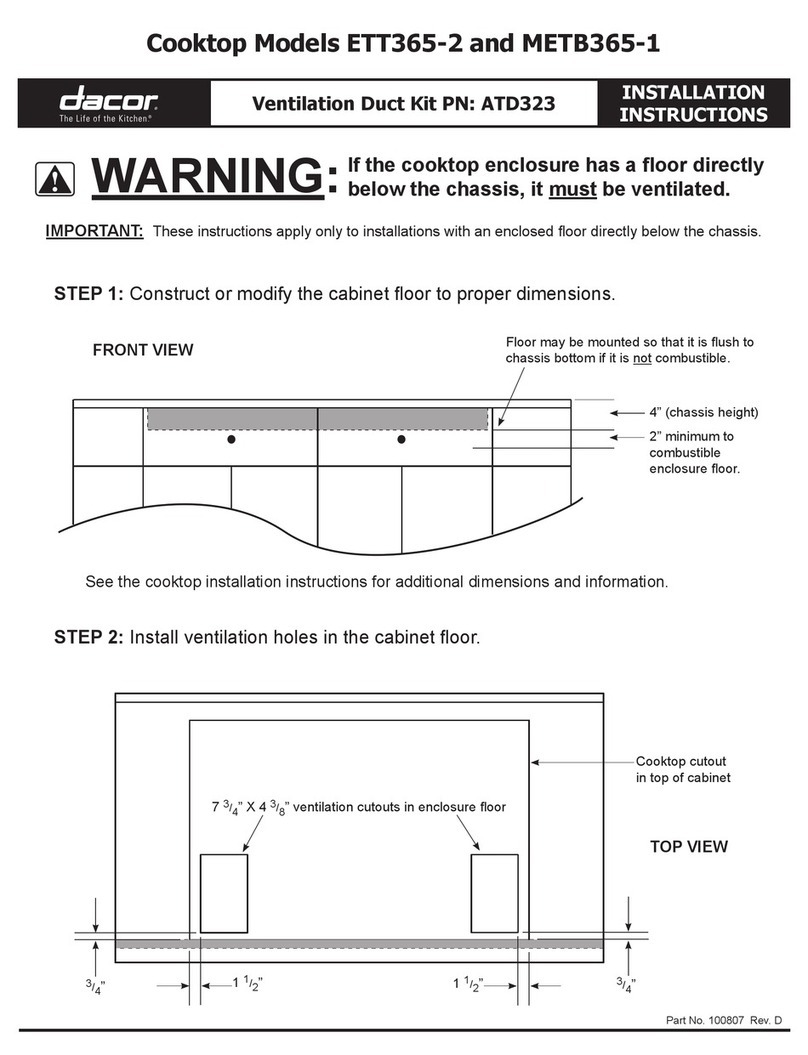

4

WARNINGS:

1. To reduce the risk of personal

injury caused by reaching

over a hot appliance, cabinet

storage space located directly

above the cooktop should be

avoided.

2. Do not store combustible

materials or items adversely

affected by heat in cabinet

areas above the appliance.

3. Follow the instructions

regarding minimum safe

clearances and installation

location. Failure to do so may

result in a fire or safety hazard.

NOTE:

When installing the cooktop and

vent into a laminated (Formica®,

etc.) or synthetic (Corian®, etc.)

countertop, follow the countertop

manufacturer’s instructions

regarding the minimum corner

radius, use of heat reflective tape,

reinforcement of corners, etc.

Plan the installation so that all required minimum

clearances between the cooktop, overhead

cabinets and adjacent vertical walls are

provided. Refer to the cooktop/range installation

instructions for the minimum dimensions specific

to the particular appliance being installed.

The DACOR Raised Vent System is designed

to remove the contaminants and by-products

that result when cooking with gas or electric

appliances. The vent system consists of the vent

intake along with a remote blower and a inline

blower if needed. The raised vent downdraft

systems are compatible for use with select

DACOR cooktops and ranges, therefore, these

instructions offer specific guidelines for mounting

the raised vents behind DACOR cooktops and

ranges.

t=max. backsplash thickness

25"

B

C

A

D

Combustible

Rear Wall

Cutout and Overall Dimensions

(CER304, CER365, ETT304, ETT365, SGM466, SGM464EM)

Countertop Preparation

Below Countertop Preparation

The raised vent intake, blower (in cabinet

mounted models only), and cooktop are

designed for installation into standard U.S.

made base cabinets. Before making the

countertop cutout, make certain that the cooktop

and vent system will clear the cabinet walls,

backsplash, and any wall studs along the back

wall within the cabinet.

Dacor

Model No.

Cutout

“A”

Cutout

“B”

Cutout

“C”

Cutout

“D”

Dimension

“t”, max.

Overall

Width

CER304 19 7/8” 28 1/2” 27 1/2” 2 3/8” 3/4” 30”

CER365 19 7/8” 34 1/2” 33 1/2” 2 3/8” 3/4” 36”

ETT304 19 7/8” 28 1/2” 27 1/2” 2 3/8” 3/4” 30”

ETT365 19 7/8” 34 1/2” 33 1/2” 2 3/8” 3/4” 36”

SGM304 22 1/4” 27 1/2” - - 3/4” 30”

SGM364 22 1/4” 33 3/4” - - 3/4” 36”

SGM365 22 1/4” 33 3/4” - - 3/4” 36”

SGM466 19 7/8” 19 7/8” 43 1/2” 2 3/8” 3/4” 46”

SGM464EM 19 7/8” 19 7/8” 43 1/2” 2 3/8” 3/4” 46”

NOTES:

1. If there is a backsplash with a

curved base at the countertop

level, then the clearance

behind the vent will be

reduced. Keep this in mind to

avoid interference.

2. If your cabinet differs from

the standard 24” deep, 36”

high cabinets shown in Figure

4, then adjust your cutout

locations accordingly to

prevent interference.

3. If a drawer or shelf is being

installed below a gas cooktop,

be certain to avoid interference

with the gas supply line and

the drawer or shelf.

4. For installation with gas

cooktops, a 90-degree elbow

must be connected to the

cooktop gas inlet to avoid

interference with the Raised

Vent plenum front.

Locate the house junction box adjacent to the

vent junction box found at the lower right of the

vent plenum.

t=max. backsplash thickness

25"

B

A

Combustible

Rear Wall

Cutout and Overall Dimensions

(SGM304, SGM364, SGM365)

Finished

Countertop

11/16" (17mm) to 3 11/16" (94mm)

to right of centerline

3 1/2" x 10 1/4"

(89mm x 260mm)

Optional

8"

(203mm)

30 13/16"

(783mm)

Rear edge of

cooktop/vent

cutout

plumbed down

Down Duct Cutout Dimensions

RV with CABP3 Blower

NOTE:

Access from the front of the

cabinet to the underside of the

cooktop, the vent system, and the

junction box must be provided

for inspection and service. Any

drawers or shelves placed below

the cooktop and in front of the

vent must be easy to remove for

access to the cooktop, vent and

junction box.

For installation of the raised vent system,

provide an opening in the countertop as shown

in the Countertop Preparation section. Position

the cutout so all required minimum clearances

are met. Make certain that the minimum flat

countertop area meets or exceeds the combined

overall width and overall depth, as shown.

NOTE:

Verify that the raised vent and

blower being installed are a

matched pair before beginning the

installation.