DRPB48 Operation Manual

Pneumatic Blind Rivet Setting Tool - DRPB48

READ THIS MANUAL CAREFULLY BEFORE USING THE TOOL !

It is IMPORTANT to follow the safety instructions for adequate protection

against injuries.

- This tool should be used ONLY to set blind rivets within the TOOL’S CAPACITY. It MUST

NOT be used for other purposes, such as hammer, etc.

- This tool should be always operated with compressed air supply within the air pressure

range 0.5Mpa ~ 0.7Mpa.

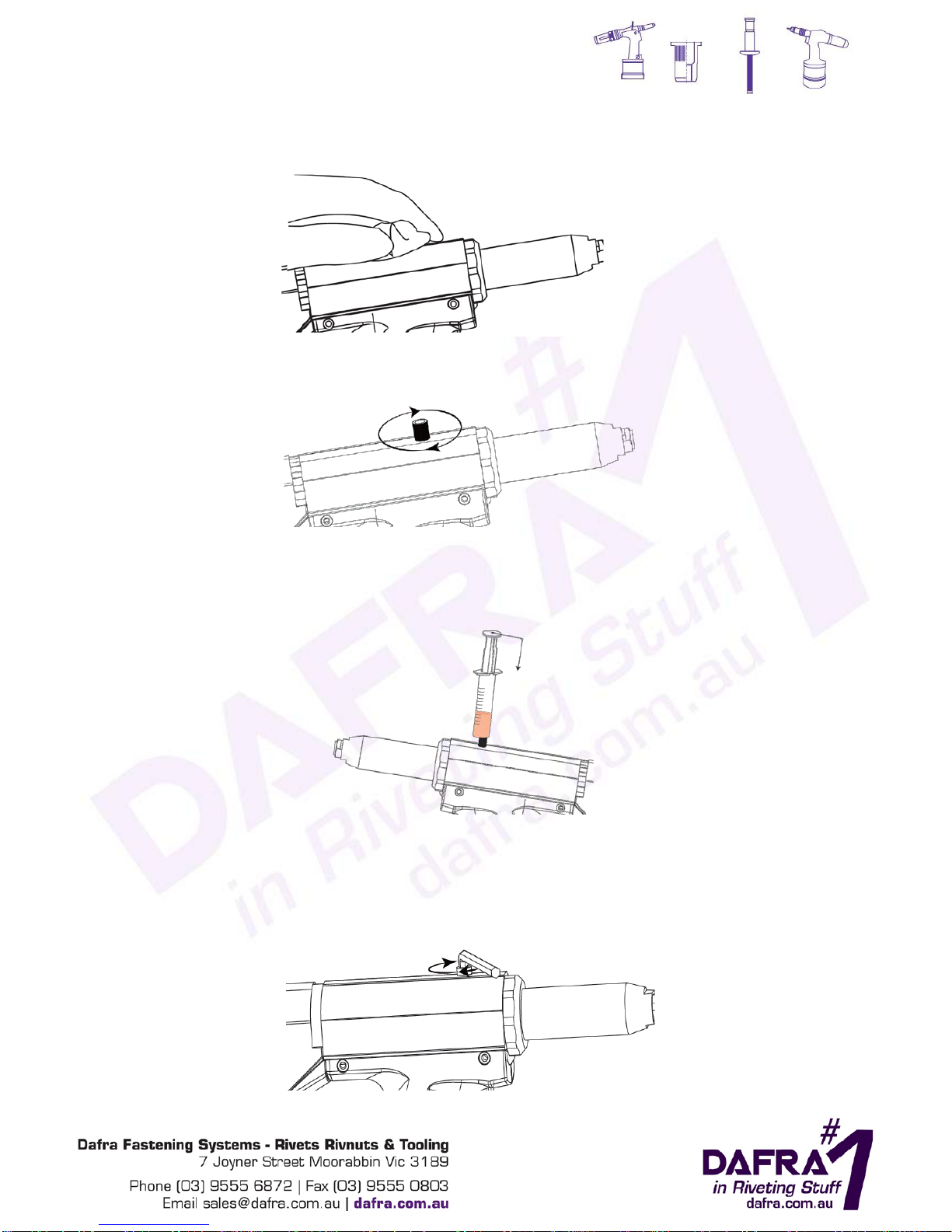

- Always DISCONNECT the air supply from the tool before changing the tool parts, such as

jaws, etc.

