– i –

Table of Contents

1 Introduction.........................................1

How to Use This Manual ............................1

Theory of Operation ..................................1

Vanguard® Software ...............................1

VFC-3000 Controller/Vanguard® Field

Controller.................................................1

Auxiliary Control Panel ..............................2

2 Components .......................................3

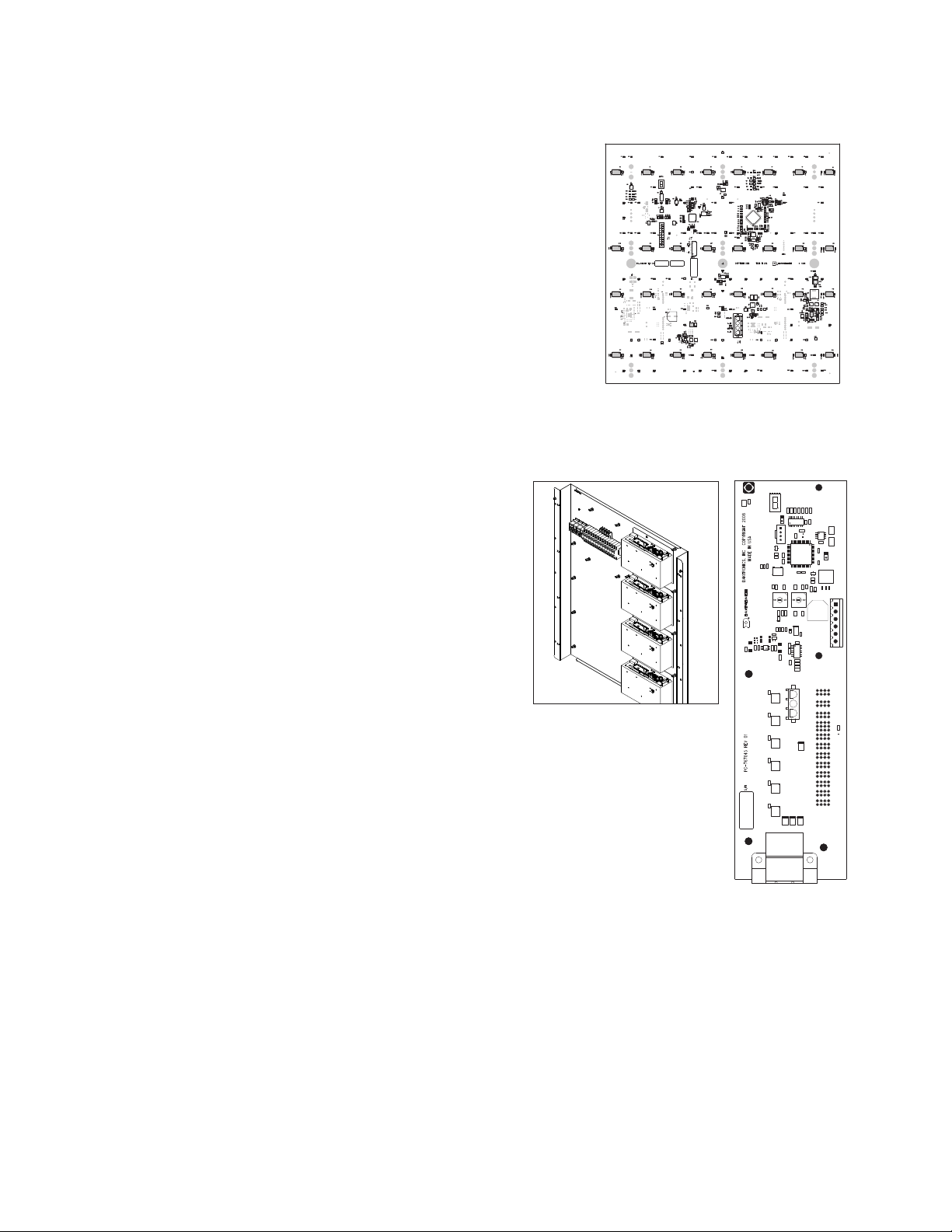

Modules ......................................................3

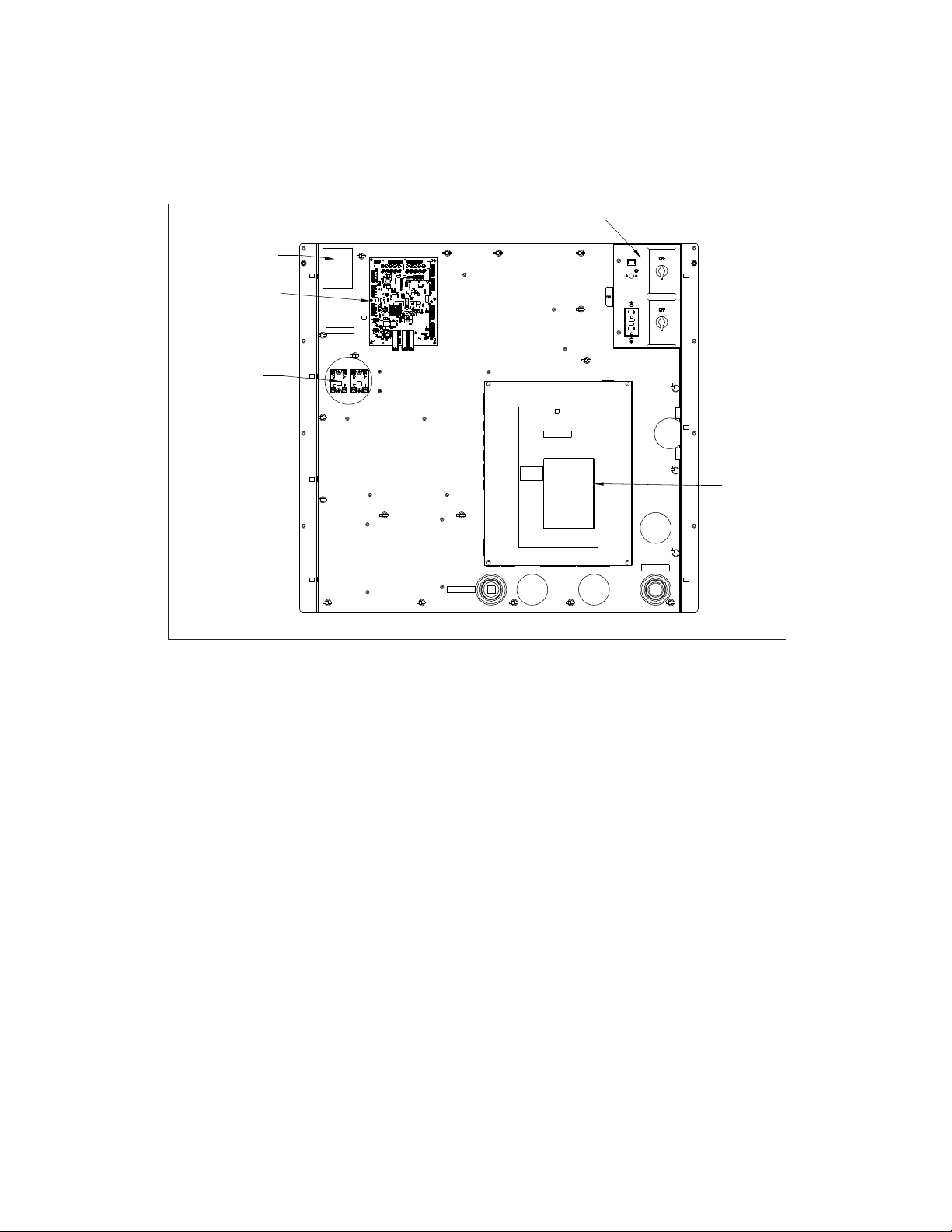

Power Supply Assembly ............................3

Power Supply Mounting Panel ..............3

Power Supplies........................................3

Isolation Board........................................3

Service Control Panel................................4

Vanguard® Control Board ......................4

Panelboard .............................................4

Surge Suppressor ....................................4

Relays ......................................................4

DC Breaker Rail ..........................................5

Display UPS System ....................................5

Sensors Network.........................................5

Rear Sensor .............................................5

Internal Sensor ........................................5

Bottom Sensor .........................................5

Door Detection........................................5

Ventilation and Heater Systems...............5

Ventilation Fans and Filters....................5

Defog Heater Fans..................................5

Fan RPM Sensors .....................................5

Lights ...........................................................6

Beacon(s) ...................................................6

UPS...............................................................6

3 Electrical Installation ..........................7

Power Installation.......................................7

Grounding ...............................................7

Power.......................................................7

Bonding Screw........................................7

Power Connections...................................7

Display Termination................................8

