1.0 INTRODUCTION

Throughout this manual there are a number of HAZ-

ARD WARNINGS that must be read and adhered to in

order to prevent possible personal injury and/or dam-

age to equipment. Three signal words “DANGER”,

“WARNING” and “CAUTION” are used to indicate the

severity of a hazard, and are preceded by the safety

alert symbol

Denotes the most serious hazard, and is used

when serious injury or death WILL result from

misuse or failure to follow specific instruc-

tions.

Used when serious injury or death MAY result

from misuse or failure to follow specific

instructions.

Used when injury or product/equipment dam-

age may result from misuse or failure to fol-

low specific instructions.

It is the responsibility and duty of all personnel

involved in the installation, operation and maintenance

of the equipment on which this device is used to fully

understand the:

procedures by which hazards can be avoided.

1.1 Description

1.1.1 The Dalin air-actuated VC clutch is specifically

designed and manufactured for severe service

encountered in grinding mill operations, where high

starting loads and sustained slippage would normally

lower clutch efficiency and reduce operating life. Con-

stricting action and ventilated construction make high

torque capacity and rapid heat dissipation possible.

1.1.2 All Dalin VC elements are supplied with long wear-

ing, NON-ASBESTOS friction material.

1.1.3 Dalin element assemblies are available for drum

diameters from 11.5 inches through 76 inches.The

element size designation indicates the nominal drum

diameter in inches, the clutch model and the width of

the friction material. For example, size “38VC1200”

indicates the element operates on a drum having a

nominal diameter of 38 inches, is an Dalin ‘VC’

series clutch and has friction material which is 12

inches wide.

1.1.4 Where diameter space is limited, or the torque

required is greater than a single element can transmit,

all sizes of Dalin VC elements can be supplied as

dual units.

