INTRODUCTION

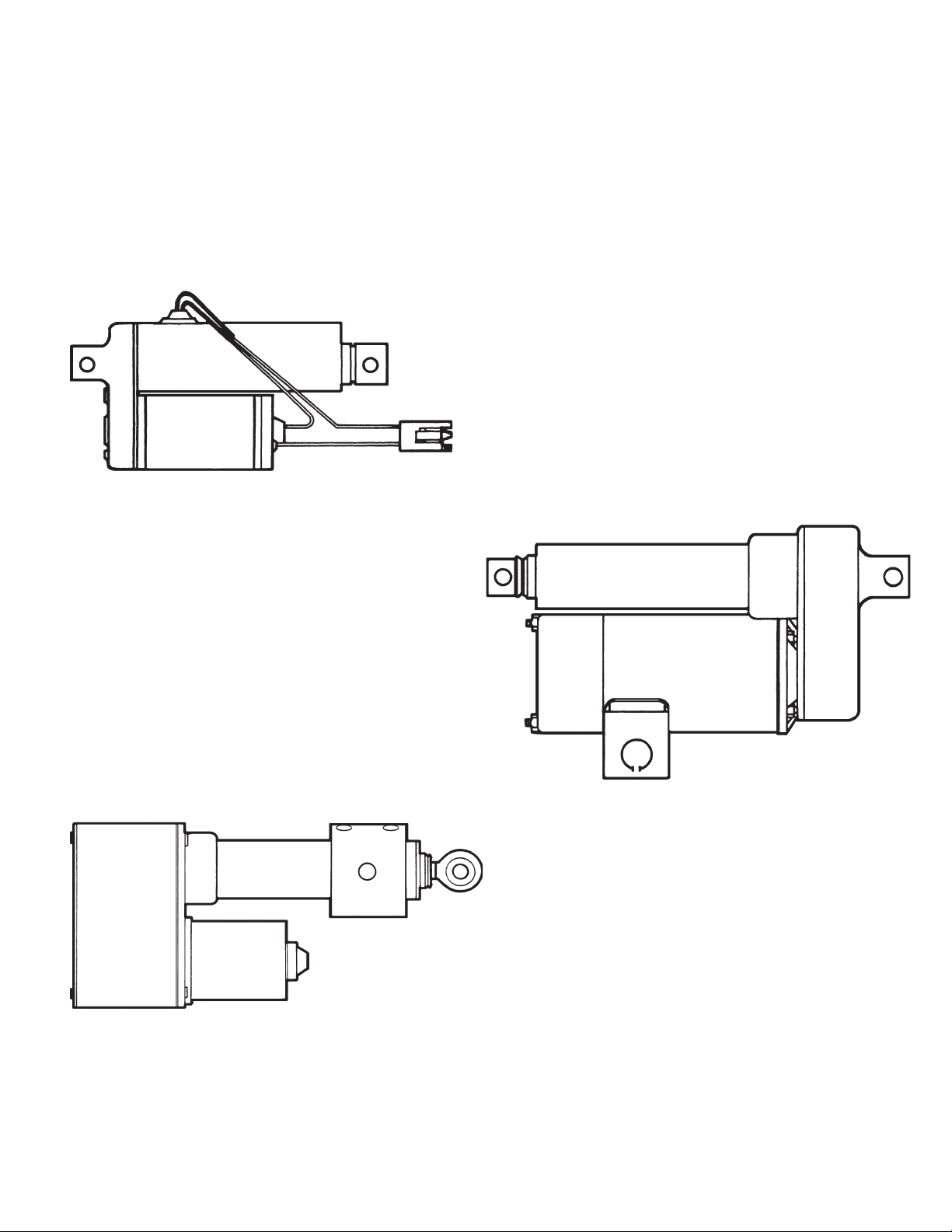

Danaher has many years of experience designing and manufacturing linear actuators for a wide variety of applica-

tions on combines, school buses, industrial sweepers, vans for the handicapped, and other mobile applications.