Conduit Sealing ......................................8

Module Connection ...............................8

Fans and Power Supplies Connection....

..................................................................8

Trafc Cabinet ...........................................8

Vanguard® Control Board Address

Setting......................................................9

4 Maintenance and Troubleshooting 10

Getting Started ........................................10

Service and Diagnostics .........................10

Module Numbering System ....................10

7-Segment Error Codes (VFC-3000

Controller).................................................11

Modules.................................................11

VCB ........................................................11

Isolation Board......................................11

7-Segment Error Codes (Vanguard®Field

Controller).................................................12

VCB ........................................................12

Modules.................................................13

Isolation Board......................................13

VFC-3000 Controller/Vanguard® Field

Controller Replacement.............................

...................................................................13

Module Replacement (20mm) ..............14

Environmental Sensors.............................14

Airow Sensor........................................14

Light/Temperature/Humidity Sensor...14

Power Supply Assembly Replacement .15

Vanguard® Control Board (VCB) ...........15

Ventilation Fan and Filter Maintenance ...

...................................................................15

Filter Replacement ...............................15

Fan Replacement.................................16

Trafc Cabinet Maintenance.................16

Trafc Cabinet Fan and Thermostat

Assembly Replacement ......................16

Trafc Cabinet Light Replacement .....16

Display Maintenance..............................16

Structure ................................................16

Earth Ground Resistance .....................16

Display Cabinet ....................................17

Temperature and Light Sensors...........17

Ventilation Fans ....................................17

Filters ......................................................17