Installation Guide

TG-0057_19 TM4 SUMO HD CO300-A1_A2_A2.5 Installation Guide

© Dana TM4 inc., 2013-2020

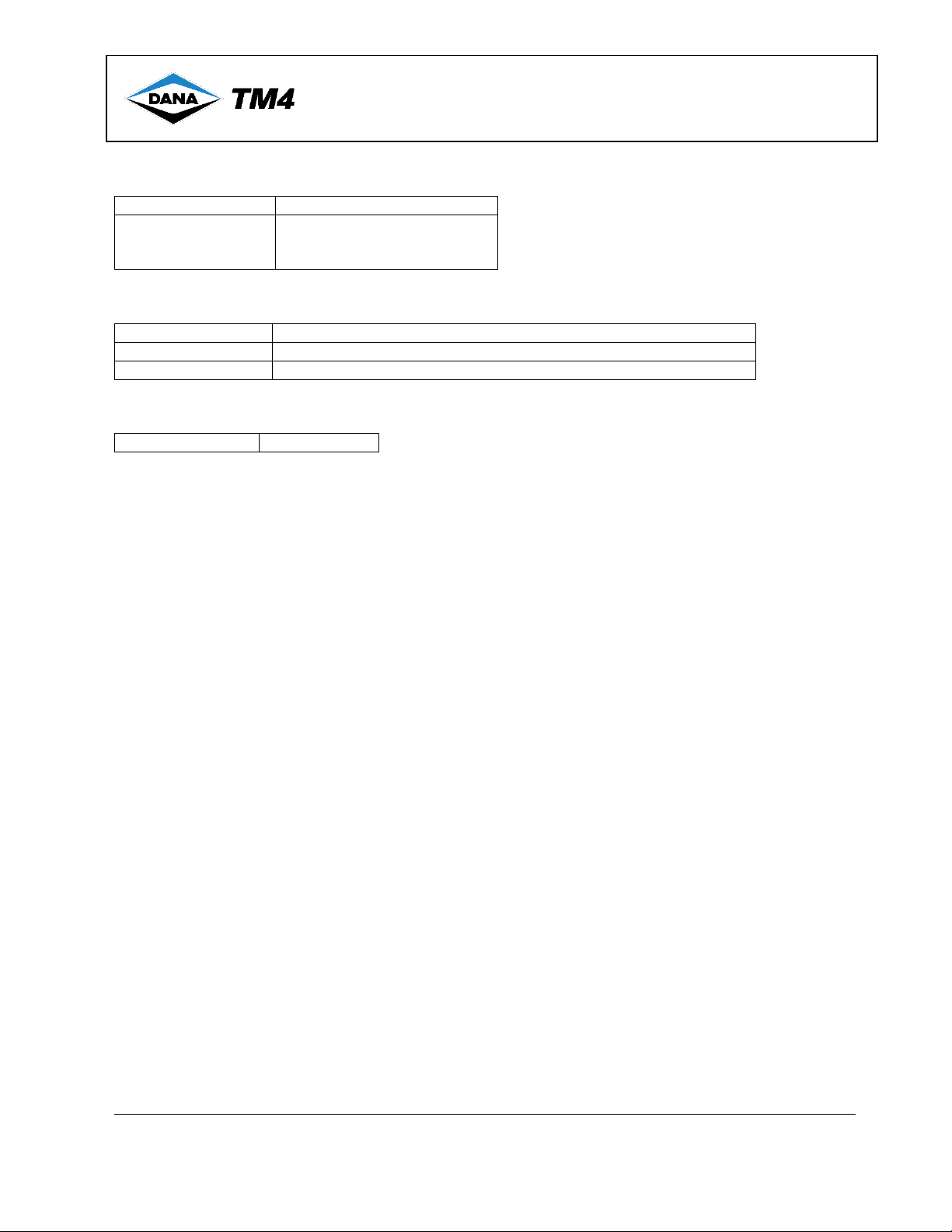

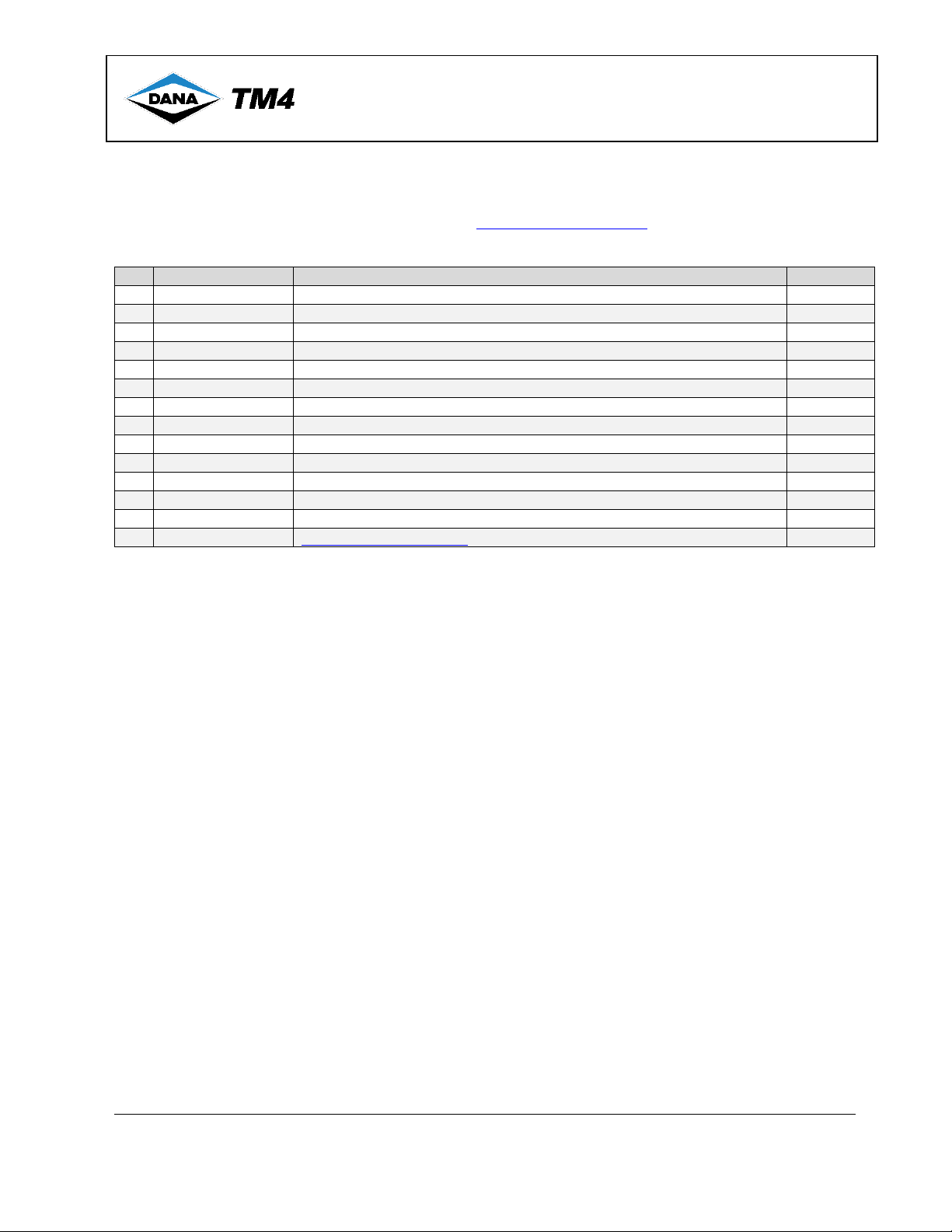

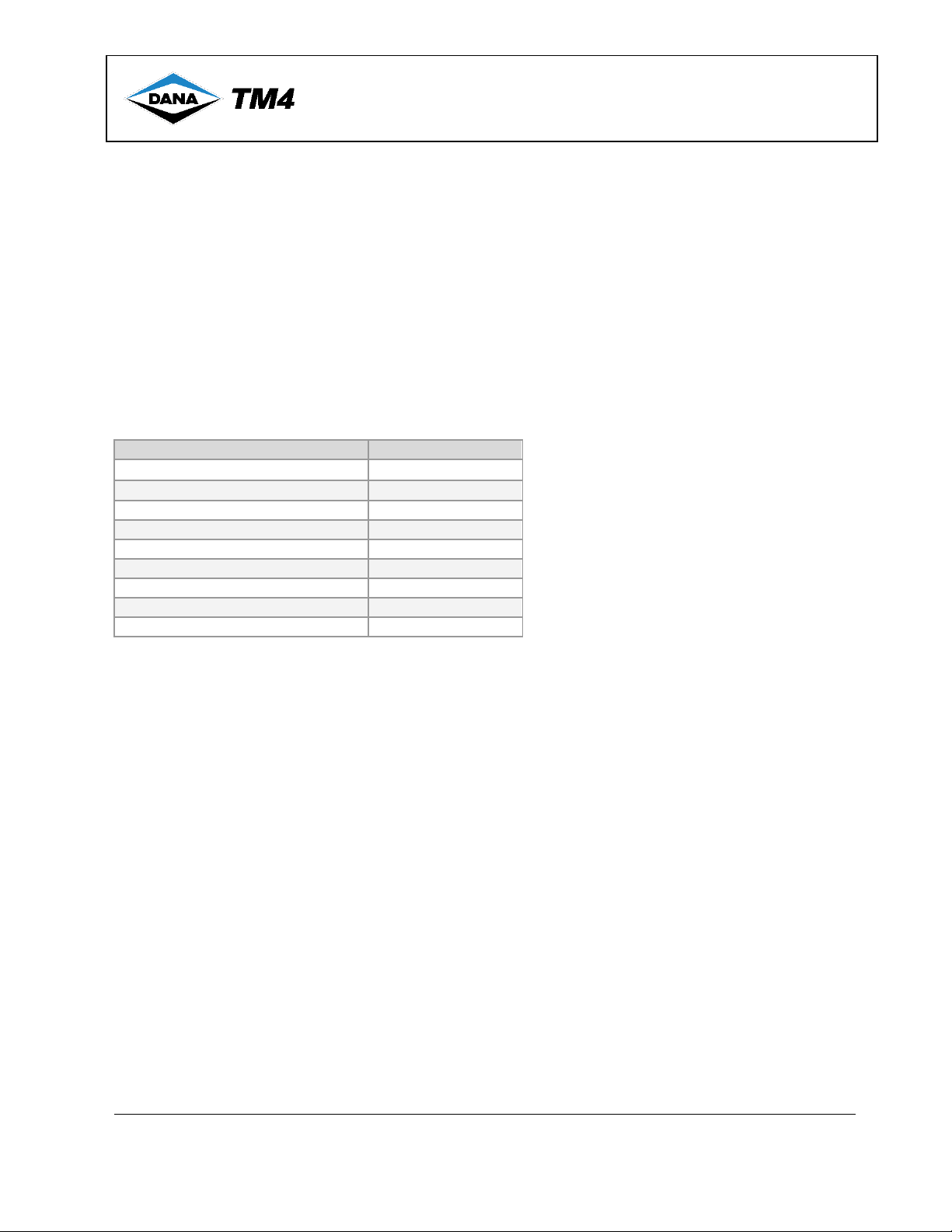

Table of contents

1Introduction ........................................................................................................................ 7

1.1 Purpose ..................................................................................................................... 7

1.2 Scope......................................................................................................................... 7

1.3 What’s new ................................................................................................................ 7

1.4 Disclaimer .................................................................................................................. 7

1.5 Safety instructions...................................................................................................... 8

1.5.1 Format and location of safety warnings in this guide ........................................... 8

1.6 Definitions, acronyms and abbreviations .................................................................... 8

1.7 References................................................................................................................. 9

2Transport and storage conditions ..................................................................................... 10

3Receiving and unpacking the MCU .................................................................................. 11

