Purchase of spare parts

Please state the serial number of your product when ordering spare parts.

The serial number identification of your product can be found on the serial

number plate recessed in the rear wall of the loudspeaker system.

The illustration of the serial number plate is shown on the left. The S/N

designation is followed by the serial number of the speaker system.

echnical Specifications

Acoustical Bandwidth with DAL DS-4L: 38Hz –100Hz

Dispersion BR218: 4π

Nominal Impedance (Re): 4Ohm

System Power: 3000W (A S), 6000W Peak

Continuous SPL: >130*dB/3000W/1m, Pink Noise Crest Factor 6dB

Peak SPL: > 136dB*/6000W/1m, Music Signal, with GA DS-4L

* 4π measurements, ground stacked measured SPL Levels are +6dB higher

Dimensions (W x H x D mm): 600 x 1200 x 600; 600 x 1200 x 732 (w. wheels),

Net Weight: 86kg (no wheels)

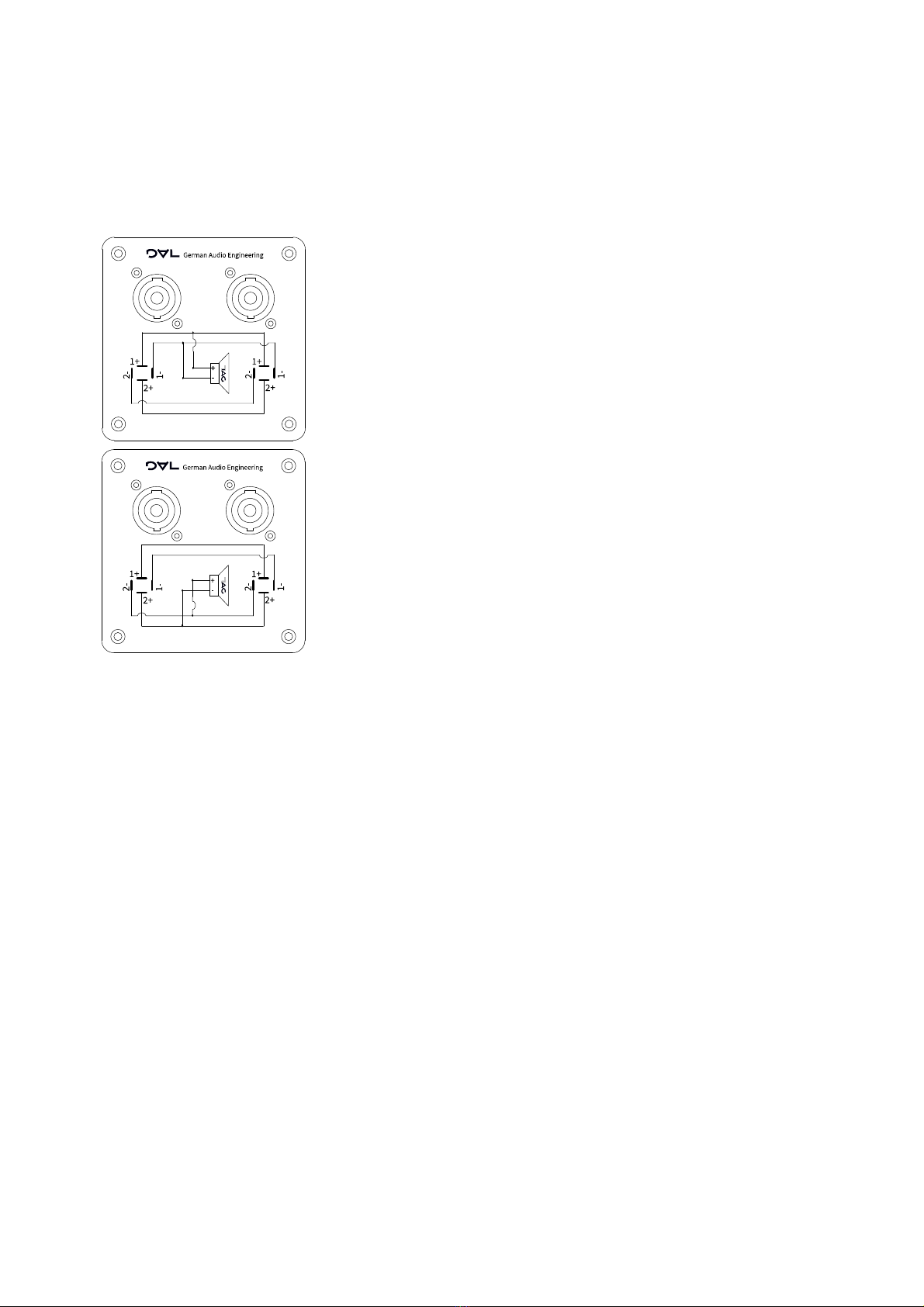

Connectivity: 2 x Speakon™ NL4 1+/1-

Standard Coating: textured black varnish, optional PU coating

Recommended Control & Drive System: DAL DS-4L

For operation recall one of the following control setups for DAL DS-4L

BR218SM: Sub Mode – stand alone operation, spaced arrays

BR218SCM: Simple cardiod mode (2 Front, 1 Back)

Operation of BR218 and DAL Control & Drive Systems

DS-4L: 1 systems per channel

echnical Notes

DAL protective grilles with foam lamination are the mechanical protection

component for the built-in transducers and offer a high acoustic transmission

as well as their affixing minimizes sonic influences of the grilles. The backing

or covering of the grilles with foam serves also as UV-light protection, dust

protection and improves the optical unobtrusive of the systems. Only

undamaged grilles and foams can fulfill these tasks. Replace warped grilles or

worn-off foams to maintain their function.

DAL loudspeaker systems with Polyurea-Coated or painted enclosures are

basically suitable for temporary outdoor operation, even in the rain.

For indefinite operation outdoors as in fixed installations, the loudspeaker

systems must be protected with a hood against direct sunlight and rain. If

necessary, the loudspeaker should be equipped with the optional front grille

with weather protection.

Most DAL loudspeaker systems can be supplied for extra charge from the

factory in a weatherproof (WR) or sea-weatherproof (SWR) variant.

For indefinite operation outdoors in subtropical and tropical areas, the

© German Audio ngineering GmbH*An der Strusbek 1*22926 Ahrensburg – User Manual DAL BR218 v1.0