- DO NOT use the tool in the environment described as below:

fuel and combustion air.

temperature rapidly rising.

humidity, rain, water, storm and thunder, lightning.

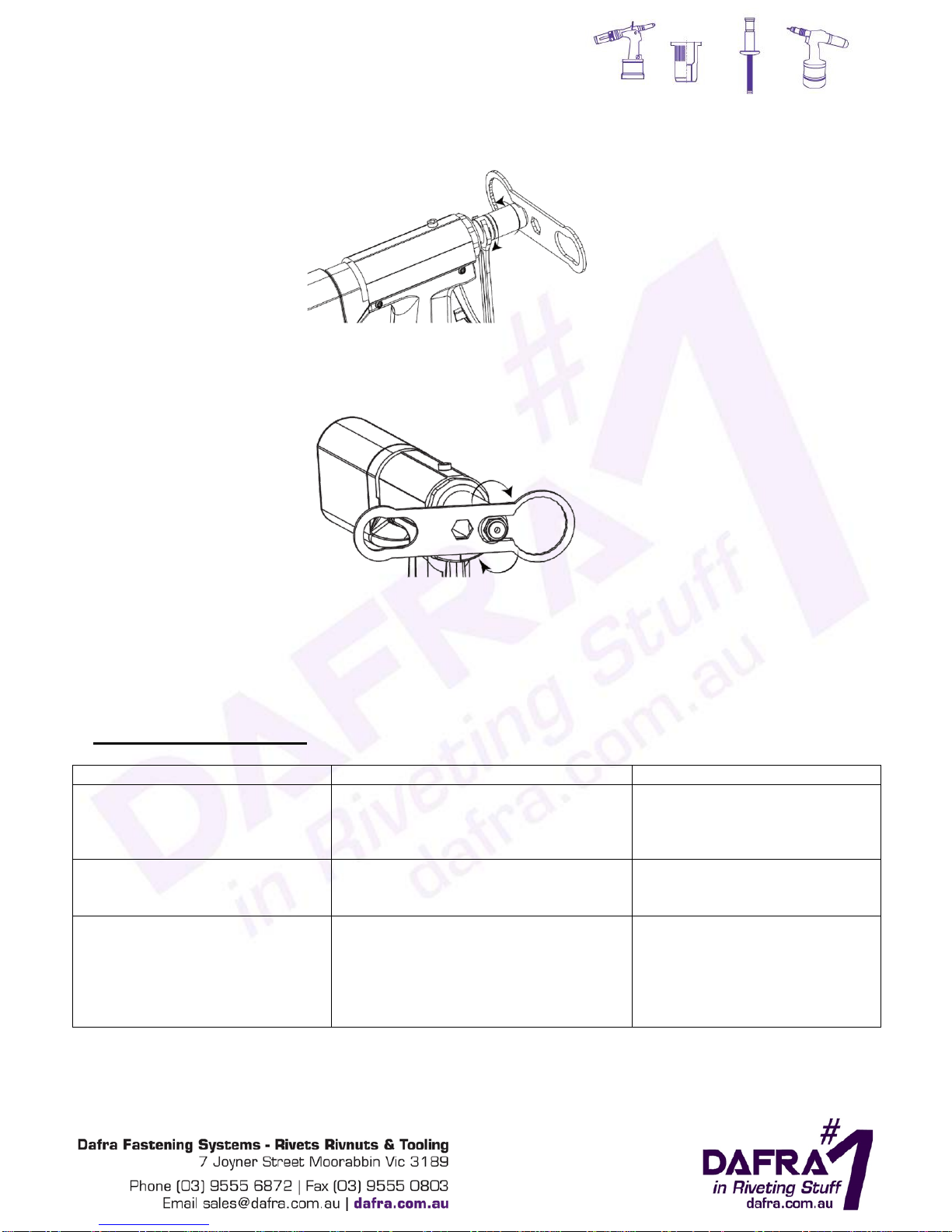

- When the tool is suspended by the operation hook during use, be sure the tool will not fall.

- When using the tool, always carry protective goggles, protective gloves, safety helmet, and

other necessary protections. It is highly recommended for safety reasons.