1.2 How It Works

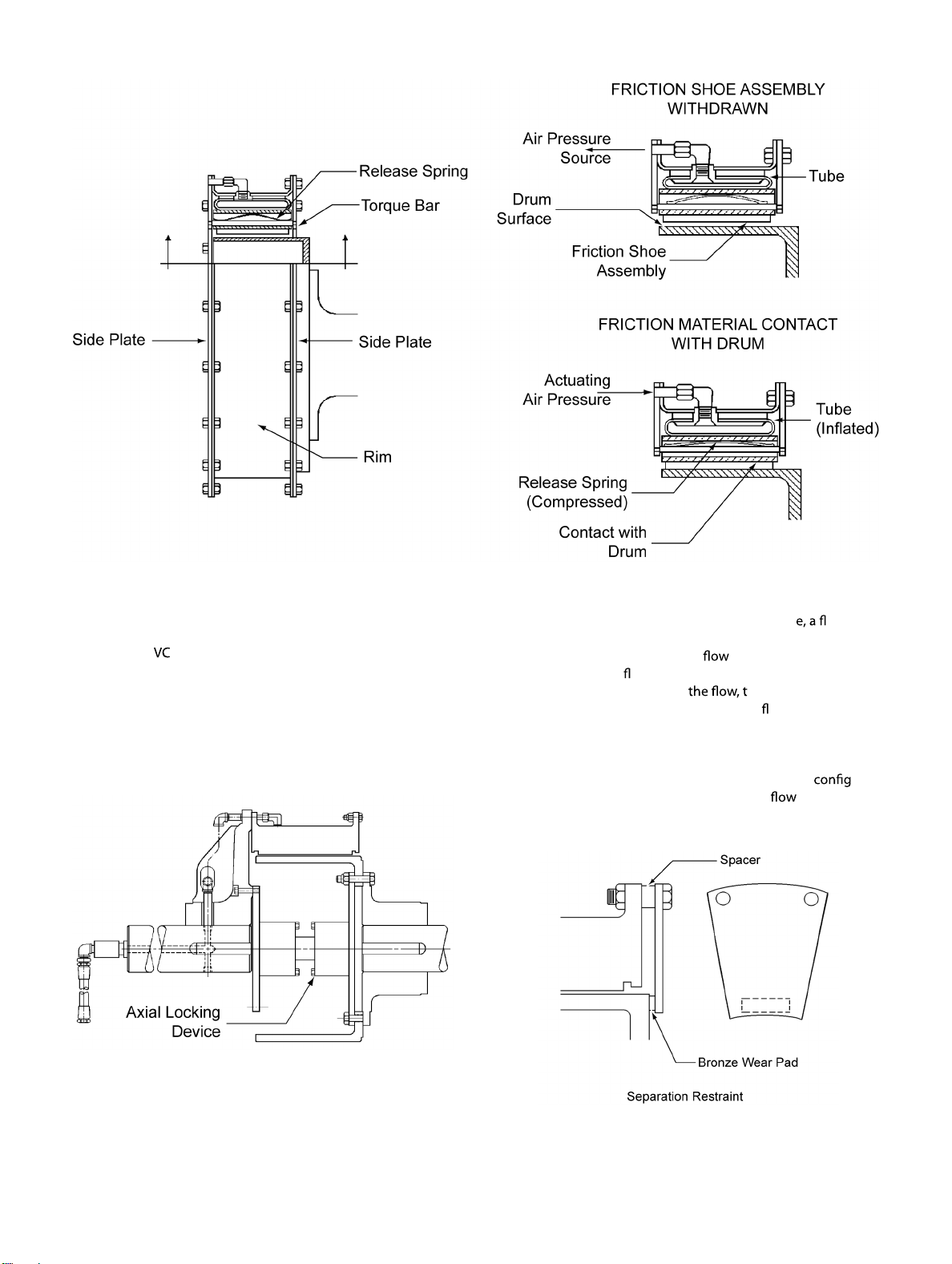

1.2.1 Referring to Figures 1 and 2, the neoprene and cord

actuating tube is contained within a steel rim which is

drilled for mounting to the driving component. As air

pressure is applied to the air actuating tube, the tube

inflates, forcing the friction shoe assemblies uniformly

against the drum, which is attached to the driven com-

ponent. The friction shoe assemblies, which consist of

friction blocks attached to aluminum backing plates,

are guided by torque bars which are secured to side

plates. The torque flow is from the driving shaft,

through the element mounting component (typically

an iron spider), through the rim/side plate structure,

through the torque bars to the backing plates and fric-

tion material, where the torque is transmitted through

the friction couple to the components mounted on the

driven shaft (clutch drum and drum mounting compo-

nent). As actuating air is exhausted, release springs

and centrifugal force assure positive disengagement.

1.2.1.1 In some cases, the spider and element assembly may

be mounted to the driven shaft rather than the driving

shaft. This “reverse-mounted” arrangement is typically

used when retrofitting a mill drive and it is more practi-

cal to drill the pinion shaft for the air supply rather than

the motor shaft In these cases, the operation and

torque flow description is opposite to what is stated

above.

1.2.2 For applications where the clutch is mounted on a

motor shaft having plain bearings, an axial locking

device is used to hold the motor on magnetic center

during operation. Refer to the INSTALLATION

section for axial locking device adjustment.

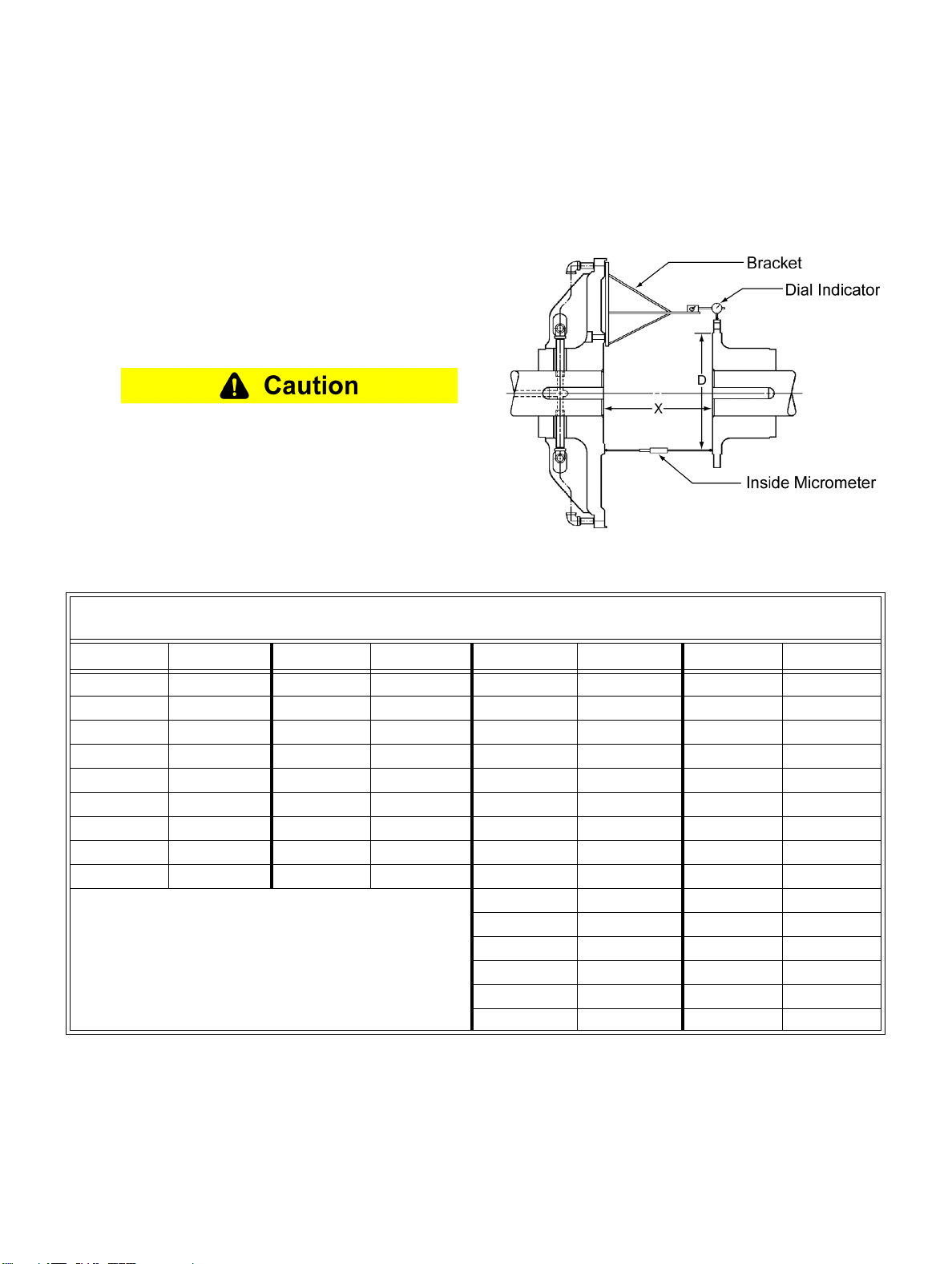

1.2.2.1 Figure 3A illustrates another type of axial locking

device called a separation restraint. This device is

attached to the clutch rim as shown, with a bronze

wear pad which rides against the clutch drum to

restrict axial movement.

Note : There is no relative motion between the drum

and wear pad when the clutch is fully engaged.