The Danaher linear actuator you have purchased is a well designed, high quality unit which will provide consistent,

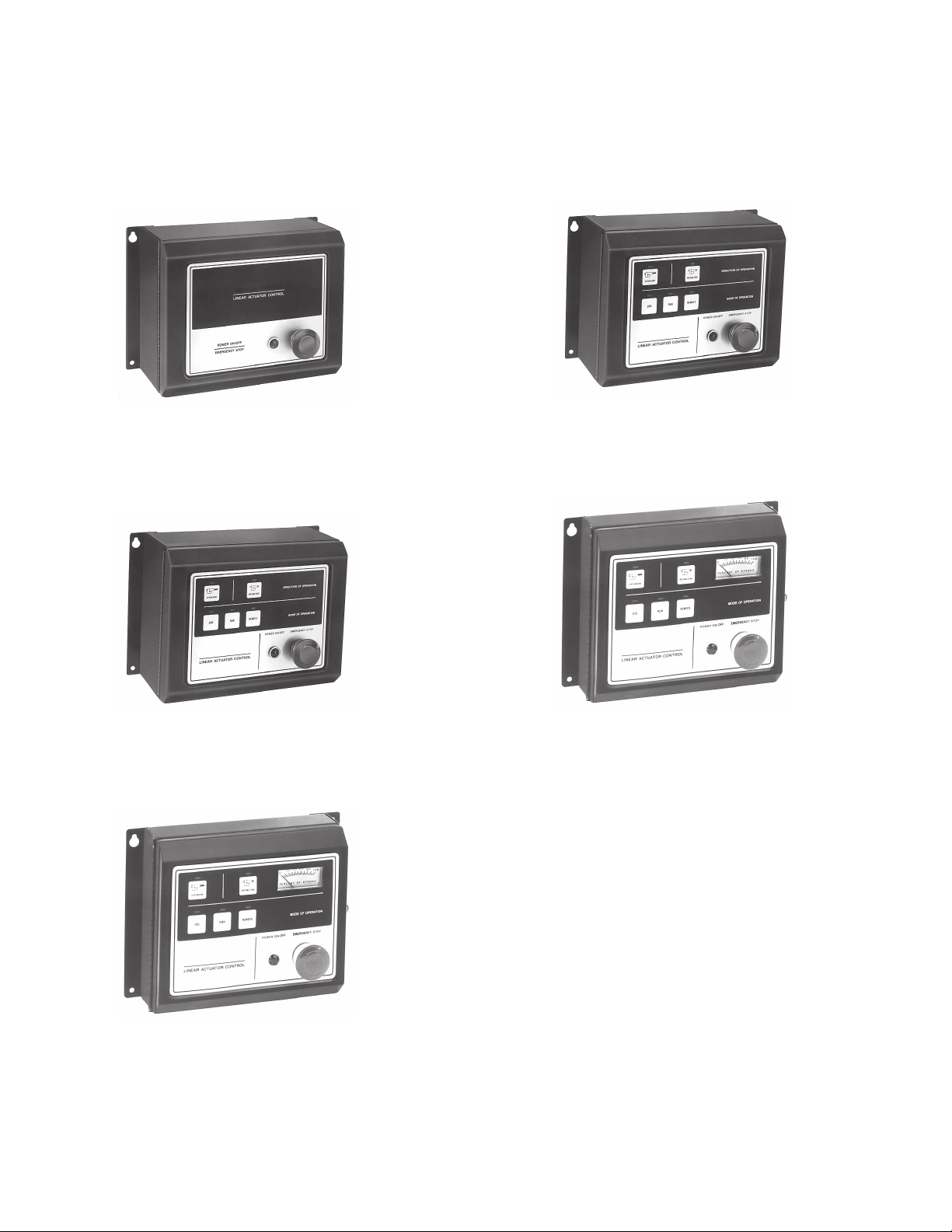

maintenance-free service throughout its life. When the Electrak 10 is mated with an MCS-2000 series control, it will

provide controlled linear force for applications which require moving, positioning, adjusting, or opening and closing

on in-plant or mobile applications.

