Page 10 of 16 / IM 1171-3

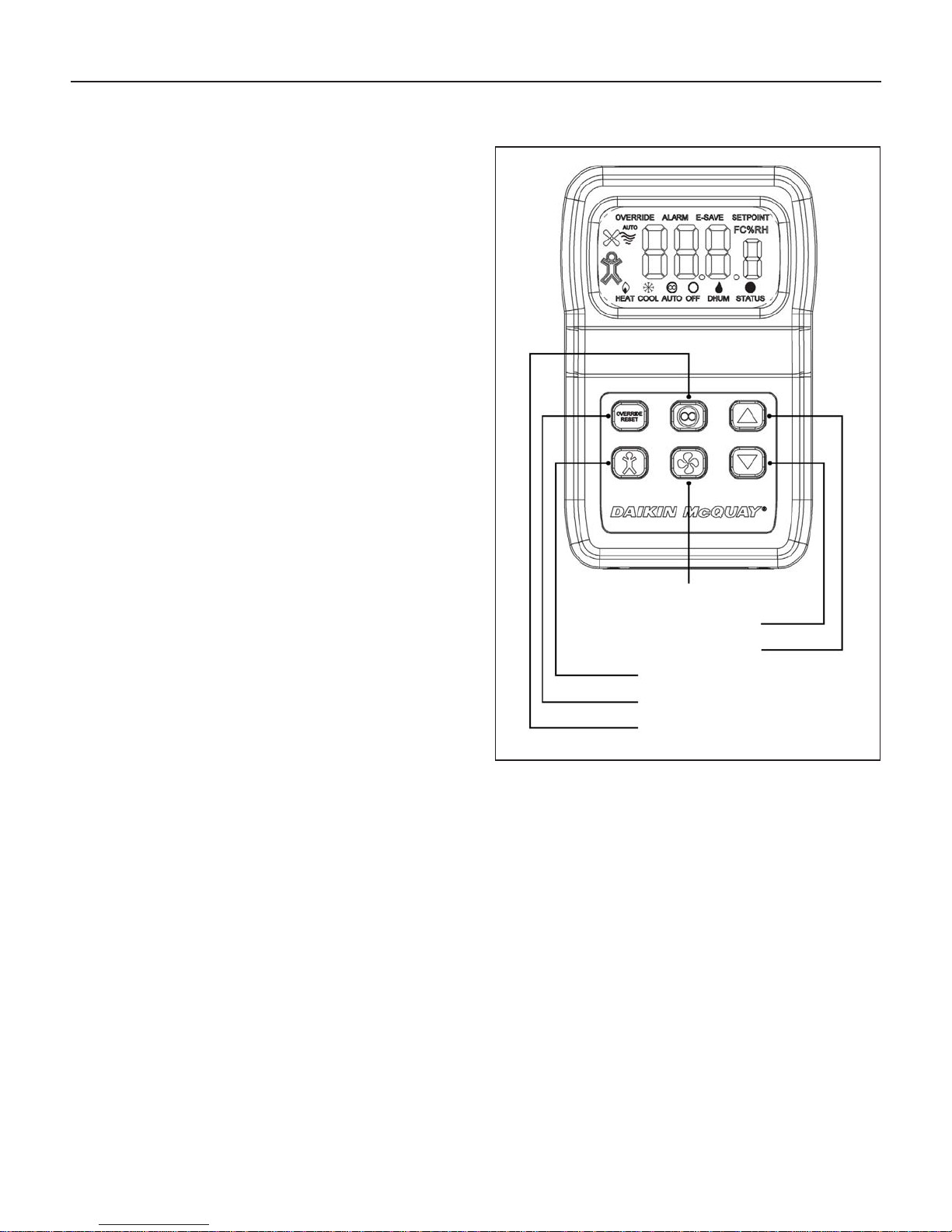

Front Panel Button Operation

System Mode Indication (FCU Only)

“Heat/Cool/Auto/Off”

The “Heat/Cool/Auto/Off” Mode Indicators on the bottom

of the display show the mode status of the sensor and are

changed by pushing the System Mode button.

