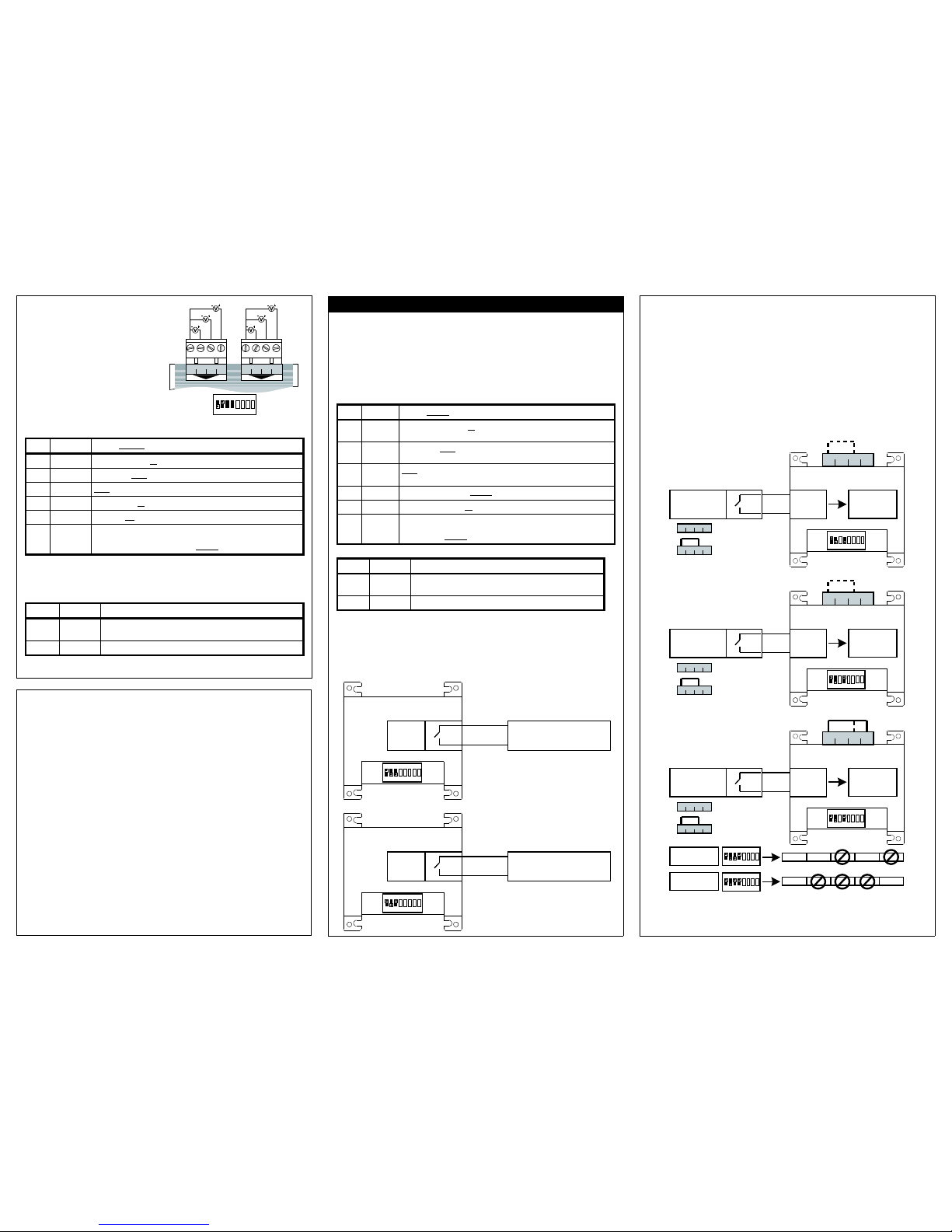

The RTD-10 can be configured to operate in a duty/standby configuration

suitable for IT and Telecoms applications. An RTD-10 master together with up

to 7 RTD-10 slaves can be configured to operate in a rotating duty/standby

configuration with the following features:

