Start-up:

V

V

Operation:

Maintenance:

4

No adjustments or similar action is necessary before starting to use the

Compact. The roller is drawn by the pickup-hitch of the tractor; which should

be about 40 cmabove the ground.

Remember to secure the draw bolt with a split pin or similar device.

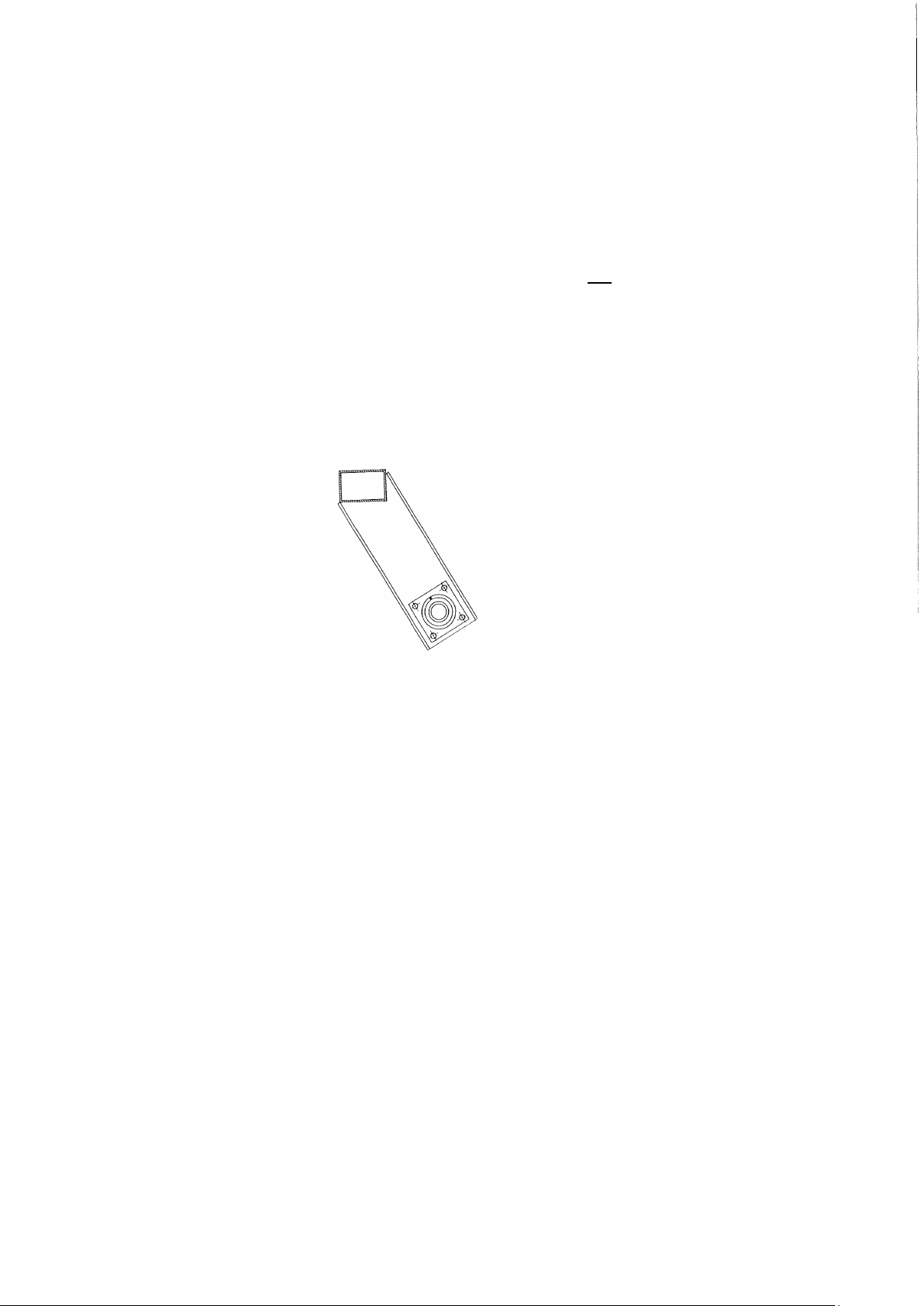

Connect the hydraulic hose (marked white) to a single-acting valve. Connect the

othertwo hoses (marked red) to a double-acting valve.

All the hoses arefitted with 1/2"connectors. If the tractor is not equipped for these,

your dealer can help. A maximumpump pressure of 160bar isrequired.

Defective hoses must be repaired or replaced immediately.A broken hose can in bad

casescause personal injury or mechanical damage to the roller.

