3

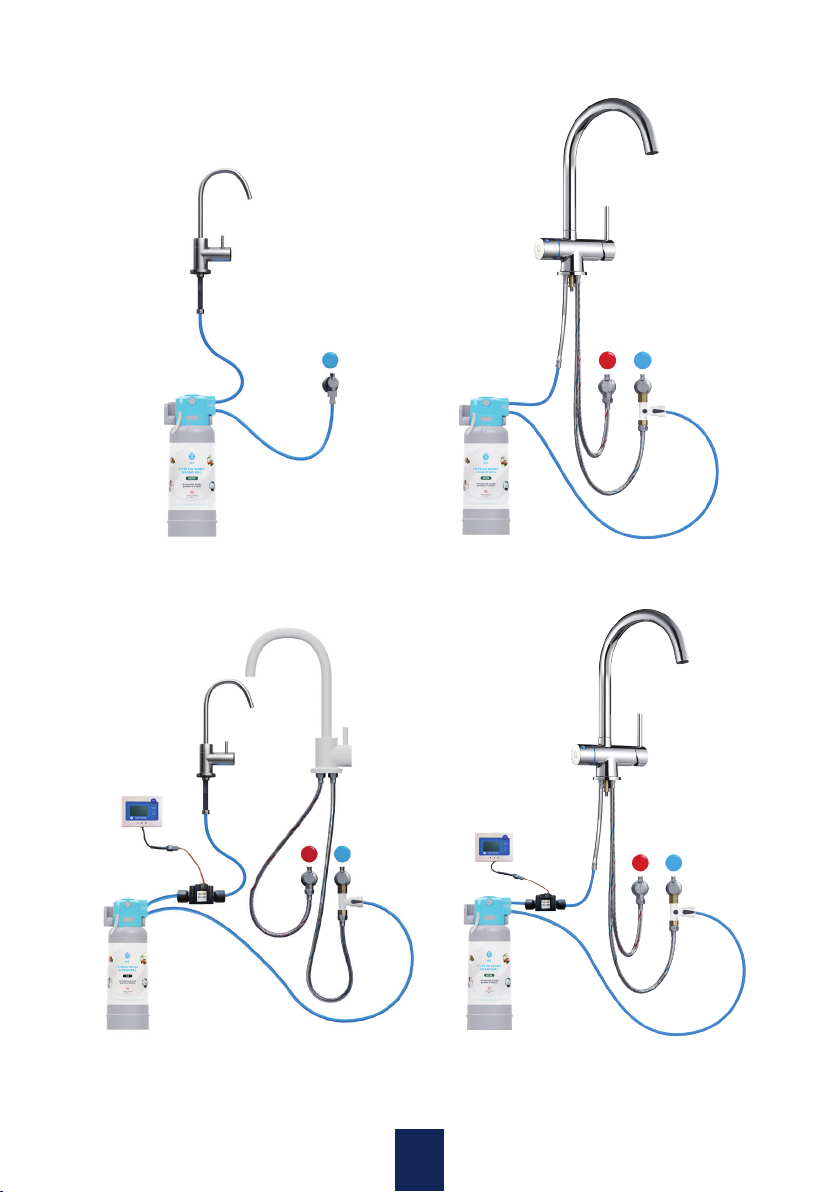

•The compact construction of the filter allows for perfect optimization of tap water by reducing the

content of lead, chlorine and undesirable substances. The use of the Flow Comfort filtration system

improves the taste of drinking water. Water becomes clear and suitable for direct consumption. The

elements of the system are adjusted for installation in a cabinet under the sink. The efficiency and

durability of the filter depend on the local properties of water as well as on the condition of the water

installation.

•The filter bed has been developed based on a high-quality activated carbon of natural origin. It is

possible that carbon particles might appear in the water. They are completely safe for health. If

swallowed, they will cause no harm to health. The construction of the filtration system uses materials

approved for contact with food.

•The Flow Comfort system includes an independent or integrated electronic indicator which reminds

the user about the need to replace the filter.

Specification

•The tap water filtration system can be connected to the cold drinking water connection. Do not use for

water that has not been analyzed for suitability for consumption.

•A shut-off valve should be installed before the filter.

•If water pressure is higher than the nominal value, a pressure-reducing valve must be installed.

•Certain groups of people e.g., people with kidney diseases or weak immune system should consult the

possibility and method of use of the filter with a specialist and/or a physician.

•It is recommended that the filtration system should not be left unused for a longer period of time. If the

system is not used for 2-3 days, flush it with 0.52 gallon of water. If the system is going to be used for

the first time after a month or longer, flush it with 5.2 gallons of water.

•Filtered water remains suitable for consumption for 1-2 days (depending on the storage conditions).

•Due to the risk of secondary pollutants in the water installation, the system has been qualified as

category 2 acc. to EN 1717.

•The DC10 Lead filter cartridge and the head must be protected against overheating and excessive

exposure to sun.

•A factory-packed D10 Lead filter cartridge is fit for use for 5 years from the date of manufacture.

Safety of use - important information

Working pressure 11.6 - 87 PSI

Maximum working pressure (if higher, use a pressure-reducing valve) 116 PSI

Temperature of feed water 39.2°F (4°C) to 86°F (30°C)

Ambient temperature during storage and transport 5°F to 104°F

Water flow Pressure in the water installation

0.8 US gal/min (gpm) 29 PSI

1.1 US gal/min (gpm) 44 PSI

1.2 US gal/min (gpm) 58 PSI

Dimensions of the filter with the head and the wall bracket 4,3 x 4,3 x 11,4 inch

Position of installation Vertical

Water connection - inlet and outlet ¼ ‘’ (6.3 mm) hose

Technical details of the filtration system