●Up to 8 duty/standby groups

●All units run on fault

●1 or 2 standby units

●Daily, Weekly or Multi-week duty rotation

●Two level alarm on high temperature and unit fault

●Thermistor space temperature alarm

●A7 (Louvre) fault code filtering

DUTY/STANDBY OP RATION

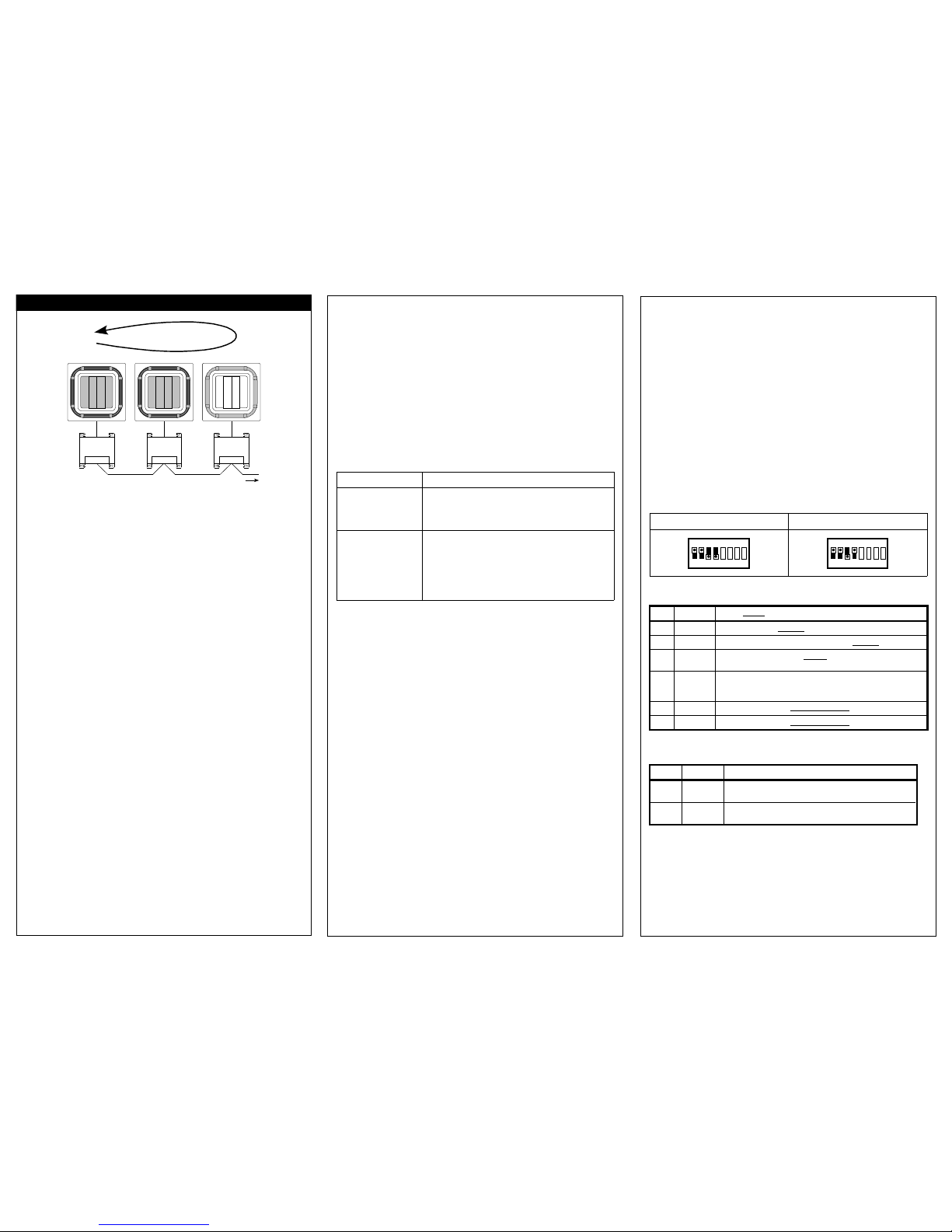

Under 'no fault' conditions the system will operate with 1 or 2 units in standby

and the remaining units operational (2 unit standby is only available if there are

at least thee RTD groups). Default rotation time is 7 days, input S3 can be

configured to select rotation times of 1 day, 2 weeks or 4 weeks if required

using specific resistor values. In addition a test-mode is available by placing a

0 ohm link on S3 which will cause the system to operate in test mode with a 60

second rotation time. The system should only be operated in test mode for

short time periods.

The RTD-10 with Address 0 (SW1.5 to SW1.8 OFF) is the Duty/Standby

master. All inputs and outputs are wired to the Master. Slave inputs should not

be wired. Slave output relays indicate the Alarm Level for that slave only.

A/C UNIT OP RATION

The unit mode is set to COOL and the mode button on the Master remote

controller is locked to prevent change. The on/off button is also locked. The

setpoint and fanspeed can be set from the RTD-10 master or the remote

controller on the master group. If S1 and S2 are wired then setpoint and

fanspeed are set by the RTD-10 inputs and the corresponding buttons on the

remote controller are locked. If S1 and S2 are not wired then the buttons on the

master remote controller are unlocked and can be used to set operating

values. In this mode the setpoint is limited to the range 20 to 32°C.