- Only use genuine spare parts for maintenance and repairs.

- All repair work must be carried out by skilled personnel, when in doubt, always return the

tool to the distributor.

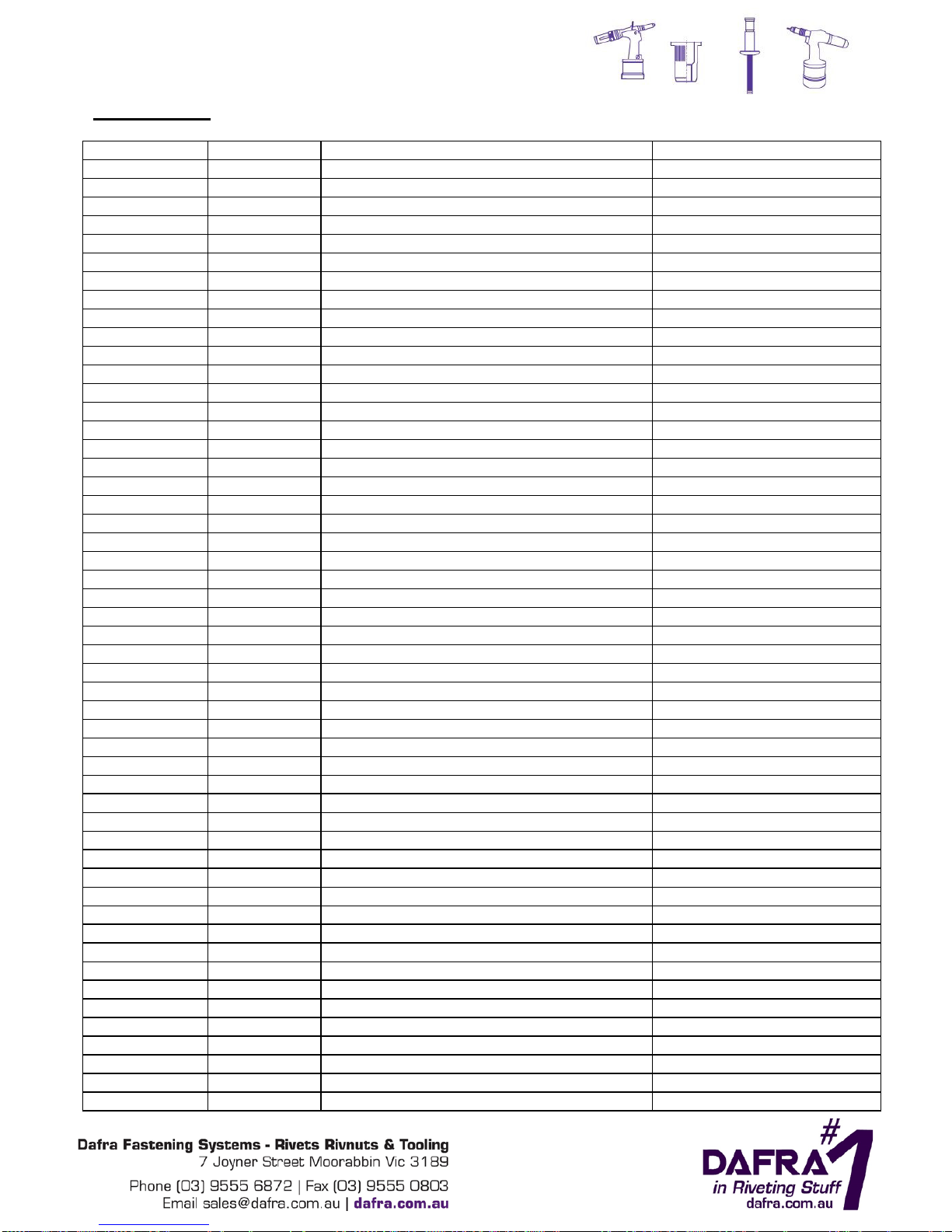

TOOL CAPACITY

Blind rivets 3.0/3.2mm ~ 4.0mm ~ 4.8/5.0mm standard – 2.4mm optional.

TOOL SPECIFICATIONS

Air supply pressure: 0.5Mpa ~ 0.7Mpa

Output traction power: 8,400N ~ 11,760 N

Stroke: 16mm

Net weight: 1.30kgs