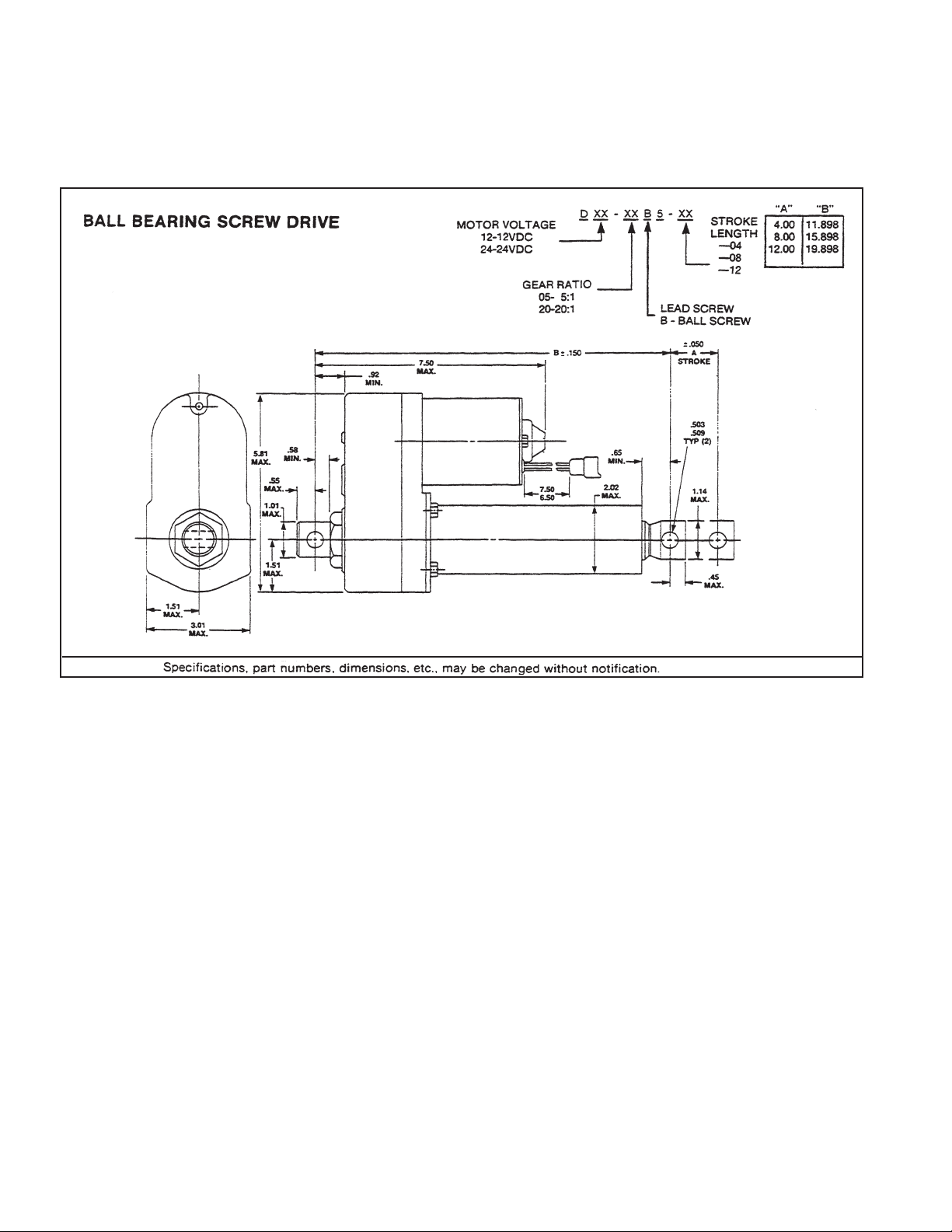

This manual provides complete information needed to install and troubleshoot Danaher D12-05B5, D12-20B5, D24-

05B5 and D24-20B5 DC linear actuators. All of these products are easy to apply and require no maintenance.

Please follow the instructions provided in this manual carefully to ensure safe, reliable operation. The Application

Notes found on page 3 are of paramount importance, so be sure to read them care thoroughly before proceeding with

installation. All stated or implied manufacturer’s warranties are voided if this product is not installed and operated in

accordance with these instructions.

Description Page

Other Actuator Products.......................................................................................... 1

Application Notes .................................................................................................... 3

Specifications .......................................................................................................... 3

