Daewoo DW-1300 User manual

Other Daewoo Washer manuals

Daewoo

Daewoo DWD-FD1022 User manual

Daewoo

Daewoo DWC-LU1011 User manual

Daewoo

Daewoo DWF-800 User manual

Daewoo

Daewoo DWF-750MS User manual

Daewoo

Daewoo DWD-MH1011 User manual

Daewoo

Daewoo DWF-753 User manual

Daewoo

Daewoo DWF-173M User manual

Daewoo

Daewoo DWF-5590DP Series User manual

Daewoo

Daewoo DWD-FU1041 User manual

Daewoo

Daewoo DWD-GM1011 User manual

Daewoo

Daewoo DWF-803 User manual

Daewoo

Daewoo DWM-160C User manual

Daewoo

Daewoo DWM-200C User manual

Daewoo

Daewoo WM510T0WU0ES User manual

Daewoo

Daewoo DWC-UD1212 User manual

Daewoo

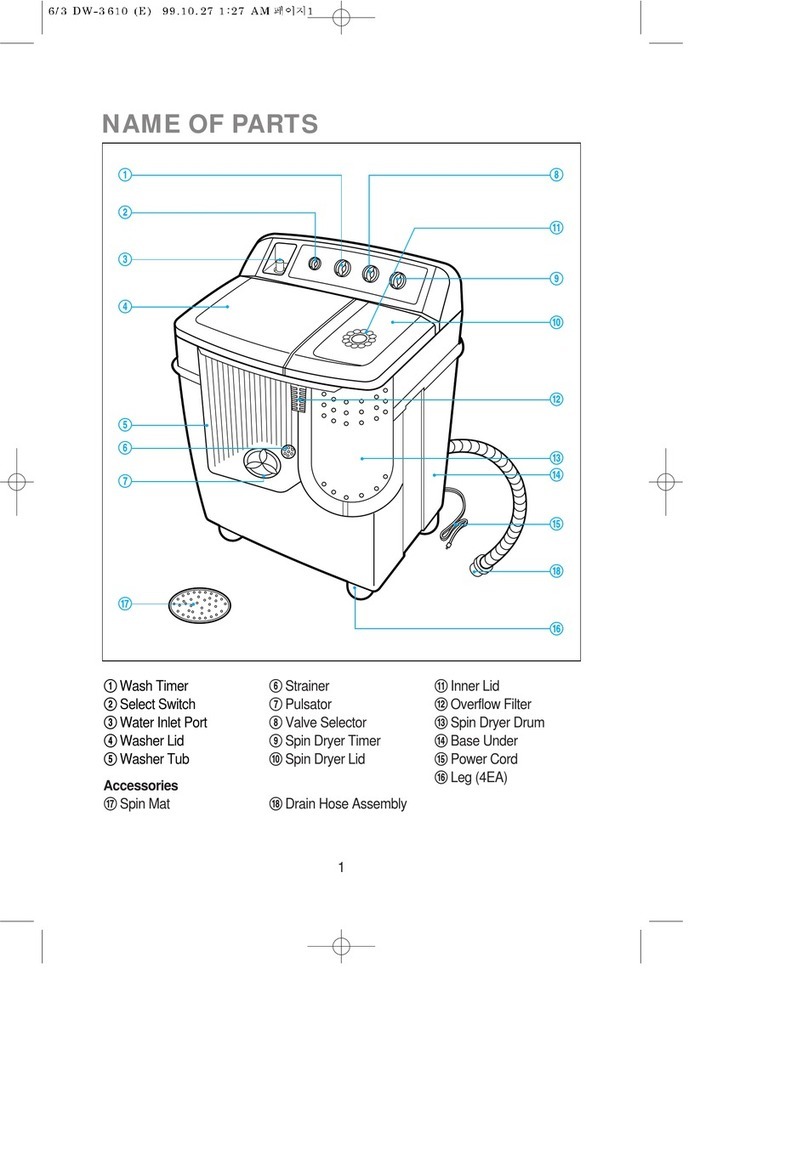

Daewoo DW-3610 User manual

Daewoo

Daewoo DWD-E1211R'S User manual

Daewoo

Daewoo DWF-900S User manual

Daewoo

Daewoo DWD-M801X User manual

Daewoo

Daewoo DWD-E113R User manual