Table of contents

Installer and user reference guide

2

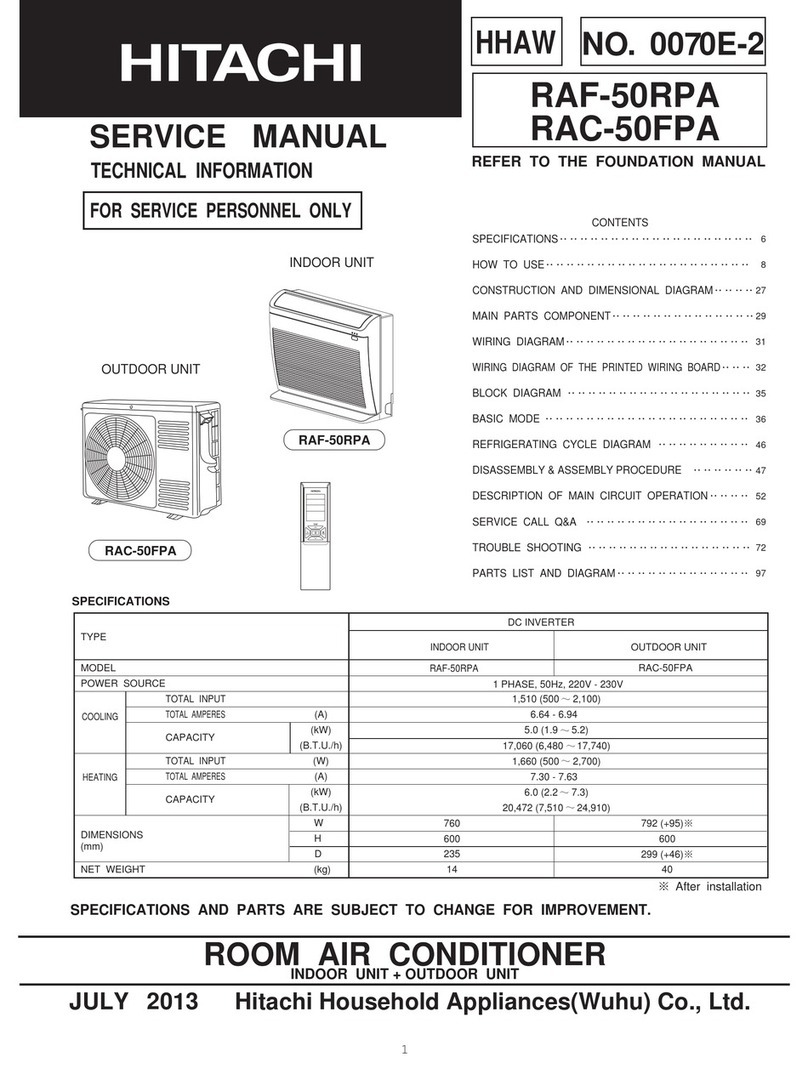

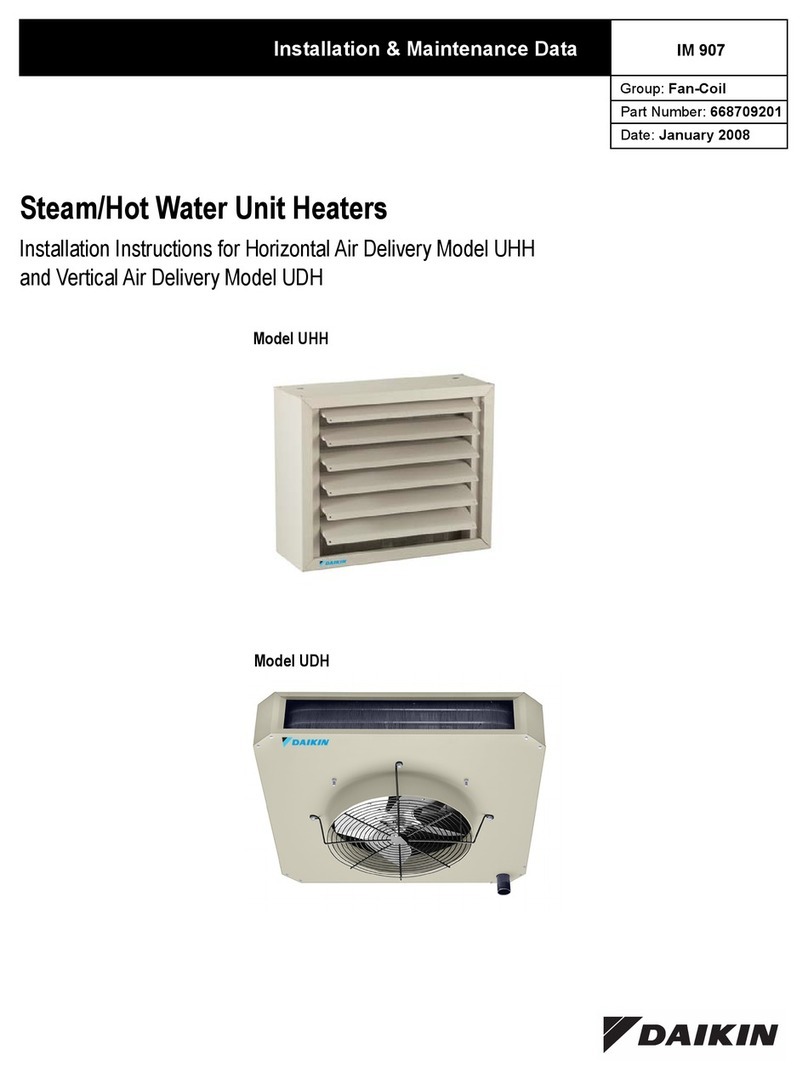

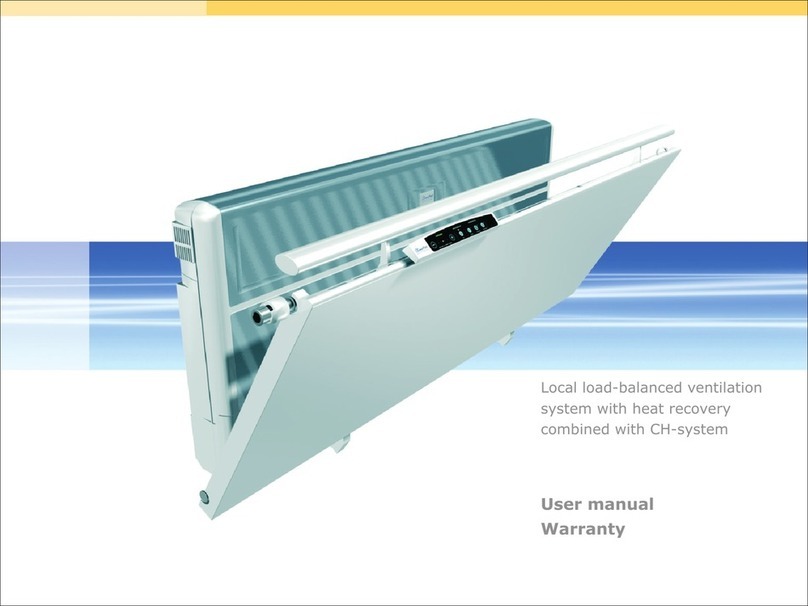

VAM350~2000J7VEB

Heat reclaim ventilation unit

4P487293-1 – 2017.08

Table of contents

1 General safety precautions 3

1.1 About the documentation .......................................................... 3

1.1.1 Meaning of warnings and symbols.............................. 3

1.2 For the user ............................................................................... 3

1.3 For the installer.......................................................................... 3

1.3.1 General ....................................................................... 3

1.3.2 Installation site ............................................................ 4

1.3.3 Refrigerant .................................................................. 4

1.3.4 Brine............................................................................ 5

1.3.5 Water .......................................................................... 5

1.3.6 Electrical ..................................................................... 5

2 About the documentation 6

2.1 About this document.................................................................. 6

For the installer 6

3 About the box 6

3.1 Overview: About the box ........................................................... 6

3.2 Heat reclaim ventilation unit ...................................................... 7

3.2.1 To unpack the heat reclaim ventilation unit................. 7

3.2.2 To remove the accessories......................................... 8

3.2.3 To handle the heat reclaim ventilation unit ................. 8

4 About the units and options 9

4.1 Overview: About the units and options...................................... 9

4.2 Identification .............................................................................. 9

4.2.1 Identification label: Heat reclaim ventilation unit......... 9

4.3 About the heat reclaim ventilation unit ...................................... 9

4.4 Combining units and options ..................................................... 9

4.4.1 Possible options for the heat reclaim ventilation unit.. 9

5 Preparation 10

5.1 Overview: Preparation............................................................... 10

5.2 Preparing the installation site .................................................... 10

5.2.1 Installation site requirements for the heat reclaim

ventilation unit ............................................................. 10