All operation must take place fromthe driver's seat andthere must be no-oneelse

in the vicinity of the machine.The changefrom transport to operational mode, and

vice versa, must be made while stationary on more or less levelground,with the

tractor almost idling. Tounfold, operate first the single- acting valve,sothat the

sidesections arelifted clear oftheir transport bearings;usethe double-acting

valvetounfold the side sections completely. Then lower the pressure from the

single-actingvalve, sothat the roller tilts down to the ground. It isadvantageous to

to allow the valves to float freelyduring rolling, if possible.

Toraise the roller, apply the pressure first with the double-acting valve, sothat the

long cylinder acrossthe roller is completely compressed. Then lift the roller

completely vertical with the single-acting valve. Fold the side sections in by means

of the double-acting valve. Lastly,lower them intotheir transport bearings using the

single-acting valve.

Theroller must be raised only for transport. It is not necessary to raise it when

tuming. It can also run backwards in the operating.position.

Recommended speed of travel: 4-5 mph.Moveslowly over stony ground. Tighten all

the screws, and alsobuh nuts, after the first working day.

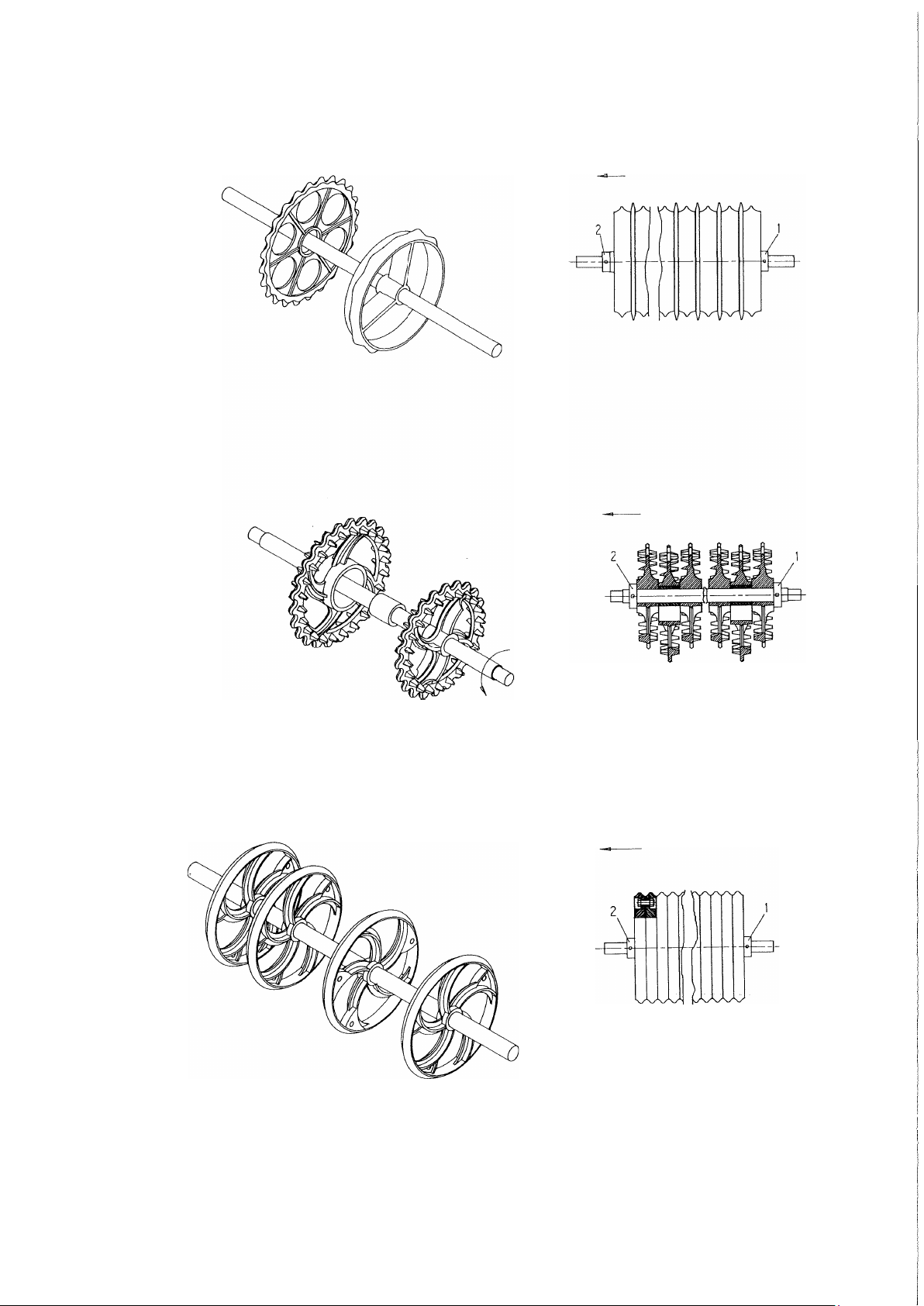

Chassis - 3 lubrication points - lubricate daily.