Duty/Standby Operation

ALARM OP RATION

Relay outputs R1 and R2 on the Master RTD-10 operate respectively as Level

1 and Level 2 alarm outputs. If a Level 2 alarm occurs then both R1 and R2 will

be closed. All units will run if a Level 1 or Level 2 alarm occurs.

All unit return air temperatures are monitored and alarm levels 1 and 2 are set

respectively at 2°C and 4°C above operating setpoint. The Auxiliary Space

Temperature sensor has the same alarm limits applied.

Any unit fault other than code A7 will result in a Level 2 alarm being generated.

An A7 (louvre fault) will generate a Level 1 alarm, but will not force units on.

The RTD-10 master will monitor all of the RTD slave devices discovered after

power-up. If any of the RTD slave devices fail to respond the RTD-10 will raise

a Level 2 alarm after 1 to 2 minutes.

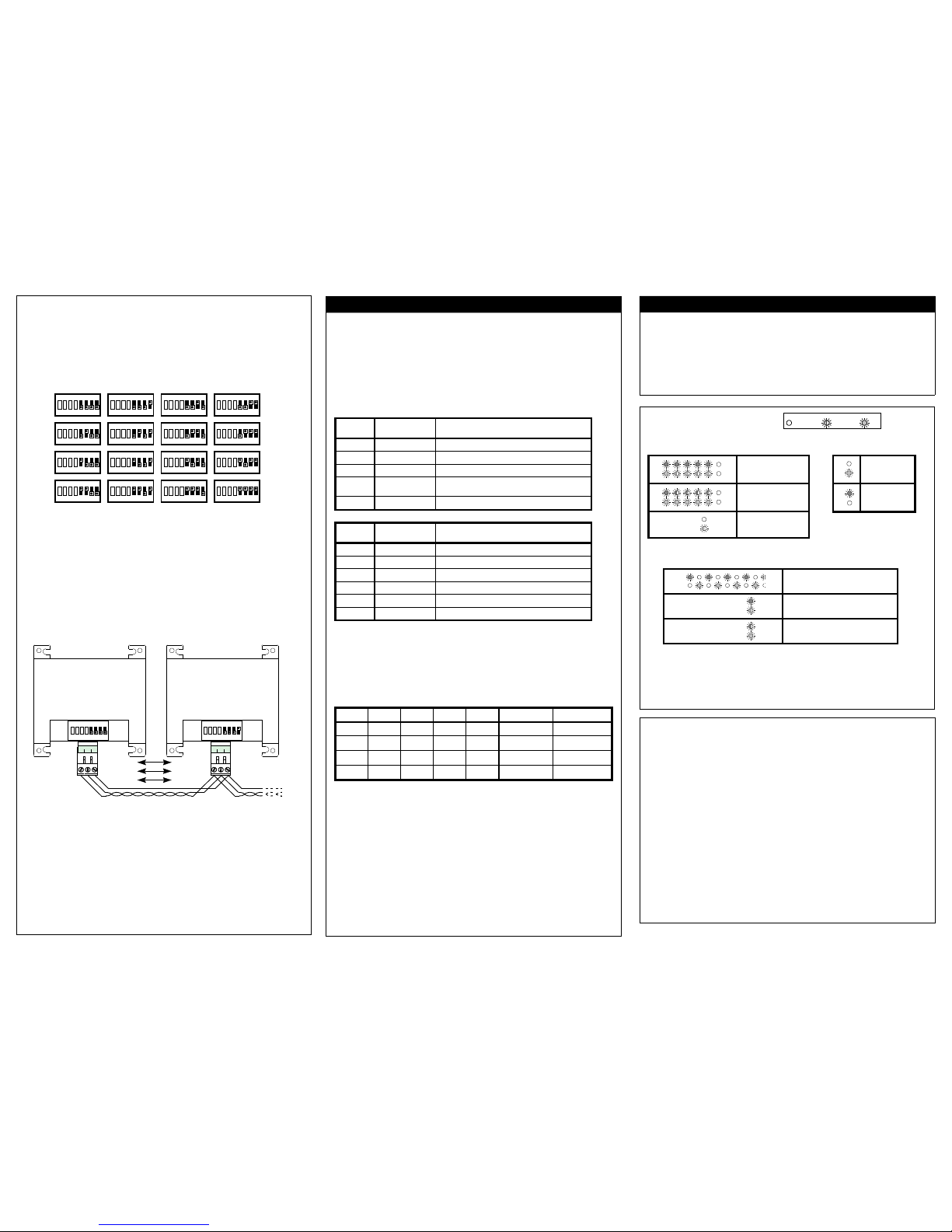

Alarm Reasons

Alarm Level 1

Output R1

Unit Return Air > Setpoint + 2°C

Aux. Space Temperature > Setpoint + 2°C

A/C Unit Louvre Fault (A7)