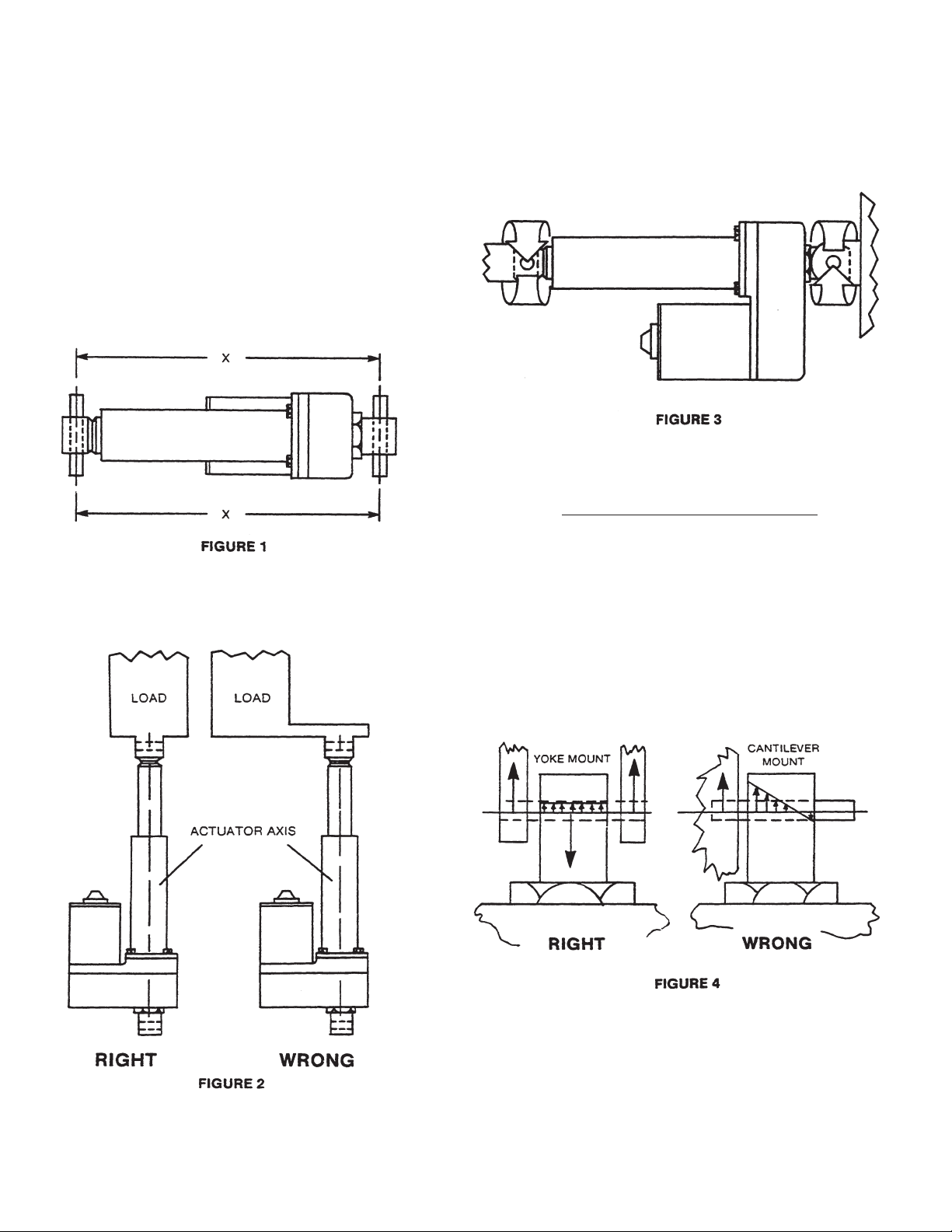

Mounting ................................................................................................................. 4

Electrical Installation ................................................................................................ 5

Troubleshooting ....................................................................................................... 7

Dimensions .............................................................................................................. 8

TABLE OF CONTENTS

WARRANTY

Danaher warrants that it will repair or replace (whichever it deems

advisable) any product manufactured and sold by it which proves

to be defective in material or workmanship within a period of one (1)

year from the date of original purchase for consumer, commercial

or industrial use.

This warranty extends only to the original purchaser and is not

transferable or assignable without Danaher’s prior consent.

Warranty service can be obtained in the U.S.A. by returning

any defective product, transportation charges prepaid, to the

appropriate Danaher factory. Additional warranty information may

be obtained by writing the Customer Service Department:

Danaher Motion

1300 N. State St.

Marengo, Il. 60152

Phone: 1-800-554-8466

A purchase receipt or other proof of original purchase will be

required before warranty service is rendered. If found defective

under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If

found not to be defective, you will be notified and, without your

consent, the item will be repaired or replaced and returned to you

at your expense.

This warranty covers normal use and does not cover damage or

defect which results from alteration, accident, neglect, or improper

installation, operation, or maintenance. Some states do not allow

limitation on how long an implied warrant lasts, so the above

limitation may not apply to you.

Danaher’s obligation under this warranty is limited to the repair or

replacement of the defective product and in no event shall Danaher

be liable for consequential, indirect, or incidental damages of any

kind incurred by reason of the manufacturer, sale or use of any

defective product. Danaher neither assumes nor authorizes any

other person to give any other warranty or to assume any other

obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY

IMPLIED WARRANTIES WHICH THE CONSUMER MAY HAVE

ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE

OF ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO

COMMERCIAL AND INDUSTRIAL USES OF THE PRODUCT, THE

FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESS OR IMPLIED BY

OPERATION OF LAW OR OTHERWISE, INCLUDING, BUT NOT

LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion may

not apply to you. This warranty gives you specific legal rights and

you may also have other rights which vary from state to state.