Roller bearings - 6 units - lubricate every 50operatinghours. Lubricate the

wheel bearings onceper season.

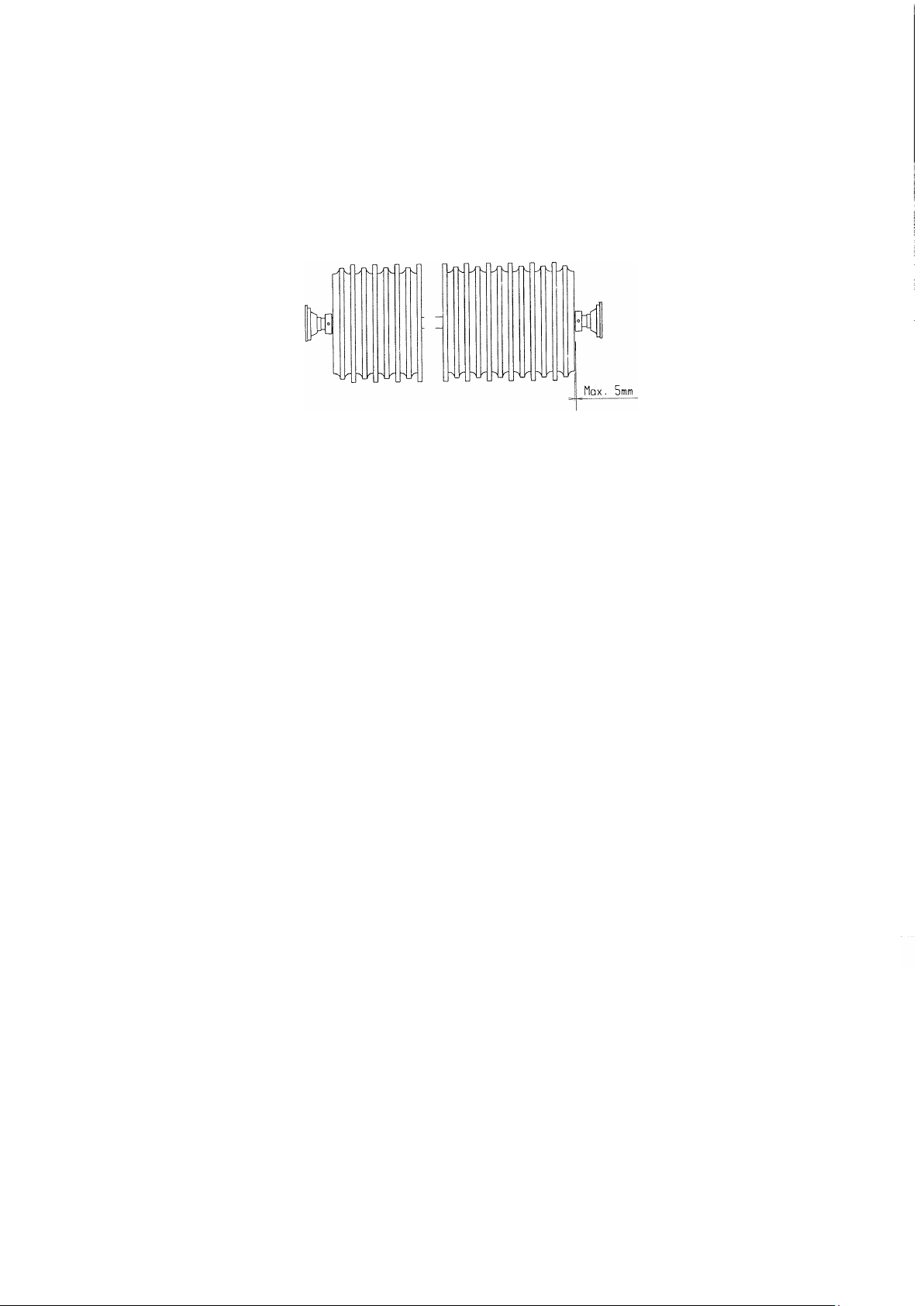

Adjust the wheel bearings once a year,followingthe instructions for replace-ment

of bearings, points 1,2,11,12and 13.