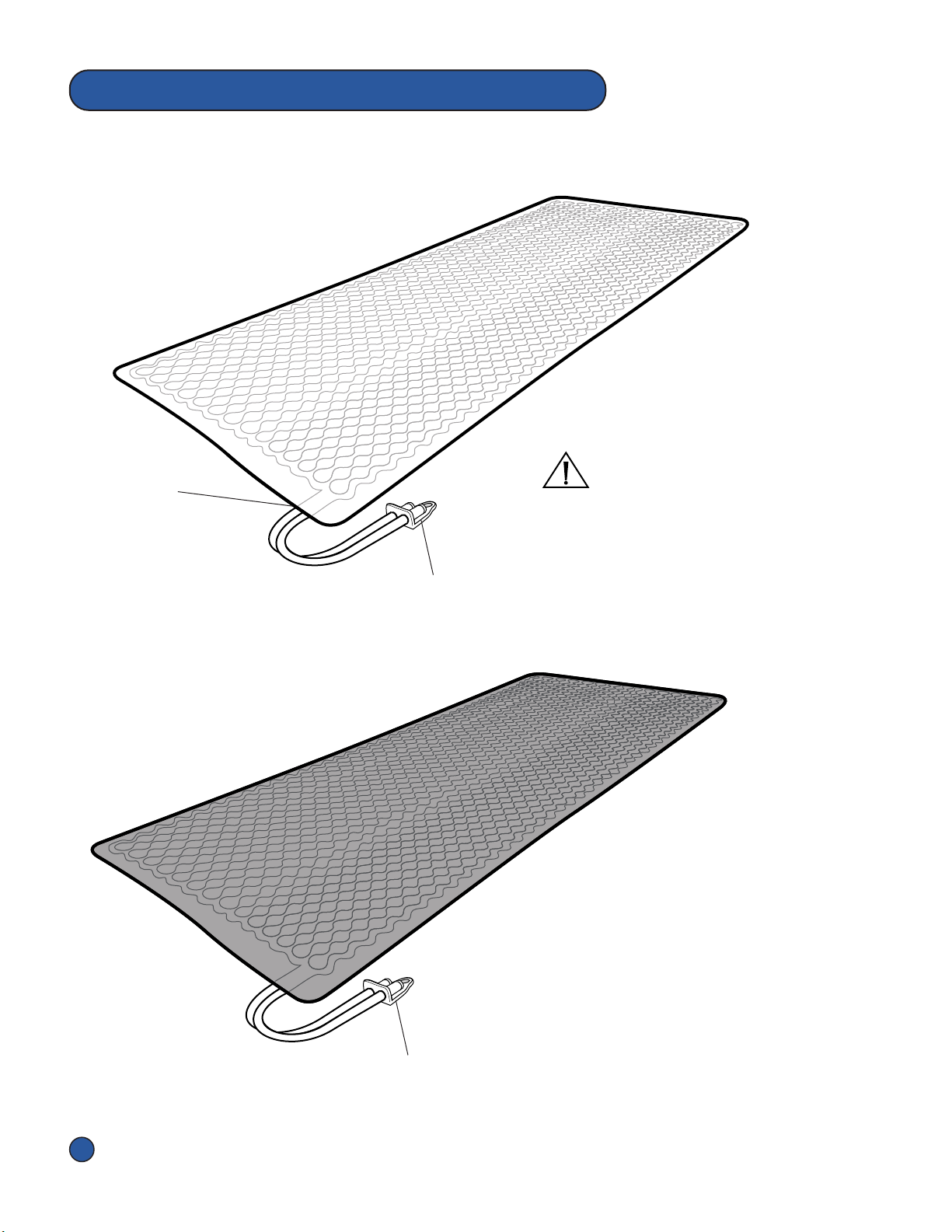

The Symbols below appear on the Pneumac Controller, Overlays, Hose Assembly,

Accessories and/or packaging.

NON

STERILE

Non-Sterile

Indicates a medical device that has not been

subjected to a sterilizaon process. Overlay labels & Overlay Box labels

Instrucons For Use

Cauon

Alerts the reader of a potenally hazardous

situaon which, if not avoided, may result in

minor or moderate injury to the user or

paent or damage to the product or other

property. This includes special care neces-

sary for the safe and effecve use of the

device and the care necessary to avoid

damage to the device that may occur as a

result of use or misuse.

Separate Collecon

Separate collecon for electronic waste

required.

Box labels, Overlay Box labels,

Overlay labels, Pneumac Controller

label, Hose Assembly label

Date of Manufacture

Indicates the date when the medical device

was manufactured.

Box labels, Pneumac Controller

label, Hose Assembly label,

Overlay labels

YYYY-MM-DD

Manufacturer

Indicates the medical device manufacturer.

Box labels & Pneumac

Controller label

UL Badge

Indicates UL compliance on markeng,

adversing, and packaging materials

Pneumac Controller label, Box

labels, Overlay labels, Hose

Assembly label

DOC# R01-0006-00004-AA

NOTE: Provides special informaon to make important instrucons clearer.