5.3 Preparing the unit ...................................................................... 10

5.3.1 To install the optional adapter printed circuit board .... 10

5.3.2 To install the duct joints .............................................. 11

5.4 Preparing the electrical wiring ................................................... 11

5.4.1 Wiring connection ....................................................... 11

5.4.2 Component electrical specifications............................ 12

5.4.3 Specifications for field supplied fuses and wires......... 12

5.5 Preparing the installation of the ducts ....................................... 13

6 Installation 13

6.1 Service space: Heat reclaim ventilation unit.............................. 13

6.2 Unit orientation .......................................................................... 13

6.3 To install the anchor bolts ......................................................... 14

6.4 Duct connections....................................................................... 14

6.5 Electrical wiring ......................................................................... 15

6.5.1 Precautions when connecting electrical wiring ........... 15

6.5.2 Opening the switch box............................................... 16

6.5.3 Electrical connections for possible additional field

supplied damper ......................................................... 19

6.5.4 Power supply connection, control wire terminals and

switches on the circuit board....................................... 19

6.5.5 Guidelines when connecting the electrical wiring ....... 19

7 System configuration 20

7.1 About control systems ............................................................... 20

7.2 Independent system .................................................................. 21

7.3 Interlocked system .................................................................... 21

7.4 Centralised control system ........................................................ 22

8 Configuration 22

8.1 Operating procedure .................................................................. 22

8.1.1 To change the settings with BRC1E53 ........................ 22

8.1.2 To change the settings with BRC301B61 .................... 23

8.2 List of settings ............................................................................ 24

8.3 Settings for all configurations ..................................................... 28

8.3.1 About setting 19(29)-0-04 and 19(29)-0-05 ................. 28

8.3.2 Independent system..................................................... 29

8.3.3 1-group linked-control system...................................... 29

8.3.4 Linked control with more than 2 groups ....................... 29

8.3.5 Direct duct connection ................................................. 30

8.3.6 Centralised control system........................................... 30

8.4 About the user interface ............................................................. 32

8.4.1 User interface for VRV-system air conditioner............. 32

8.4.2 User interface for heat reclaim ventilation units ........... 33

8.5 Detailed explanation of settings ................................................. 34

8.5.1 To monitor the unit's operation..................................... 34

8.5.2 About the fresh-up operation ....................................... 34

8.5.3 About the external damper operation........................... 35

8.5.4 About the carbon dioxide sensor ................................. 35

8.5.5 About the nighttime free cooling operation .................. 37

8.5.6 About the pre-cool and pre-heat function..................... 37

8.5.7 About preventing a feeling of draft............................... 37

8.5.8 About 24-hour ventilation ............................................. 37

8.5.9 About the ultra-low setting ........................................... 37

8.5.10 About the electrical heater operation ........................... 38

8.5.11 About external linkage input......................................... 38

8.5.12 About filter contamination check .................................. 38

9 Commissioning 38

9.1 Overview: Commissioning.......................................................... 38

9.2 Precautions when commissioning .............................................. 38

9.3 Checklist before commissioning................................................. 38

9.4 Checklist during commissioning ................................................. 38

9.4.1 About the test run......................................................... 38

10 Hand-over to the user 39

11 Maintenance and service 39

11.1 Overview: Maintenance and service .......................................... 39

11.2 Maintenance safety precautions................................................. 39

11.2.1 To prevent electrical hazards....................................... 39

11.3 Checklist for maintenance of the heat reclaim ventilation unit ... 39

12 Troubleshooting 39

12.1 Overview: Troubleshooting......................................................... 39

12.2 Precautions when troubleshooting ............................................. 40

12.3 Solving problems based on error codes ..................................... 40

12.3.1 Error codes: Overview ................................................. 40

13 Disposal 40

14 Technical data 40

14.1 Wiring diagram: Heat reclaim ventilation unit ............................. 40

For the user 41

15 User interface 41

16 Before operation 41

17 Energy saving and optimum operation 41

18 Maintenance and service 42

18.1 Maintenance of the air filter ........................................................ 42

18.2 Maintenance of the heat exchange element .............................. 43

19 Troubleshooting 43

20 Relocation 43

21 Disposal 43