3.1 Safety warnings related to handling the MCU........................................................... 11

3.2 Inspecting and moving the MCU .............................................................................. 11

4Installing the MCU in the vehicle ...................................................................................... 12

4.1 Planning to install the MCU ...................................................................................... 12

4.1.1 Respecting CSC and MKC markings on interface drawings .............................. 12

4.2 Preventing damage to the MCU ............................................................................... 12

4.2.1 Using separate brackets to support MCU and motor ......................................... 13

4.2.2 Respecting the physical integrity of the MCU .................................................... 13

4.2.3 Protecting the casing from external loads.......................................................... 13

4.2.4 Correctly positioning the MCU........................................................................... 13

4.3 Securing the MCU.................................................................................................... 15

4.4 Installing the cooling system .................................................................................... 17

4.4.1 Safety warnings related to handling the cooling agent....................................... 17

4.4.2 Parallel configuration......................................................................................... 18

4.4.3 Serial configuration ........................................................................................... 19

4.4.4 Coolant inlet/outlet specifications ...................................................................... 19

4.4.5 Coolant specifications ....................................................................................... 20

4.5 Electrical installation................................................................................................. 21

4.5.1 Safety instructions related to electrical installation............................................. 21

4.5.2 General information for installing and handling cables/harnesses ..................... 22

4.5.3 Example installation sequence .......................................................................... 23

4.5.4 Grounding the system ....................................................................................... 23

4.5.5 Phase cables .................................................................................................... 25

4.5.6 Motor sensor interface harness ......................................................................... 27

4.5.7 Connecting the VMU interface harness ............................................................. 29

4.5.8 Connecting the high-voltage battery .................................................................. 34

4.5.9 Connecting the auxiliary battery to the MCU ..................................................... 38

4.5.10 CAN interface.................................................................................................... 39