• “Cool” on the display means the unit will only provide

cooling.

• “Heat” on the display means the unit will only provide

heating.

• “Auto” on the display means the unit switches

automatically to provide cooling or heating.

• “Off” on the display means the unit will not provide

cooling, heating or fan operation.

There should always be one indicator “On” unless the sensor

has no power or has a problem. The System ModeAnalog Out-

put voltage on Term. 2 will change based on the system mode.

Fan Speed Indication (FCU Only)

“Auto/High/Medium/Low”

The Fan Speed Indicators on the display show the fan speed

status (Auto/High/Medium/Low) and are changed by pushing

the Fan Mode button.

“Fan & 4 Wavy Lines & Auto” - the fan stages up

or down automatically depending on the demand

for cooling or heating.

“Fan & 4 Wavy Lines” - the fan runs continuously

at high speed regardless of the system mode setting

of Heat/Cool/Auto.

“Fan & 3 Wavy Lines” - the fan runs continuously

at medium speed regardless of the system mode

setting of Heat/Cool/Auto.

“Fan & 2 Wavy Lines” - the fan runs continuously

at low speed regardless of the system mode setting

of Heat/Cool/Auto.

“Fan & No Wavy Lines” - Indicates the fan is Off.

There should always be one indicator “On” unless the sensor

has no power or has a problem. The Fan SpeedAnalog Out-

put voltage on Terminal 6 will change based on the fan speed

selection.

System Mode Indication (WSHP Only)

“Heat/Cool/Auto/Off/Dhum”

The “Heat/Cool/Auto/Off/Dhum” Mode Indicators on the

display show the mode status of the sensor and are changed

by pushing the System Mode button.

• “Cool” on the display means unit will only provide

cooling.

• “Heat” on the display means the unit will only provide

heating.

• “Auto” on the display means the unit can switch

automatically to provide cooling or heating or

dehumidication.

• “Off” on the display means the unit will not provide

cooling, heating, dehumidication or fan operation (“E”

terminal goes Low).

• “Dhum” on the display means that only dehumidication

will operate.

There should always be one indicator “On” unless the sensor

has no power or has a problem. The System ModeAnalog

Output voltage on Terminal 2 will change based on the sys-

tem mode selection.

Fan Indication (WSHP Only)

“Auto/On”

The Fan Indicators on the left side of the display show the fan

status (Auto/On) of the sensor and are changed by pushing

the Fan Mode button.

“Fan & 4 Wavy Lines & Auto” - the fan runs on

a call for cooling, heating or Dhum. Otherwise the

fan is off.

“Fan & 4 Wavy Lines” - the fan is running

continuously regardless of the heating, cooling or

Dhum demand.

“Fan & No Wavy Lines” - the fan is Off when the

system mode is “Off”.

Override/Reset Button (Timed

Override & Alarm Reset):

When the “Override/Reset” Button is pressed, the thermis-

tor sensor is shorted. If held for more than 3 seconds but less

than 11 seconds, it puts the controller into a timed Occupied

Override (the time is set by the controller). If the unit is in

alarm, then holding the “Override/Reset” Button for more than

11 seconds will clear all alarms in the controller but only if the

cause of the alarm has already returned to its non-alarm condi-

tion. Some alarms will not reset from the digital room sensor.

In this case, power to the unit must be cycled off for 5 sec-

onds to clear the alarm. Continuously resetting alarms from

the room sensor could damage the controller. Please call a

service technician when repeated alarm resets are required to

keep the unit operational.

Occupied Button (Occupied/

Unoccupied Request):

Note: Terminal “U” opens HI to source power on power-up

“Occcupied”

When the “Occupancy” Button is pushed, the current “Oc-

cupied” or “Unoccupied” status of the sensor will be toggled

to the opposite condition for 20 seconds. Both the display and

“U” terminal output reect the new status during the 20

seconds. If a conrmation signal is received from the control-

ler into the Status Input terminal “1” within 20 seconds, then

the new occupancy condition remains; otherwise the “U” ter-

minal will return to the original state and the “Occupied” Icon

will ash the desired occupancy state every 8 seconds.