Alarm Level 2 xists

Alarm Level 2

Output R2

Unit Return Air > Setpoint + 4°C

Aux. Space Temperature > Setpoint + 4°C

A/C Unit Fault (except A7)

A/C Unit Missing (U5 Fault)

RTD-10 Slave Missing (master RTD-10)

RTD-10 No slaves found (master RTD-10)

RTD-10 Master not found (slave RTD-10)

If a Level 1 or Level 2 alarm occurs due to a unit or communications fault then

all units will run until all faults are cleared.

If a Level 1 or Level 2 alarm occurs due to a high temperature on an indoor unit

or the Auxiliary Space sensor then all units will run until temperature has reset

and will continue to run on for 20 minutes before reverting to normal

Run/Standby operation. In Test Mode (rotation = 60s) the run on time will be 40

seconds..

If a Level 2 alarm occurs due to an Indoor Unit Fault then all units will run until

the Indoor Unit Fault has cleared and will continue to run on for 10 minutes

before reverting to normal Run/Standby operation. In Test Mode (rotation =

60s) the run on time will be 20 seconds.

OV RRID ALL ON/OFF

Input S5 is a volt-free contact input that overrides all units ON if closed circuit.

Input S6 is a volt-free contact input which overrides all units OFF if closed

circuit.

AUXILLIARY SPAC S NSOR

An auxiliary space sensor is required to provide alarm monitoring in the

controlled space.

The sensor should be a 10kΏ NTC Thermistor mounted on a suitable vertical

surface in the monitored space. The sensor should be wired to the RTD-10

using a twisted pair cable no longer than 100 metres. The Auxiliary sensor will

raise alarms even if the units are overridden off.

Duty/Standby Operation

INSTALLATION

All RTD interfaces must be networked together using the 3 wire RS485

network, each RTD must then have a network address set in the range 0 to 7

(see section RTD Networking). The RTD-10 Duty/Standby Master must have

an address of 0. The remaining RTD slaves should have addresses in the

range 1 to 7. If there are less than 7 slaves then start the addressing at 1 and

allocate each slave consecutively upwards.

The Master and Slave RTD-10s will both initially indicate a Level 2 alarm. The

master alarm will clear when it discovers at least one slave RTD-10. The slave

alarm will clear when the master discovers the slave. If communications fails

with a slave RTD-10 the master will generate a Level 2 alarm after 120s.

CONFIGURATION

The Run/Standby configuration is selected using the RTD-10 DIP switch

settings. Both master and slave devices must have the DIP switches set. The

position of SW1.4 on the master determines whether the system operates with

1 unit or 2 unit standby. The possible switch configurations are as follows:

1 Unit Standby 2 Unit Standby

INPUT CONFIGURATION

Input Name Range (default)

S1 Setpoint 0..10kΏ : 16..32°C (from RC)

S2 Fanspeed Low=1.1kΏ, High=2.2kΏ, HighHigh*=3.3kΏ (from RC)

S3 Rotation 60s<=1.1kΏ, 1 Day=2.2kΏ, 1 Week=3.3kΏ, 2 Weeks=4.7kΏ,

4 Weeks=6.8kΏ

S4 Auxiliary

Space

Temp

10kΏ NTC Thermistor

Recommended part: RS Stock No. 813-806

S5 All On All On = Closed Circuit, Normal Operation = Open Circuit

S6 All Off All Off = Closed Circuit, Normal Operation = Open Circuit

*HighHigh fanspeed operates if available, otherwise selects High fanspeed

R LAY CONFIGURATION

Output Name Operation

R1 Alarm

Level 1

Closed when Alarm Level 1 or 2 occurs

R2 Alarm

Level 2

Closed when Alarm Level 2 occurs

Caution: Relays rated for maximum 1A, 24VAC/30VDC

MODBUS OP RATION

When operating in Duty/Standby mode the RTD devices CANNOT be

connected to an external Modbus Master as this will disrupt operation.

Duty/Standby Operation